Target material assembly forming method

A target and component technology, which is applied in the direction of welding/cutting medium/material, welding medium, manufacturing tools, etc., can solve the problem that the welding strength of target components needs to be improved, and achieve small differences in thermal expansion coefficients, reduce thermal stress, and enhance bonding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It can be seen from the background art that the welding strength of the target assembly manufactured in the prior art needs to be improved.

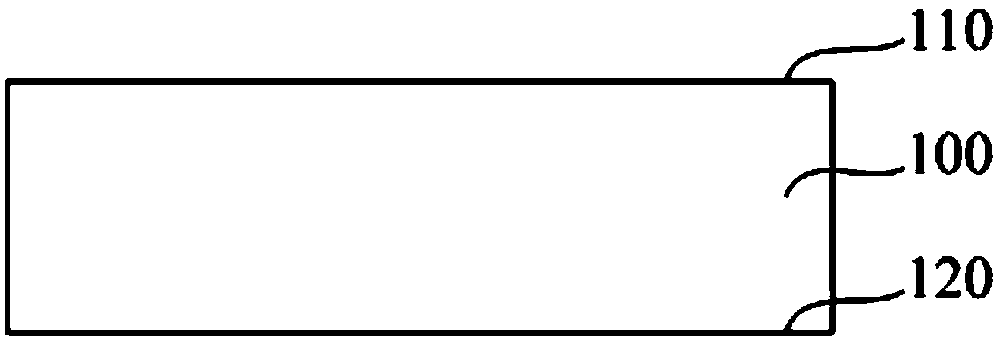

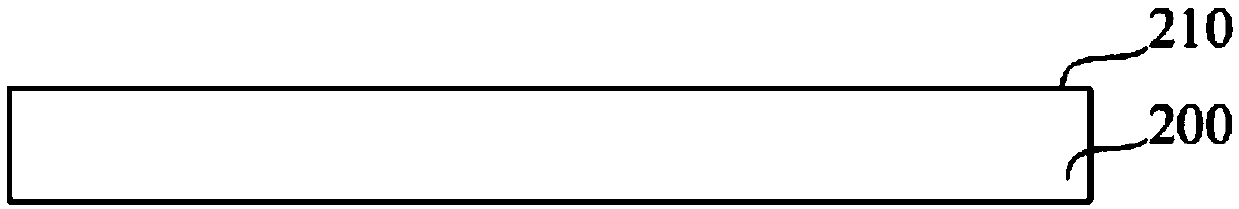

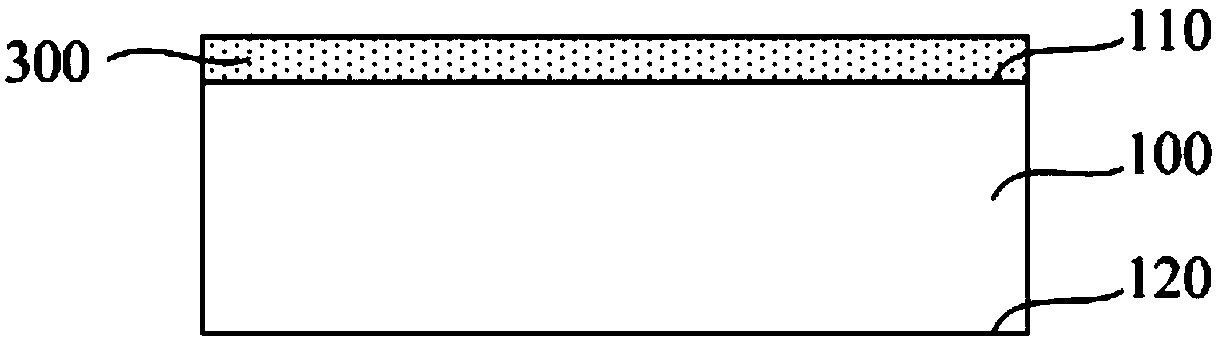

[0026] The analysis is now combined with a method for forming a target assembly. The process steps of forming a target assembly mainly include: providing a ceramic target, the ceramic target has a target welding surface; providing a metal back plate, and the metal back plate has a back plate welding surface; brazing material is placed on the target welding surface and the back plate welding surface, and the ceramic target and the metal back plate are welded to form a target assembly.

[0027] The welding strength of the target assembly prepared by the above method for forming the target assembly is poor. After analysis, it is found that the reasons for the poor welding strength of the target assembly include: On the one hand, during the welding process of the ceramic target and the metal back plate In this case, the wetting and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com