High temperature alloy protective technology

A high-temperature alloy and technology technology, applied in the field of material science, can solve the problems of dense oxide coating, large difference in linear expansion coefficient, easy cracking, etc., to achieve the effect of improving high temperature performance, reducing alloy corrosion rate, and isolating corrosive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 applies bonding layer and composite oxide coating on K38G superalloy

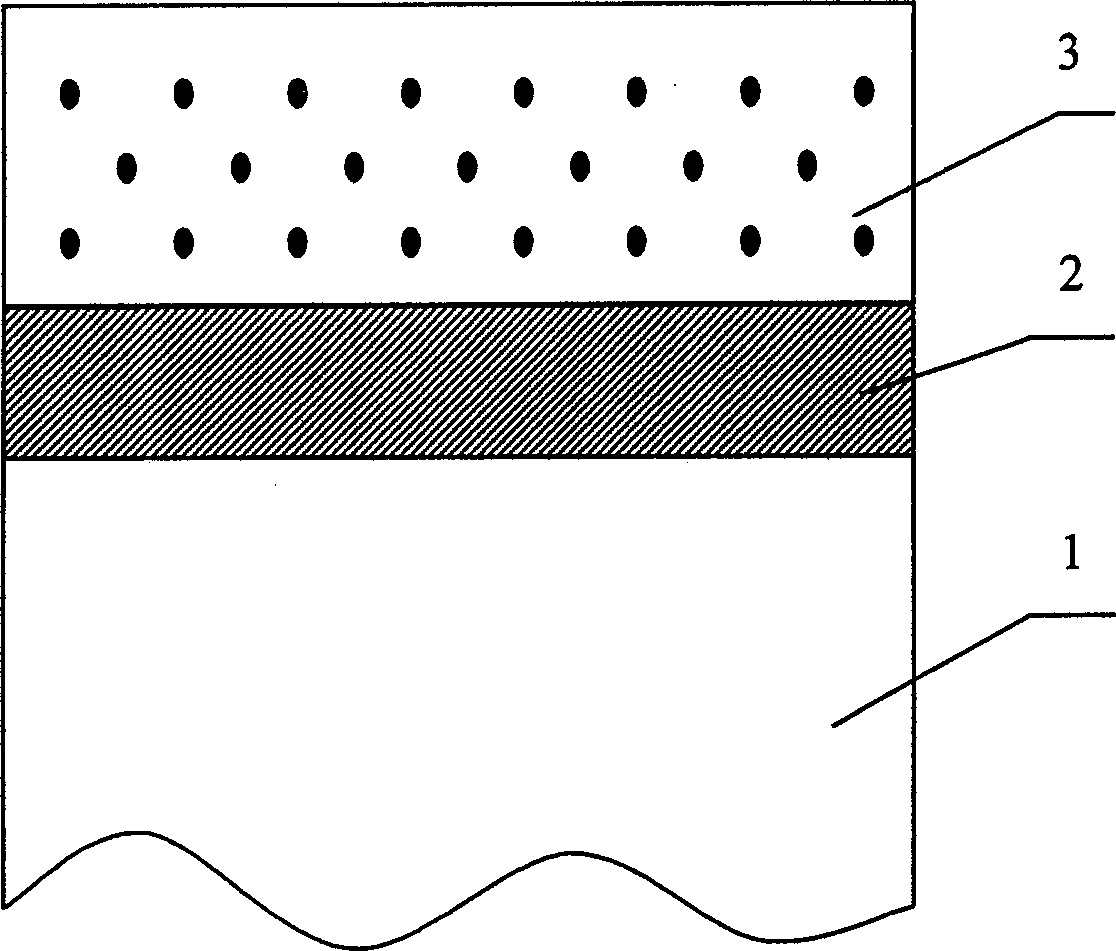

[0036] When the K38G superalloy is oxidized, Cr 2 o 3 The main mixed oxide film has poor oxidation resistance above 1000 °C. A bonding layer (2) with the same composition as the K38G superalloy substrate was fabricated on the sample substrate (1) by a sputtering method, with a thickness of 4 μm.

[0037] Prepare raw materials to be reacted according to the following ratio: Al 2 o 3 : 30% by weight; Y 2 o 3 : 3% by weight; enamel powder: balance. Wherein, the composition of enamel powder is according to weight percent: ZrO 2 : 5%, Al 2 o 3 : 6%; ZnO: 9%; CaO: 4%; B 2 o 3 : 4%; Na 2 O: 4%; K 2 O: 6%; TiO 2 : 2%; SiO 2 :margin. Mix the above raw materials into anhydrous ethanol and wet ball mill to make a suspension, then spray on the surface of the bonding layer (2) to a thickness of 20 μm; finally sinter at 1000°C for 15 minutes, and air cool to room temperature to make a ...

Embodiment 2

[0038] Embodiment 2 Apply bonding layer and composite oxide coating on IN738 superalloy

[0039] When IN738 superalloy is oxidized, Cr 2 o 3 The main mixed oxide film has poor oxidation resistance above 1000 °C. A bonding layer (2) with the same composition as the IN738 superalloy substrate was fabricated on the sample substrate (1) by an arc ion plating method, with a thickness of 4 μm.

[0040] Raw materials are prepared according to the following ratio: MgO: 25% by weight; Y 2 o 3 : 3% by weight; enamel powder: balance. Wherein, each composition composition of enamel powder is according to weight percent: ZrO 2 : 5%; Al 2 o 3 : 6%; ZnO: 9%; CaO: 4%; B 2 o 3 : 4%; Na 2 O: 4%; K 2 O: 6%; TiO 2 : 2%; SiO 2 :margin. Mix the above raw materials into anhydrous ethanol and wet ball mill to form a suspension, then spray on the surface of the bonding layer (2) to a thickness of 20 μm; finally sinter at 1000°C for 15 minutes, and air cool to room temperature to form a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com