Dye preparing device for leather dyeing

A dye and leather technology, which is applied in the field of dye preparation equipment, can solve the problems of inaccurate preparation and uneven preparation, and achieve good stirring and mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

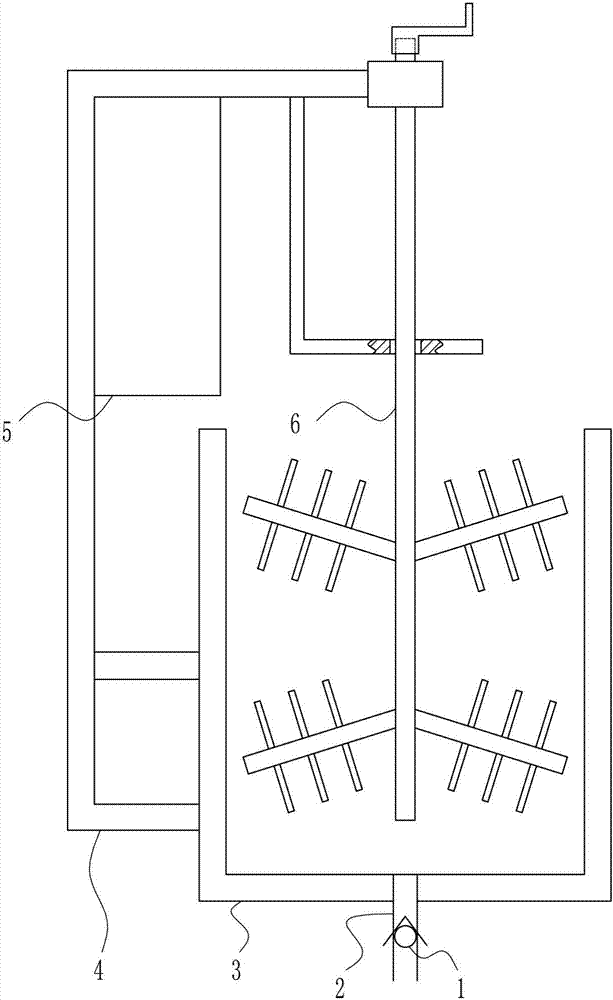

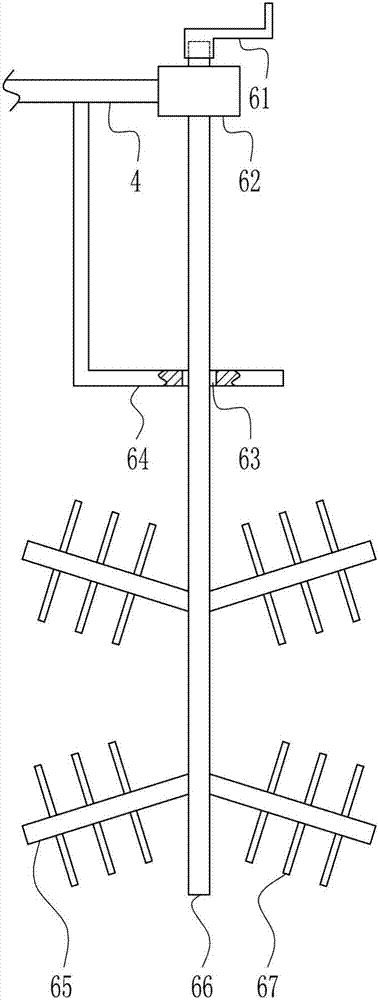

[0046] A dye preparation device for leather dyeing, such as Figure 1-11 As shown, it includes a one-way valve 1, an outlet pipe 2, a preparation box 3, a support 4, a preparation device 5 and a stirring device 6, and the top of the support 4 is provided with a preparation device 5 and a stirring device 6, and the preparation device 5 is arranged on the stirring device The left side of 6, the bottom right end of support 4 is connected with preparation box 3, and the middle part of preparation box 3 bottoms is connected with water outlet pipe 2, and water outlet pipe 2 is provided with check valve 1.

Embodiment 2

[0048] A dye preparation device for leather dyeing, such as Figure 1-11 As shown, it includes a one-way valve 1, an outlet pipe 2, a preparation box 3, a support 4, a preparation device 5 and a stirring device 6, and the top of the support 4 is provided with a preparation device 5 and a stirring device 6, and the preparation device 5 is arranged on the stirring device The left side of 6, the bottom right end of support 4 is connected with preparation box 3, and the middle part of preparation box 3 bottoms is connected with water outlet pipe 2, and water outlet pipe 2 is provided with check valve 1.

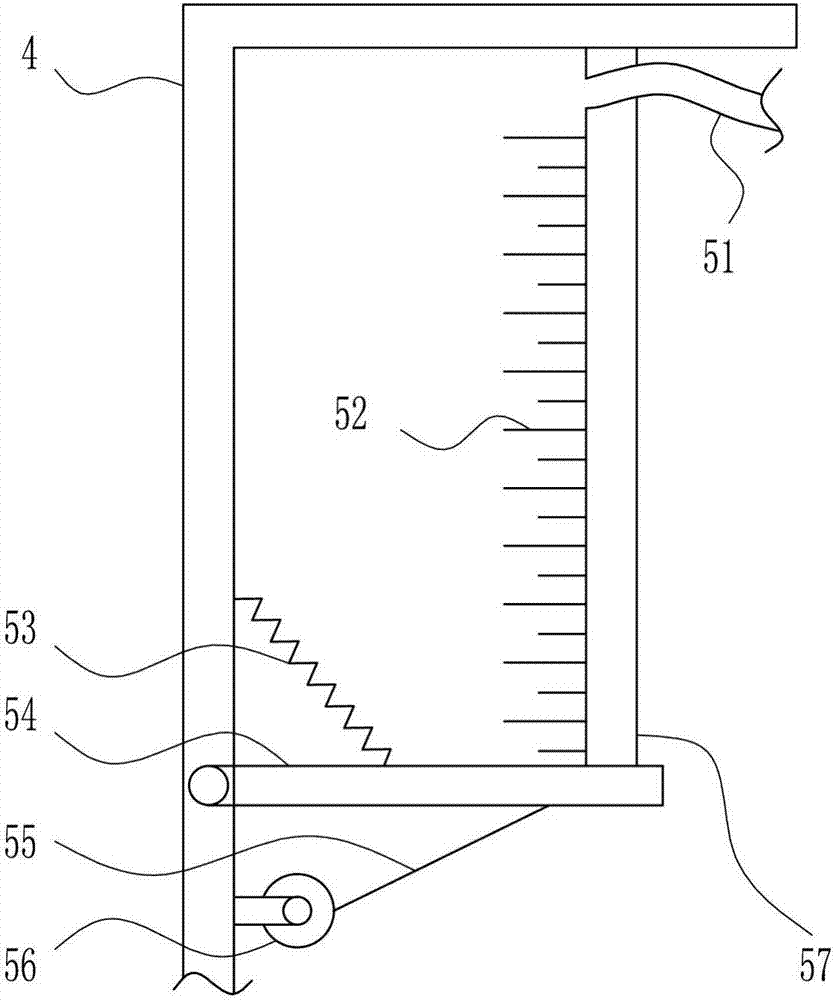

[0049] The preparation device 5 includes a hose 51, a first scale 52, a first spring 53, a baffle 54, a first pull cord 55, a first electric reel 56 and a transparent box 57, and the left side of the top of the bracket 4 is A transparent box body 57 is provided with a first scale 52 arranged on the transparent box body 57, a hose 51 is connected to the upper right side of the tra...

Embodiment 3

[0051] A dye preparation device for leather dyeing, such as Figure 1-11 As shown, it includes a one-way valve 1, an outlet pipe 2, a preparation box 3, a support 4, a preparation device 5 and a stirring device 6, and the top of the support 4 is provided with a preparation device 5 and a stirring device 6, and the preparation device 5 is arranged on the stirring device The left side of 6, the bottom right end of support 4 is connected with preparation box 3, and the middle part of preparation box 3 bottoms is connected with water outlet pipe 2, and water outlet pipe 2 is provided with check valve 1.

[0052] The preparation device 5 includes a hose 51, a first scale 52, a first spring 53, a baffle 54, a first pull cord 55, a first electric reel 56 and a transparent box 57, and the left side of the top of the bracket 4 is A transparent box body 57 is provided with a first scale 52 arranged on the transparent box body 57, a hose 51 is connected to the upper right side of the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com