Surfacing treatment method of winding drum of wire drawing machine

A wire drawing machine reel and surface surfacing technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large area of wear-resistant layer of wire drawing machine reel, difficult control of spray welding quality, and low qualified rate of finished products, etc. problems, to overcome surface quenching and flame spray welding, high hardness, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are as follows:

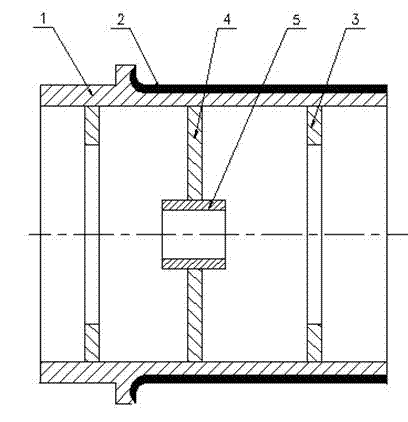

[0018] Surfacing treatment is carried out on the surface of the wire drawing machine drum with a diameter of φ1270mm. The wire drawing machine drum is mainly composed of the drum body 1, the surfacing layer 2, the anti-deformation support ring 3, the anti-deformation support plate 4 and the processing positioning sleeve 5. The material of the reel body 1 is rolled from low carbon steel plate Q235.

[0019] The implementation steps of a surface welding treatment method for a reel of a wire drawing machine in the present invention are as follows:

[0020] (1) After the reel body is stress-relieved and heat-treated, the outer circle of the car is left with a surfacing layer thickness of 4mm, and the center positioning hole is turned out at the same time;

[0021] (2) The surface of the reel body is pretreated by sandblasting, degreasing and dewatering;

[0022] (3) The reel is preheated to 350-400°C in the electric f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com