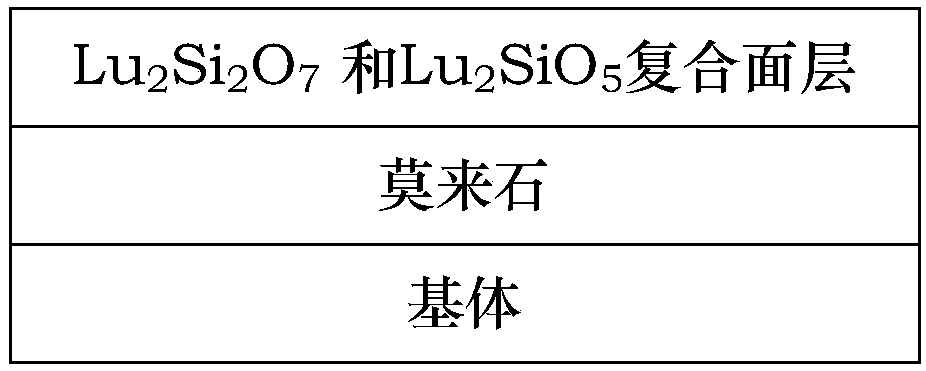

A rear earth lutetium silicate composite environmental barrier coating and a preparing method thereof

A lutetium silicate and environmental barrier technology is applied in the field of rare earth lutetium silicate composite environmental barrier coating on the surface of SiC/SiC material and its preparation, which can solve the problem that the use of environmental barrier coating cannot be satisfied, and the coating is prone to microcracks. , poor process controllability and other problems, to achieve good water vapor corrosion resistance, excellent water vapor resistance, and reduce thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

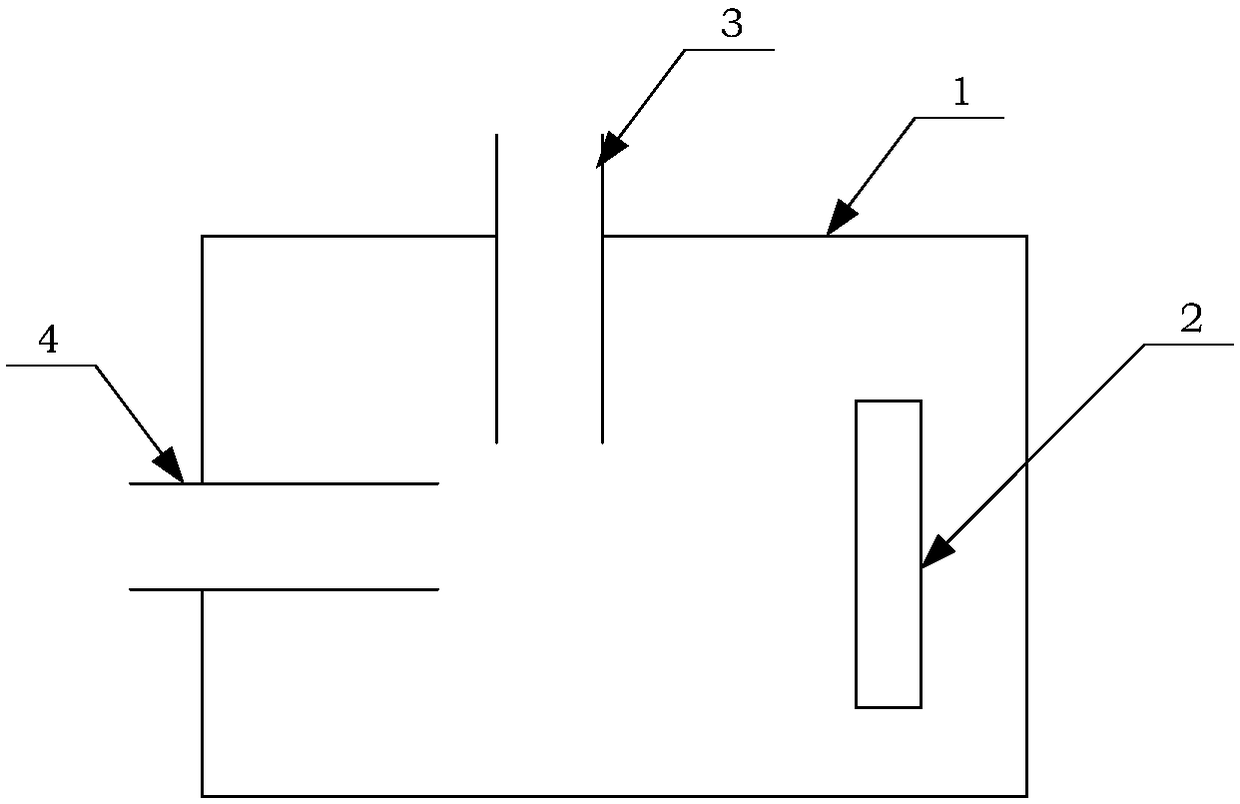

[0045] Take the SiC / SiC material with a size of 20mm×20mm×4.0mm as the substrate 2, clean it with acetone, ethanol, and ultrasonic for 20 minutes in sequence, and then dry it in an oven at 110°C for 2 hours; the cleaned and dried SiC / SiC substrate Installed on the jig placed in the vacuum chamber 1, evacuated to 0.3Mpa, backfilled with argon to 50Mpa, and then evacuated to 1.2Mpa.

[0046] The parameters for preparing the mullite layer are: voltage 80V, current 800A, flow rate of argon gas in the plasma gas is 85L / min, hydrogen gas in the plasma gas is 10L / min, powder feeding amount is 15g / min, and the spraying distance is 800mm; The temperature is controlled at 1100° C.; the thickness of the mullite layer is 150 μm.

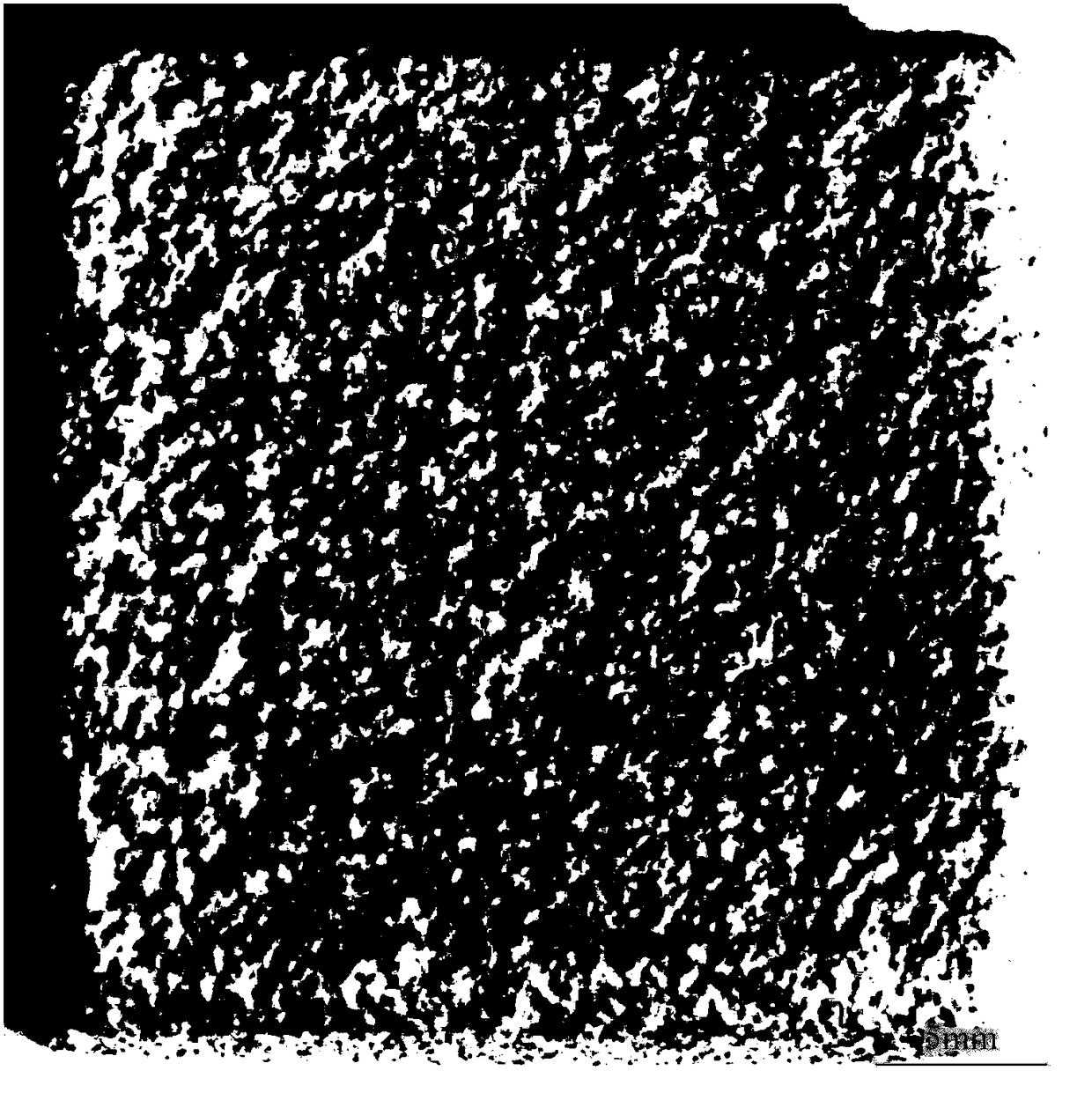

[0047] Preparation of Lu with a mass ratio of 6:4 2 Si 2 o 7 and Lu 2 SiO 5 The parameters of the surface layer are: voltage 60V, current 700A, flow rate of argon gas in the plasma gas is 100L / min, hydrogen gas in the plasma gas is 10L / min, powder feeding r...

Embodiment 2

[0052] Take the SiC / SiC material with a size of 20mm×20mm×4.0mm as the substrate 2, clean it with acetone, ethanol, and ultrasonic for 20 minutes in sequence, and then dry it in an oven at a temperature of 110°C for 2 hours. The cleaned and dried SiC / SiC substrate Installed on the jig placed in the vacuum chamber 1, evacuated to 0.3Mpa, backfilled with argon to 50Mpa, and then evacuated to 2Mpa.

[0053] The parameters for preparing the mullite layer are: voltage 90V, electric current 900A, argon gas flow in the plasma gas is 95L / min, hydrogen in the plasma gas is 15L / min, powder delivery rate is 10g / min, and the spraying distance is 900mm; The temperature is controlled at 1100° C.; the thickness of the mullite layer is 150 μm.

[0054] Preparation of Lu with a mass ratio of 6:4 2 Si 2 o 7 and Lu 2 SiO 5 The parameters of the surface layer are: voltage 70V, current 800A, flow rate of argon gas in the plasma gas is 120L / min, hydrogen gas in the plasma gas is 20L / min, powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com