Movable adjustable-stirring-radius reaction kettle

A stirring radius, mobile technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of poor heat dissipation, inconvenient handling, etc. Improve heat dissipation, easy to move, better stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

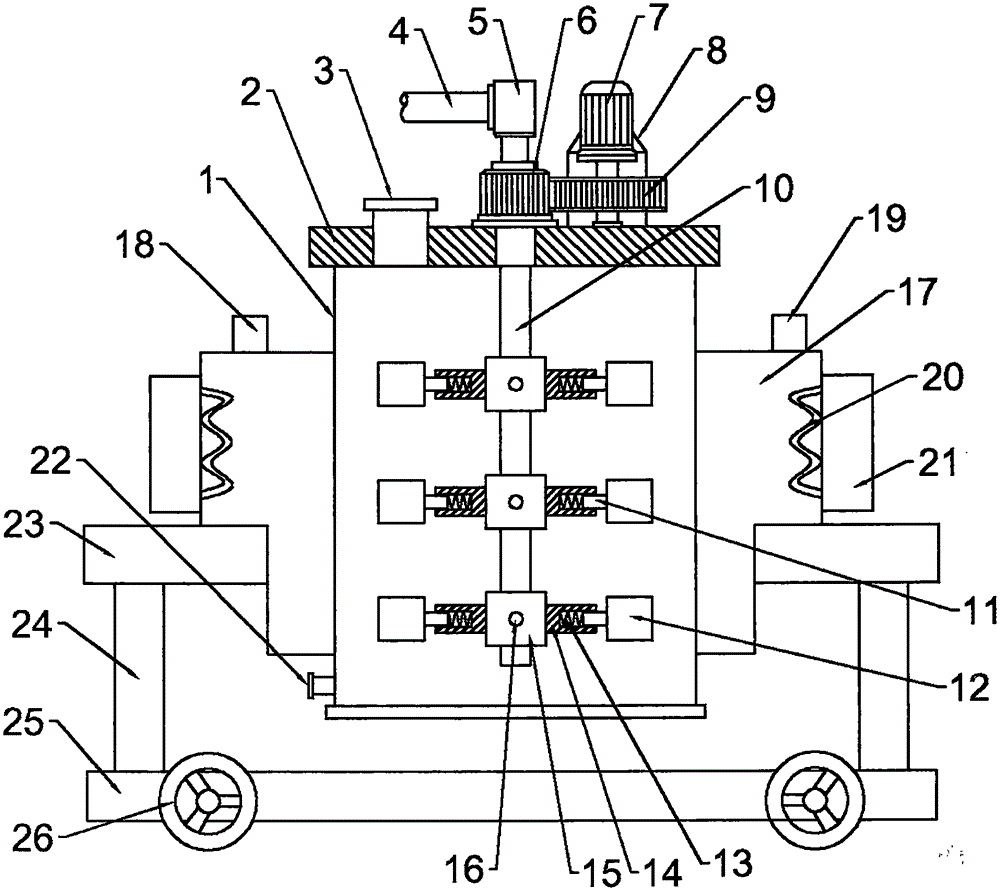

[0017] see figure 1 , a movable stirring radius adjustable reaction kettle, comprising a kettle body 1, a sealing cover 2 is connected above the kettle body 1, a feed port 3 is opened on the left side of the upper end of the sealing cover 2, and a motor 7 is also installed on the sealing cover 2, The motor 7 is fixed on the frame 8, the output end of the motor 7 is connected to the transmission gear 6 through the driving gear 9, the transmission gear 6 is fixed on the stirring shaft 10, and the stirring shaft 10 vertically passes through the sealing cover 2 and is arranged in the center of the kettle body 1 On the axis, the interior of the stirring shaft 10 is a hollow structure. The top of the stirring shaft 10 is connected to the liquid feeding pipe 4 through the right-angle liquid inlet valve 5. The stirring shaft 10 is located inside the kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com