Patents

Literature

128results about How to "Small difference in coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

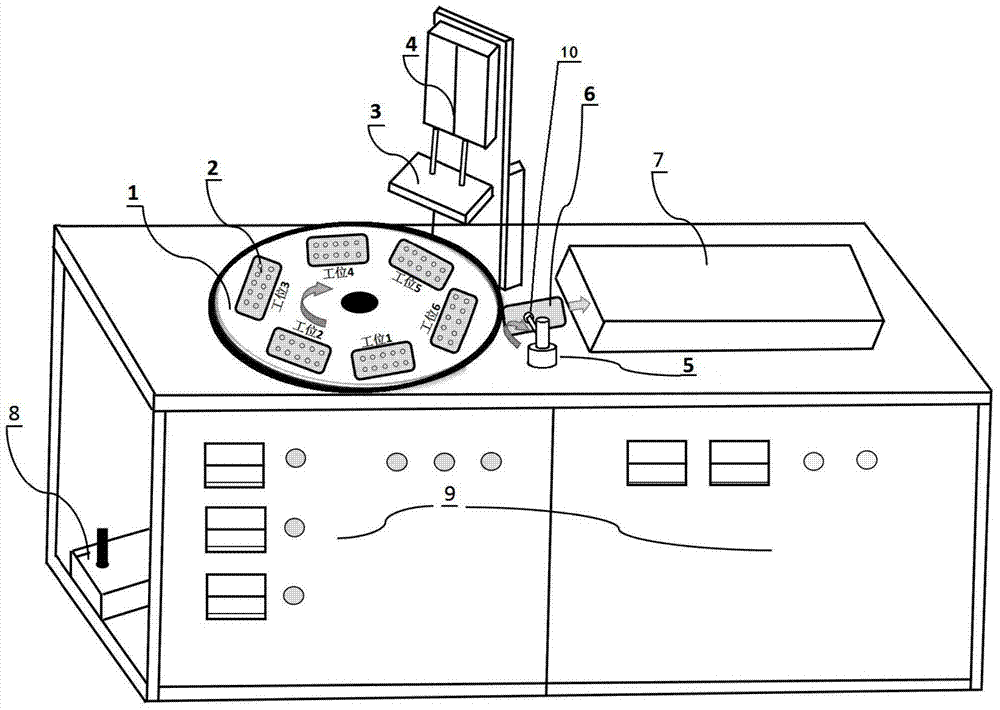

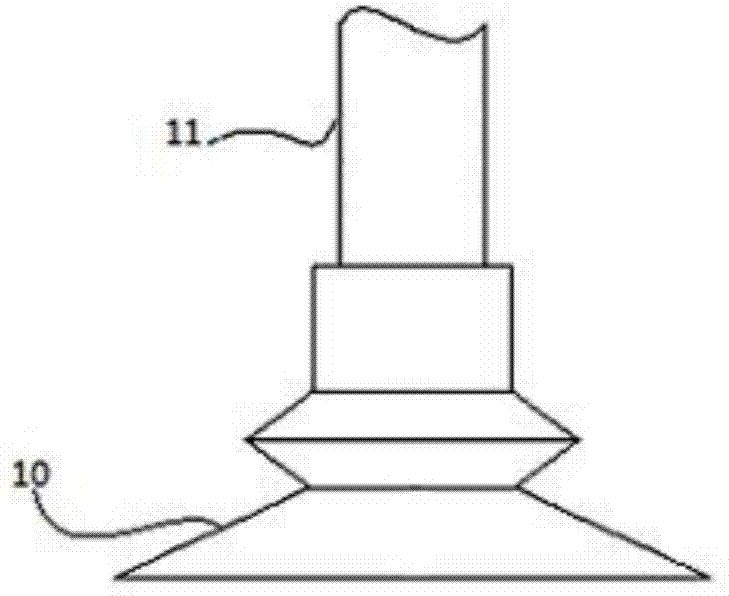

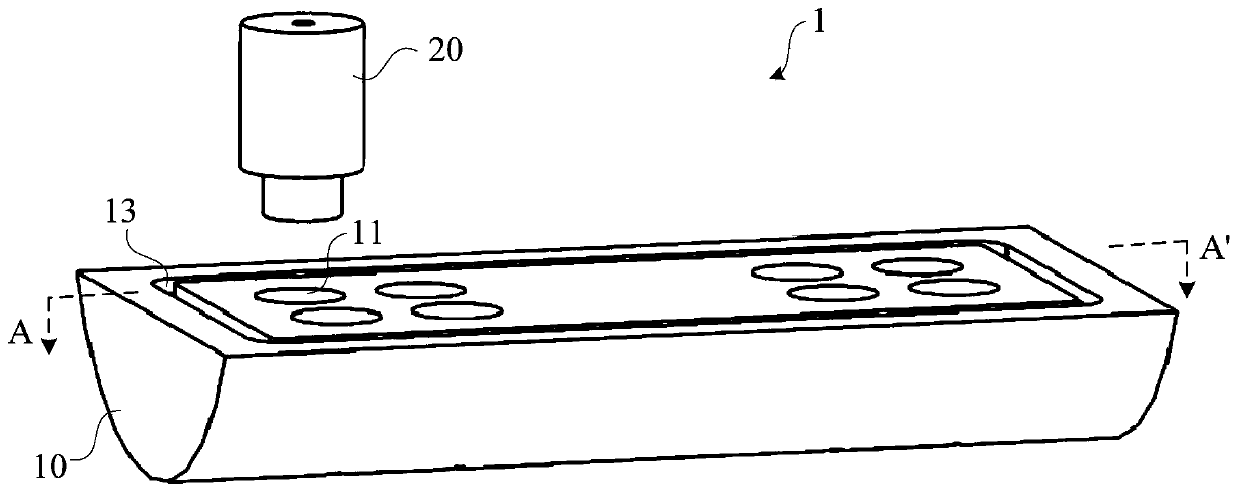

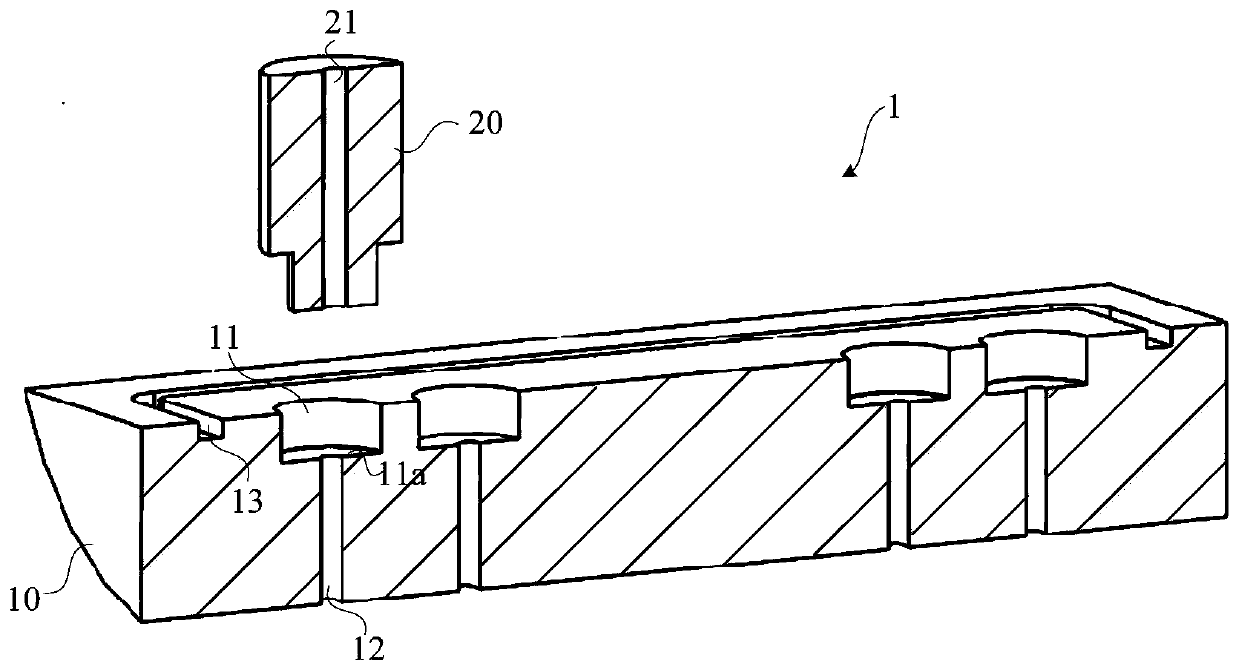

3D Curved ultrathin glass bending and forming device and manufacturing method

ActiveCN104843976ASmooth surfaceReduce stressGlass reforming apparatusGlass productionPhysicsElectrical control

The invention discloses a 3D curved ultrathin glass bending and forming device and a manufacturing method. The device comprises a rotor disc, concave dies, a convex die, a cylinder, a glass transfer mechanism, a tunnel furnace, a vacuum system and an electric control operating system, and a plurality of concave dies are arranged on the rotor disc. By adopting the device, the concave dies and the convex die are quickly heated in different stages; the ultrathin glass is sequentially placed on the concave dies of the rotor disc and is subjected to preheating; when the ultrathin glass rotates and reaches the corresponding work station on the convex die, the convex die is pressed, and a far infrared lamp tube is utilized to quickly heat to the glass softening point; in addition, the ultrathin glass on the concave dies is sucked and the convex die is pressurized by virtue of the vacuum system, so that the ultrathin glass is bended; the ultrathin glass is transferred to the tunnel furnace to be cooled by virtue of the glass transfer mechanism, so that the 3D curved ultrathin glass can be manufactured.

Owner:海程光电科技有限公司

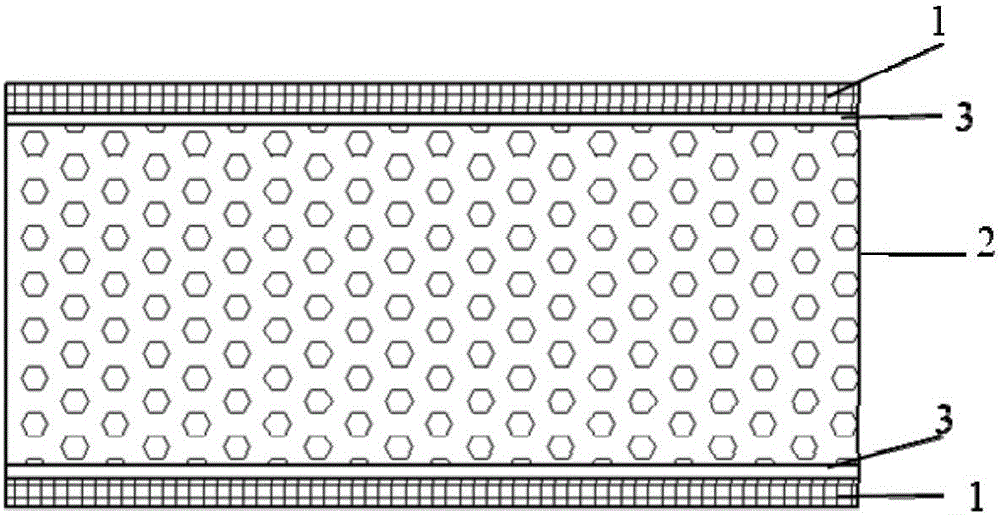

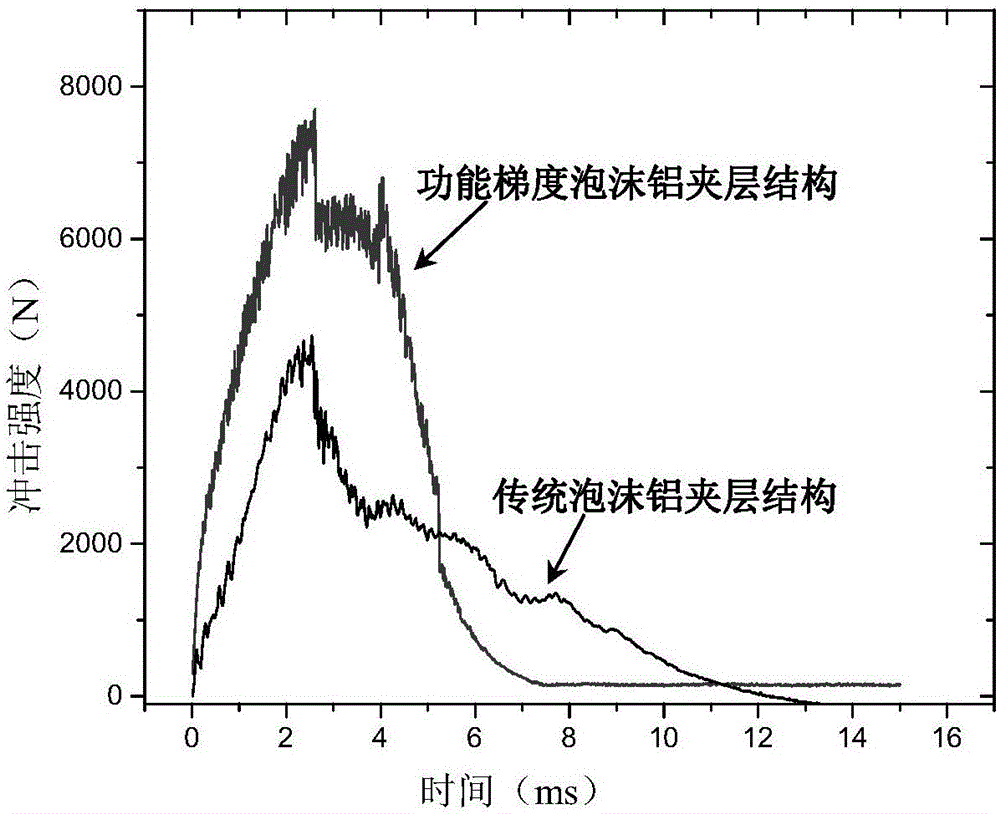

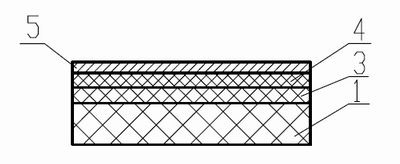

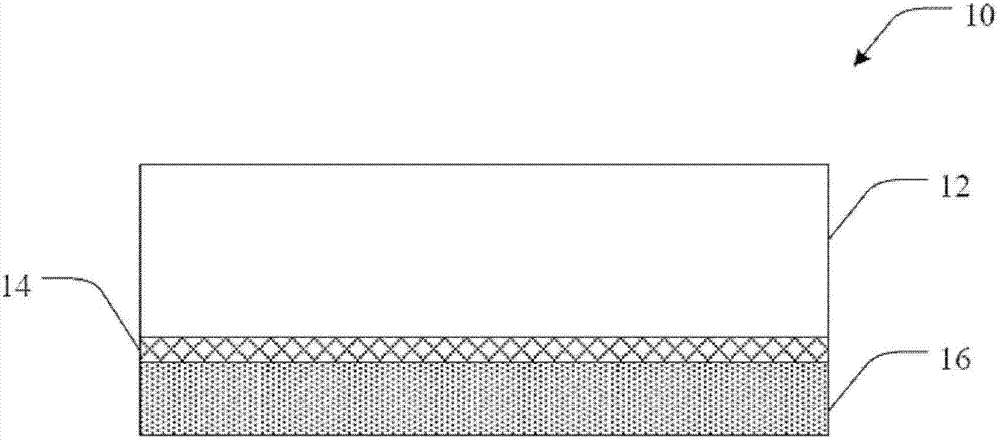

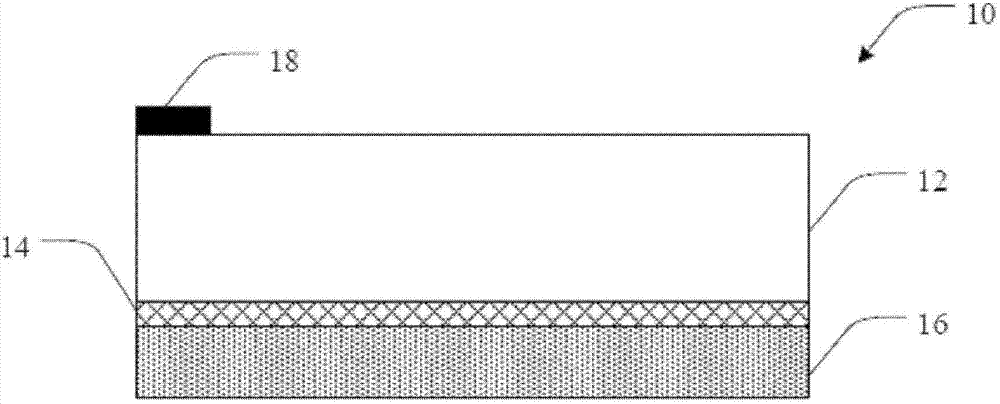

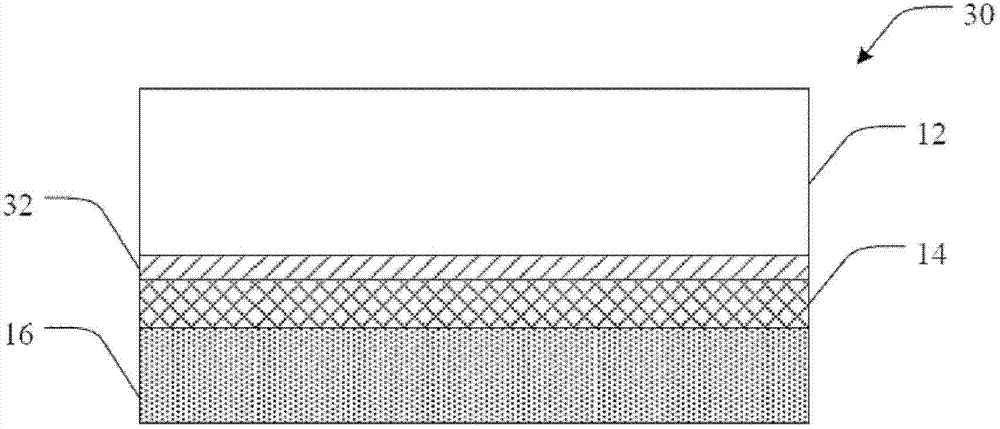

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

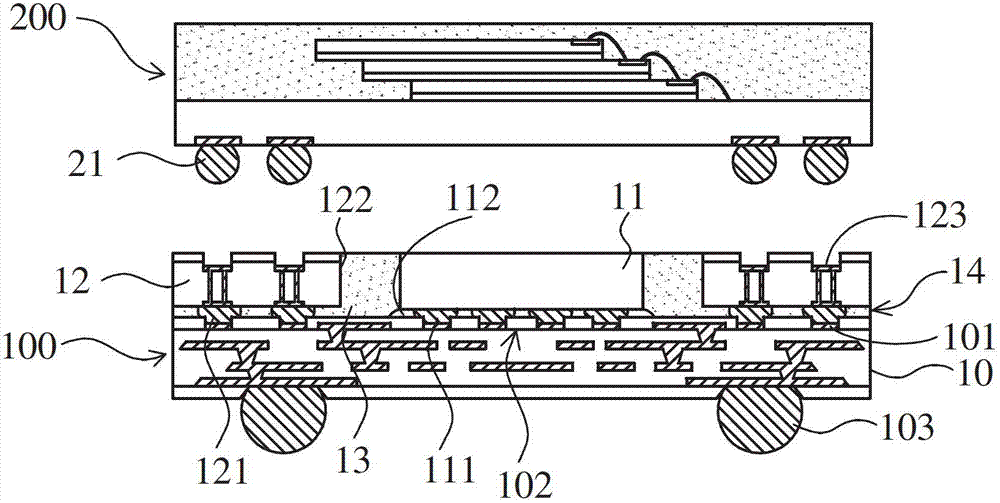

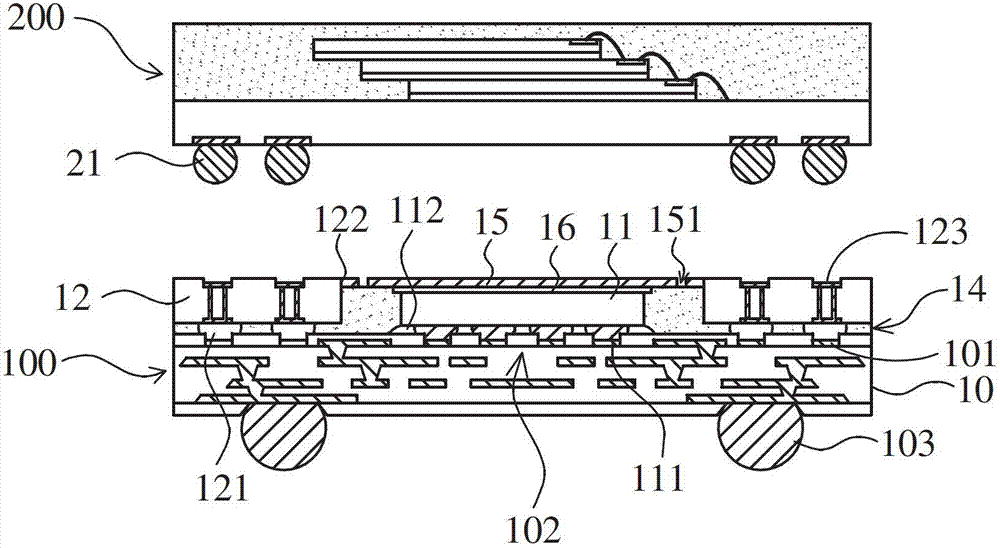

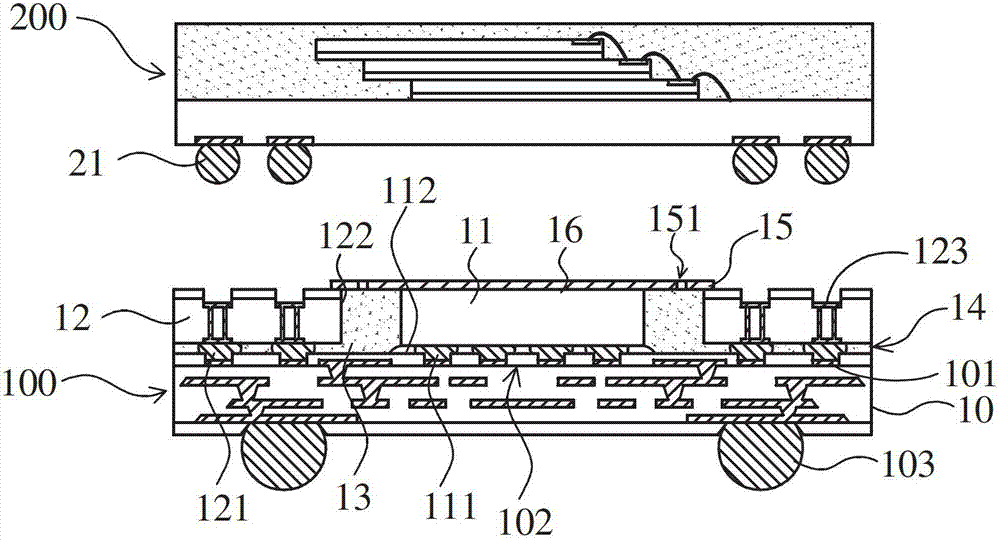

Semiconductor packaging structure for stacking and manufacturing method thereof

ActiveCN102738094ASolve warpingSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention discloses a semiconductor packaging structure for stacking and a manufacturing method thereof. The semiconductor packaging structure comprises a bottom substrate, a chip, an annular switchover substrate and packaging colloid. The bottom substrate is provided with a plurality of welding pads and a chip bearing area; the chip is fixedly arranged on the chip bearing area of the bottom substrate; a plurality of switchover assemblies and an opening are arranged on the annular switchover substrate; the switchover assemblies surround the opening and are electrically connected with the welding pads of the bottom substrate; the packaging colloid is filled in a gap between the bottom substrate and the annular switchover substrate, and is filled in the opening of the annular switchover substrate; and the packaging colloid in the opening is exposed to one top surface of the chip. With the adoption of the annular switchover substrate, the upper side and the lower side of a packaged body are slightly different in coefficient of thermal expansion, so that the warping rate is relatively lowered.

Owner:ADVANCED SEMICON ENG INC

Aluminum electrically conductive slurry used for solar cell and preparation method thereof

ActiveCN103177791ASmall difference in coefficient of thermal expansionImprove warping problemNon-conductive material with dispersed conductive materialCable/conductor manufactureAluminiumPolycrystalline silicon

The invention provides aluminum electrically conductive slurry used for a solar cell and a preparation method thereof. The aluminum electrically conductive slurry used for the solar cell comprises the following components: aluminum powder, glass powder, an organic carrier and an inorganic additive powder, wherein the inorganic additive powder with the intermediate grain size D50 of 0.1-5.0 microns is one or more selected from beta-eucryptite, zirconium tungstate or zirconium vanadate. After the aluminum electrically conductive slurry used for the solar cell is silk-screen printed to a crystal silicon solar cell and is sintered into a film, the metal film is attached to a silicon substrate firmly. The aluminum electrically conductive slurry used for the solar cell has a smooth and compact surface, is free from aluminum beads and aluminum blistersm and has high photoelectric conversion efficiency; the warping degree of the cell is small; and the average warping degree of the 156*156 type polycrystalline silicon solar cell is less than 0.50 mm.

Owner:BYD CO LTD

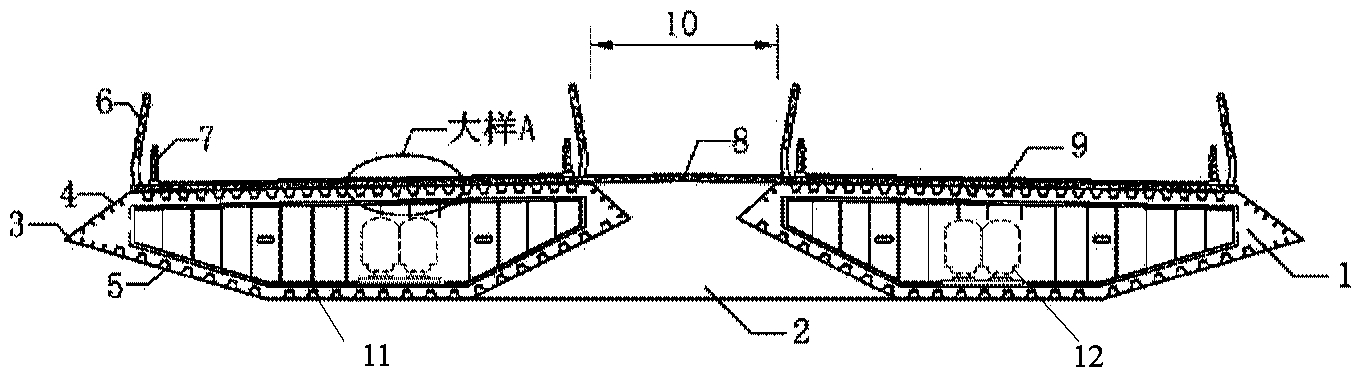

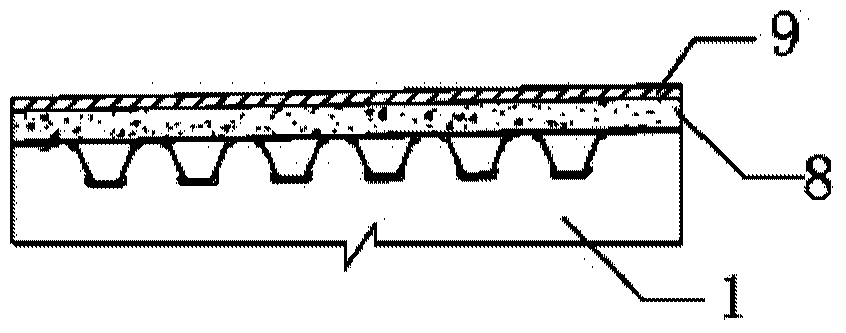

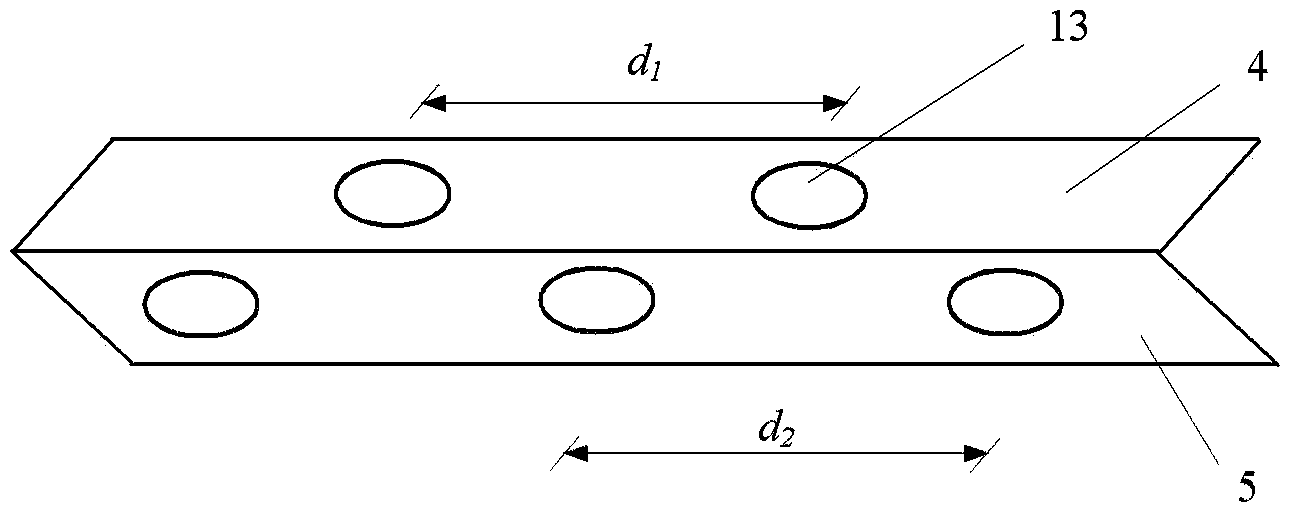

Split streamline steel-concrete composite box girder

ActiveCN103452036AGood aerodynamic shapeIncrease structural dampingBridge materialsBridge deckLight rail

The invention discloses a split streamline steel-concrete composite box girder comprising two or three horizontal steel-concrete composite box girder units. An air nozzle is disposed outside each steel-concrete composite box girder unit. A channel 4m-20m in horizontal width is formed between each two steel-concrete composite box girder units. Connecting beams are disposed at intervals of 4m-20m longitudinally along the channels. A top plat of each steel-concrete composite box girder unit is a concrete plate, and a bridge deck pavement for automobiles is paved on the top plate; a bottom plate and an oblique web in each girder unit are reinforced steel plates; rails for trains or light rail vehicles are arranged on the bottom plate; each oblique web is provided with round, elliptical or polygonal light holes. The split streamline steel-concrete composite box girder has the advantages that wind proofing stability of bridges can be improved effectively, vortex-induced vibration is suppressed, durability of the bridge deck pavement is improved, and the girder is applicable to highway bridges or highway and light-railway bridges and is simple in structure and well economical.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

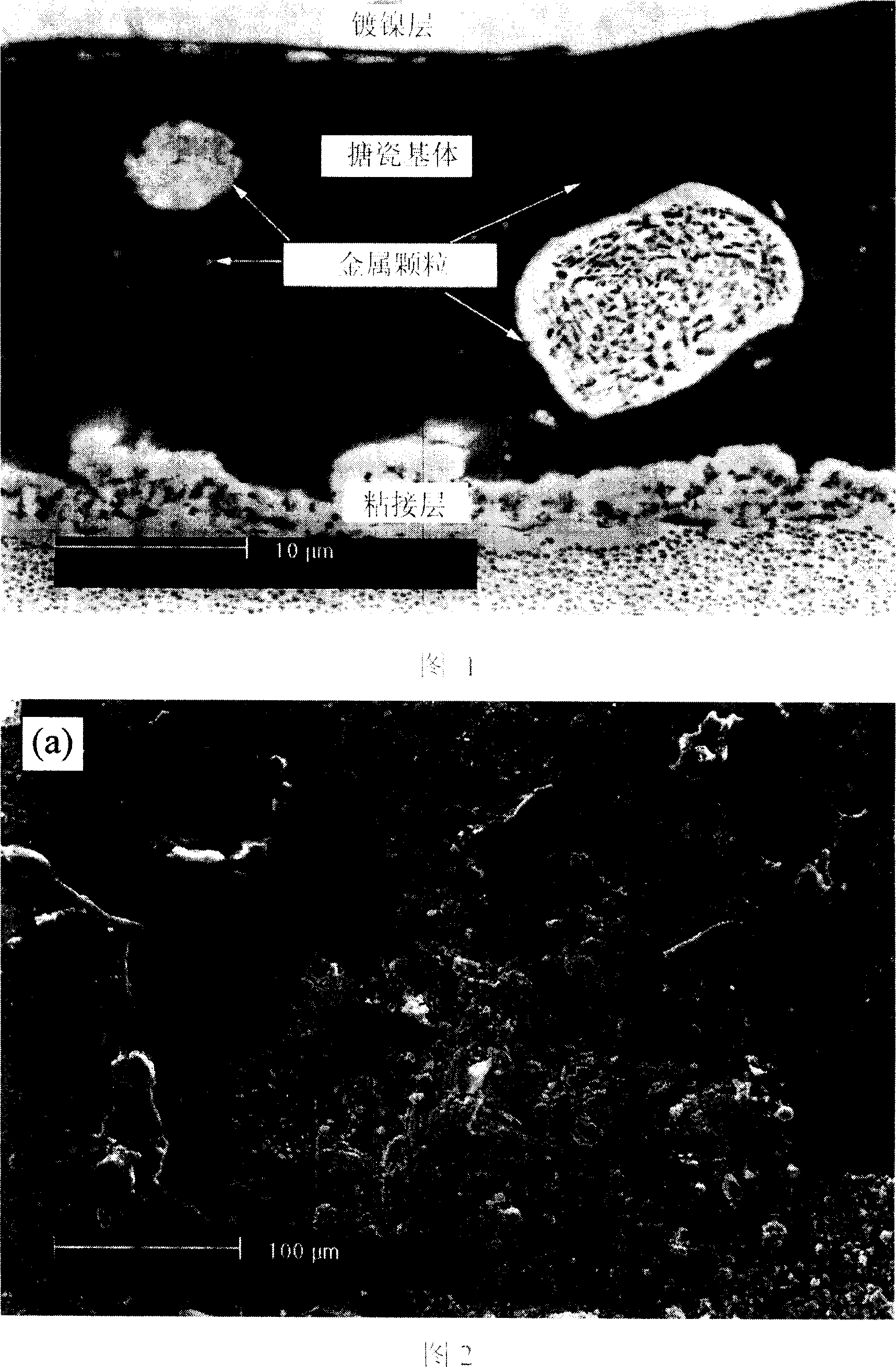

High temperature alloy protective technology

InactiveCN1858304AReduce corrosion rateAccelerated corrosionSuperimposed coating processAlloy substrateSuperalloy

The high temperature alloy protecting technology includes the first forming binding layer in the same components as the substrate on the surface of the high temperature alloy substrate and the subsequent baking composite oxide coating on the surface. The composite oxide coating consists of basic enamel material and added Al2O3 or MgO in 10-40 wt% and Y2O3 in 1-5 wt%; and the basic enamel material consists of ZrO2 3-6 wt%, Al2O3 3-6 wt%, ZnO 8-12 wt%, CaO 3-6 wt%, B2O3 3-6 wt%, Na2O 3-6 wt%, K2O 5-8 wt%, TiO2 1-4 wt% and SiO2 for the rest. The present invention raises the high temperature oxidation resistance and heat corrosion resistance of the substrate and raise the stripping-off resistance of the coating and avoids the mutual diffusion between elements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

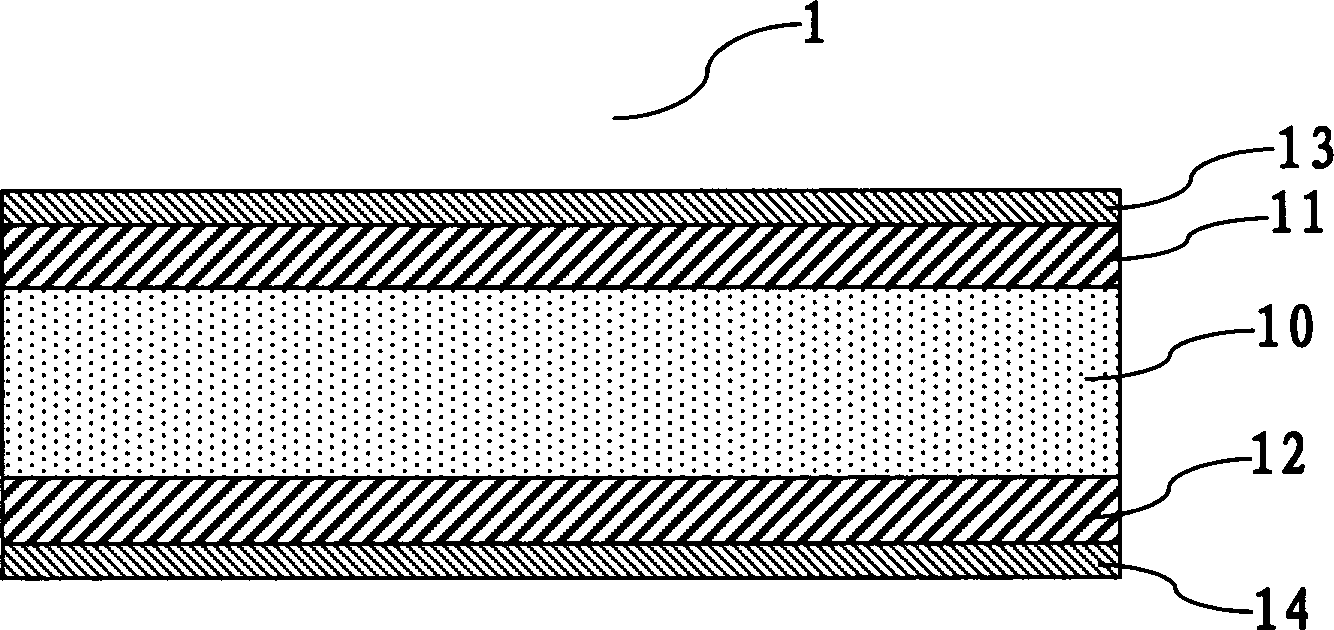

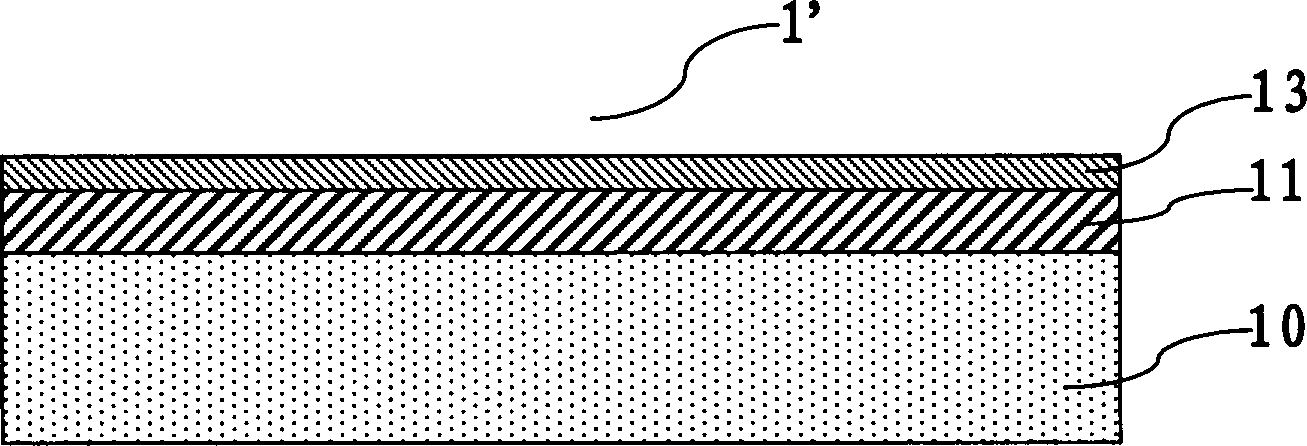

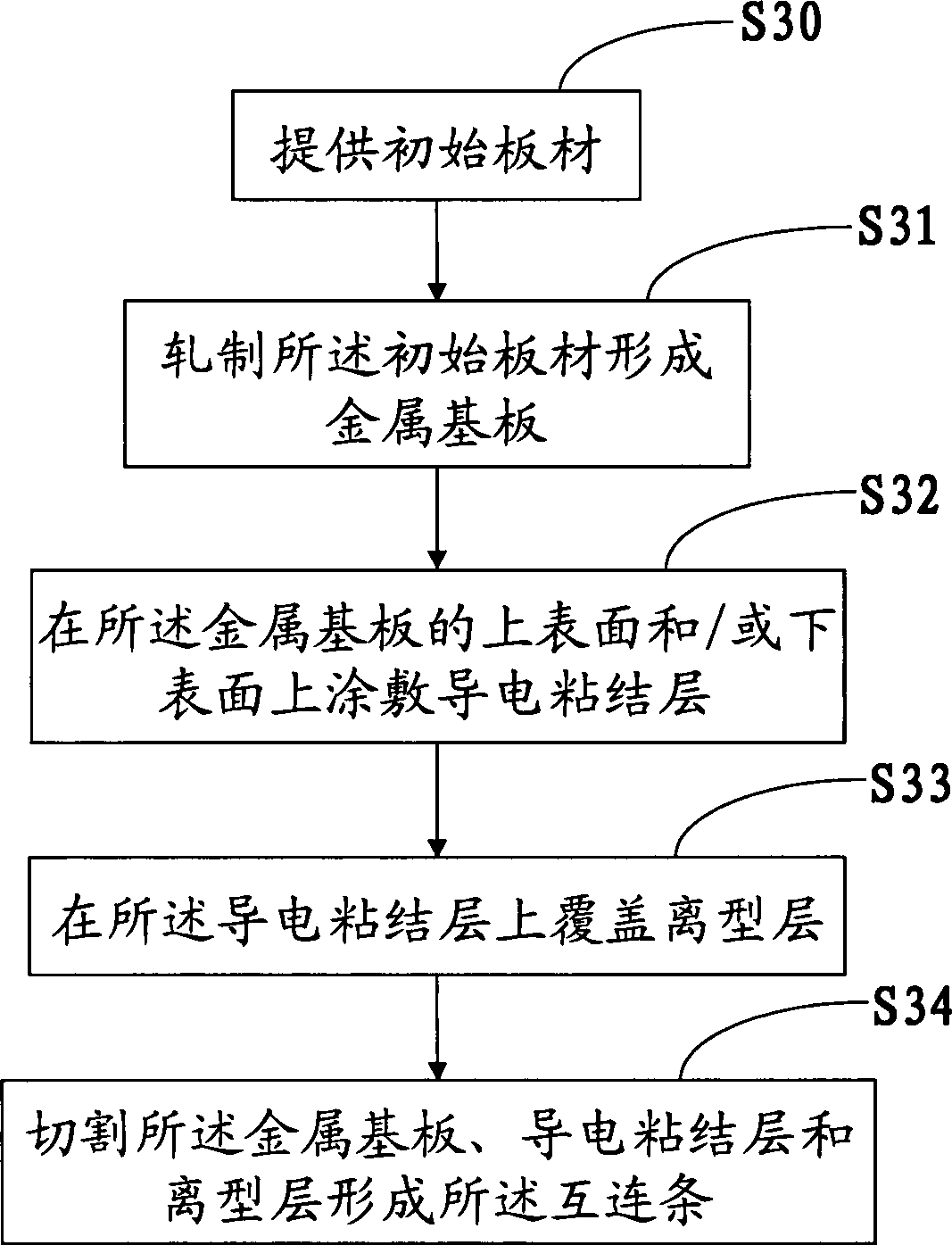

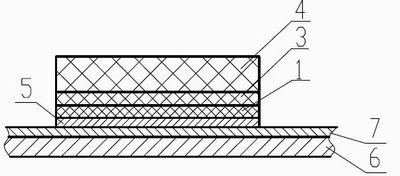

Interconnector used for solar cell and manufacturing method thereof, and solar cell interconnection method and assembly thereof

ActiveCN104064615ASmall difference in coefficient of thermal expansionAvoid bendingFinal product manufacturePhotovoltaic energy generationManufacturing efficiencyMetal substrate

The invention provides an interconnector used for a solar cell and a manufacturing method thereof, and a solar cell interconnection method and an assembly thereof. In the prior art, an interconnector is in welding connection with a solar cell so that problems of high heating temperature, and bending, subfissure and fragments caused by incapability of interconnection materials in reducing the difference of thermal expansion coefficients of the interconnector and the solar cell exist; and when adhesive connection is adopted, the interconnector and a conductive adhesive layer are of a split structure so that manufacturing efficiency is lower. The interconnector used for the solar cell includes a metal base material, and a conductive adhesive layer and a separation layer, which are sequentially laminated on the metal base material. The manufacturing of the interconnector is as follows: providing a metal substrate; coating the upper and / or lower surface of the metal substrate with the conductive adhesive layer which covers the isolation layer; and finally cutting the metal substrate, the conductive adhesive layer and the isolation layer so as to form the interconnector. Therefore, the difference of the thermal expansion coefficients of the interconnector and the solar cell can be reduced effectively and thus bending, subfissure and fragments of the solar cell caused by the difference are prevented; and moreover, the manufacturing efficiency and the power of the solar cell assembly can be improved.

Owner:WUXI SUNTECH POWER CO LTD

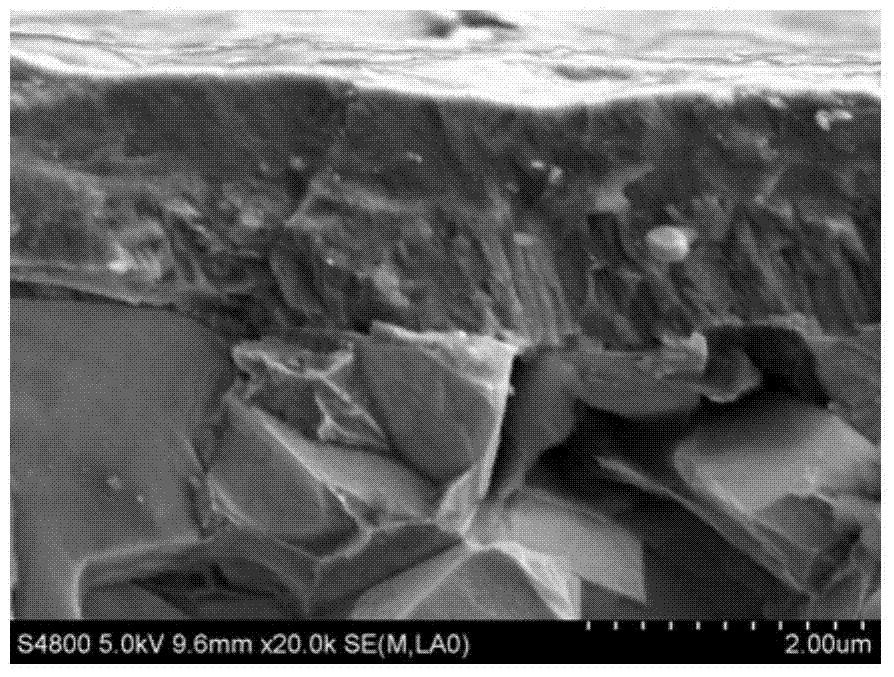

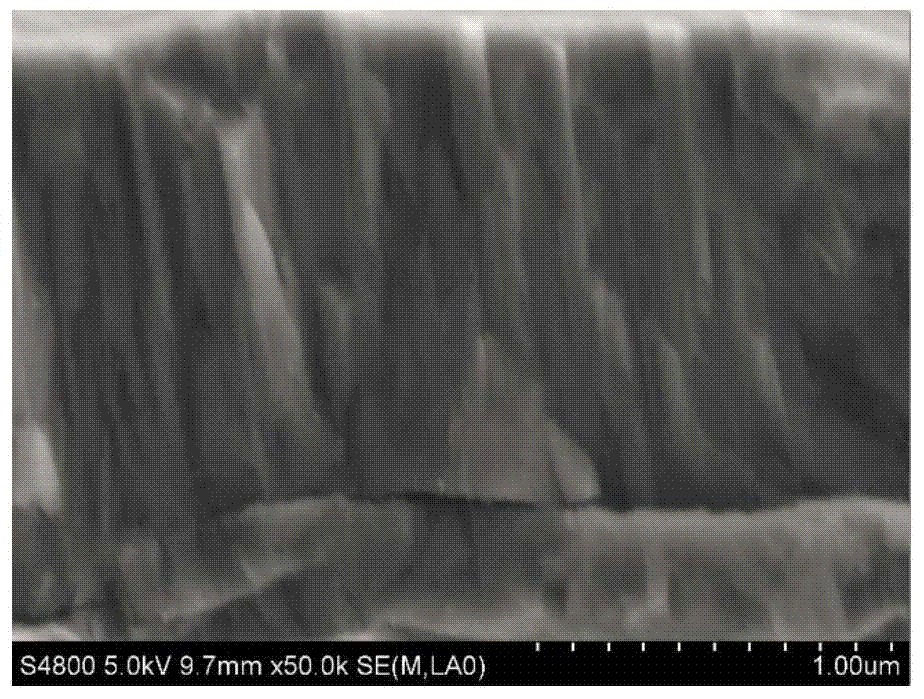

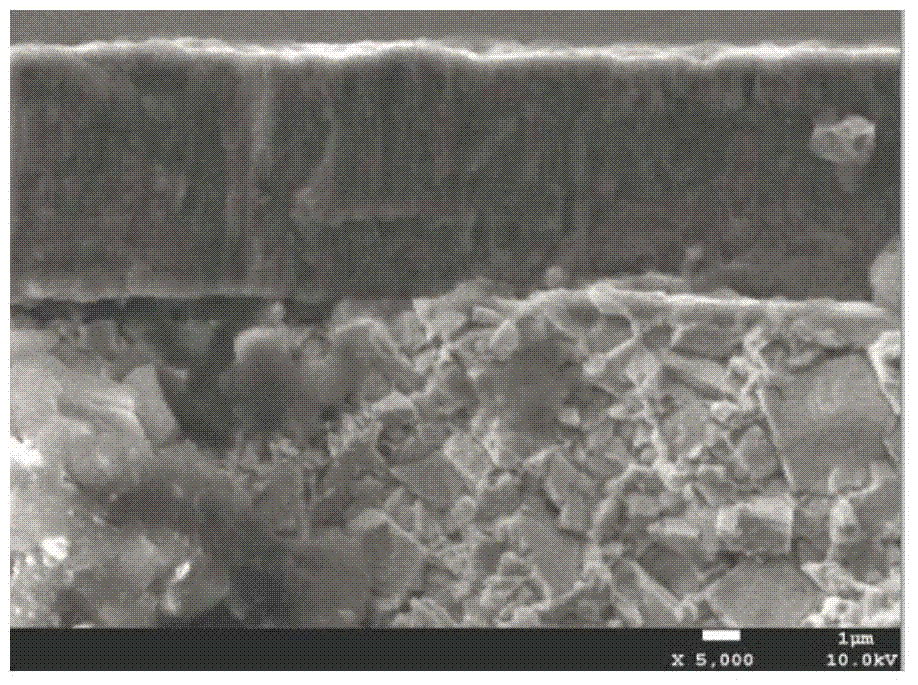

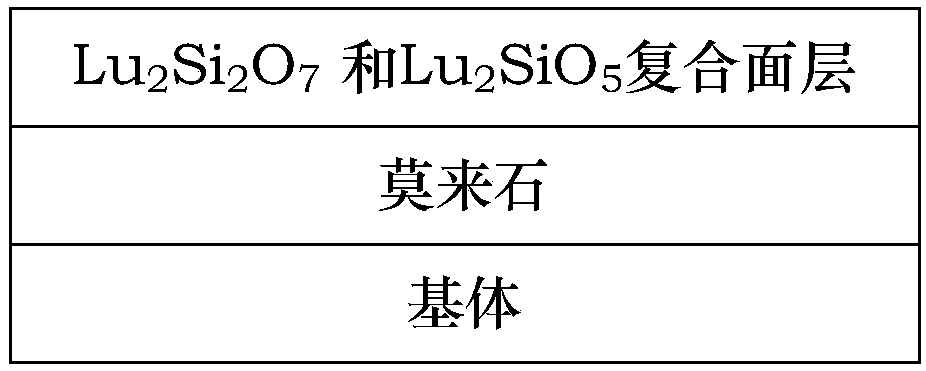

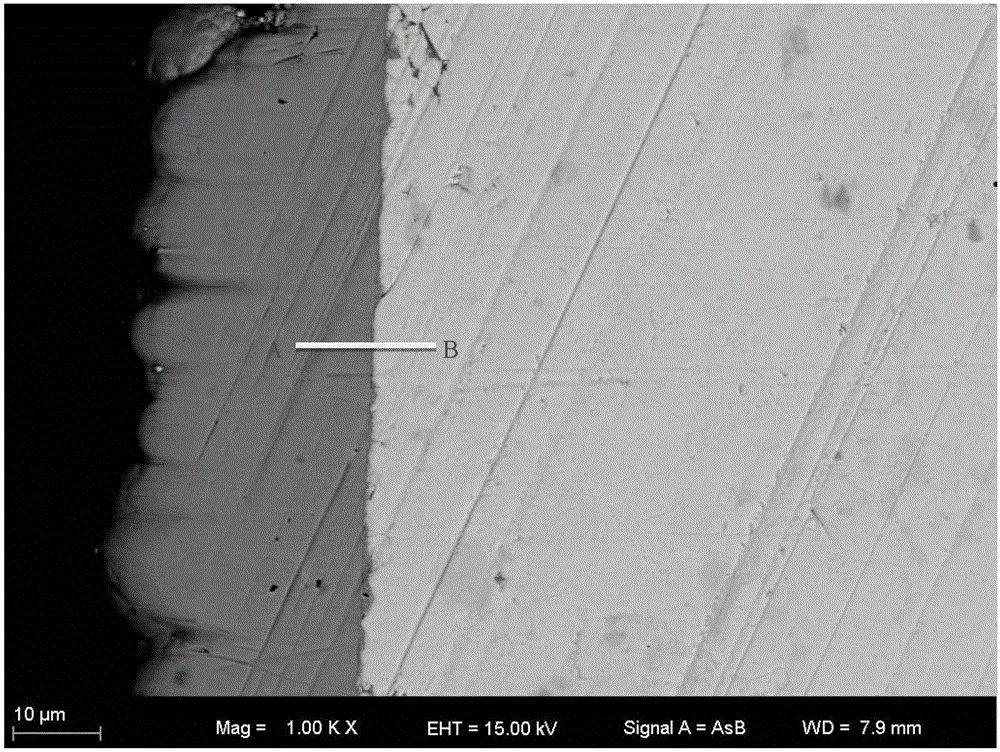

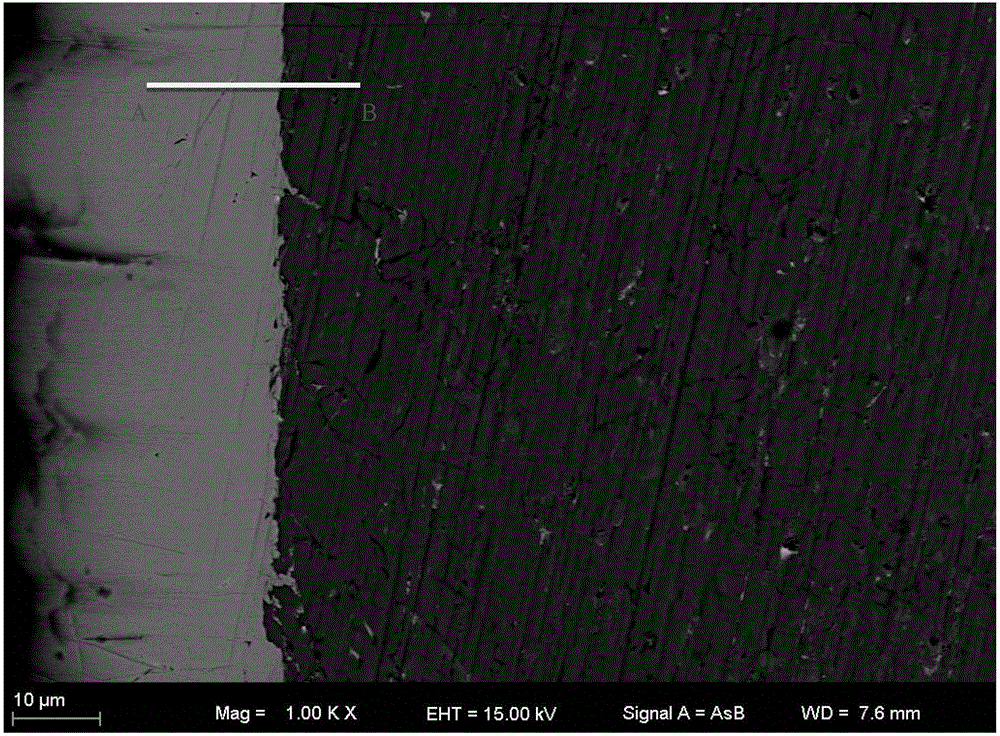

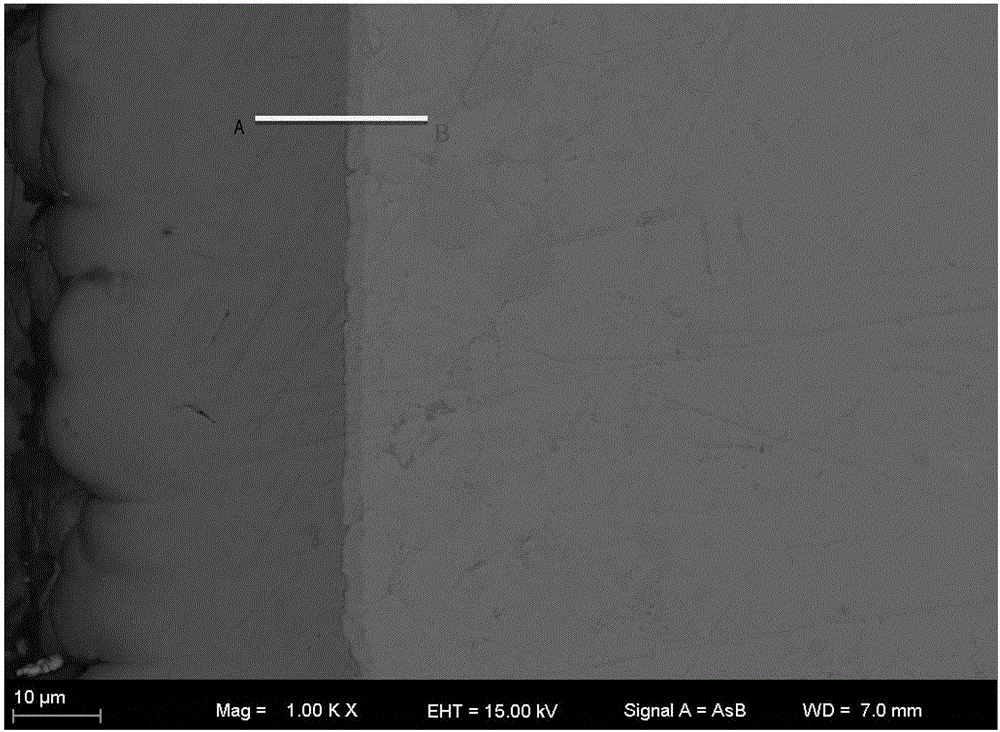

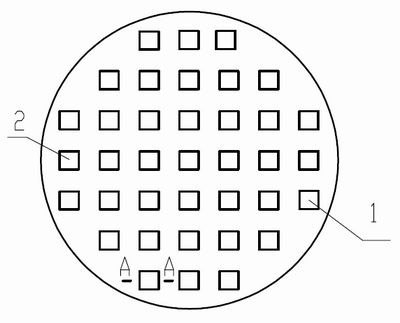

A rear earth lutetium silicate composite environmental barrier coating and a preparing method thereof

A rear earth lutetium silicate composite environmental barrier coating and a preparing method thereof are disclosed. The composite environmental barrier coating includes a SiC / SiC matrix, a mullite layer and a composite surface layer consisting of Lu2Si2O7 and Lu2SiO5 in a mass ratio of 6:4. The preparing method combining plasma spraying and physical vapor deposition is adopted, and mullite powderhaving a particle size of 18-58 [mu]m and Lu2Si2O7-Lu2SiO5 composite powder having a particle size of 62-105 [mu]m are adopted as raw materials to prepare the mullite layer on the SiC / SiC matrix andthe composite surface layer on the mullite layer in order. The coating prepared by the method has good resistance to water oxygen corrosion at 1723 K, effectively retards generation of cracks and effectively avoids oxidation and performance degradation of the SiC / SiC matrix at high temperatures.

Owner:BEIHANG UNIV

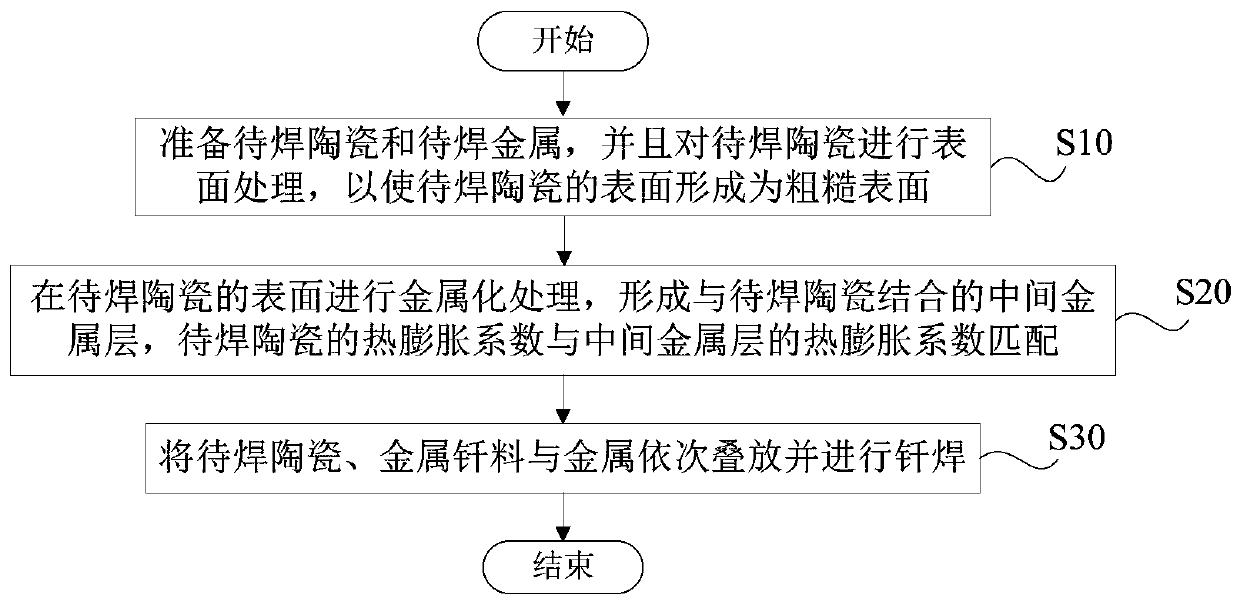

Brazing method for ceramic and metal

InactiveCN109734469ASmall difference in coefficient of thermal expansionReduce thermal stressThermal expansionFiller metal

The invention provides a brazing method for ceramic and metal. The brazing method includes preparing to-be-welded ceramic and to-be-welded metal, and subjecting the to-be-welded ceramic to surface treatment to form a smooth surface of the to-be-welded ceramic; metallizing the surface of the to-be-welded ceramic to form an intermediate metal layer combined with the to-be-welded ceramic, wherein thethermal expansion coefficient of the to-be-welded ceramic is matched with that of the intermediate metal layer; sequentially stacking the to-be-welded ceramic, brazing filler metal and the to-be-welded metal before brazing. The brazing method has the advantages that the brazing filler metal can well infiltrate the to-be-welded ceramic with the metallized surface, the intermediate metal layer canmake the thermal expansion coefficient of a brazing interface between the ceramic and the metal exhibit gradient transition, and thermal expansivity differences caused by different interfacial materials are reduced, so that the thermal stress of joints is reduced, and the performance is improved.

Owner:SHENZHEN SIBIONICS CO LTD

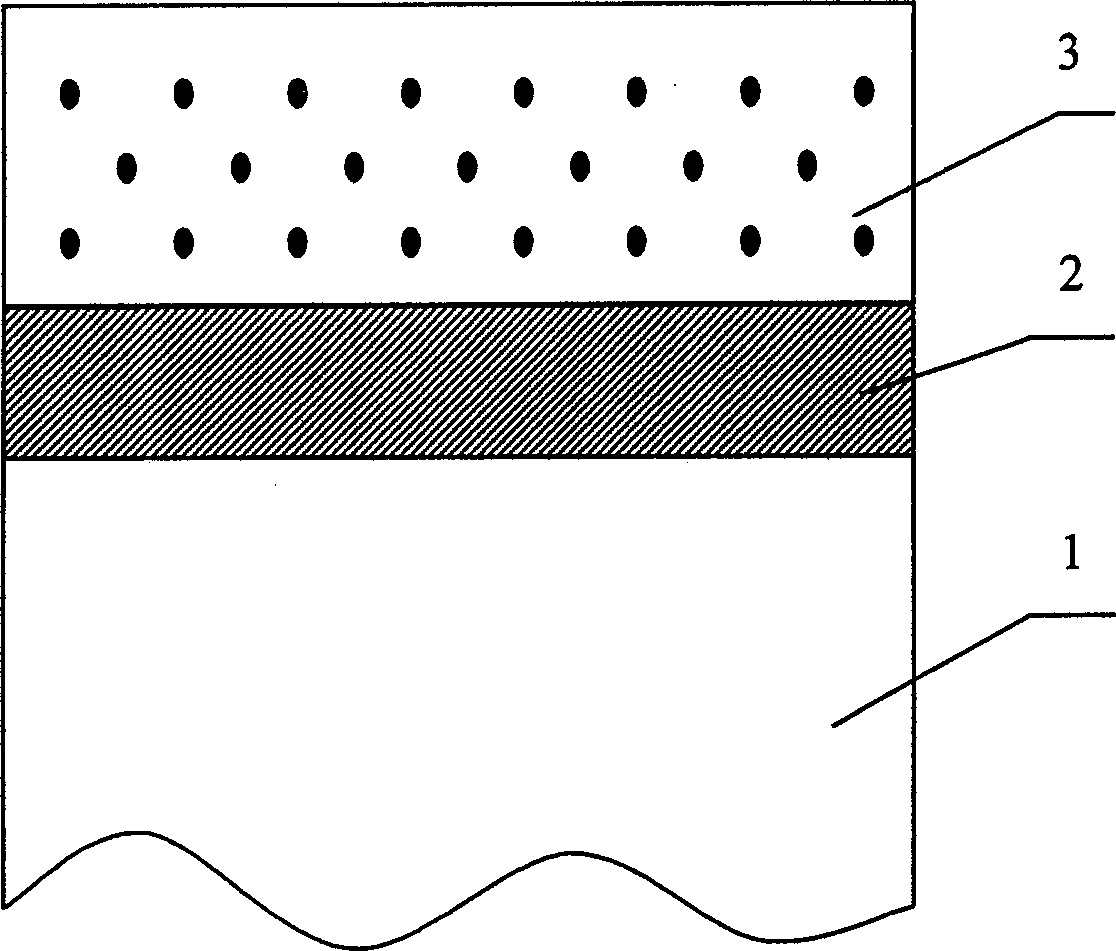

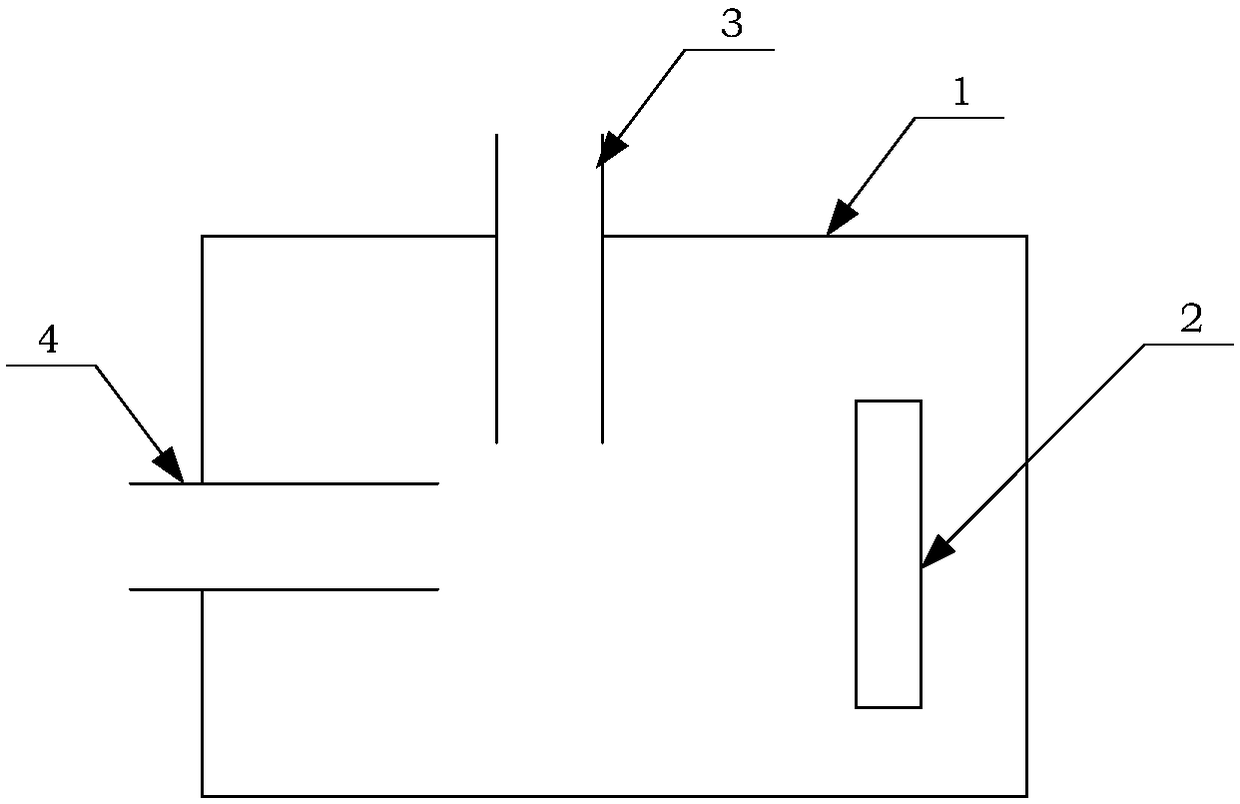

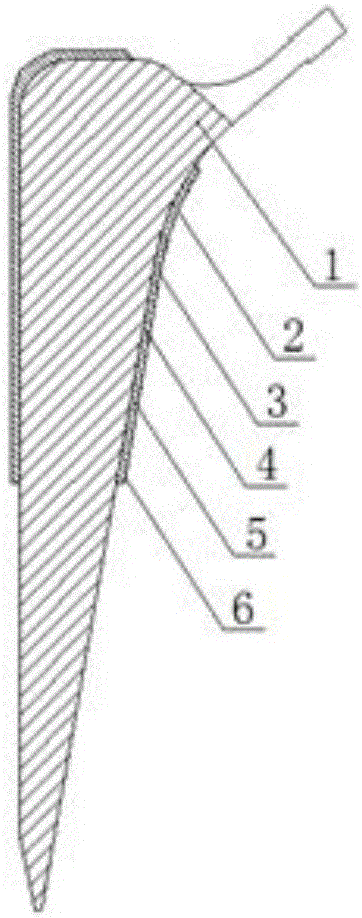

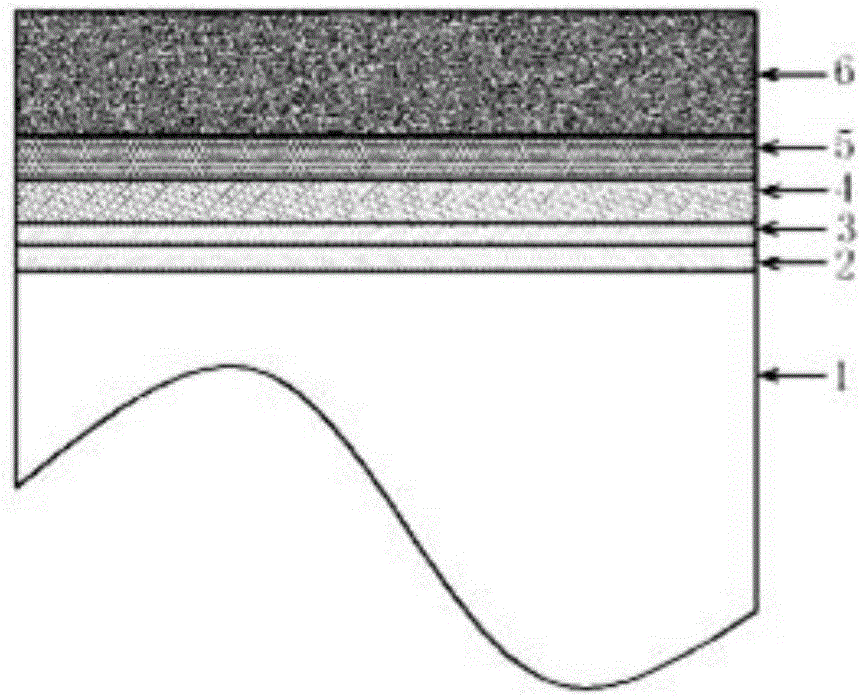

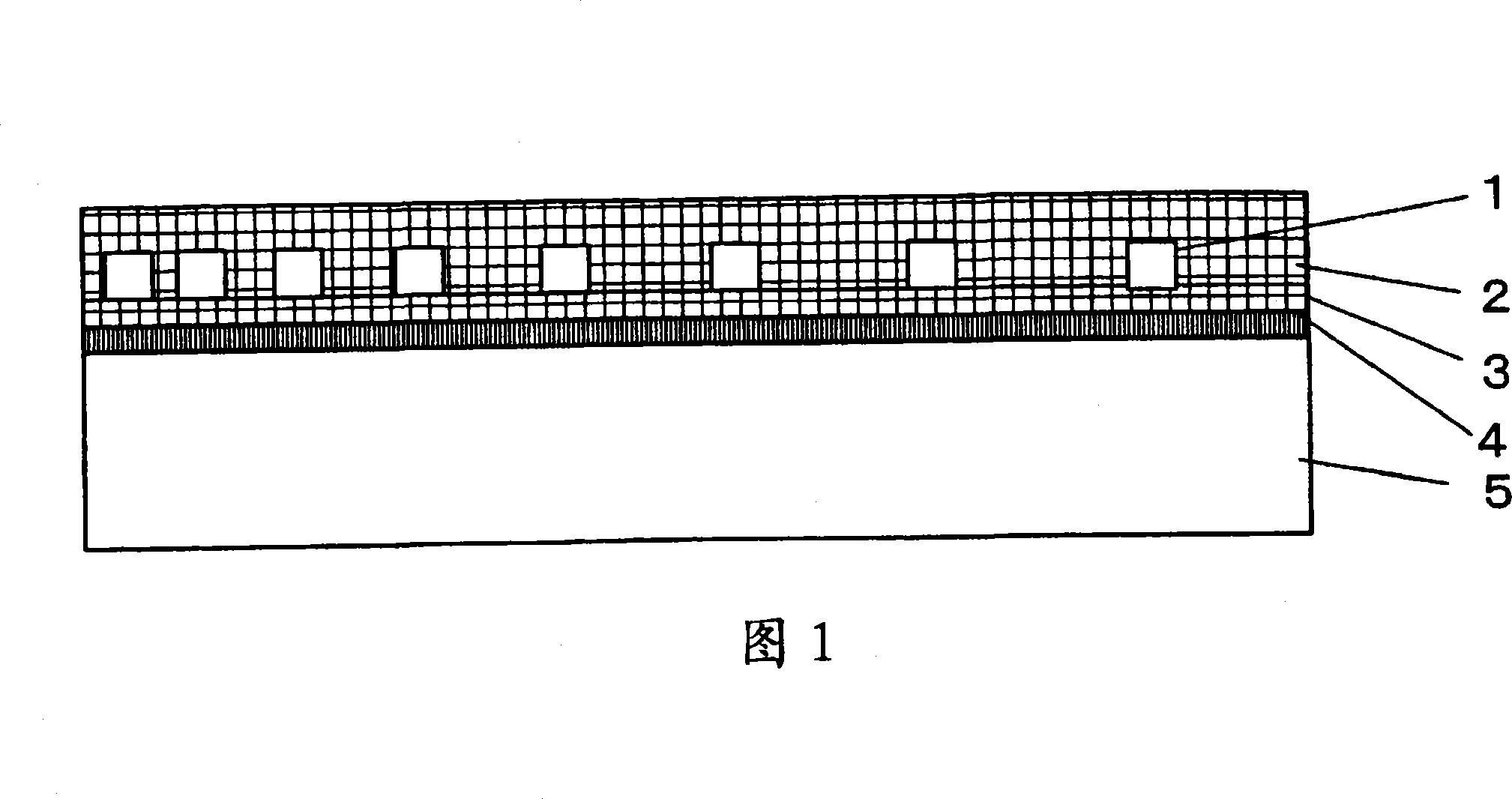

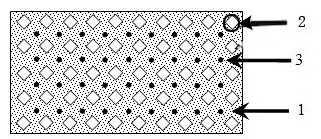

Hip prosthesis handle surface nanometer biological active coating and preparing method thereof

ActiveCN105779955AReduce internal stressImprove adhesionVacuum evaporation coatingSputtering coatingIonBiocompatibility Testing

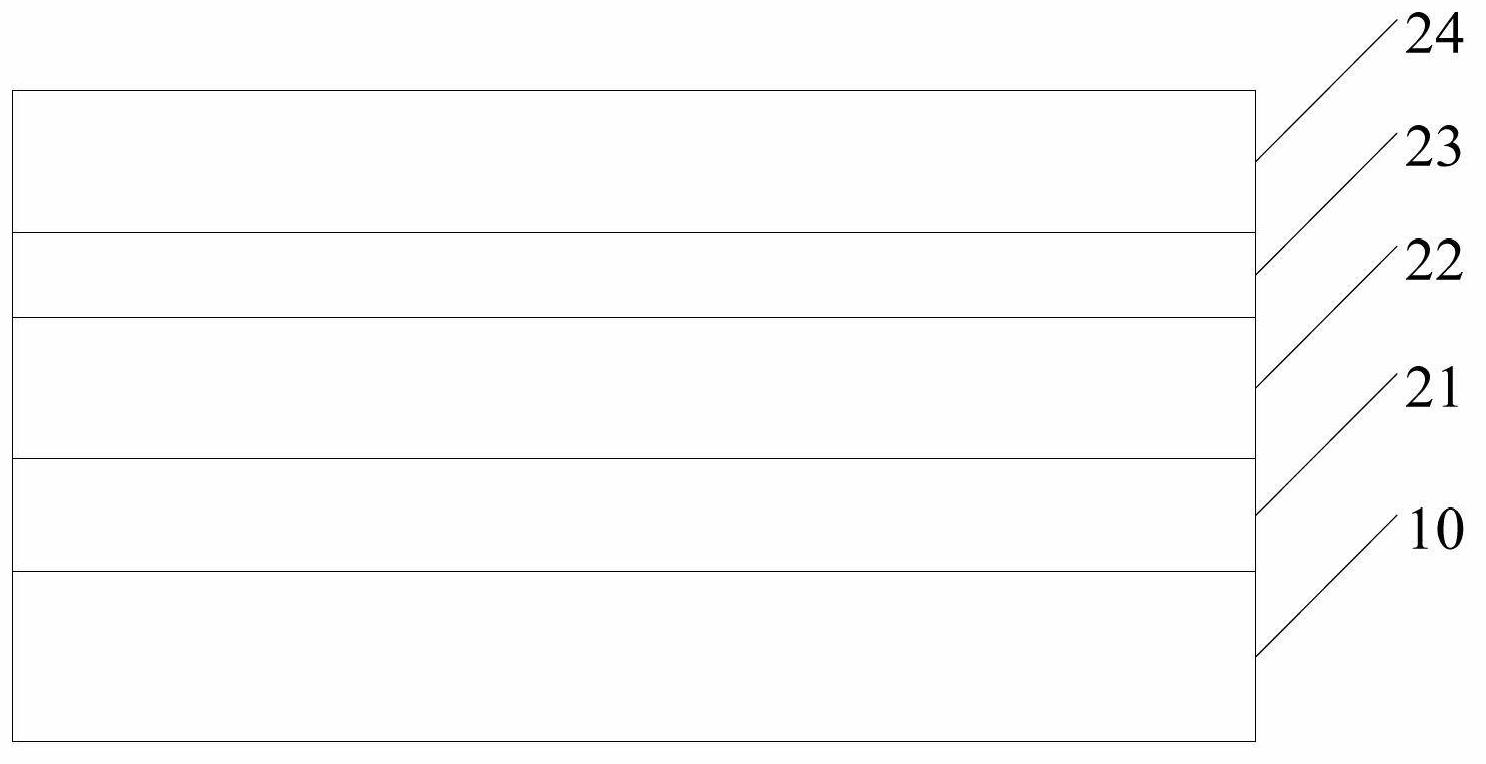

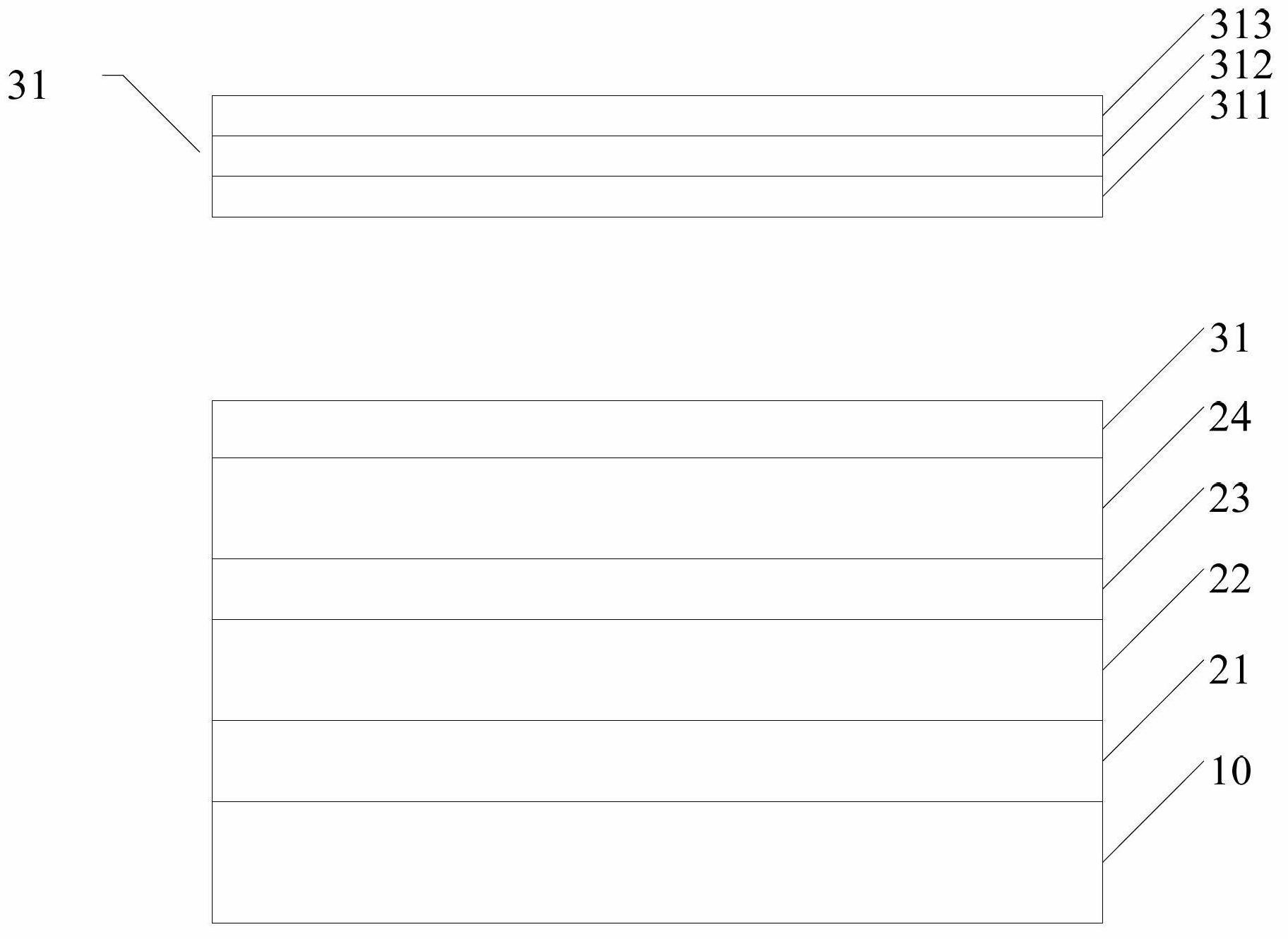

The invention relates to a hip prosthesis handle surface nanometer biological active coating and a preparing method thereof. The hip prosthesis handle surface nanometer biological active coating is characterized in that a joint handle surface is sequentially formed by a Ti6Al4V matrix (1), a metal Ti layer (2), a metal Ti and compact ceramic mixing layer (3), a compact ceramic layer (4), a compact ceramic and BAG / HA / Si mixing layer (5) and a BAG / HA / Si multi-element biological active layer (6). A non-equilibrium magnetic sputtering technology is adopted for sequential deposition of a multifunctional nanometer gradient composite coating with continuously-changed ingredients. The coating prepared from the method has the good biological activity, the good biocompatibility and the good membrane-matrix bonding strength, and BAG and HA are compounded so that the degradation speed of the coating can be regulated and controlled to be closer to the human tissue; a compact transition layer can effectively prevent releasing of harmful metal ions; and Si is a catalyst for converting BAG to apatite and plays an important role in initial bone calcification. By means of the hip prosthesis handle surface nanometer biological active coating and the preparing method, the bonding strength of the prosthesis handle and the surface coating can be improved, firm chemical bonding with the human bone tissue can be formed, releasing of the harmful metal ions is reduced, and the using reliability of the prosthesis handle is improved.

Owner:CHINA UNIV OF MINING & TECH

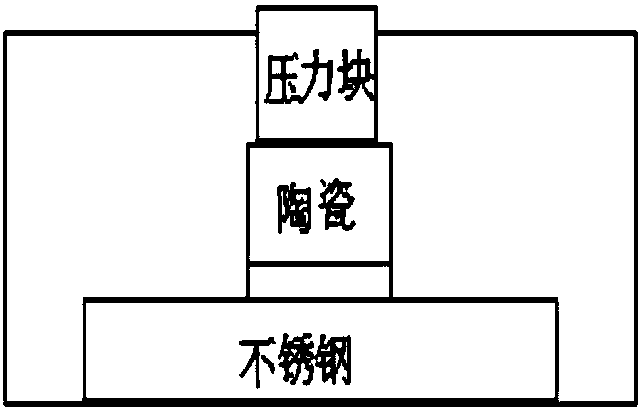

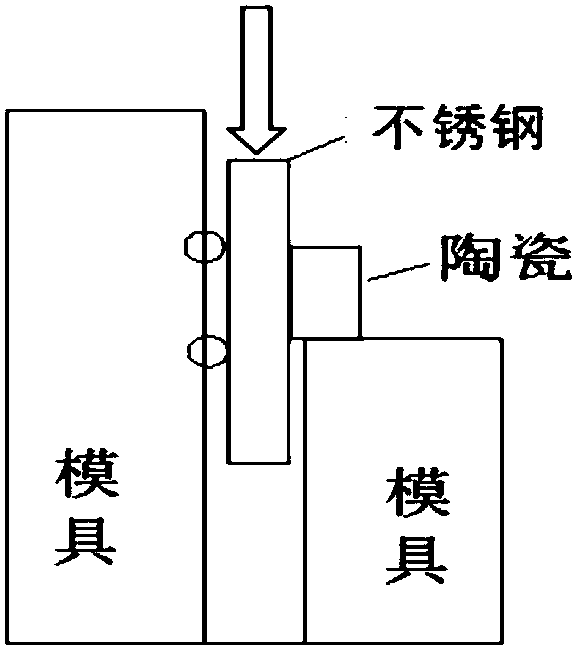

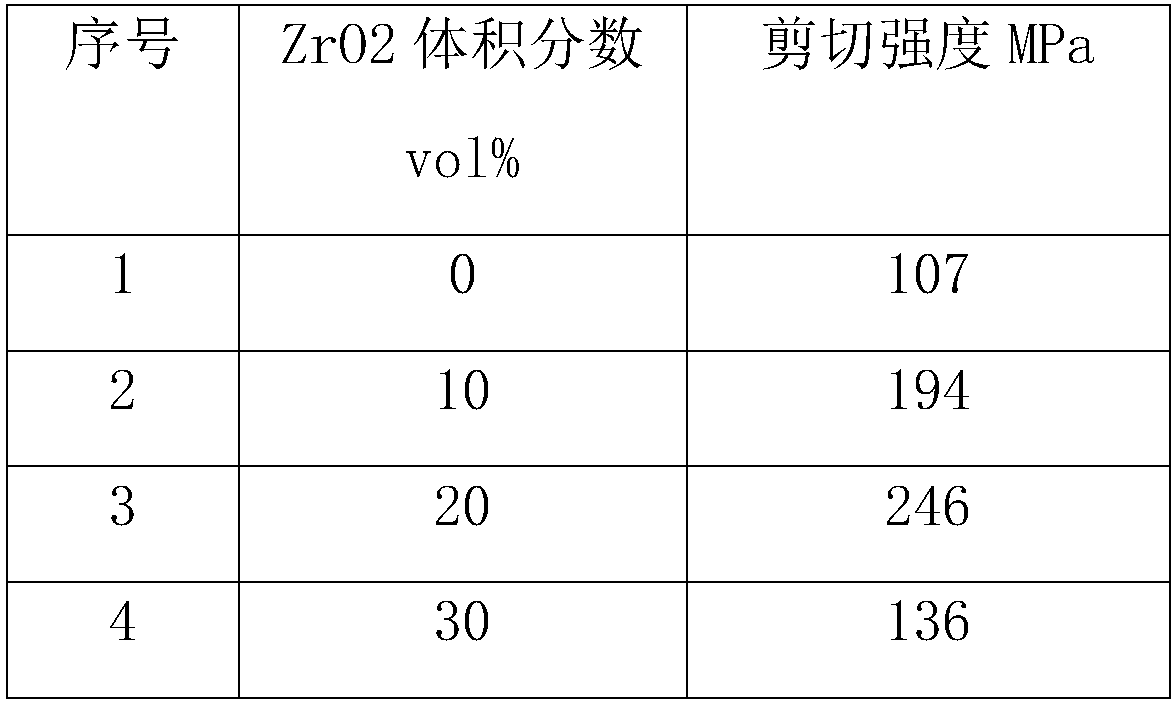

Welding connection method of oxide ceramic and metal

InactiveCN108546095AProne to residual stressSmall difference in coefficient of thermal expansionOxide ceramicComposite ceramic

The invention discloses a welding connection method of oxide ceramic and metal, using brazing filler metal as an interlayer to connect ceramic and stainless steel metal in a vacuum high temperature environment. The method comprises the following steps: step S1: preparing the ceramic; step S2: making a brazing sample; step S3: performing high-temperature high-vacuum brazing on the sample. The invention relates to the field of connection between different materials, in particular to a connection method of the oxide ceramic and the stainless steel metal, integrating performance advantages of bothceramic and metal in application. Particularly a brazing connection method of aluminum oxide ceramic as well as composite ceramic thereof and the stainless steel metal is disclosed; the used interlayer adopts (Ag72-Cu28)96Ti4 brazing filler metal. The toughness, strength, wear resistance and the like can meet the application requirements in fields such as kitchenware, mobile phone cover plates, auto parts and aviation.

Owner:GUANGDONG UNIV OF TECH

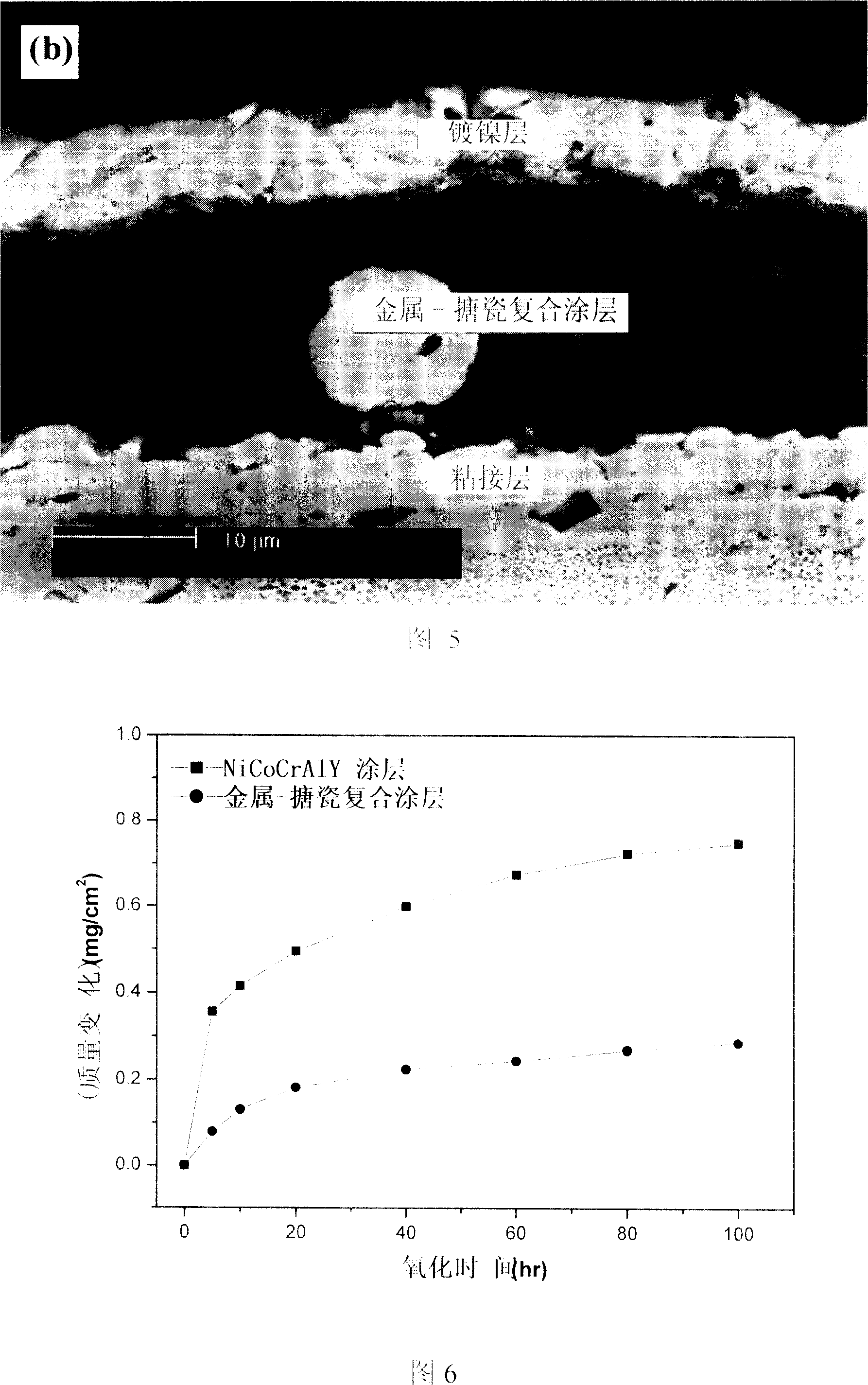

High-temperature alloy protecting coating and method of preparing the same

InactiveCN101109086AImprove thermal shock resistanceImprove thermal shock performanceThermal expansionSuperalloy

A protection coating for a hi-temp alloy is characterized in that, the coating is a compound coating of metal and enamel formed by spreading some metallic powder on an enamel substrate. Wherein, the metallic powder is MCrAlY powder of high thermal expansion rate coefficient and good resistance to hi-temp corrosion, M is one from Ni, Co, NiCo or any combination of them. Way for preparing the protection coating for hi-temp alloy is: first of all the metallic powder is fully mixed with the enamel powder, then the mixed powder is sprayed on the surface of a specimen, still then a metal-enamel compound coating spread on the enamel substrate is formed by high temperature sintering. The metal-enamel compound coating prepared by the invention is not only furnished with excellent resistance to hi-temp corrosion, but also highly improved thermal expansion rate coefficient because of the addition of plastic metallic powder, and greatly improved thermal vibration property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

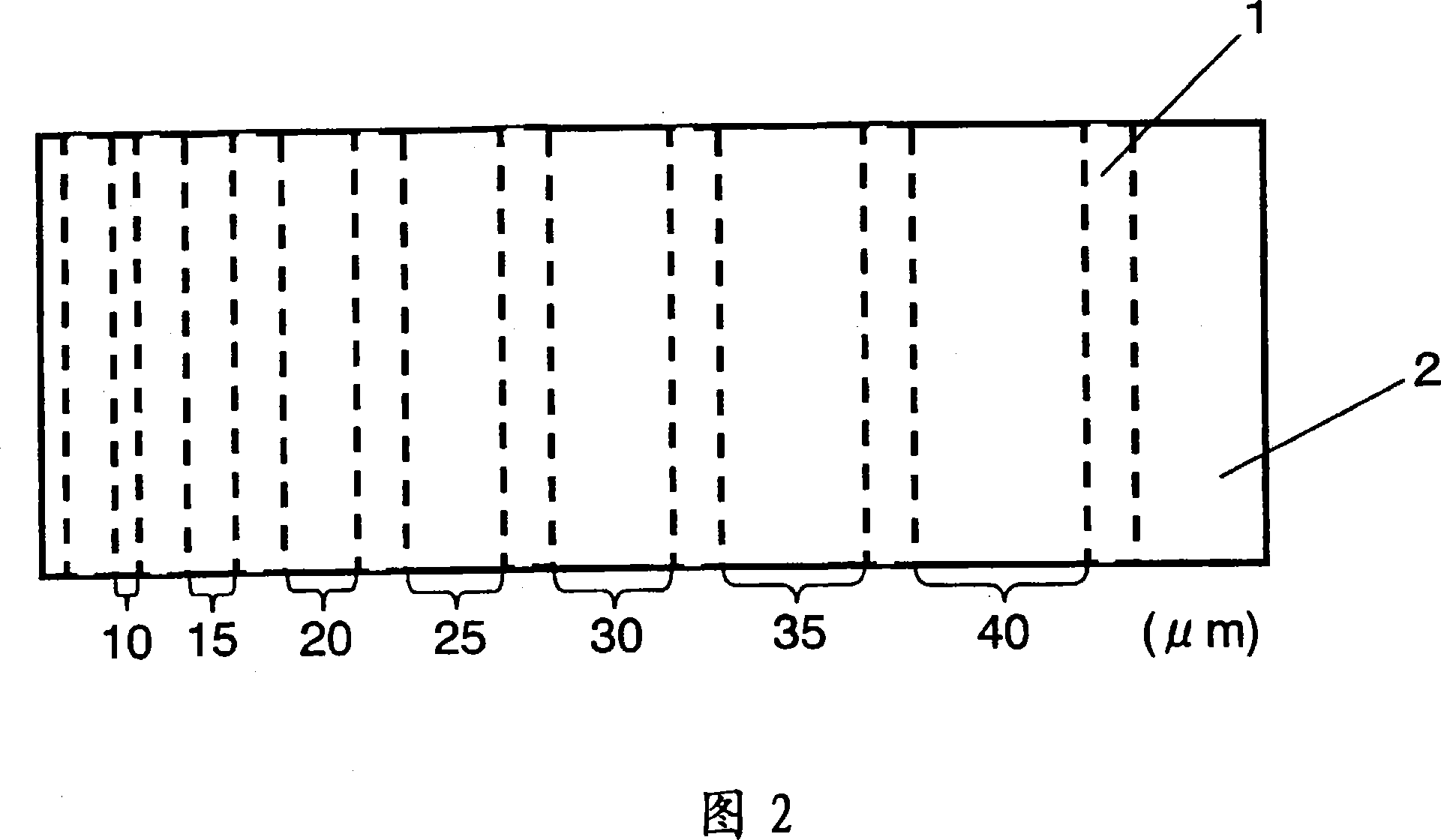

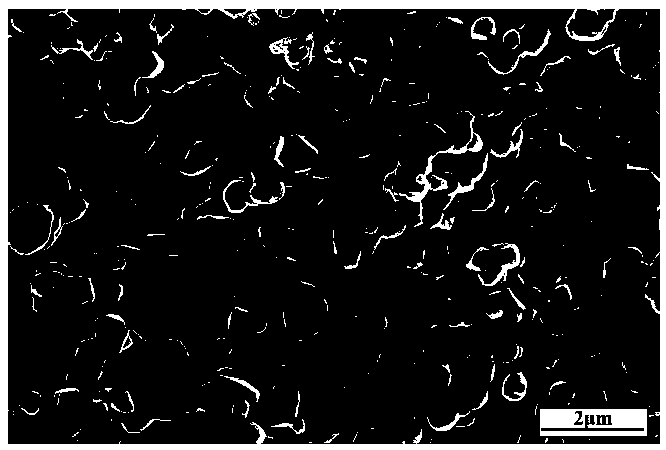

Optical wiring resin composition and photo-electric composite wiring board

InactiveCN101014890ALittle temperature dependenceSmall optical propagation lossCircuit optical detailsPrinted circuit aspectsRefractive indexEngineering

An optical wiring resin composition slightly different in thermal expansion coefficient from an electric wiring board, close in process temperature to it, small in light propagation loss, and suitable for combination with an electric wiring board; and a photo-electric composite wiring board. The optical wiring resin composition is a resin composition comprising inorganic fillers having an average particle size of 1nm through 100nm and resin, wherein the ratio nf / nr between the refractive index nf of the inorganic filler and the refractive index nr of the resin satisfies 0.8 through 1.2, the thermal expansion coefficient of the resin component is -1*10-5 / DEG C through 4*10-5 / DEG C, the true temperature dependency of its refractive index at -20 DEG C through 90 DEG C is -1*10-4 / DEG C through 1*10-4 / DEG C, and the resin layer is substantially free from light absorption at a wavelength of 0.6-0.9 m or at a wavelength of 1.2-1.6 m.

Owner:TORAY IND INC

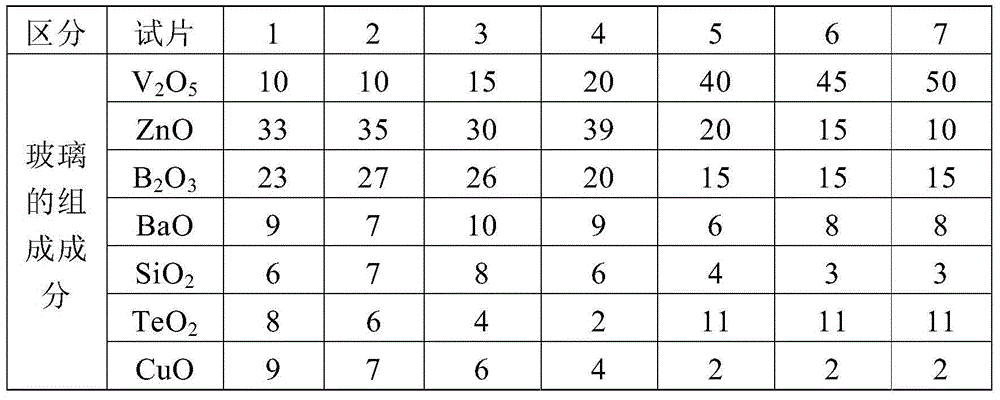

Glass Frit Using Glass Powder With Low Melting Point And Crystalline Ceramic Filler With Low Expansion And Paste Comprising The Same

ActiveCN104973785ASmall difference in coefficient of thermal expansionReduced loss of adhesionWater resistanceOLED

Disclosed are a glass frit using low melting point glass powder with superior durability, sealing reliability, and water resistance which is suitable for an OLED panel sealing, and a low expansion crystalline ceramic filler which controls a coefficient of thermal expansion, and a paste including the same. According to the present invention, the low melting point glass frit comprises the low melting point glass powder consisting of 0.1-20mol% of V2O5, 30-60mol% of ZnO, 10-30mol% of B2O3, 0.1-10mol% of BaO, 0.1-10mol% of SiO2, 0.1-15mol% of TeO2, and 2-20mol% of at least one of CuO, Fe2O3, and Co3O4; and less than 70 parts by weight of low expansion crystalline ceramic filler with respect to 100 parts by weight of the low melting point glass powder.

Owner:BASS PUBLIC

Target material assembly forming method

InactiveCN110937911ASmall difference in coefficient of thermal expansionReduce thermal stressWelding/cutting media/materialsSoldering mediaComposite materialWeld strength

The invention relates to a target material assembly forming method, which comprises: providing a ceramic target material, wherein the ceramic target material is provided with a target material weldingsurface; providing a metal back plate, wherein the metal back plate is provided with a back plate welding surface; plating nickel on the welding surface of the target material to form a nickel plating layer; placing a solder on the surface of the nickel plating layer and the welding surface of the back plate, and welding the ceramic target material and the metal back plate to form the target material assembly. According to the invention, the welding strength between the ceramic target material and the metal back plate can be improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

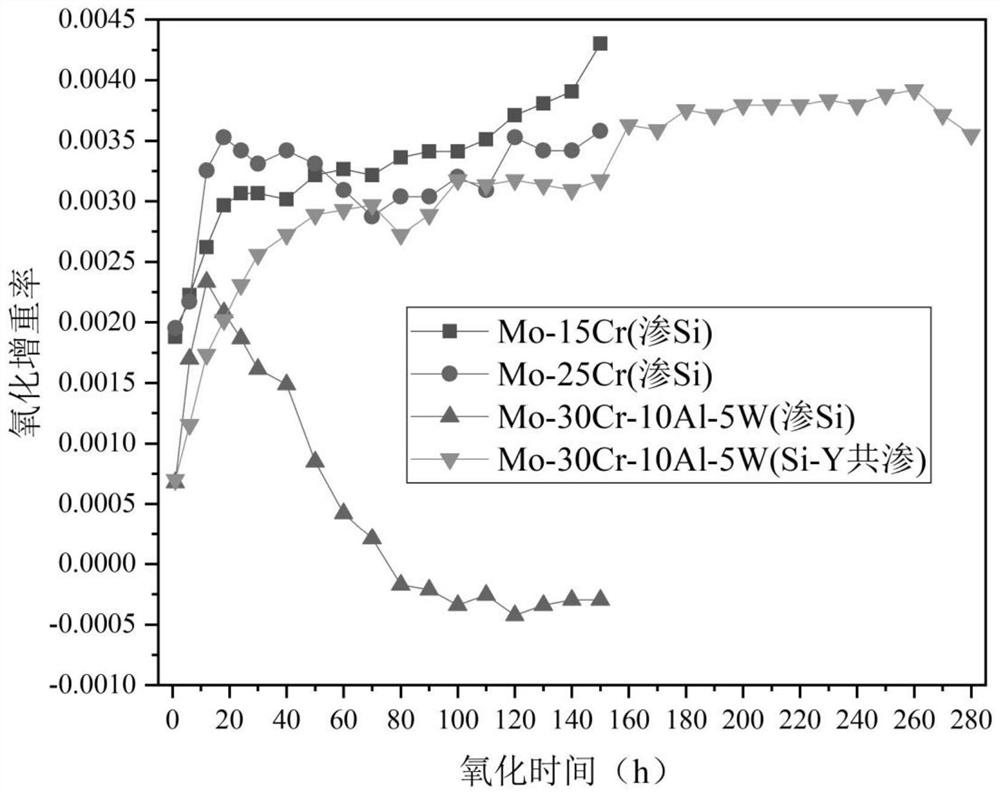

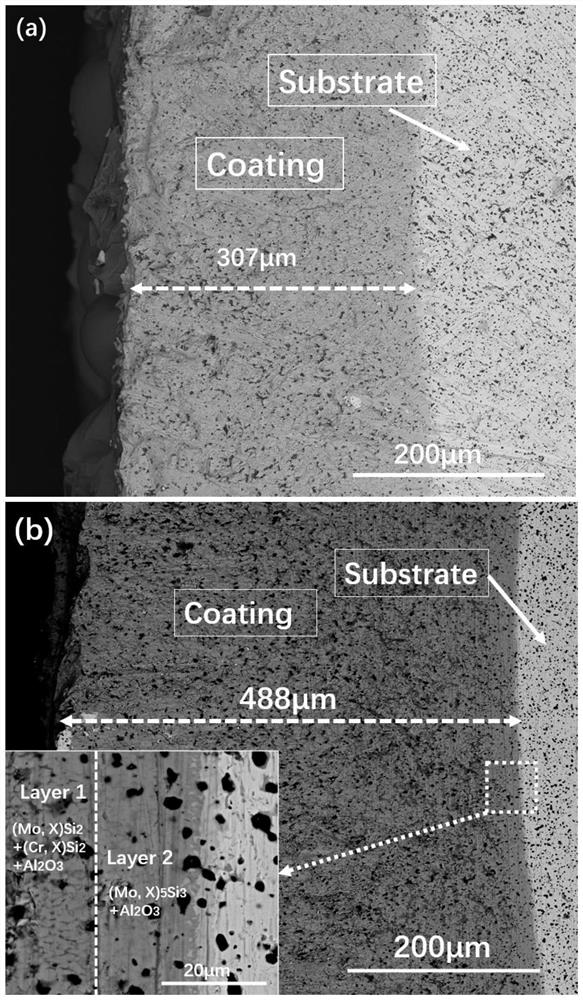

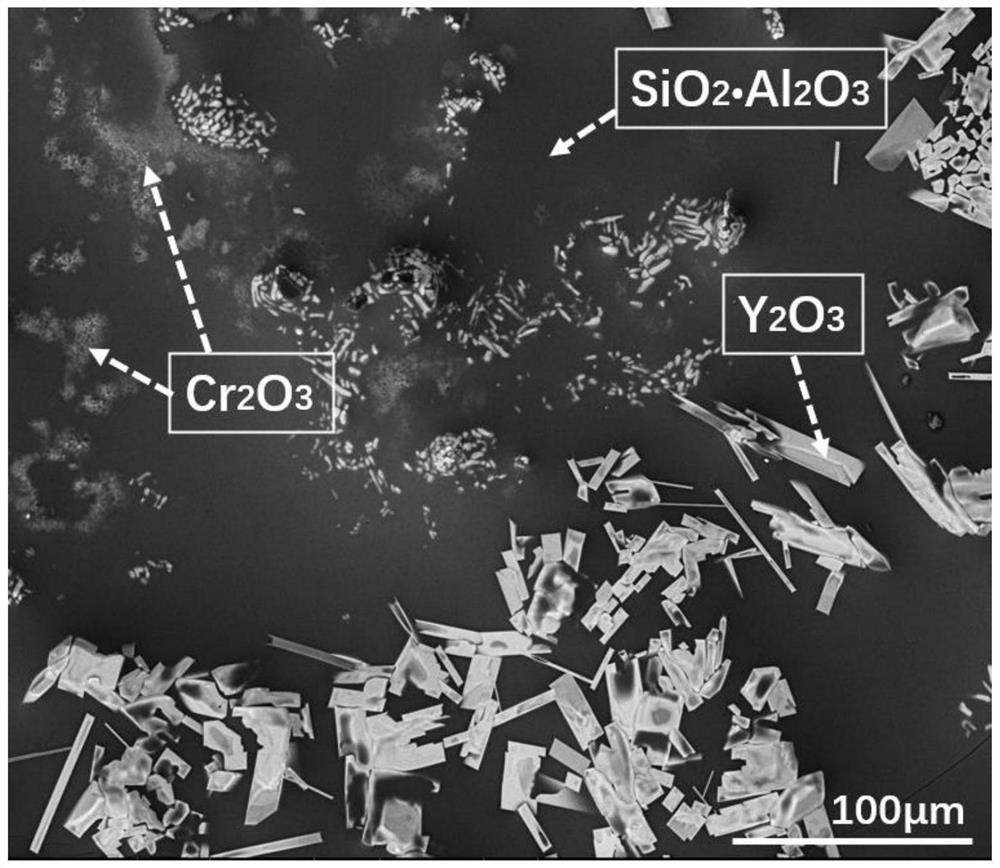

Molybdenum alloy containing antioxidant composite coating and preparation method thereof

ActiveCN113025951AImprove antioxidant capacityImprove bindingSolid state diffusion coatingOxidation resistantSurface modification

The invention discloses a molybdenum alloy containing an antioxidant composite coating and a preparation method thereof, and relates to the technical field of high-temperature alloy thermal protection. The molybdenum alloy containing the antioxidant composite coating comprises a molybdenum alloy matrix and a composite coating on the surface of the molybdenum alloy matrix; the composite coating at least comprises a (Mo, X)Si2 phase and a (Cr, X)Si2 phase; the composite coating can further have a double-layer structure; the outer layer at least comprises the (Mo, X)Si2 phase and the (Cr, X)Si2 phase; the inner layer at least comprises a (Mo, X)5Si3 phase; X in the (Mo, X)Si2 represents Cr, Ti or W; and X in the (Cr, X)Si2 represents Mo, Ti or W. The preparation method comprises the following steps: preparing the molybdenum alloy matrix and preparing the composite coating on the surface of the alloy by adopting co-permeation; and the molybdenum alloy protected by the (Mo, X)Si2-(Cr, X)Si2-based composite coating is prepared by adopting a method for combining matrix alloying and surface modification, an alloying and compounding method and a multi-layer structure combined modification silicide coating. The molybdenum alloy has excellent medium-temperature and high-temperature oxidation resistance.

Owner:NANCHANG UNIV

Surfacing treatment method of winding drum of wire drawing machine

InactiveCN103203519AAvoid crackingSmall difference in coefficient of thermal expansionArc welding apparatusHardnessEngineering

The invention discloses a surfacing treatment method of a winding drum of a wire drawing machine. The surfacing treatment method comprises the following steps of: carrying out cylindrical turning a winding drum body subjected to destressed heat treatment, carrying out sand-spraying oil-removing and water-removing pretreatment on the surface, preheating the winding drum in an electric furnace to be 350-400 DEG C, carrying out automatic surfacing with submerged arcs, stopping the surfacing when a surfacing layer reaches 5-6mm, then carrying out slow-cooling treatment, heating the winding drum in the electric furnace to be 400 DEG C, insulating for 2 hours, cooling along with the furnace, and finally forming the winding drum by turning and grinding. The surfacing treatment method has the advantages that the hardness of the winding drum reaches HRC57-60, the wear resistance is good and the service life is long.

Owner:GUIZHOU WIRE ROPE

Alloy electrode for skutterudite thermoelectric element and preparation method thereof

ActiveCN106299099AImprove conductivityGood welding performanceThermoelectric device manufacture/treatmentThermoelectric device detailsChemical platingSkutterudite

The invention relates to an alloy electrode for a skutterudite thermoelectric element and a preparation method thereof. The alloy electrode provided by the invention is an alloy electrode deposited at two end parts of the skutterudite thermoelectric element. The alloy electrode is made of a Ni-Mo alloy or a Ni-W alloy, wherein the molar percentage content of Mo in the Ni-Mo alloy is 10%-40%, the molar percentage content of W in the Ni-W alloy is 5%-40%. In the invention, the selected electrode material is a Ni(Mo) or Ni(W) alloy electrode prepared through an electroplating or chemical plating method. The alloy electrode is good in conductivity and excellent in weldability, the coefficient of thermal expansion of a Ni-containing electrode can be adjusted through substances with a small coefficient of thermal expansion such as Mo and W, and the difference between the electrode material and a skutterudite thermoelectric material in coefficient of thermal expansion is reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Method for manufacturing gallium nitride-based LED (Light Emitting Diode) with vertical structure

InactiveCN102185046AHigh thermal conductivitySmall difference in coefficient of thermal expansionSemiconductor devicesSemiconductor materialsSilicon alloy

The invention discloses a method for manufacturing a gallium nitride-based LED (Light Emitting Diode) with a vertical structure. The method comprises the following steps of: (1) extending an n-type semiconductor layer and a p-type semiconductor layer on a sapphire substrate in sequence to form an LED wafer, performing metal evaporation on the surface of the LED wafer and treating in a nitrogen atmosphere at the temperature between 200 DEG C and 400 DEG C for 1-10 minutes to form a p electrode, and partitioning the LED wafer into independent LED chips; (2) evaporating gold layers on the upper surface and the lower surface of a composite metal substrate respectively, wherein the composite metal substrate is made of a copper-molybdenum alloy or an aluminum-silicon alloy; (3) reversely welding the independent LED chips obtained in the step (1) onto the upper surface of the composite metal substrate respectively; (4) stripping substrates of the LED chips; and (5) manufacturing an n-type electrode on an n-type semiconductor material of each LED chip. In the method, a CuMo or AlSi composite metal substrate with high thermal conductivity is taken as a transfer substrate and has a small thermal expansion coefficient difference from a transferred LED chip, the thermal stress is small, and the bonding yield is increased.

Owner:TONGHUI ELECTRONICS

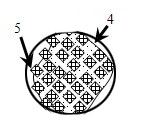

Method for manufacturing grinding wheel work layer with abrasive particle dressing function

ActiveCN102172902ASolve the disadvantages of easy aggregationSmall difference in coefficient of thermal expansionGrinding devicesWear particleBoron nitride

The invention relates to a method for manufacturing a polycrystalline cubic boron nitride (PCBN) grinding wheel work layer with an abrasive particle dressing function, belonging to the manufacture field of superhard grinding material tools. The method comprises the following steps: abrading particles for Cu-Sn-Ti alloy powder and PCBN, fusing TiC particles, preparing a blank and sintering at hightemperature. The PCBN abrasive particle is formed by sintering CBN (cubic boron nitride) microcrystalline particles and AlN binder at high temperature and under high pressure. Once the CBN microcrystalline particles are blunt, the junction interface of CBN microcrystalline 5 and AlN binder is weakened along with the rise of the grinding force and the grinding temperature, so that the blunt CBN microcrystalline particles fall, and new CBN microcrystalline particles are quickly exposed to participate in the grinding process. The micro-breaking characteristics of the PCBN abrasive particles cause the superhard grinding material grinding wheel to still keep high sharp degree and avoid the phenomenon that grinding force and grinding temperature rapidly rise.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Silicon nitride-based ceramic ball as well as preparation method and application thereof

InactiveCN111533561AImprove wear resistanceImprove corrosion resistanceShaftsBearing componentsCarbide siliconWear resistance

The invention discloses a silicon nitride-based ceramic ball as well as a preparation method and application thereof. The silicon nitride-based ceramic ball is formed by depositing a silicon carbide layer on the surface of a silicon nitride ceramic ball. Compared with a silicon nitride ball without a silicon carbide layer deposited, the disclosed silicon nitride-based ceramic ball is not prone tocorrosion and weightlessness in strong acid, strong alkali and kinematic friction states, meanwhile, an interface in contact with the strong acid and strong alkali environment is compact pure siliconcarbide and free of sintering aids, and the silicon nitride-based ceramic ball has better wear resistance, corrosion resistance and the like and can be applied to the field of wear-resistant bearings.

Owner:佛山华骏特瓷科技有限公司

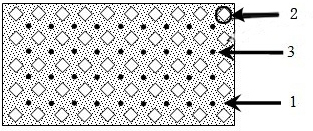

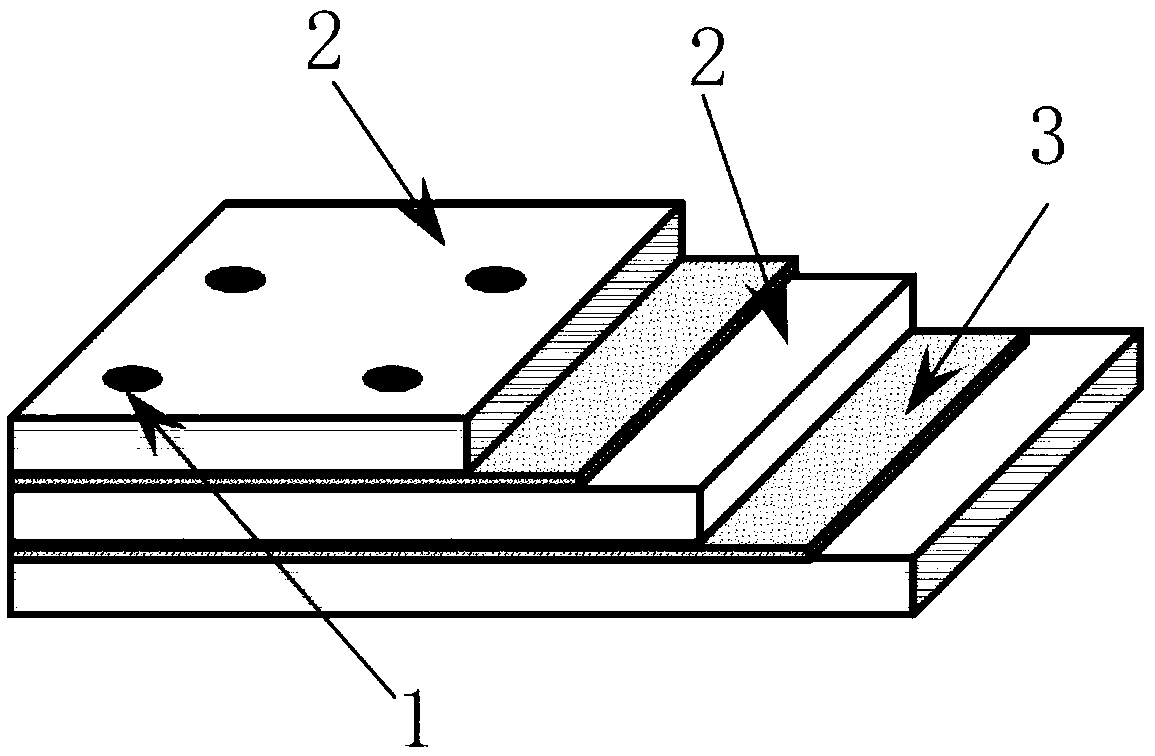

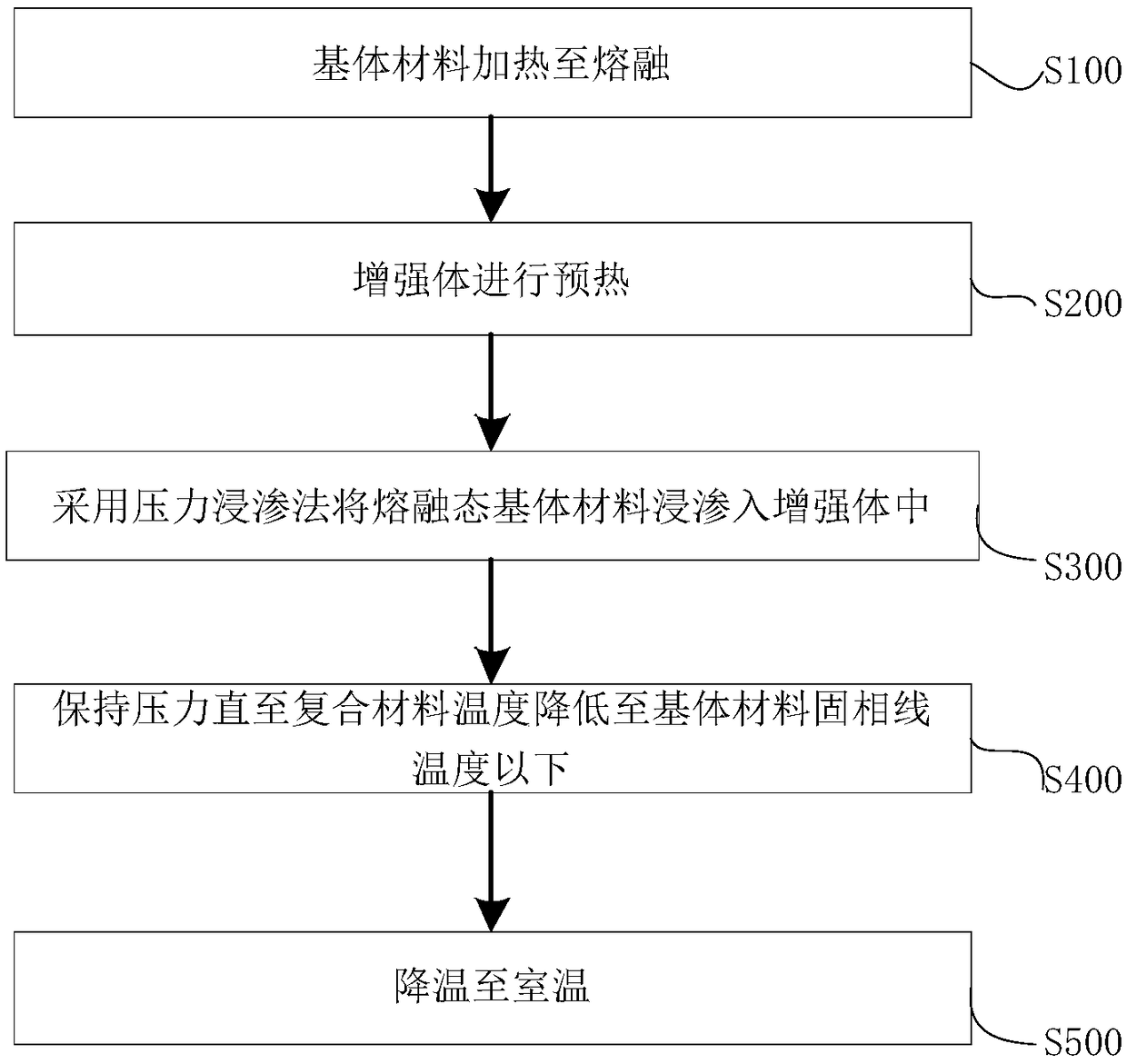

Multi-scale reinforced low/negative thermal expansion magnesium-based composite material and preparation method thereof

The invention discloses a multi-scale reinforced low / negative thermal expansion magnesium-based composite material and a preparation method thereof. The composite material comprises a base material and a reinforcement body, wherein the base material is prepared from magnesium alloy; the reinforcement body has a multi-scale 2.5D laminated structure, and comprises continuous fiber layers, negative expansion particle layers and Z-direction puncture reinforced fibers, wherein the continuous fiber layers and the negative expansion particle layers are alternately distributed; the upper surface layerand lower surface layer of the reinforcement body are the continuous fiber layers, and negative expansion particles are evenly distributed between the continuous fiber layers and bundles; Z-directionpuncture fiber bundles puncture and reinforce the continuous fiber layers and the negative expansion particle layers along the Z direction. The composite material effectively overcome the adverse effects, caused by'thermal expansion and contraction', on the traditional structural materials in a service process.

Owner:山东大华新材料集团有限公司

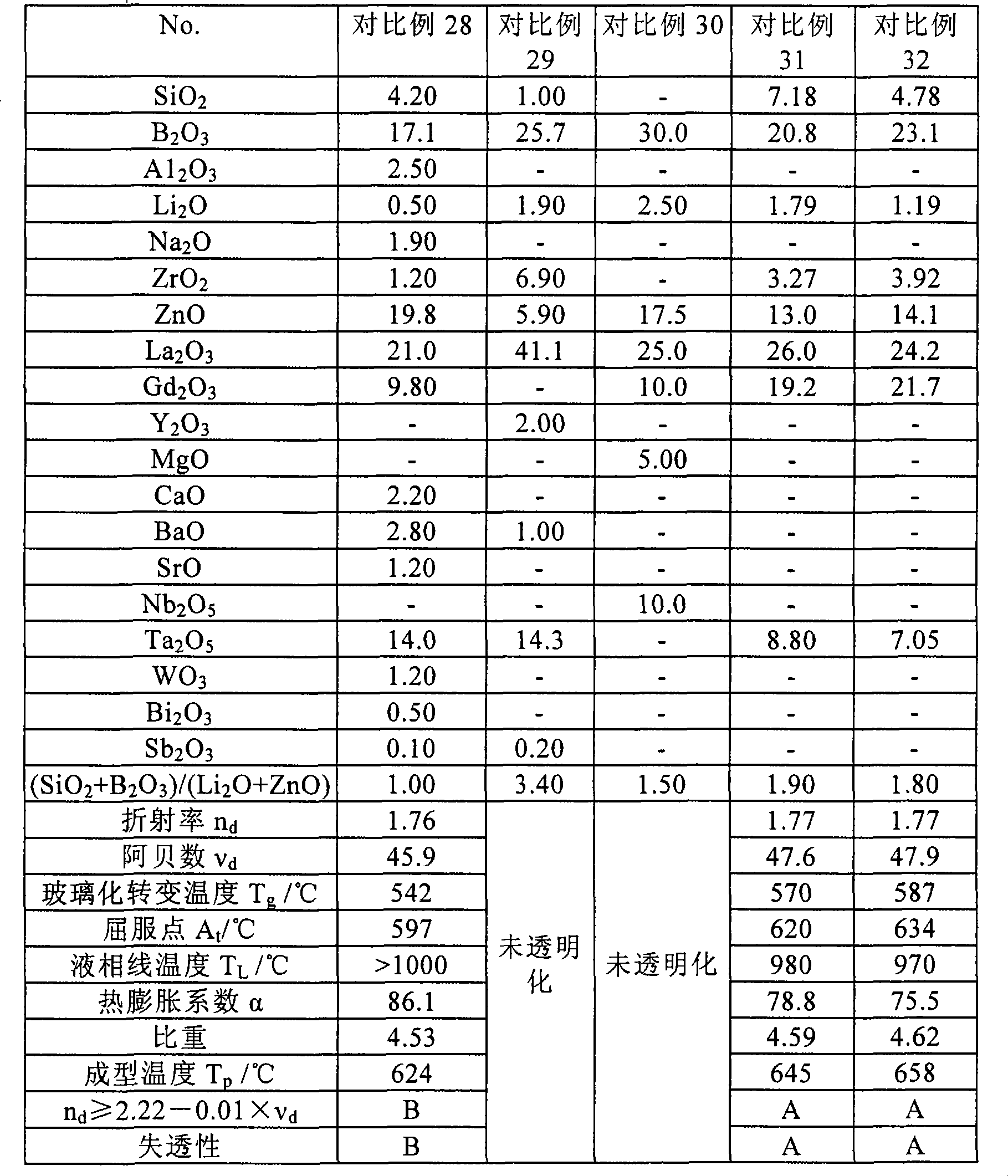

Optical glass and lens using the same

InactiveCN101466647AHigh refractive indexSmall dispersionOptical elementsOptical glassLanthanum compounds

Disclosed is an optical glass which comprises the following components (% by mass in terms of an oxide): B2O3: 13-27%; La2O3: 20-35%; Gd2O3: 5-25%; ZnO: 5-20%; Li2O: 0.5-3%; Ta2O5: 0.5-15%; and WO3: 0.5-10%, and which has a mass-based ratio between the total amount of SiO2 and B2O3 and the total amount of ZnO and Li2O (i.e., a (SiO2+B2O3) / (ZnO+Li2O) ratio) of 1.35 to 1.65. Also disclosed is a lens comprising the optical glass.

Owner:AGC INC

Stress regulated semiconductor and associated methods

InactiveCN102893419ASmall difference in coefficient of thermal expansionSemiconductor/solid-state device detailsSolid-state devicesCarbon layerElectrical conductor

Stress regulated semiconductor devices and associated methods are provided. In one aspect, for example, a stress regulated semiconductor device can include a semiconductor layer, a stress regulating interface layer including a carbon layer formed on the semiconductor layer, and a heat spreader coupled to the carbon layer opposite the semiconductor layer. The stress regulating interface layer is operable to reduce the coefficient of thermal expansion difference between the semiconductor layer and the heat spreader to less than or equal to about 10 ppm / DEG C.

Owner:RITEDIA CORPORATION

Method for alleviating thermal stress of porous silicon nitride ceramic and transparent aluminum nitride ceramic in connection process

ActiveCN108299004AAvoid crackingSmall difference in coefficient of thermal expansionCeramicwareOxygenNitride

The invention relates to a method for alleviating thermal stress of a porous silicon nitride ceramic and a transparent aluminum nitride ceramic in a connection process. By adopting the method, the porous silicon nitride ceramic is adopted as a transition layer to relieve the thermal stress of the porous silicon nitride ceramic and the transparent aluminum nitride ceramic in the connection process,the porosity of the porous silicon nitride ceramic is 30-70%, preferably 45-60%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

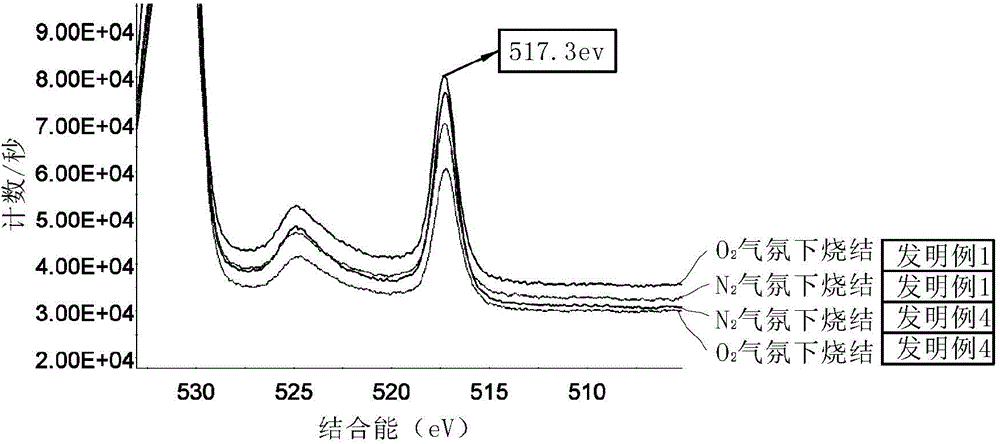

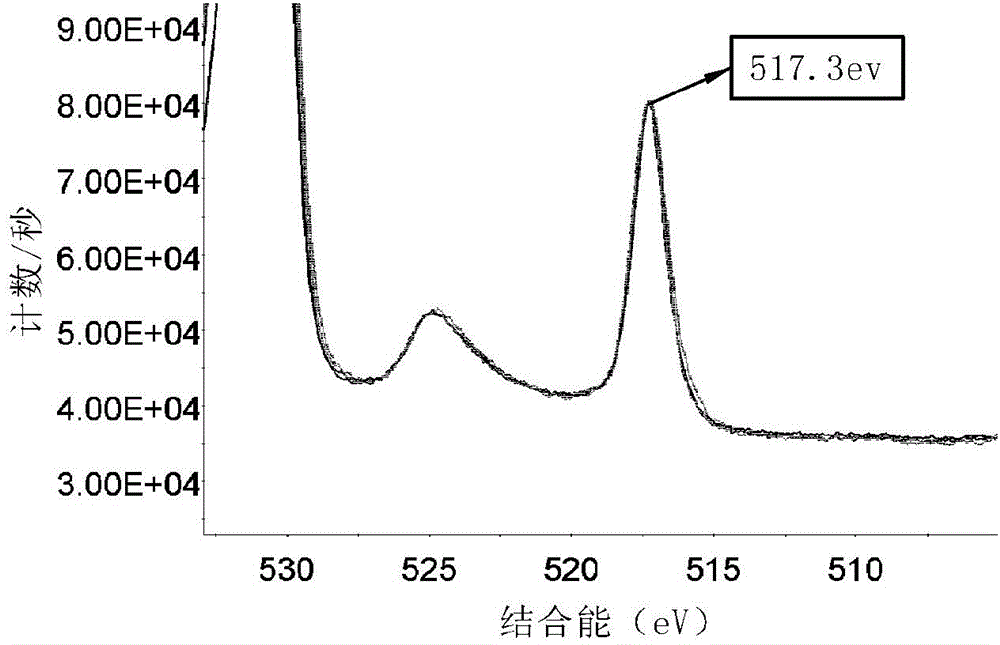

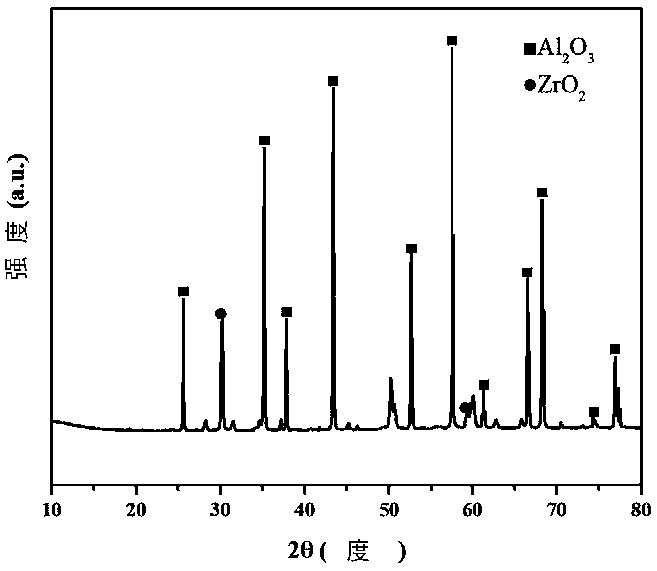

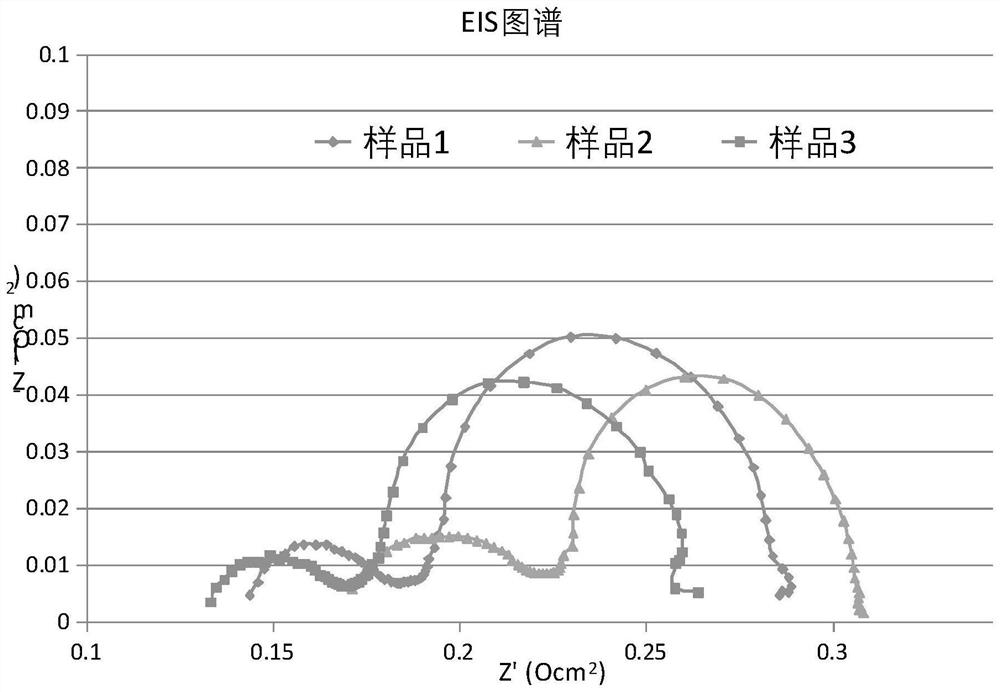

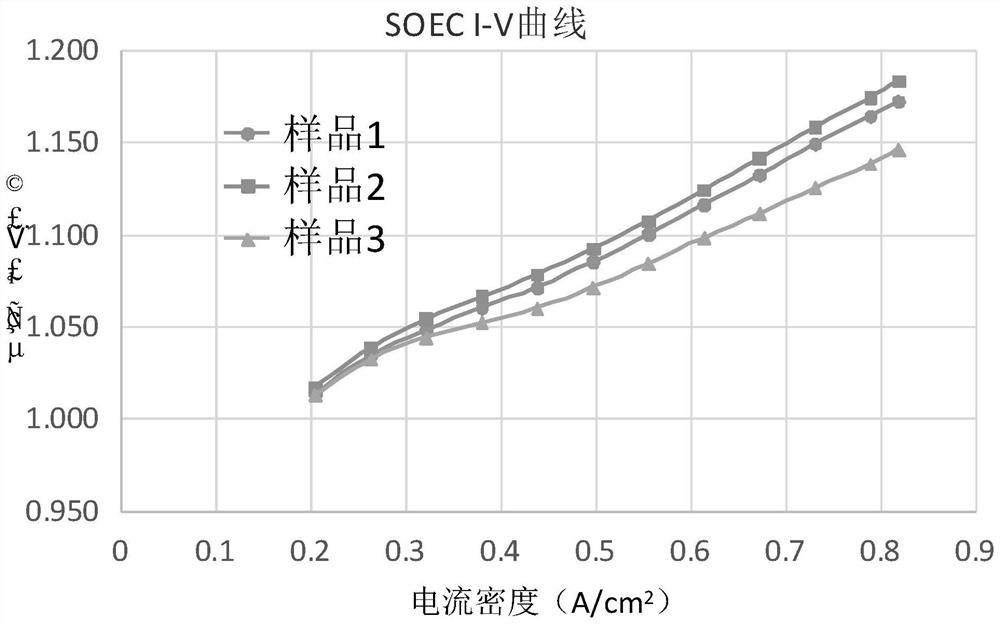

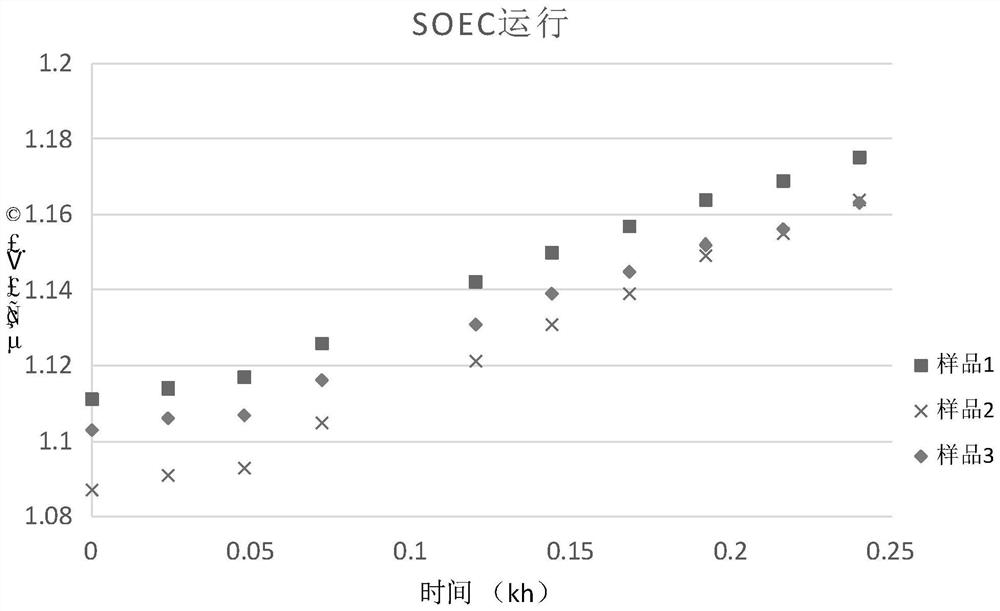

Oxygen electrode slurry of solid oxide electrolytic cell, preparation method of oxygen electrode slurry and solid oxide electrolytic cell

ActiveCN111962098ALower impedanceLower overpotentialCellsElectrode shape/formsMetal oxide nanoparticlesElectrolytic cell

The invention belongs to the technical field of solid oxide electrolytic cells, and particularly relates to oxygen electrode slurry of a solid oxide electrolytic cell, a preparation method of the oxygen electrode slurry and the solid oxide electrolytic cell. The invention provides a preparation method of oxygen electrode slurry of the solid oxide electrolytic cell, which comprises the following steps: step 1, loading metal oxide nanoparticles in an oxygen electrode powder material to prepare oxygen electrode powder; and 2, mixing the oxygen electrode powder, a second pore-forming agent and a binder to prepare the oxygen electrode slurry of the solid oxide electrolytic cell. The invention provides oxygen electrode slurry of the solid oxide electrolytic cell, a preparation method of the oxygen electrode slurry and the solid oxide electrolytic cell, and can effectively overcome the technical defects that the initial internal resistance of the existing SOEC is large and the impedance of anoxygen electrode is increased quickly.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

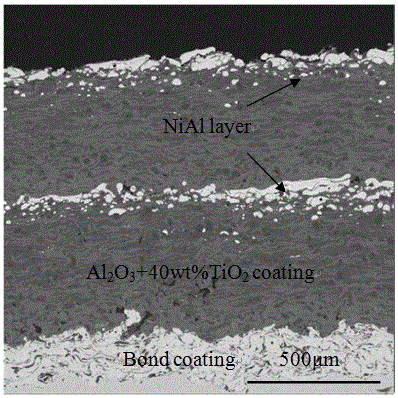

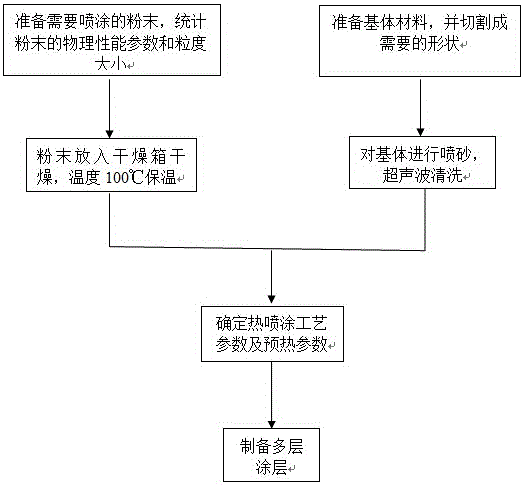

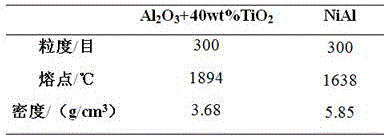

Method for preparing multi-layer coating by adopting thermal spraying method

ActiveCN106011721AImprove preparation efficiencyGood coating performanceMolten spray coatingThermal sprayingVolumetric Mass Density

The invention discloses a method for preparing a multi-layer coating by adopting a thermal spraying method, and belongs to the technical field of composite coatings. The method comprises the following steps: adopting a single spraying mode in a thermal spraying process, and feeding mixed powder of two or more different spraying materials on the same path; accelerating different powder in plume flow to obtain different speeds; and enabling different powder to have different difference while being sprayed to a basal body, thereby obtaining powder of different densities or grain sizes of the multi-layer coating. Compared with the prior art, the method enables coatings to be combined with each other better, so that the coatings have stronger plasticity; the method has the advantages of making preparation of a thicker coating possible, reducing defects on an interface and the like. The method further has the characteristics of being simple in process and equipment, saving time and energy, being high in efficiency and the like.

Owner:KUNMING UNIV OF SCI & TECH

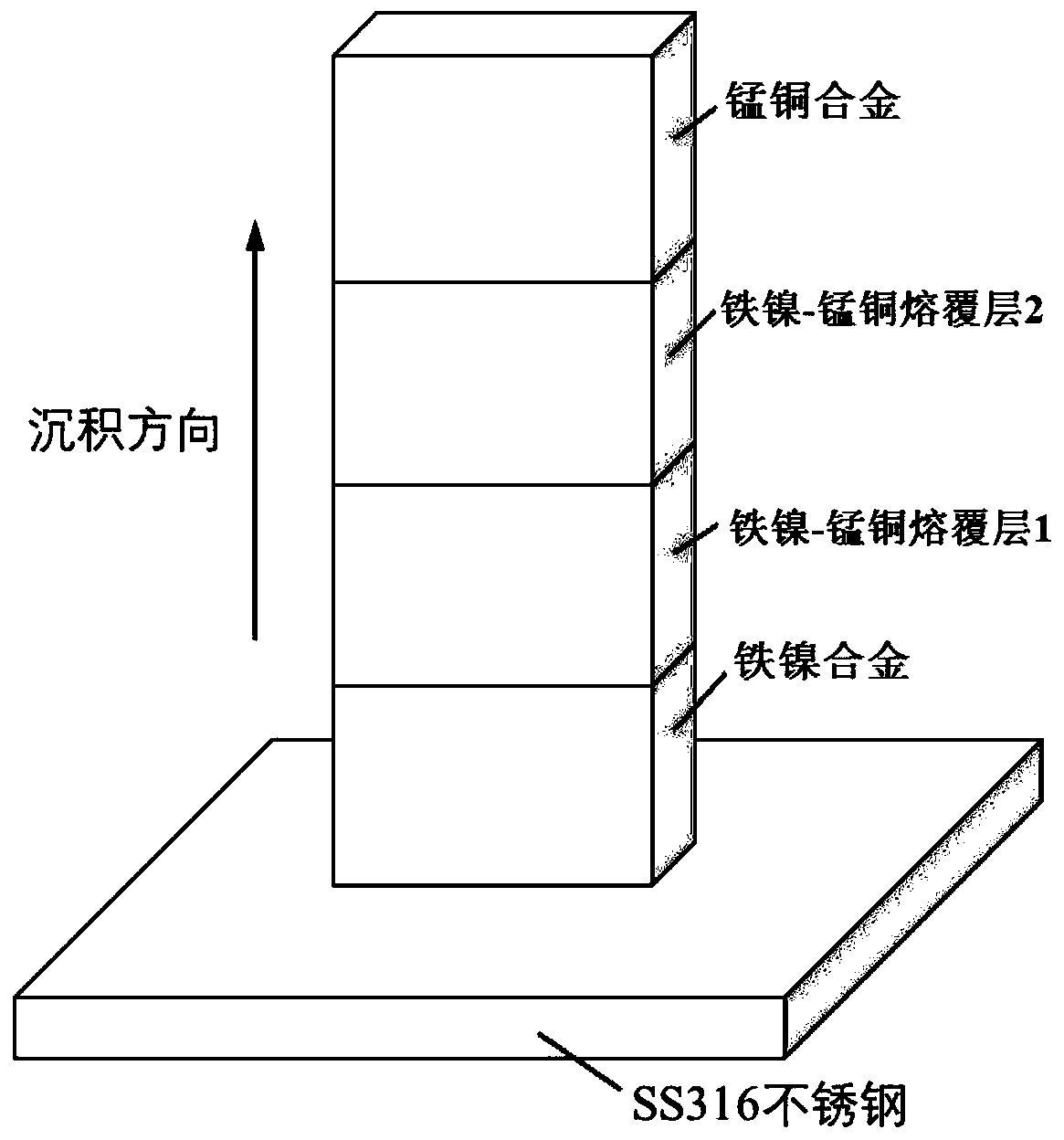

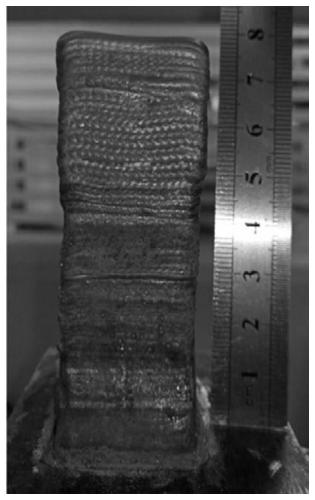

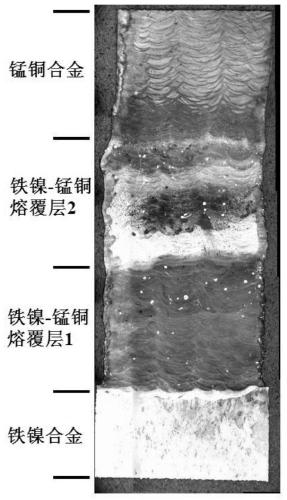

Laser additive manufacturing method for iron nickel-manganese copper dissimilar material metal part

ActiveCN111408720AAvoid crackingAvoid defects such as undissolved particlesAdditive manufacturing apparatusIncreasing energy efficiencyFernicoManganese

The invention discloses a laser additive manufacturing method of an iron nickel-manganese copper dissimilar material metal part. The method comprises the following steps that firstly, an iron-nickel alloy is deposited on a substrate by adopting a laser additive manufacturing method; secondly, mixed powder composed of iron-nickel alloy powder with the iron-nickel alloy powder mass content larger than 70% or smaller than 50% and manganese-copper alloy powder serves as a raw material, and an iron nickel-manganese copper transition area is formed through deposition with the laser additive manufacturing method; and thirdly, manganese-copper alloy is deposited on the iron nickel-manganese copper transition area through the laser additive manufacturing method, the substrate is removed, and the iron nickel-manganese copper dissimilar material metal part is obtained. According to the method, by adjusting the deposition direction and controlling the transition path of the mixed powder, the defects of cracking, undissolved particles and the like of the iron nickel-manganese copper gradient material are overcome, and the obtained iron nickel-manganese copper dissimilar material metal part is compact in structure and small in transition area size, has the damping performance and low expansion performance and is wide in application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

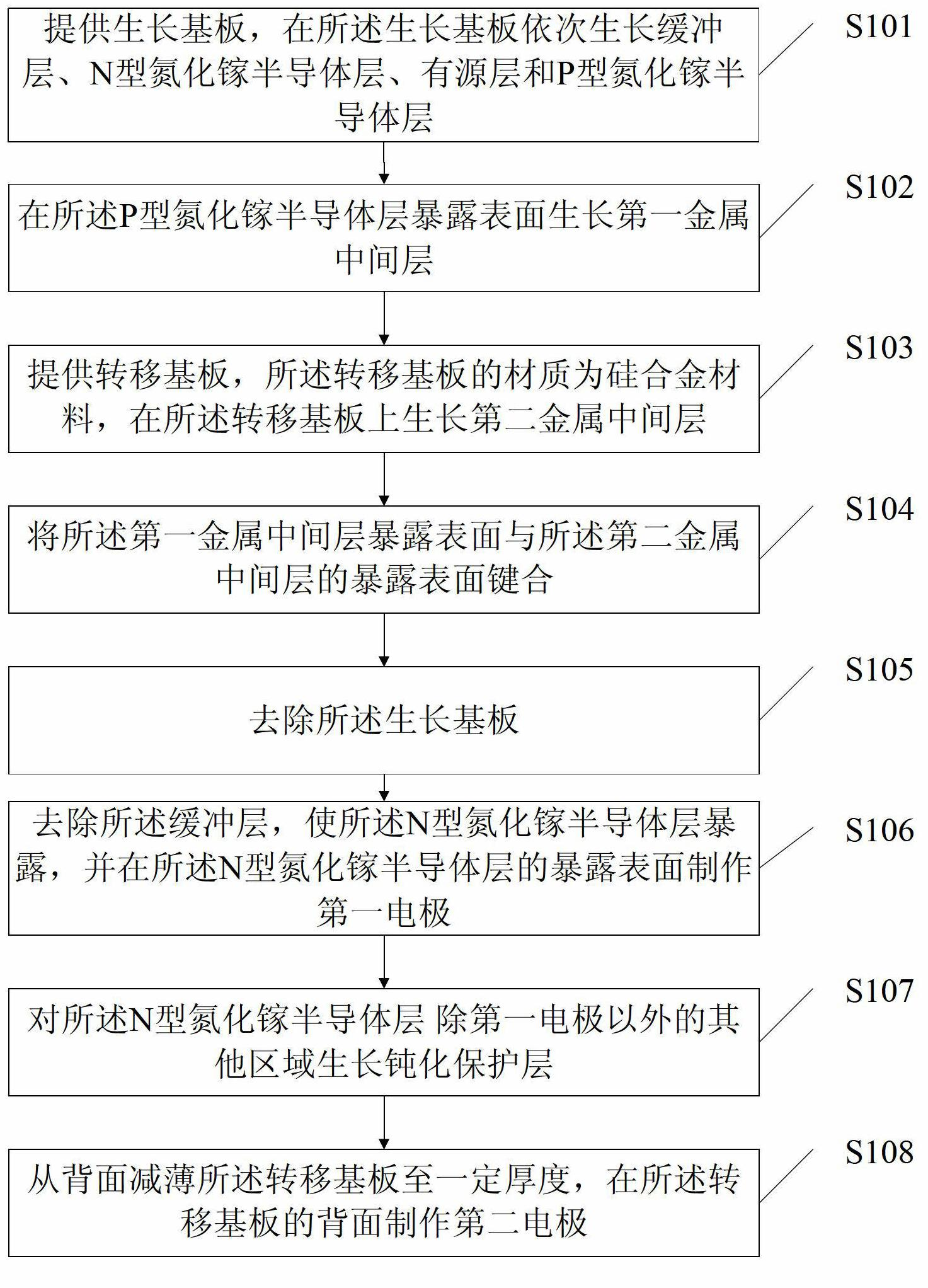

Inversed LED (Light Emitting Diode) chip structure and preparation method of inversed LED chip

InactiveCN102683524AReduce warpageIncrease saturation currentSemiconductor devicesSilicon alloyThermal expansion

The invention provides an inversed LED (Light Emitting Diode) chip structure which comprises a silicon alloy substrate, a metal middle layer, a P-type gallium nitride semiconductor layer, an active layer and a N-type gallium nitride semiconductor layer sequentially stacked from bottom to top. According to the inversed LED chip structure, a transfer substrate made of silicon alloy which is approximate to a growth substrate in thermal expansion coefficient is adopted as the substrate of the LED chip to reduce the staggered damage of lattices of an LED chip apparatus layer, therefore, the leakage current is reduced, and the performance of product is improved. The invention further provides a preparation method of the inversed LED chip structure.

Owner:HANGZHOU SILAN AZURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com