Method for preparing multi-layer coating by adopting thermal spraying method

A multi-layer coating and thermal spraying technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of multiple spraying, achieve good coating performance and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

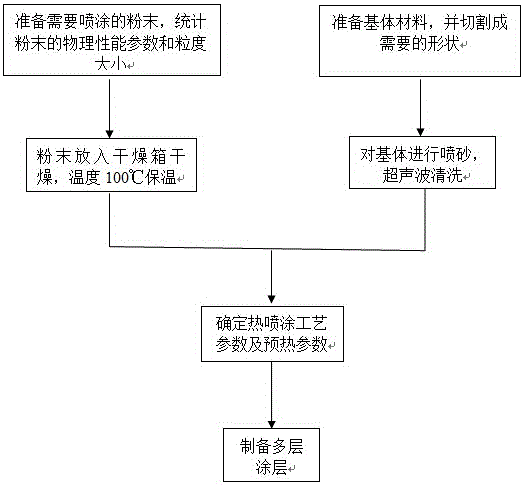

Method used

Image

Examples

Embodiment 1

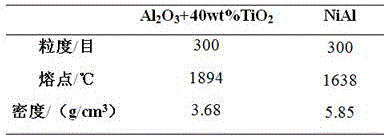

[0029] The spray material used in this embodiment is Al 2 o 3 +40wt%TiO 2 , NiAl mixed powder, wherein, the particle size, fusing point, density of each powder are as shown in table 1:

[0030] Table 1

[0031]

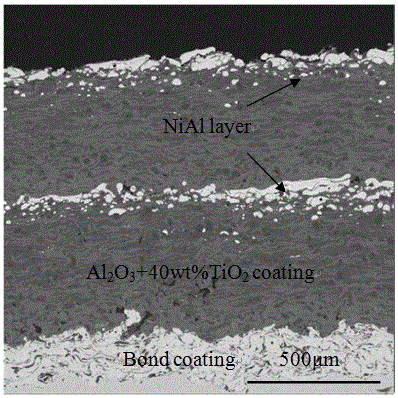

[0032] Preparation of Al by powder feeding in the same way 2 o 3 +40wt%TiO 2 / NiAl multilayer coating, the prepared multilayer coating is as figure 1 As shown, the spraying distance is 110mm; the current is 550A, the voltage is 70V; N 2 Flow rate 2400L / h; Ar flow rate 2000L / h; powder feeding voltage 10V; Al 2 o 3 +40wt%TiO 2 It is mechanically mixed with NiAl at a ratio of 5:1; the moving speed of the spray gun is 6mm / s; the thickness of the prepared coating is about 500μm; the hardness is about 800HV; the bonding strength reaches 90Mpa.

Embodiment 2

[0034] The spray material used in this embodiment is Al 2 o 3 +40wt%TiO 2 , the mixed powder of MgO, wherein, the granularity of each powder, fusing point, density are as shown in table 2:

[0035] Table 2

[0036]

[0037] Preparation of Al by powder feeding in the same way 2 o3 +40wt%TiO 2 / MgO, spray distance 100mm; current 580A, voltage 70V; N 2 Flow rate 2400L / h; Ar flow rate 2000L / h; powder feeding voltage 10V; Al 2 o 3 +40wt%TiO 2 It is mechanically mixed with MgO at a ratio of 4:1; the moving speed of the spray gun is 6mm / s; the thickness of the prepared coating is about 500μm; the hardness is about 900HV; the bonding strength reaches 80Mpa.

Embodiment 3

[0039] The spray material used in this embodiment is Al 2 o 3 +40wt%TiO 2 , YSZ (ZrO 2 +8wt%Y 2 o 3 ) mixed powder, wherein the particle size, melting point, and density of each powder are as shown in Table 3:

[0040] table 3

[0041]

[0042] Preparation of Al by powder feeding in the same way 2 o 3 +40wt%TiO 2 / YSZ multi-layer coating, spraying distance 100mm; current 600A, voltage 70V; N 2 Flow rate 2400L / h; Ar flow rate 2000L / h; powder feeding voltage 10V; Al 2 o 3 +40wt%TiO 2 Mechanically mix with YSZ according to the ratio of 4:1; the moving speed of the spray gun is 6mm / s; the thickness of the prepared coating is about 400μm; the thickness of each layer is controlled by controlling the ratio of the two powders; the hardness is about 900HV; the bonding strength Reach 90Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com