Hip prosthesis handle surface nanometer biological active coating and preparing method thereof

A hip joint prosthesis, bioactive technology, applied in coating, prosthesis, metal material coating process, etc., can solve the problems of artificial hip joint handle and surrounding bone tissue not firm, overflowing, easy to loosen, etc. , to achieve the effect of improving biological activity and biocompatibility, improving reliability and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

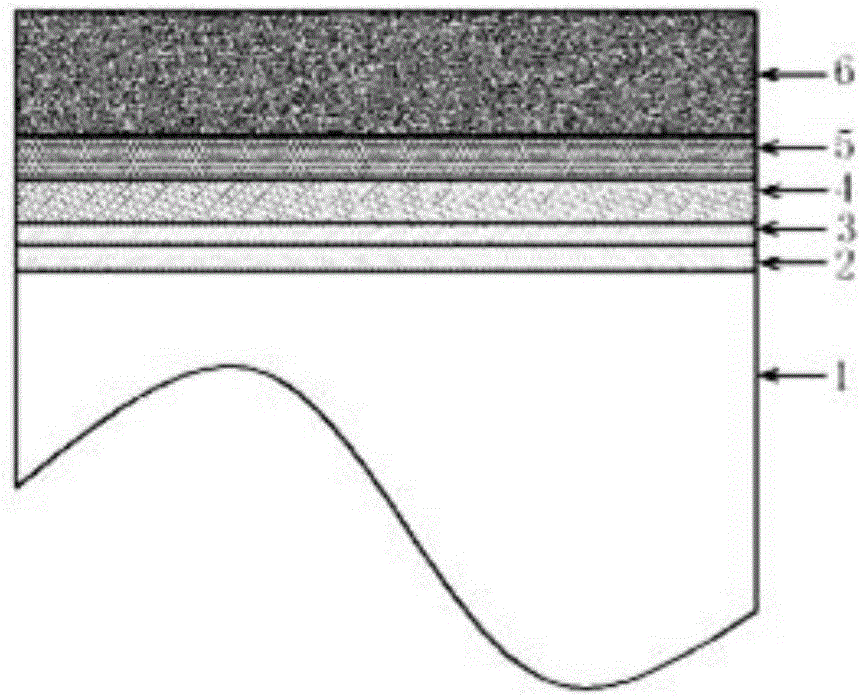

[0029] The preparation method of nano-bioactive coating: the multi-component nano-gradient composite coating on the surface of the artificial hip joint is prepared by a multi-target magnetron sputtering surface functional thin film deposition system, and the sputtering process ensures that the vacuum degree of the cavity body reaches 1-5× 10 -5 Between Pa, the target-base distance is adjusted within the range of 60-100mm, and the rotation speed of the base frame is adjusted within the range of 5-10r / min, including the following steps in turn:

[0030] ①Substrate pretreatment: Grind and polish the Ti6Al4V substrate with sandpaper. After the surface roughness meets the requirements, clean it in acetone and ethanol solutions for 10-15 minutes respectively; Perform acid etching and activation treatment on the surface of the mixed solution, heat the mixed solution in a water bath to 70°C, and keep it warm for 30 minutes, then ultrasonically clean the activated substrate again, and ...

Embodiment 1

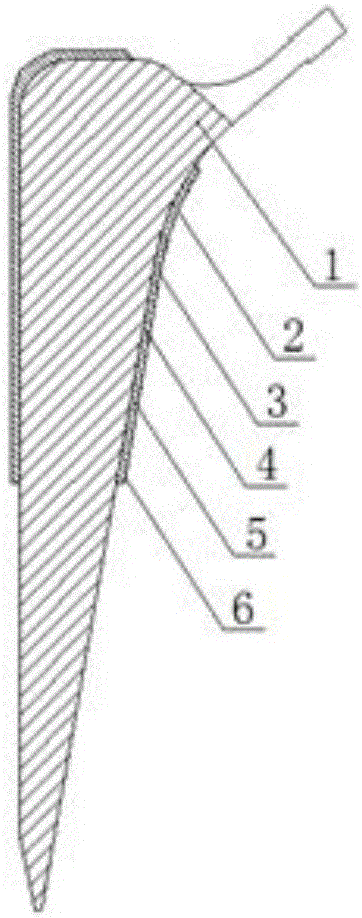

[0037] Example 1: figure 1 The middle coat is only distributed in the proximal 1 / 2-2 / 3 of the articular handle.

[0038] (1) After the polished Ti6Al4V substrate is ultrasonically cleaned, it is placed in a mixture of sulfuric acid (66.3%) and hydrochloric acid (10.6%) with a mass percentage of 1:1 and heated to 70°C in a water bath, and it is kept for 30 minutes for acid etching and activation treatment , ultrasonically clean the acid-etched substrate, and dry it in a drying oven for later use;

[0039] (2) Adjust the target-base distance to 60mm, and evacuate until the vacuum degree of the cavity body reaches 2×10 -5 Pa, argon gas is introduced, the flow rate of argon gas is 120sscm, the discharge pressure is 1.0Pa, the bias power is adjusted to -500V, the pollutants on the surface of the substrate and the inner wall of the cavity are cleaned and the surface is activated for 15 minutes;

[0040] (3) Adjust the argon gas flow rate to 100sscm, keep the discharge pressure unc...

Embodiment 2

[0046] (1) Put the polished Ti6Al4V substrate in acetone and alcohol for ultrasonic cleaning for 15 minutes each, and dry it in a drying oven for later use;

[0047] (2) Adjust the target-base distance to 80mm, and evacuate until the vacuum degree of the cavity body reaches 1×10 -5 Pa, argon gas is introduced, the flow rate of argon gas is 100sscm, the discharge pressure is 1.0Pa, the bias power is adjusted to -800V, the substrate surface and the inner wall of the cavity are cleaned and the surface is activated for 15 minutes;

[0048](3) Adjust the discharge pressure to 0.8Pa, keep the argon gas flow constant, turn off the bias power supply, adjust the intermediate frequency power supply current 1A to clean the titanium target, the DC power supply current 1A to clean the silicon target, the RF power supply Ⅰ power 300W to clean the ceramic target, and the RF power supply Ⅱ Power 300W to clean the composite target of HA and bioactive glass, and clean the pollutants on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com