Patents

Literature

60results about How to "Does not cause eutrophication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ascorbic acid phosphorus-free corrosion and scale inhibitor, and preparation method thereof

ActiveCN102225809ADoes not cause eutrophicationWide variety of sourcesScale removal and water softeningGluconatesPollution

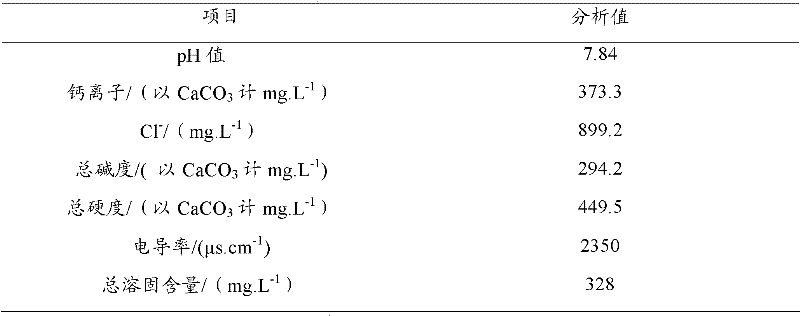

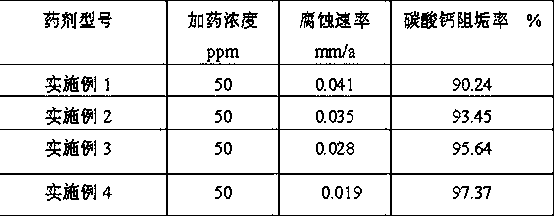

The invention discloses an ascorbic acid phosphorus-free corrosion and scale inhibitor which is applicable for treatment of industrial circulating cooling water. The corrosion and scale inhibitor is prepared by compounding a maleic acid compound, an acrylic acid terpolymer, ascorbic acid, a sulfamic acid compound, a zinc salt, a gluconate and distilled water. The ascorbic acid phosphorus-free corrosion and scale inhibitor provided by the present invention provides good corrosion inhibition and scale inhibition effects for carbon steel equipment. The dosage of the phosphorus-free corrosion and scale inhibitor is 20 mg.L<-1> - 50 mg.L<-1> in the industrial circulating cooling water having an alkalinity less than 400 mg.L<-1>, a hardness less than 500 mg.L<-1>, a pH value less than 8.2, a conductance controlled from 0[mu]s.cm<-1>-2400[mu]s.cm<-1>. A plurality of experiment results show that the corrosion and scale inhibitor provides a annual corrosion rate lower than 0.04 mm.a<-1> and a calcium carbonate inhibition rate higher than 98% for the A3 carbon steel. Advantages of the ascorbic acid phosphorus-free corrosion and scale inhibitor and the preparation method are as follows: the discharged waste water during using the corrosion and scale inhibitor does not provide a eutrophic pollution caused by phosphor for water body; the environment is environment-friendly; agent cost for treating each ton of the water is less than 0.12 yuan; the product preparation process is simple.

Owner:WUHAN UNIV OF TECH +1

Dephosphorization flocculating agent and preparation method thereof

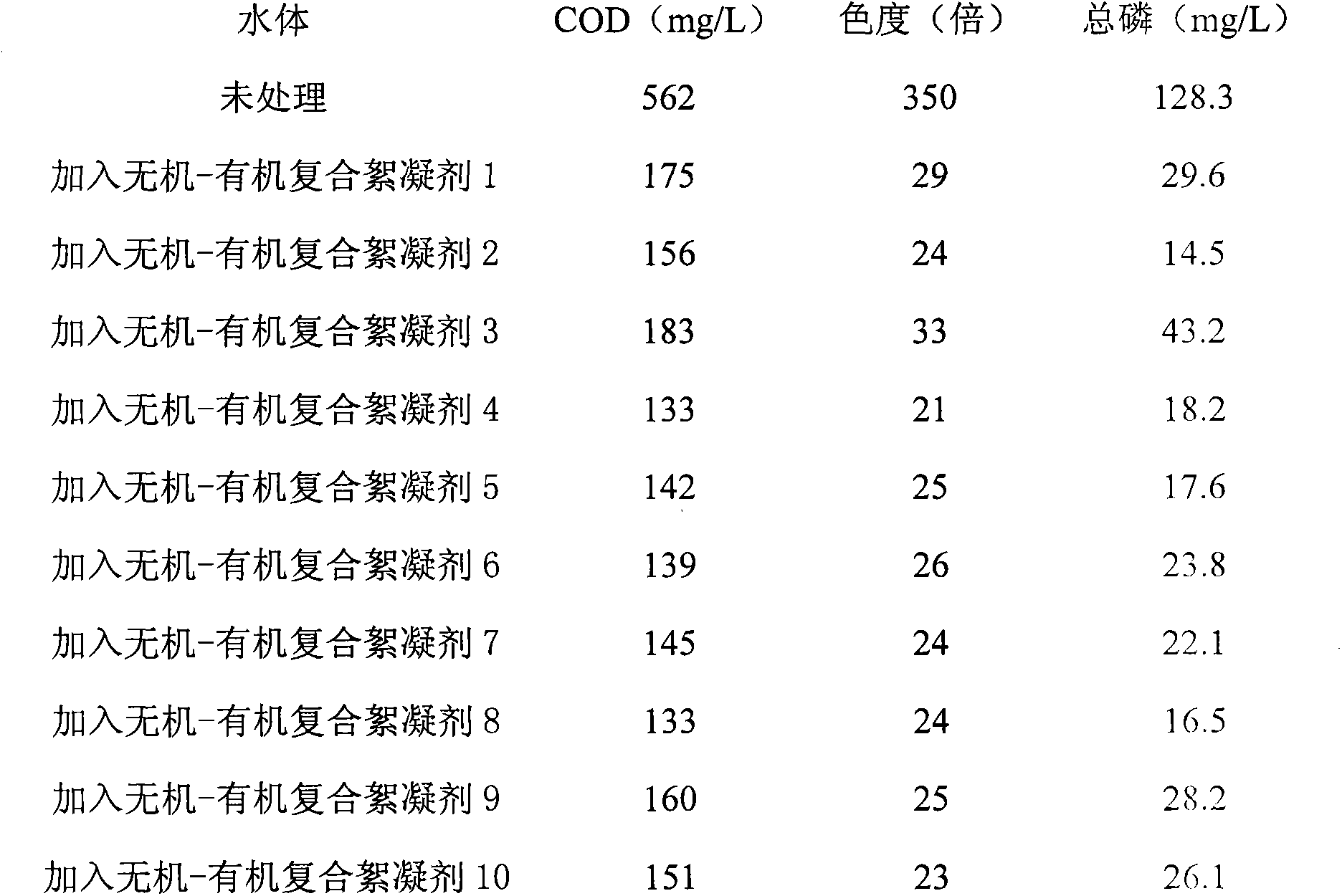

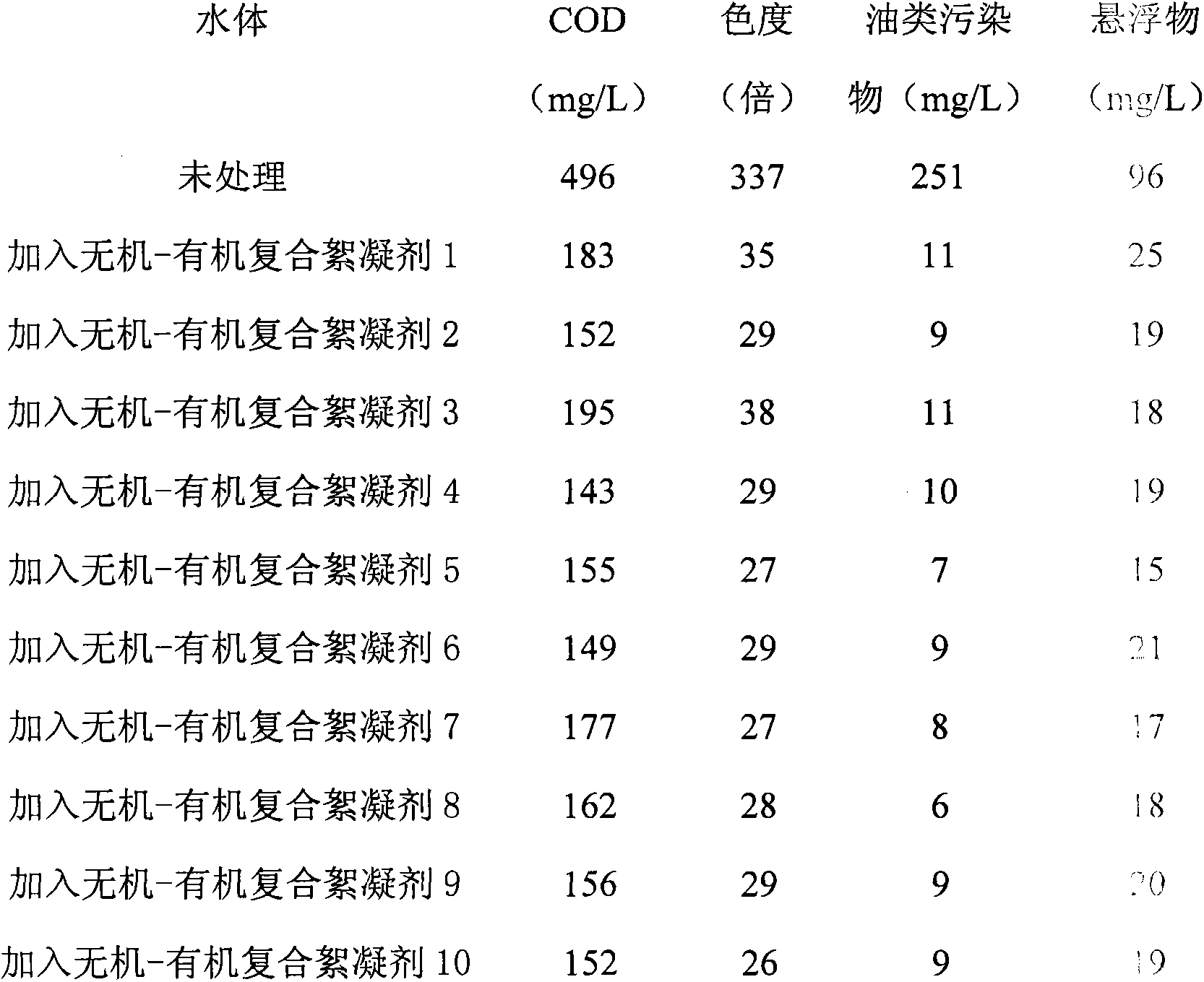

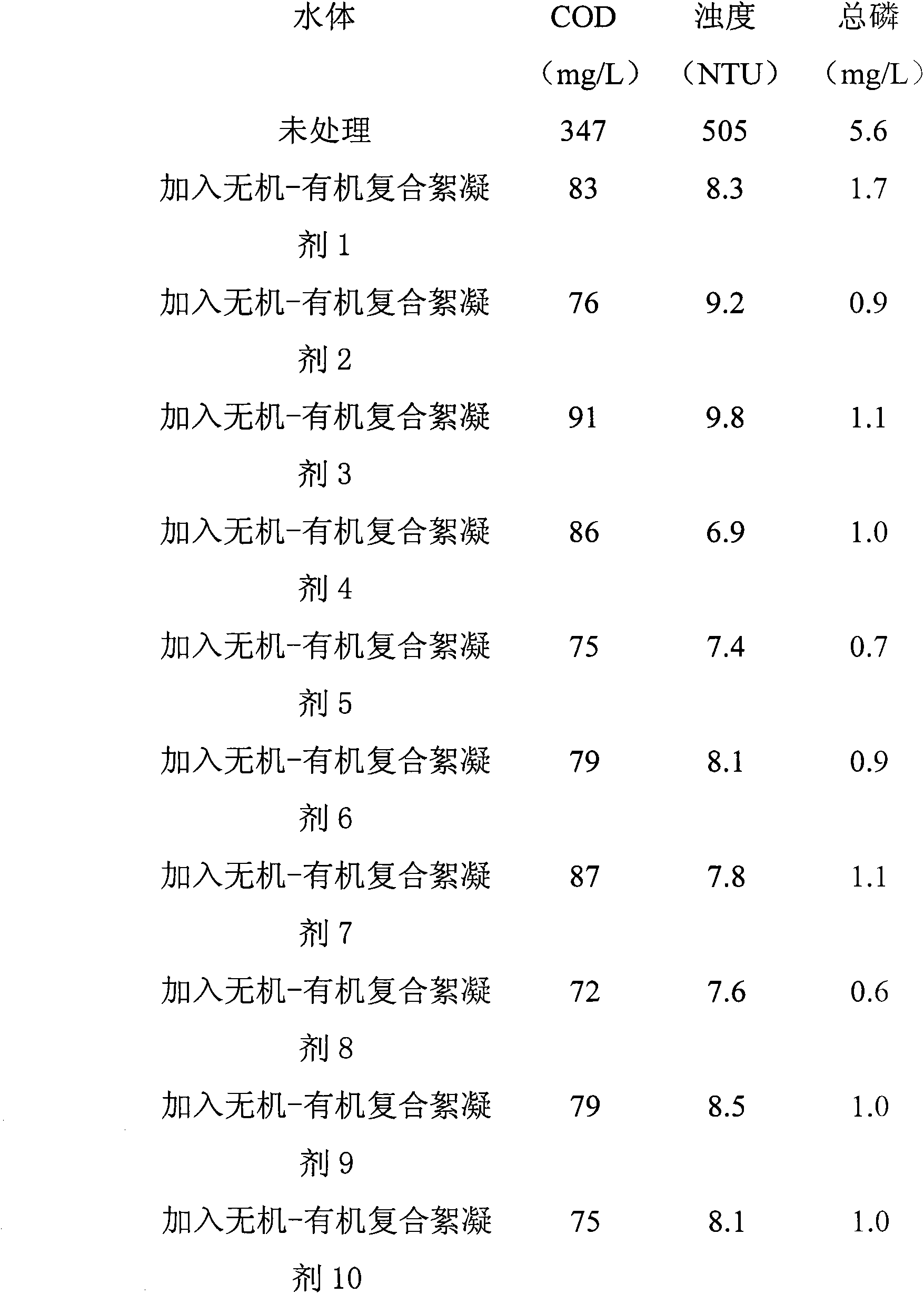

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

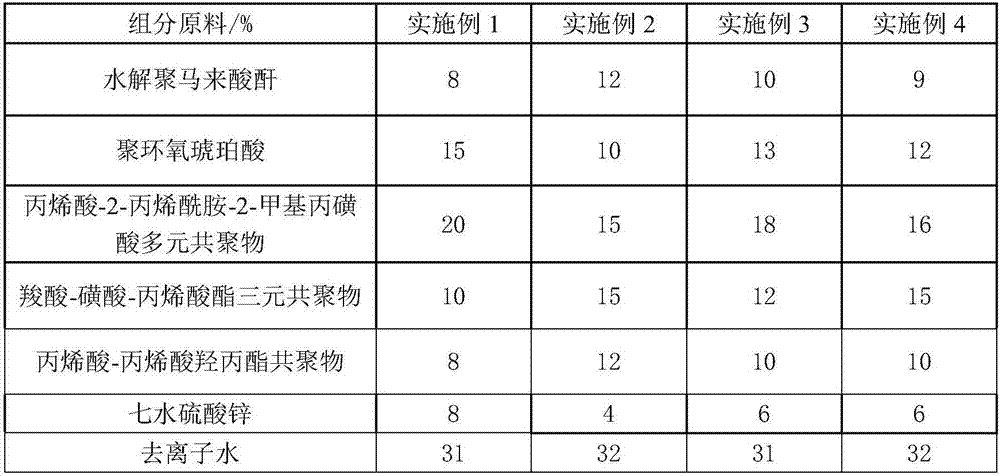

Non-phosphorus corrosion and scale inhibitor

InactiveCN108002558AGood chemical stabilityImprove thermal stabilitySpecific water treatment objectivesScale removal and water softeningEutrophicationZinc sulphate heptahydrate

The invention discloses a non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following components in percentage by weight: 8 to 12 percent of hydrolytic polymaleic anhydride, 10 to 15 percent of polyepoxysuccinic acid, 15 to 20 percent of acrylic acid-2-acrylamido-2-methylpropanesulfonic acid multipolymer, 10 to 15 percent of carboxylic acid-sulfonic acid-acrylate terpolymer, 8 to 12 percent of acrylic acid-hydroxypropyl acrylate copolymer, 4 to 8 percent of zinc sulphate heptahydrate and the balance of deionized water. The invention further discloses a preparation method of the corrosion and scale inhibitor. The preparation method comprises the following steps: weighing the components according to the formula; adding the components into a stirrer in sequence; stirring at normal temperature and under normal pressure to obtain the corrosion and scale inhibitor. The corrosion and scale inhibitor disclosed by the invention has the advantages of freeness from phosphorus, adoption of safe and environment-friendly components, simple production process, high scale-inhibiting efficiency, high corrosion-inhibiting performance, prevention of eutrophication of a water body caused by discharge of phosphorus, and very high compatibility; the adhesion of microorganisms to equipment can be reduced effectively, and the corrosionand and scale inhibiting performance can be enhanced greatly.

Owner:新疆水处理工程技术研究中心有限公司

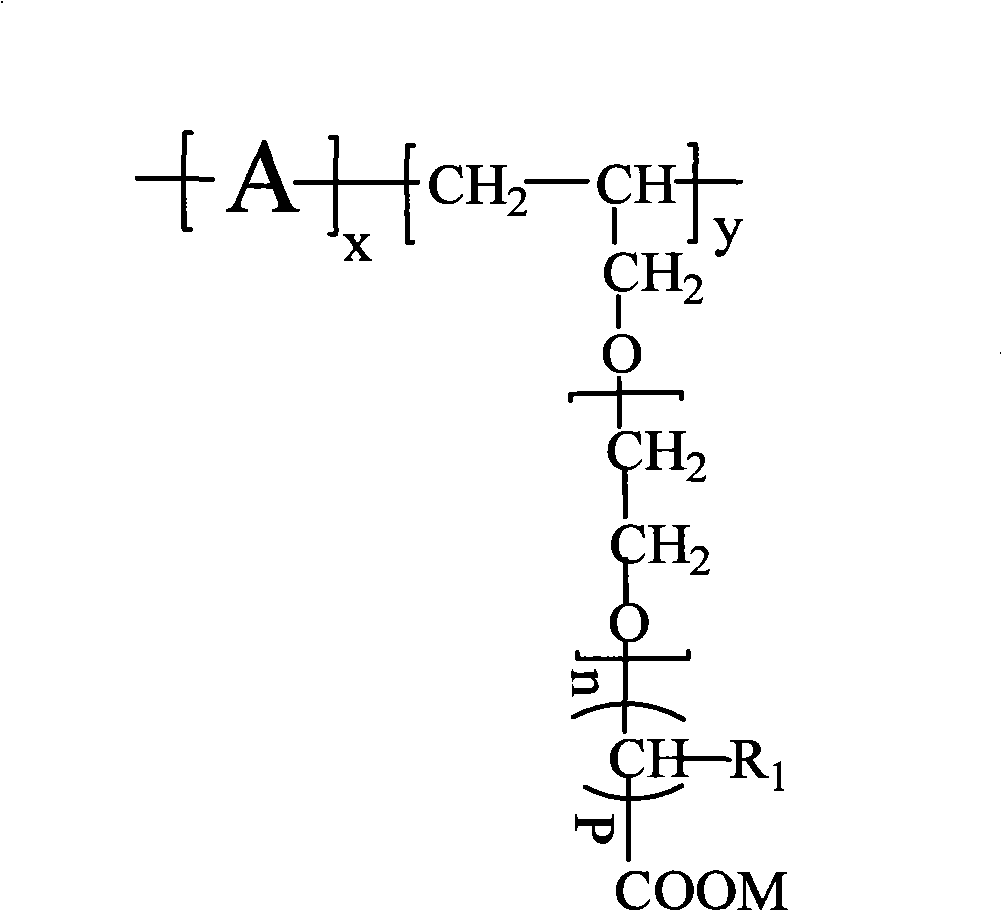

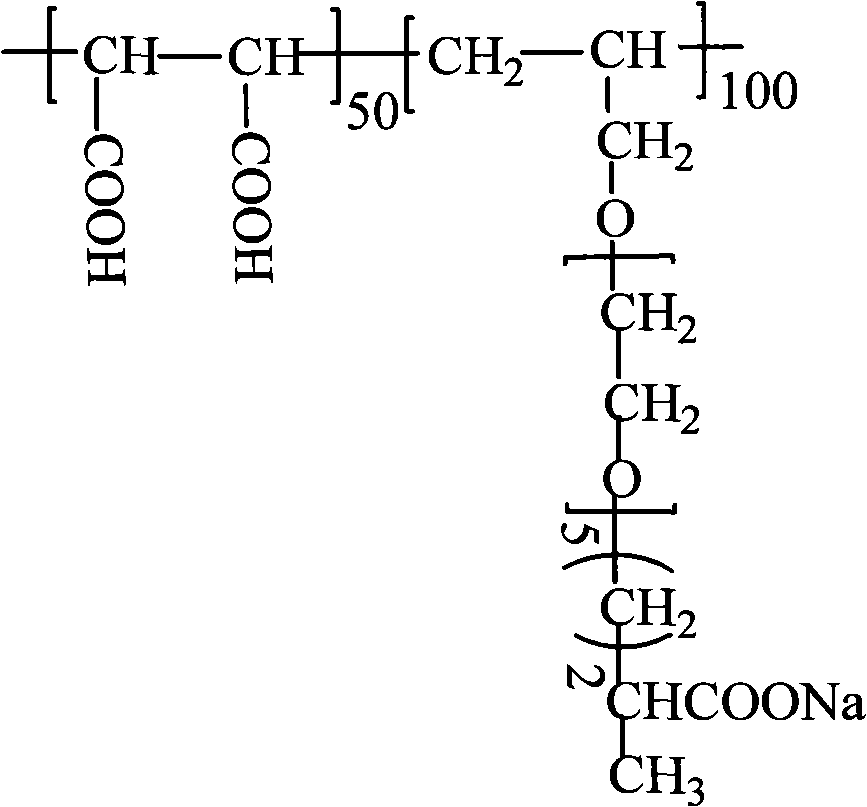

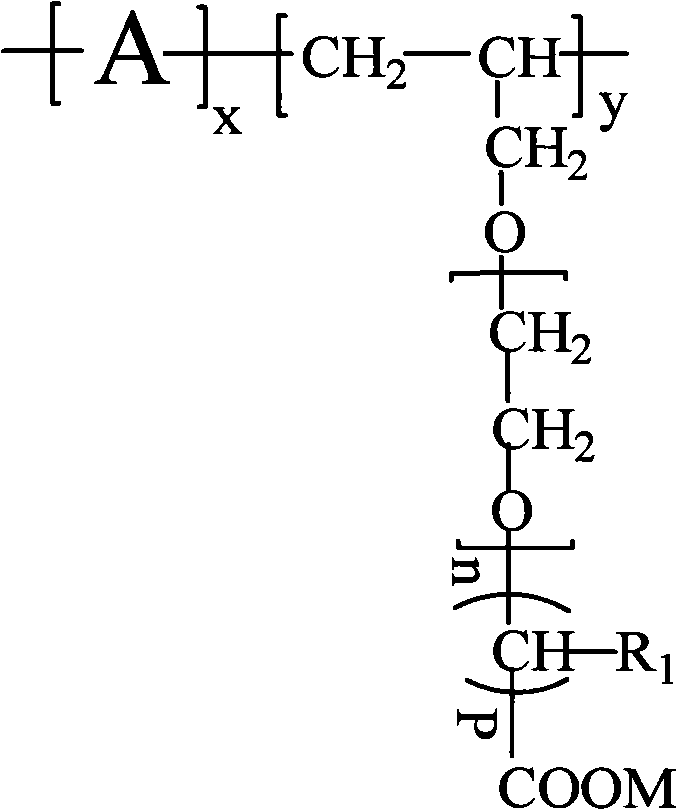

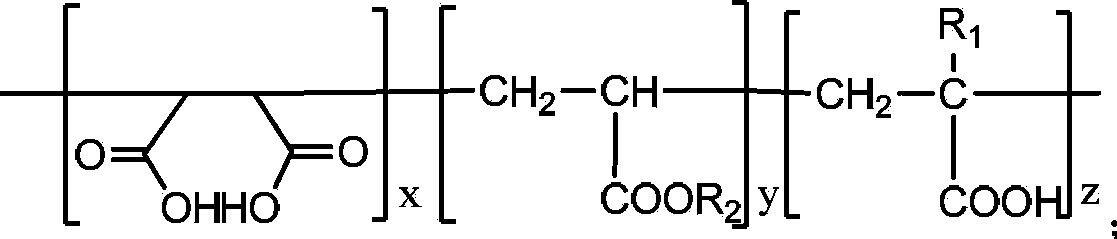

Phosphate-free polyether scale inhibitor and preparation method thereof

ActiveCN101899134AGood compatibilityHigh inhibitory effectScale removal and water softeningPhosphateDouble bond

The invention relates to a phosphate-free polyether scale inhibitor (APEX) which is a product of free radical polymerization of a polyether reaction monomer prepared by a lactone process and a monomer which contains a vinyl unsaturated double bond. The scale inhibitor comprises a structural general formula shown in the specification, wherein A is a constitutional repeating unit after the copolymerization of the monomer which contains the vinyl unsaturated double bond; R1 is H or a C1-C5 low-carbon alkyl; a value of P is 2 to 10; M is H<+>, K<+> or Na<+>; the polymerization degree x is 1 to 5,000; the polymerization degree y is 1 to 5,000; and the polymerization degree n is 1 to 100.

Owner:JIANGSU JIANGHAI CHEM +1

Corrosion and scale inhibitor for treating circulating cooling water

InactiveCN103496794AReduce phosphorus contentExcellent corrosion and scale inhibitionTreatment using complexing/solubilising chemicalsEngineeringCarboxylic acid

The invention discloses a corrosion and scale inhibitor for treating circulating cooling water. The corrosion and scale inhibitor is composed of the following raw materials in percentage by mass: 3-15% of polyaspartic acid, 0-8% of organic phosphine, 2-10% of phosphine carboxylic acid, 5-10% of carboxyl group-containing polymer, 1-3% of copper corrosion inhibitor, 0-16% of zinc salt and the balance of water. The corrosion and scale inhibitor disclosed by the invention is low in phosphorus content and biodegradable, and no water body eutrophication is caused by pollution discharge; the corrosion and scale inhibitor has excellent corrosion and scale inhibition properties and can effectively improve the heat exchange effect of a central air conditioning refrigerating unit when being applied in a central air conditioning circulating cooling water system, the average temperature difference of a condenser is not larger than 1.0 DEG C and the average temperature difference of an evaporator is not larger than 2.4 DEG C, and thus safe, stable and economical operation of the unit is ensured.

Owner:广东省石油化工研究院

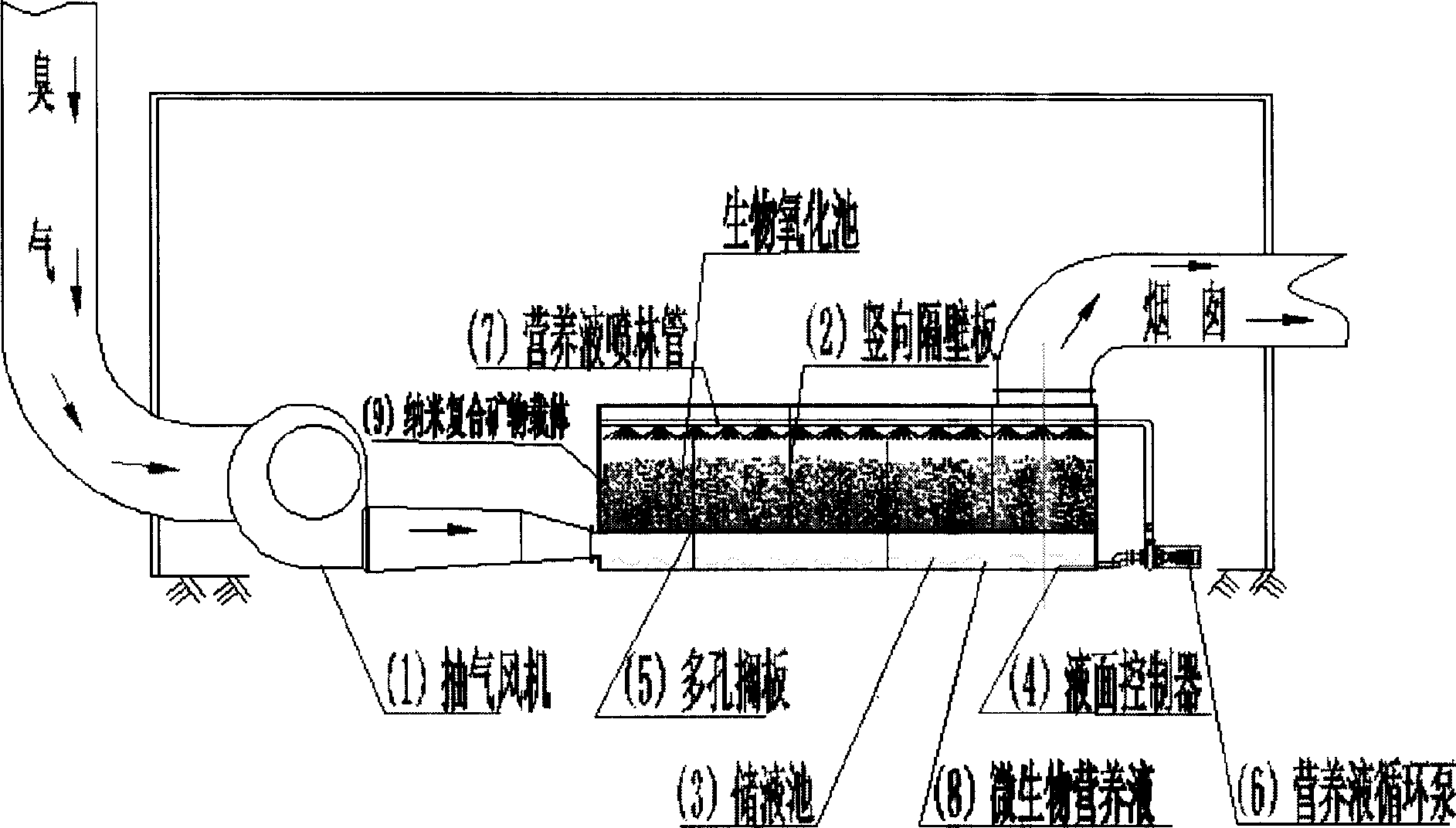

Method and apparatus for treating malodorous gas by using composite microorganism and nano composite carrier

InactiveCN101011591AImprove stabilityImprove effectivenessDispersed particle separationDeodrantsSludgeBiological filter

The invention relates to a method for using composite microbe and nanometer composite carrier to treat the gas with bad smell, and relative device. The box of biological filter is divided by several upright baffle plates, which contains microbe nourishment storage pool, a liquid level controller, a porous baffle plate, a nourishment spray tube, and a nourishment circulate pump, while the bad smell flows in the box to contact with the nanometer composite mineral carrier stacked on the porous baffle plate, to degrade the object via the microbe group on / in the nanometer composite mineral carrier into the material without toxicity and harm, as water, carbon dioxide, nitrogen gas and sulfur. And the invention uses the bad smell object as the carbon source, energy source, nitrogen source and sulfur source of microbe to realize circulation, save cost and reduce nourishment consumption. The invention has simple structure and low cost, while the LQ-SSB composite microbe group and nanometer composite mineral carrier have high stability and efficiency.

Owner:张涉

Special liquid fertilizer for potato-seeding supplemental irrigation

InactiveCN102320877ANutritionally balanced and comprehensiveGood fertilizer effectFertilizer mixturesNitrogen fertilizerPotassium oxide

The invention relates to a special liquid fertilizer for potato-seeding supplemental irrigation. The special liquid fertilizer is a liquid fertilizer prepared by matching an inorganic nitrogen fertilizer, an inorganic phosphorus fertilizer, an inorganic potassium fertilizer, a medium and micro fertilizer and water, wherein the content of total nutrients (N+P2O5+K2O+medium and microelements) is greater than or equal to 29.84 percent, wherein the total nutrients comprise 9.38-20.49 percent of nitrogen, 4.34-12.62 percent of phosphorus pentoxide, 4.7-15.28 percent of potassium oxide, 0.53-0.68 percent of calcium, 0.35-0.48 percent of magnesium, 0-4.05 percent of sulfur, 0.06-0.1 percent of iron, 0.08-0.1 percent of manganese, 0.08-0.13 percent of copper, 0.17-0.19 percent of zinc, 0.04-0.06 percent of boron and 0.002-0.003 percent of molybdenum. In the invention, by combining production-area soil-nutrient supplying levels, the nitrogen fertilizer and the phosphorus fertilizer are additionally applied in a pointed way, the potassium fertilizer is properly supplemented, the deficiency of the medium and micro fertilizer is prevented, the special liquid fertilizer has the characteristics of balanced and comprehensive nutrients, strong specificity, high nutrient concentration, totally-ionic state, environmental protection, no pollution, low cost, simple manufacturing process and the like, the yield of potatoes can be improved, the quality is improved, the agricultural input is reduced, and an ecological environment is improved.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

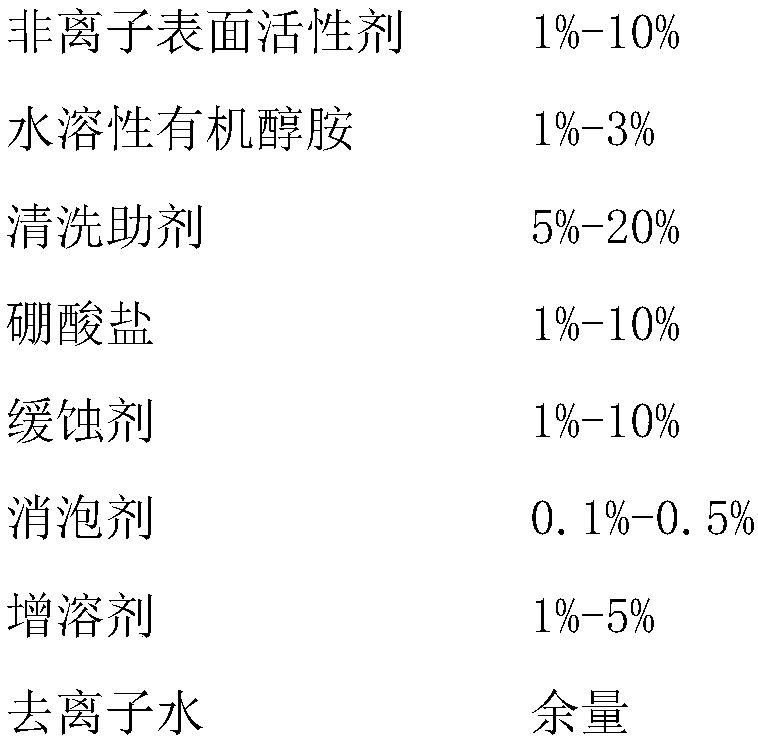

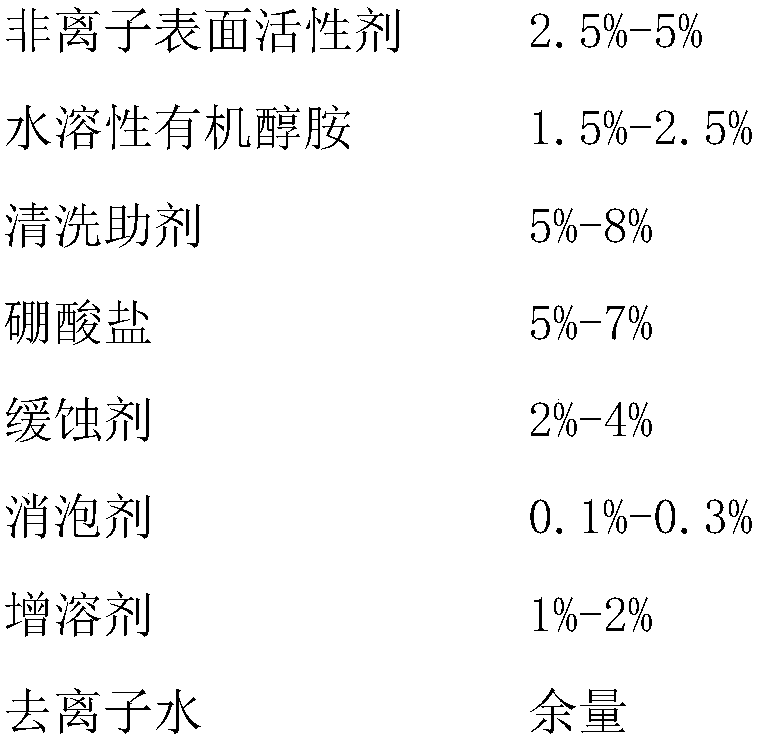

Environment-friendly waterborne industrial cleaning agent with low COD (Chemical Oxygen Demand) value

InactiveCN107904028AReduce COD valueGood cleaning effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolventChemistry

The invention discloses an environment-friendly waterborne industrial cleaning agent with a low COD (Chemical Oxygen Demand) value. The environment-friendly waterborne industrial cleaning agent with the low COD value is prepared from the following components in percentage by weight: 1 to 10 percent of a nonionic surfactant, 1 to 3 percent of waterborne organic alcohol amine, 5 to 20 percent of ancleaning aid, 1 to 10 percent of borate, 1 to 10 percent of a corrosion inhibitor, 0.1 to 0.5 percent of a defoaming agent, 1 to 5 percent of a solubilizer and the balance of deionized water, whereinthe sum of use amounts of all the components is 100 percent. Compared with the prior art, the environment-friendly waterborne industrial cleaning agent is an environment-friendly cleaning agent due tothe fact that phosphorus is not contained, so that water eutrophication is avoided when the environment-friendly waterborne industrial cleaning agent is used; in addition, the COD value is relatively-low, so that an excellent cleaning effect is achieved, as well as the burden of industrial sewage treatment is greatly reduced and the pollution to the environment is reduced while the same cleaningeffect is achieved.

Owner:重庆信人科技发展有限公司

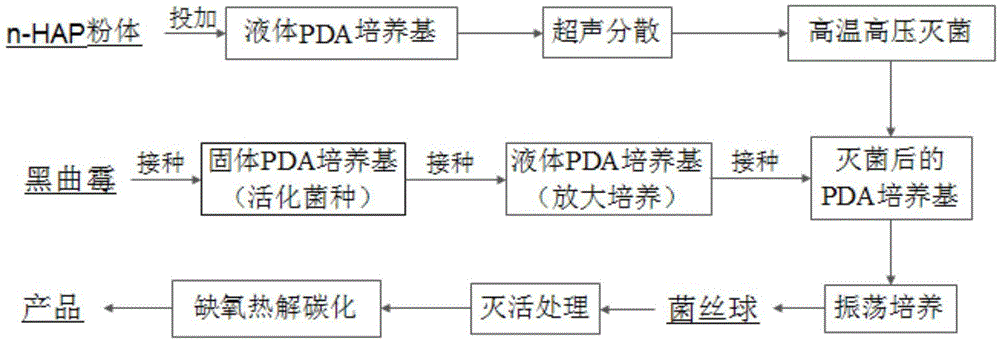

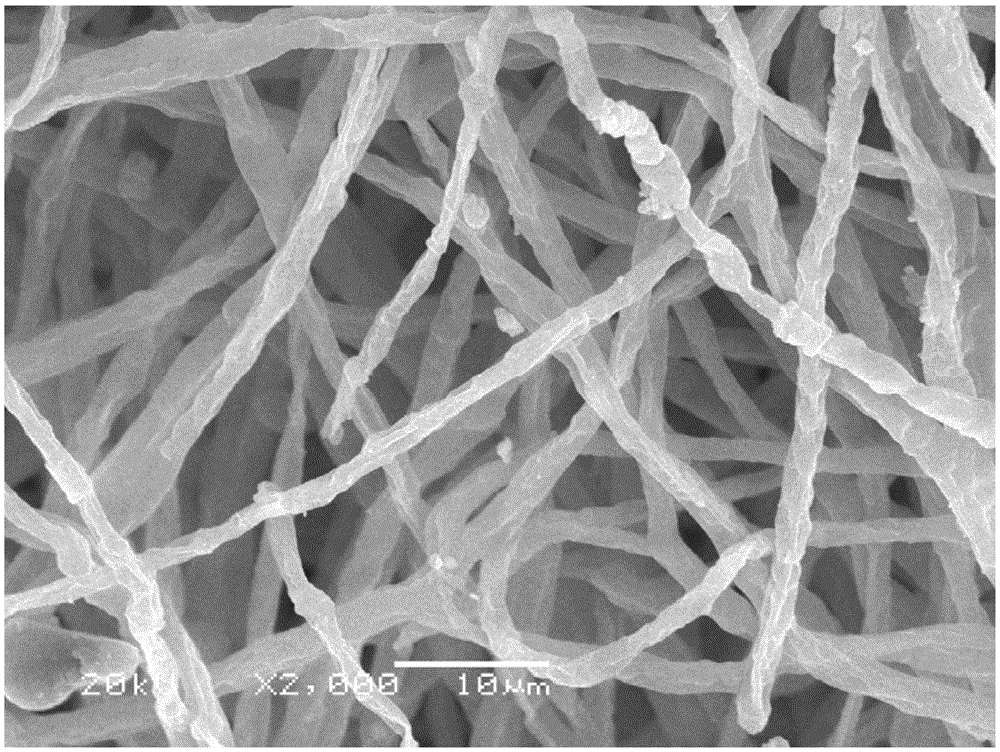

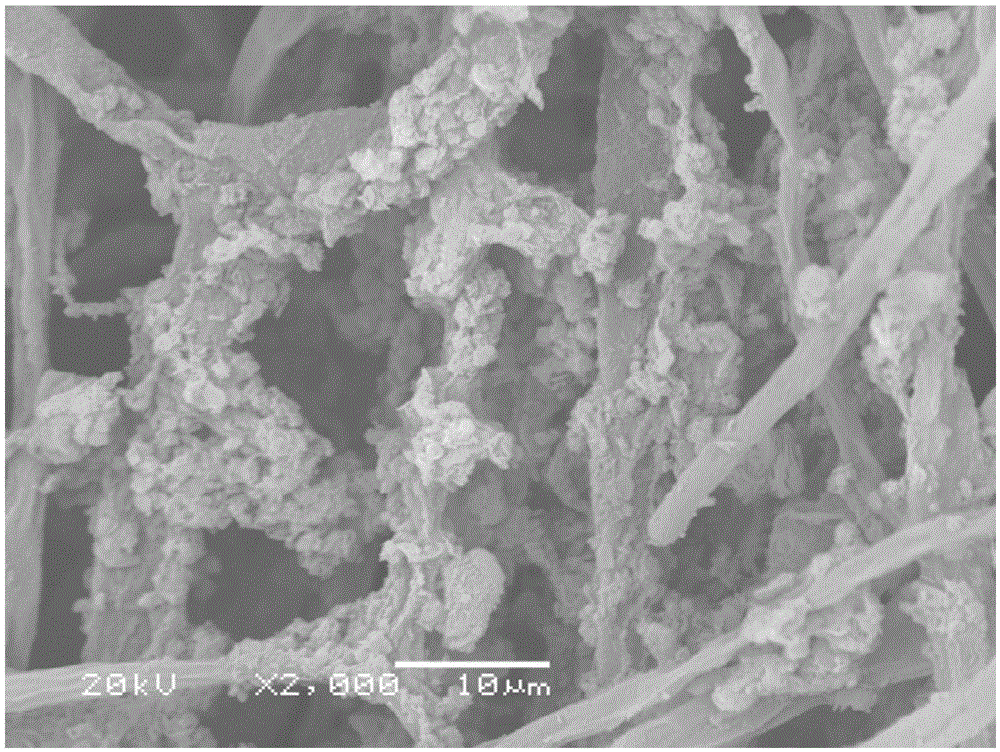

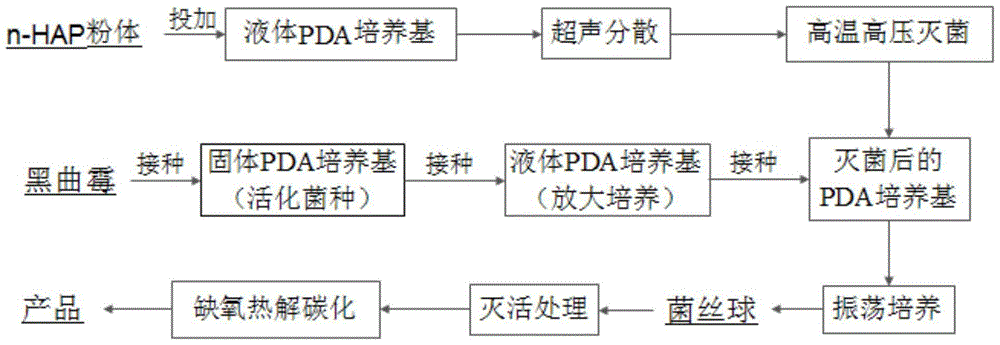

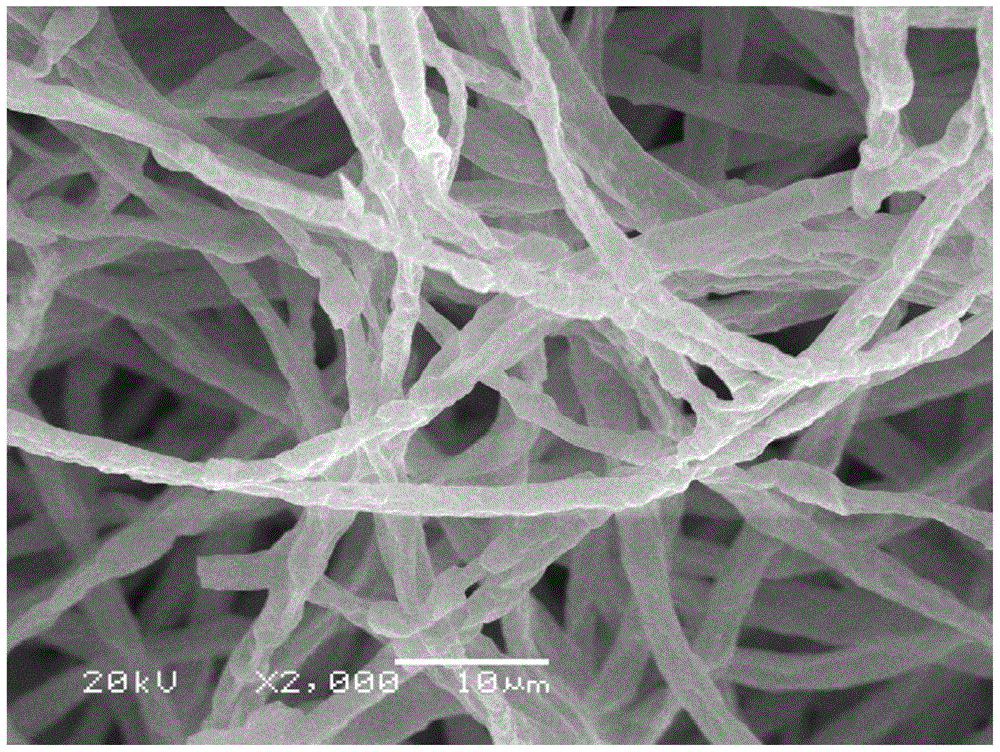

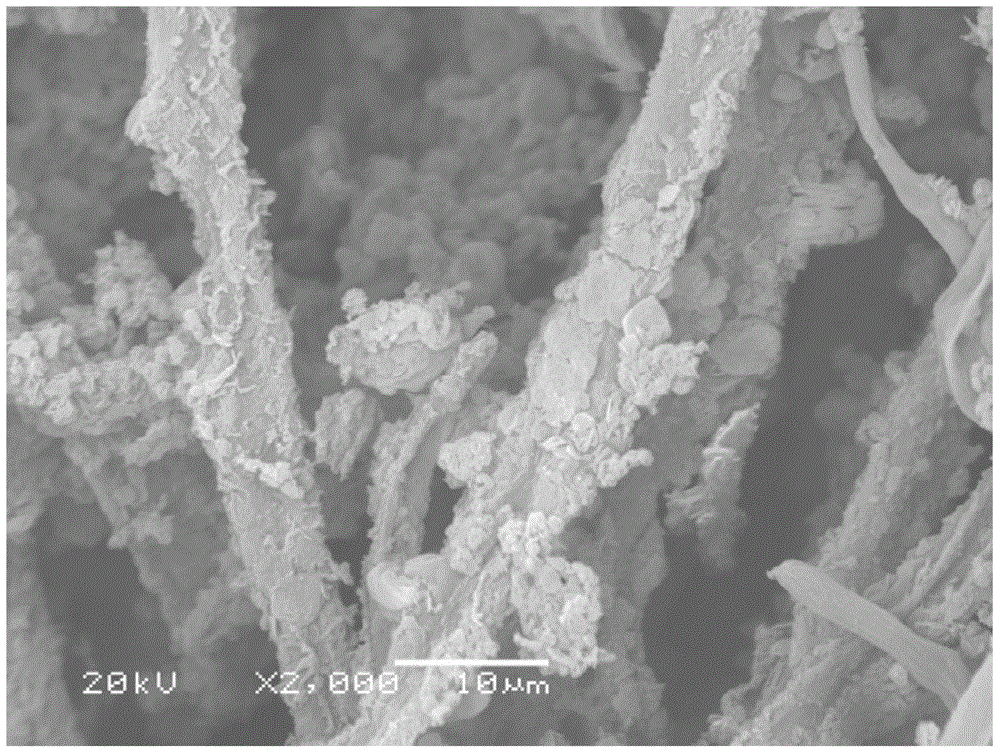

Phosphorus-based biochar material, and preparation and application thereof

ActiveCN105598158ALarge specific surface areaBioadhesiveContaminated soil reclamationMaterials preparationCarbonization

The invention discloses a phosphorus-based biochar material, and preparation and application thereof. The phosphorus-based biochar material with a special structure and a special function is formed by performing anoxia high-temperature carbonization on mycelium pellets which are wrapped with nano hydroxyapatite and serve as a raw material. The synthesized phosphorus-based biochar material is uniformly mixed with soil according to a certain ratio to obtain a mixture; and after the mixture is cured for 7 days, the content of cadmium in an effective state in the soil is reduced by 44.8 to 50.1 percent, so that the treatment effect of the phosphorus-based biochar material is better than that of a pure-phosphorus-based material. The material preparation process is simple, and the cost is lower; biological degradation can be realized, and no secondary pollution is caused; and therefore, the phosphorus-based biochar material is an environment-friendly material.

Owner:CENT SOUTH UNIV

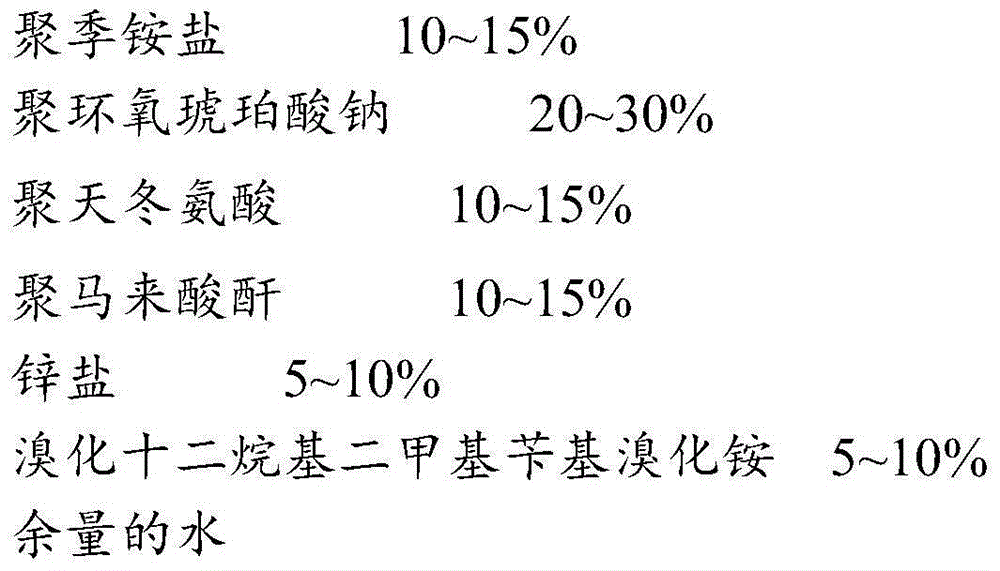

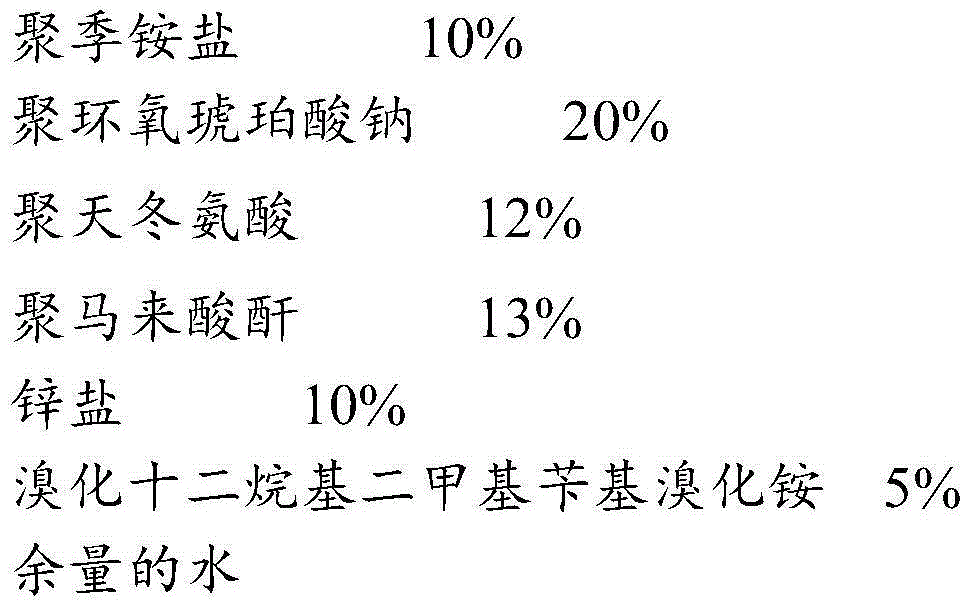

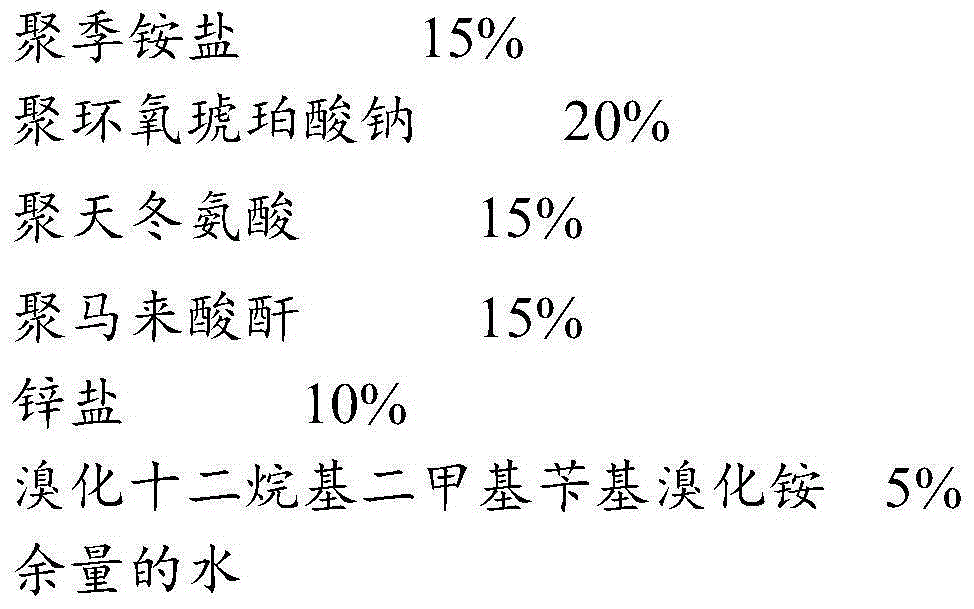

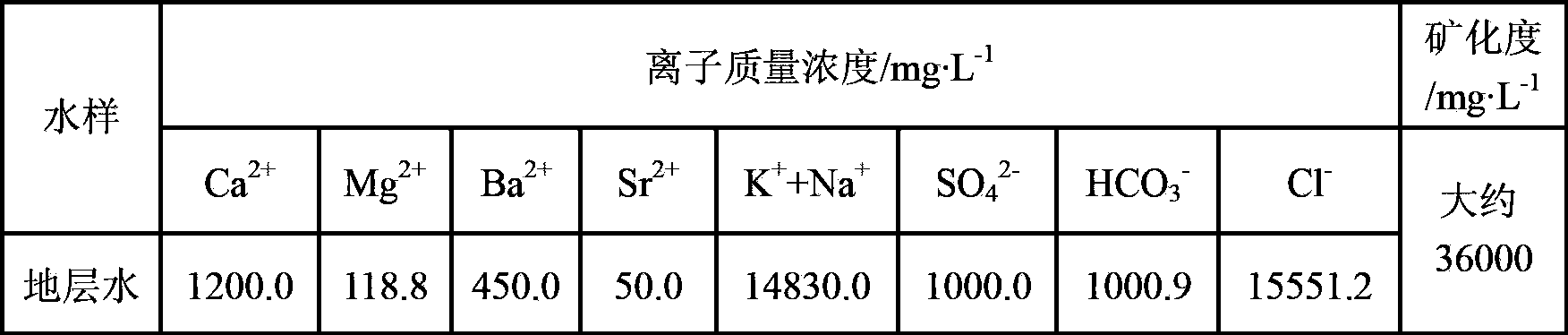

Bactericidal scale and corrosion inhibitor for seawater desalination

The invention provides a bactericidal scale and corrosion inhibitor for seawater desalination, and belongs to the technical field of chemical engineering. The bactericidal scale and corrosion inhibitor comprises, by weight, 10-15% of polyquaternary ammonium salt, 20-30% of sodium polyepoxysuccinate, 20-30% of polyaspartic acid-polymaleic anhydride, 5-10% of a zinc salt, 5-10% of dodecyl dimethyl benzyl ammonium bromide, and the balance of water. The bactericidal scale and corrosion inhibitor has scale inhibition, corrosion inhibition and sterilization functions, and all components of the bactericidal scale and corrosion inhibitor have very good intermiscibility, cooperativity and complementarity, so the bactericidal scale and corrosion inhibitor can substitute present single function scale and corrosion inhibitors and bactericides, and has comprehensive functions; and a formula and a preparation method of the bactericidal scale and corrosion inhibitor are green, compound raw materials adopted in the invention contain no phosphorus and cause no water eutrophication, discharged water causes no pollution to environment, and the preparation method is simple and feasible, is a clean technology, and has no emission of industrial three wastes.

Owner:安徽省蓝天能源环保科技有限公司

Application of phosphorus base charcoal material to remediation of lead contaminated soil

ActiveCN105689374ALarge specific surface areaBioadhesiveContaminated soil reclamationCarbonizationPollution

The invention discloses application of a phosphorus base charcoal material to remediation of lead contaminated soil. According to the phosphorus base charcoal material, microorganisms are used as raw materials; and a phosphorus base material with a specific ratio is doped to form the phosphorus base charcoal material with special structure and functions through anaerobic high-temperature carbonization. The material is simple in preparation process, lower in cost, biodegradable and free of secondary pollution; and the obtained phosphorus base charcoal material has a better effect on remediation of the lead contaminated soil, and the bioavailability of lead in the soil can be effectively reduced. The synthesized phosphorus base charcoal material is uniformly mixed with soil by a certain ratio; and after fixation by 7 days, available lead in the soil is reduced by 33.0-59.8%, so that the phosphorus base charcoal material has a better remediation effect compared with a pure phosphorus base material.

Owner:CENT SOUTH UNIV

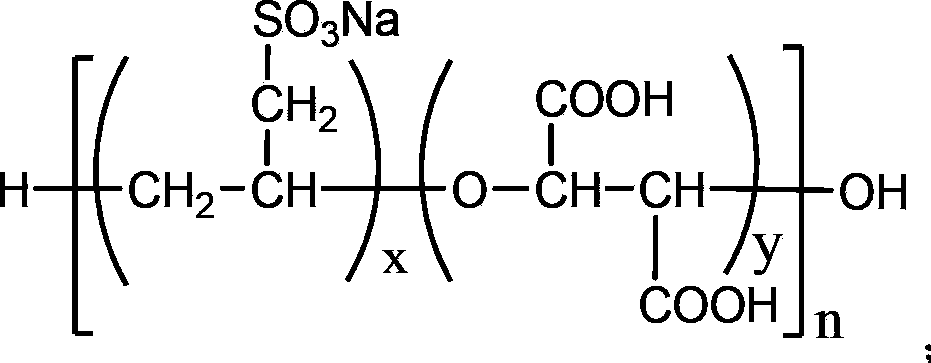

Efficient composite scale inhibitor

The invention relates to an efficient composite scale inhibitor which belongs to the technical field of industrial water treatment agent design and is characterized by compounding, by mass, 25-75% of a terpolymer barium strontium scale inhibitor and 25-75% of a binary copolymer calcium scale inhibitor, the binary copolymer calcium scale inhibitor is a copolymer of epoxy succinic acid and sodium allysulfonate, and the terpolymer barium strontium scale inhibitor is a copolymer prepared by adding acrylic acid or methacrylic acid and acrylate in maleic anhydride. The efficient composite scale inhibitor is free of phosphorus in formulation, may not cause the water body eutrophication in use, is friendly to the environment, is suitable for calcium, barium, strontium and other ion containing water body, the preparation method is simple, the cost is low, anti salt performance is good, stability is good, applicability is wide, and the scale inhibition effect is better by same dose amount compared with that of the single terpolymer barium strontium scale inhibitor or the binary copolymer calcium scale inhibitor.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Non-phosphorus composite scale and corrosion inhibitor and preparation method thereof

InactiveCN108017162AGood anti-scaling effectReduce usageTreatment using complexing/solubilising chemicalsCorrosion inhibitorCopper

The invention relates to a non-phosphorus composite scale and corrosion inhibitor and a preparation method thereof. The inhibitor is prepared from, by mass, 10-20 parts of polycarboxylate, 15-30 partsof amino acid polymers, 10-15 parts of zinc salt, 10-15 parts of sodium salt, 1-2 parts of copper corrosion inhibitor, 10-20 parts of sulfonic acid polymers and the balance water. The preparation method of the inhibitor comprises the steps that the water and the zinc salt are added into a reaction kettle by weight and heated to 40-55 DEG C, and the sodium salt is added to the reaction kettle andstirred till the sodium salt is completely dissolved; polycarboxylate, amino acid polymers, the copper corrosion inhibitor and sulfonic acid polymers are added to the reaction kettle in sequence and mixed; sampling is conducted, materials are taken out after detection is qualified, and labeling and warehousing are conducted. The non-phosphorus composite scale and corrosion inhibitor is applied tocirculation cooling water, has the efficient scale inhibition effect and causes no pollution to the environment, adsorption film and sedimentation film which can be formed on the metal surface have the corrosion inhibition effect, formation of all kinds of scale is prevented, and it is guaranteed that a system runs normally.

Owner:唐山市金沙工贸有限公司

Environment-friendly airfield pavement deicing agent and preparation method thereof

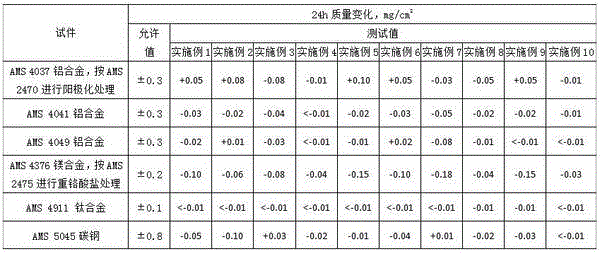

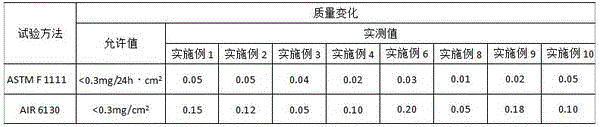

InactiveCN106350010AAvoid corrosionDoes not degrade its corrosion inhibition performanceOther chemical processesPropanoic acidCarboxylic acid

The invention belongs to the technical field of pavement deicing agents and particularly relates to an environment-friendly low-corrosive deicing agent suitable for airfield pavements and a preparation method thereof; the deicing agent is made from C1-C4 organic acid salts and a composite corrosion inhibitor, C1-C4 organic acid salts are one or more of potassium salts or sodium salts of formic acid, acetic acid, propionic acid, lactic acid and succinic acid, and the composite corrosion inhibitor comprises water-soluble silicon compounds and multicomponent organic carboxylates. The pavement deicing agent discussed herein is safe to aircraft materials, is particularly efficient in inhibiting the corrosion of cadmium-plated steel parts due to repeated contact with the deicing agent, meets all airworthiness requirements for airfield pavement deicing agents provided in currently effective international universal standards AMS11431 and AMS1435, and is suitable particularly for airfield pavement deicing and ice control.

Owner:成都民航六维航化有限责任公司 +1

Radix Salviae Miltiorrhizae cultivating and transplanting method

InactiveCN106068983APromote growthIncrease harvest yieldBiocideGrowth substratesGround temperatureGreenhouse

The invention relates to an artificial Radix Salviae Miltiorrhizae cultivating method, and aims to provides a planting method capable of greatly improving yield of Radix Salviae Miltiorrhizae and guaranteeing quality of Radix Salviae Miltiorrhizae. According to the technical scheme, the Radix Salviae Miltiorrhizae cultivating and transplanting method comprises the following steps: (1) seedling culturing in a green house: sowing Radix Salviae Miltiorrhizae seeds and culturing seedlings in the greenhouse in November of every year; (2) transplanting to a field: after Radix Salviae Miltiorrhizae seedlings emerge for 75 days, transplanting the Radix Salviae Miltiorrhizae seedlings to the field, and covering the Radix Salviae Miltiorrhizae seedlings with black mulching films to guarantee growth of Radix Salviae Miltiorrhizae; (3) field management: guaranteeing water and fertilizer, preventing and controlling diseases and insect pests well, and removing the black mulching films in the May on the daytime at the temperature which is above 20 DEG C stably; and (4) harvesting: harvesting in the October or the November. The seedlings are cultured in the greenhouse in winters, are transplanted to the field in the end of the February and at the beginning of the March, and are covered by the black mulching films to guarantee the ground temperature and promote growth of Radix Salviae Miltiorrhizae, compared with a cultivating method of sowing seeds in the spring, the method can prolong the effective growth period of Radix Salviae Miltiorrhizae for about half a year, and can guarantee that the yield of Radix Salviae Miltiorrhizae in the current year is improved by 110% or above, and the quality of Radix Salviae Miltiorrhizae is excellent.

Owner:张晓莉

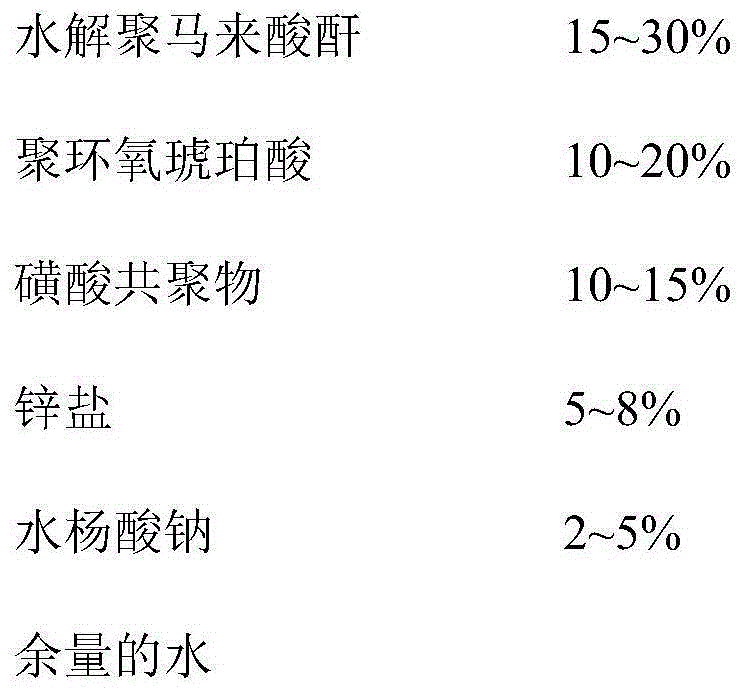

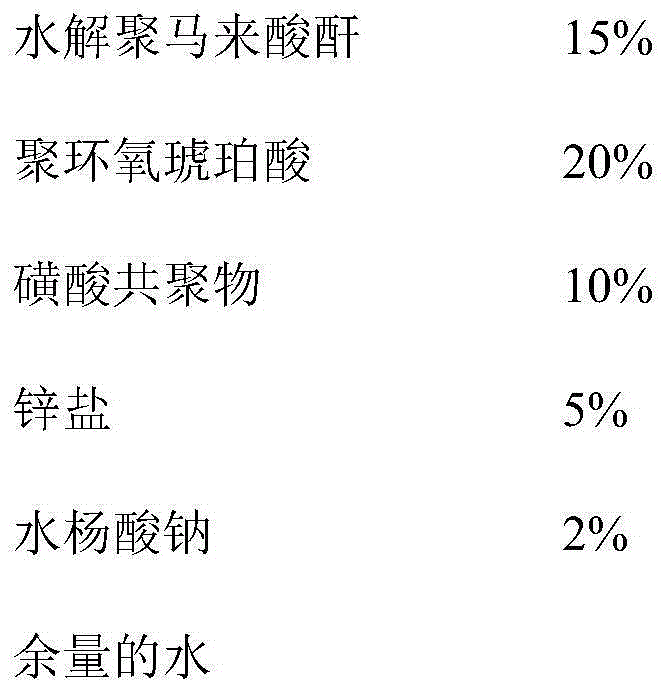

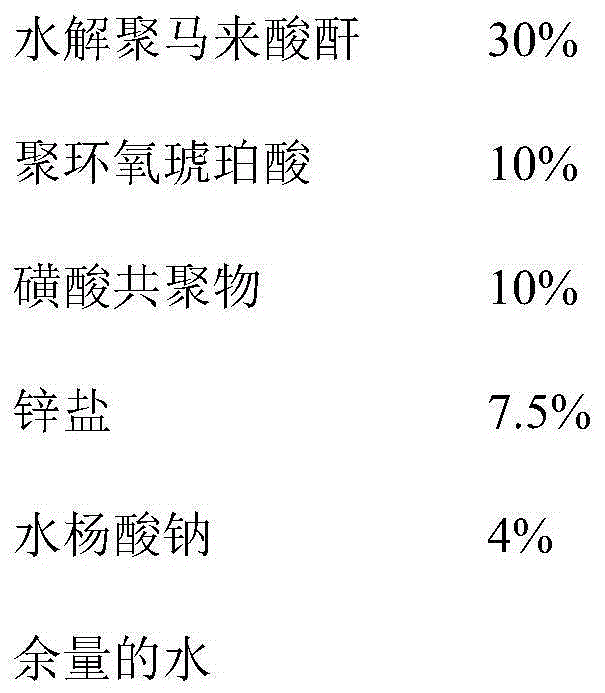

Scale and corrosion inhibitor for power cycling water system

InactiveCN105016490AImprove complexation effectEnhance the anti-scaling and dispersing effectTreatment using complexing/solubilising chemicalsElectric power systemSodium salicylate

A scale and corrosion inhibitor for a power cycling water system belongs to the technical field of water treatment of a power system. The invention aims to provide a preparation method for a composite scale inhibitor which is simple in process flow, low in production cost, stable in quality and efficient in scale prevention and corrosion deceleration, and is a phosphorus-free formula product. The scale and corrosion inhibitor comprises the ingredients in percentage by weight: 15-30% of hydrolytic polymaleic anhydride, 10-20% of polyepoxysuccinic acid, 10-15% of a sulfonic acid copolymer, 5-8% of zinc salt, 2-5% of sodium salicylate and the balance of water. The compound raw materials adopted are non-toxic, low in price and efficient, and the production process of the scale and corrosion inhibitor is simple in flow, the product quality is stable, and the corrosion and scale inhibition rate is greater than 95%. Meanwhile, the production process of the scale and corrosion inhibitor is an environmental-friendly clean process which is free of industrial three waste discharge, simple to operate, low in production cost and suitable for industrialized scale production.

Owner:安徽省蓝天能源环保科技有限公司

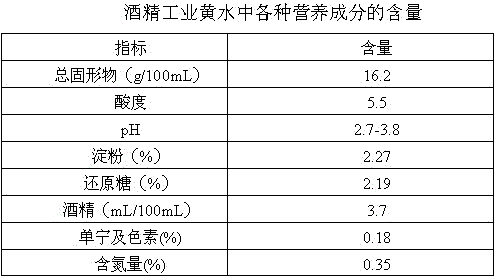

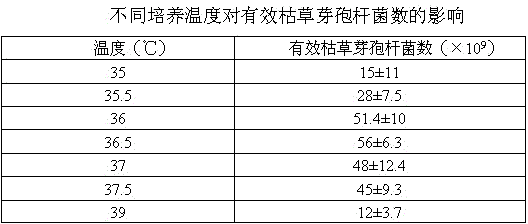

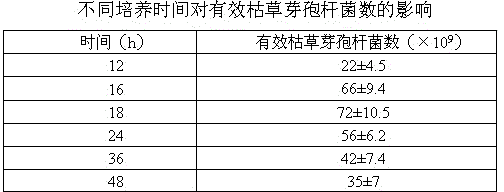

Method for production of bacillus subtilis preparation by utilizing ethanol industrial yellow water

InactiveCN104004676AImprove comprehensive utilization valueImprove the ecological environmentBacteriaMicroorganism based processesChemistryEcological environment

A method for production of a bacillus subtilis preparation by utilizing ethanol industrial yellow water includes collection and treatment of the ethanol industrial yellow water, cultivation of bacillus subtilis in the ethanol industrial yellow water, and receiving and preparation of the bacillus subtilis. The method for production of the bacillus subtilis by utilizing the ethanol industrial yellow water not only can make full use of the ethanol industrial yellow water, reduce the treatment cost of the yellow water, optimize comprehensive utilization of the yellow water and improve the ecological environment, but also can expand sources of a nutrition substrate in a conventional bacillus subtilis preparation production, lower the production costs and expand the application scope of bacillus subtilis.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of scale and corrosion inhibitor for chemical industry field

InactiveCN103130338ADoes not cause eutrophicationEutrophication suitable forTreatment using complexing/solubilising chemicalsChemical industrySulfate

The invention discloses a preparation method of a scale and corrosion inhibitor for the chemical industry field and belongs to the technical field of chemical industry. The preparation method of the scale and corrosion inhibitor for the chemical industry field is technically characterized in that polymaleic anhydride with an average molecular weight higher than 5500 is used as a main raw material; water is used as a solvent; carboxyl (-COOH) in the raw material is hydrolyzed to be -CO- and -OH; zinc sulfate is added; and metal zinc ions and the polymaleic anhydride with high molecular weight form a stable complexation material through a complexation reaction. The preparation method of the scale and corrosion inhibitor for the chemical industry field is simple in technological process of production, stable in product quality and high in scale and corrosion inhibition rate. Meanwhile, the production process is an environment-friendly cleaning process. The preparation method of the scale and corrosion inhibitor for the chemical industry field is free from discharging of three industrial wastes, simple and convenient to operate, low in production cost and suitable for industrialization scale production.

Owner:安徽省蓝天能源环保科技有限公司

Phosphate-free corrosion inhibition antisludging agent and preparation method thereof

InactiveCN101607764AEffective protectionIsolated contactScale removal and water softeningSodium acetatePhosphate

The invention relates to phosphate-free corrosion inhibition antisludging agent and a preparation method thereof. Phosphate-free corrosion inhibition antisludging agent is synthesized mainly by A and B; molar ratio of A and B is 2:1, wherein A is low molecular organic carboxylic acid or salt containing carboxylic group, sulfonic group or carbon-carbon double bond and B is one or more of quadrol, diethylenetriamine, and triethylene tetramine. The preparation method thereof is as follows: firstly, A is dissolved in ethanol, benzene, methylbenzene or dimethylbenzene, and switched to a three-neck flask; B is condensed with sodium dodecyl benzene sulfonate or sodium acetate; the condensed product is poured into the three-neck flask; the reaction temperature is controlled; the product is stirred for 1-3h in the temperature of 100 to 170 DEG C, and then the product reacts for 2-4h in the temperature of 160 to 200 DEG C, and finally is decompressed and distilled in the temperature of 80 to 160 DEG C to obtain claybank stringy liquid which is the product. The product is used for rotating hanging sample test of Q235 carbon steel; when dosage is 5mg-L, annual corrosion rate can be reduced to 0.080mm-a and corrosion inhabitation rate reaches 76.6%. When the product is combined with Zn saline solution, the corrosion inhabitation rate can reach 83% and the antisludging rate can reach 95%.

Owner:WUHAN UNIV OF TECH

Preparation method of hydroxyapatite nanocomposite material

InactiveCN107694513ARapid complexationLittle releaseAluminium silicatesWater contaminantsEutrophicationApatite

The invention belongs to the technical field of sewage treatment, in particular to the technical field of a preparation method of a hydroxyapatite nanocomposite material. The removal mechanism of Cd2+, Cu2+, and Zn2+ in hydroxyapatite nanocomposites is firstly the rapid complexation of heavy metal ions on the surface of hydroxyapatite, and then the heavy metal ions diffuse into the particles and exchange with Ca2+ to form a complex containing heavy metal ions. Ionic hydroxyapatite. For Pb2+, in addition to the adsorption of fixed cations, the dissolution of hydroxyapatite and the precipitation of Pb10(PO4)6(OH)2 contributed most of the removal of Pb2+, and heavy metal ions such as Cd2+, Cu2+, Zn2+ were absorbed by hydroxyapatite It is adsorbed by stone nanocomposite material. The performance of this material is stable. The nano-scale hydroxyapatite powder wrapped by zeolite releases slowly, which can maintain long-term effectiveness, and the release of phosphorus is not large, which will not cause eutrophication of water body.

Owner:WUHAN XINGTIANYU ENVIRONMENTAL ENG

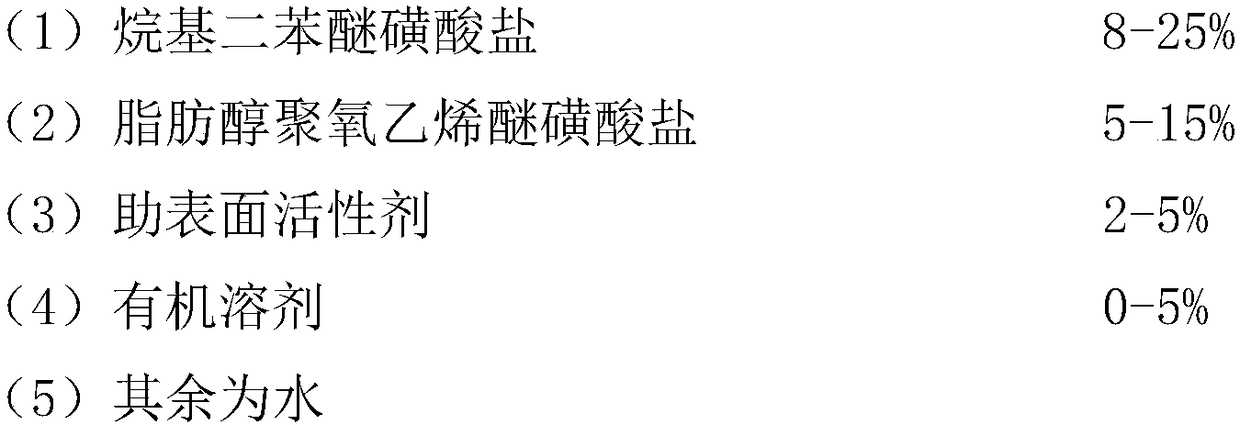

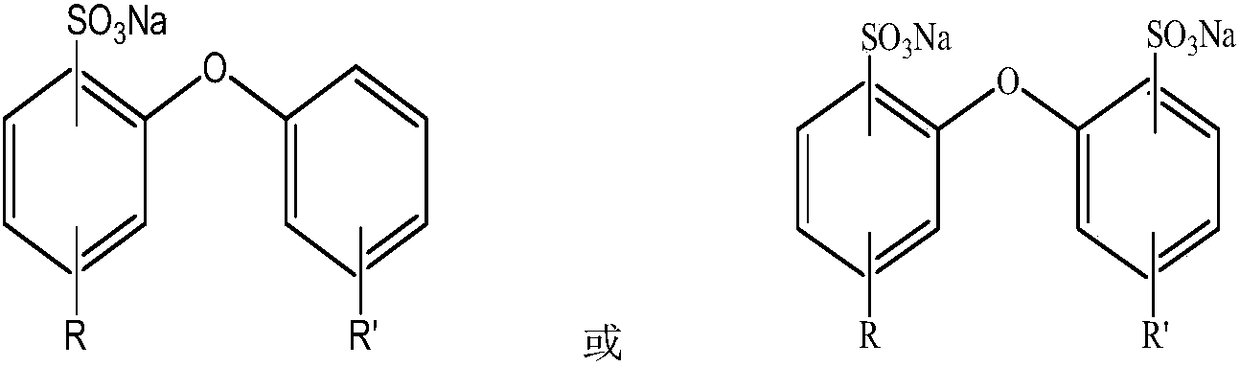

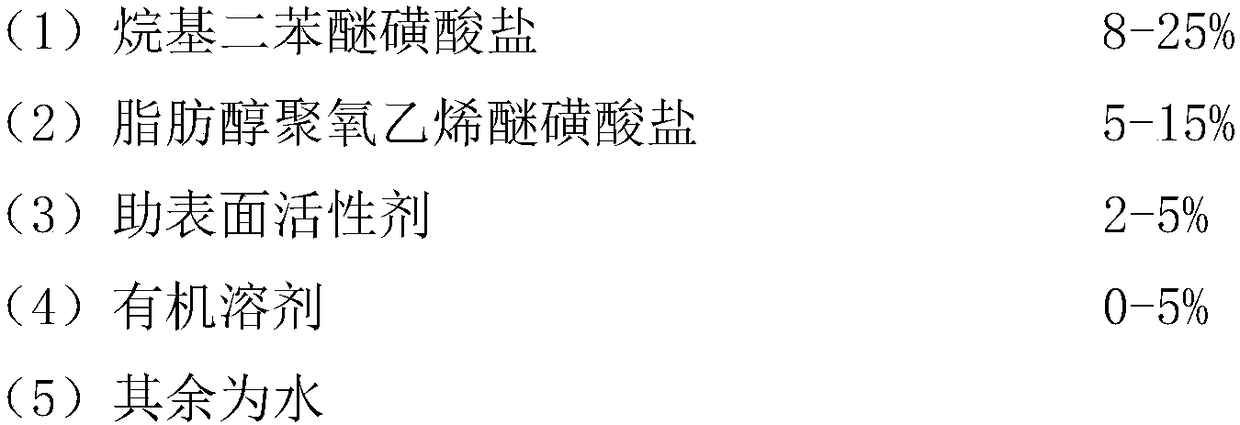

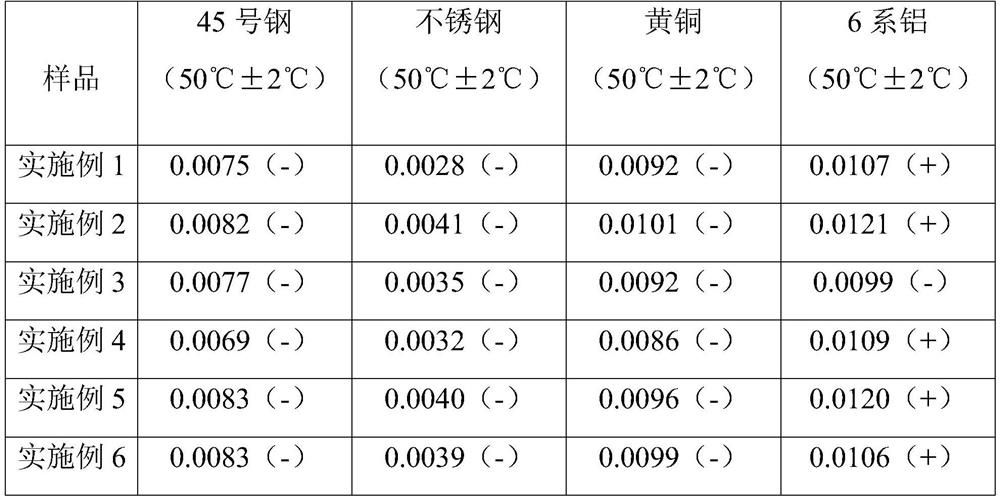

Alkali-free oil displacement agent with high temperature resistance and high salinity and preparation method thereof

The invention discloses an alkali-free oil displacement agent with high temperature resistance and high salinity. The alkali-free oil displacement agent comprises the following components in percentage by mass: 8-25% of alkyl diphenyl ether sulfonate, 5-15% of fatty alcohol polyoxyethylene ether sulfonate, 2-5% of a co-surfactant, 0-5% of an organic solvent and the balance of water. The alkali-free oil displacement agent provided by the invention has the advantages of low cost, environmental protection, high temperature resistance and high salinity.

Owner:CHINA RES INST OF DAILY CHEM IND

Aviation engine carbon deposit cleaning agent and preparation method thereof

InactiveCN112680289AClean up thoroughlyGuaranteed integrityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentEnvironmental geology

The invention provides an aviation engine carbon deposit cleaning agent and a preparation method thereof. The aviation engine carbon deposit cleaning agent comprises the following components in parts by weight: 10-25 parts of alcohol ether solvent, 5-10 parts of closed dodecylbenzene sulfonic acid, 2-8 parts of a sophorolipid biosurfactant, 2-5 parts of alkenyl succinic anhydride, 2-5 parts of a complexing agent, 2-5 parts of a ternary polycarboxylic acid composition, 1-3 parts of a compound corrosion inhibitor, 1-10 parts of an alkalinity improver, 0.1-1.0 part of a defoaming agent and 50-70 parts of water. The aviation engine carbon deposit cleaning agent is suitable for various assemblies made of different materials in an engine, can protect all the assemblies of the engine from being corroded, oxidized and discolored, meanwhile, removes carbon deposit and dirt on all the assemblies of the engine thoroughly, and guarantees a good cleaning effect.

Owner:苏州禾川化学技术服务有限公司

Process of cultivating salvia miltiorrhiza by raising seedlings in greenhouse

InactiveCN106068987APromote growthIncrease harvest yieldBiocidePlant growth regulatorsSalvia miltiorrhizaGround temperature

The invention relates to an artificial cultivation method of salvia miltiorrhiza, and aims to provide a planting method capable of greatly increasing the yield of the salvia miltiorrhiza and guaranteeing the quality of the salvia miltiorrhiza. According to the technical scheme, the method comprises the following steps: (1), raising of seedlings in a greenhouse: sowing salvia miltiorrhiza seeds and raising the seedlings in the greenhouse in November every year; (2), transplantation to a field: after 75 days of germination, transplanting the seedlings to the field and covering the seedlings with black mulching films to ensure growth of the salvia miltiorrhiza; (3), field management; providing sufficient water and fertilizers, preventing and controlling plant diseases and insect pests, and removing the black mulching films after the daytime temperature remains above 20 DEG C in May; (4), harvesting: harvesting in October or November. The method promotes salvia miltiorrhiza growth with greenhouse seedling raising in winter, the seedlings are transplanted to the field in the end of February and at the beginning of March, and by the black mulching films, the ground temperature is ensured. Compared to the method of sowing seeds in spring, the method prolongs the effective growth cycle of the salvia miltiorrhiza by about half a year, and increases annual yield of the salvia miltiorrhiza by 110% or above, and moreover, the quality of the salvia miltiorrhiza is excellent.

Owner:张晓莉

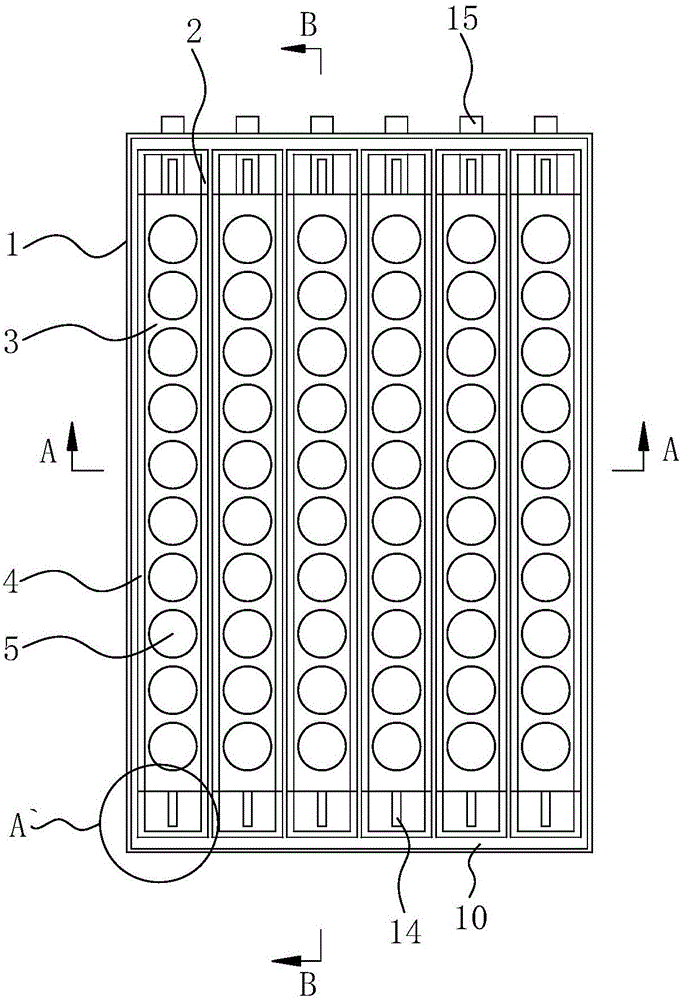

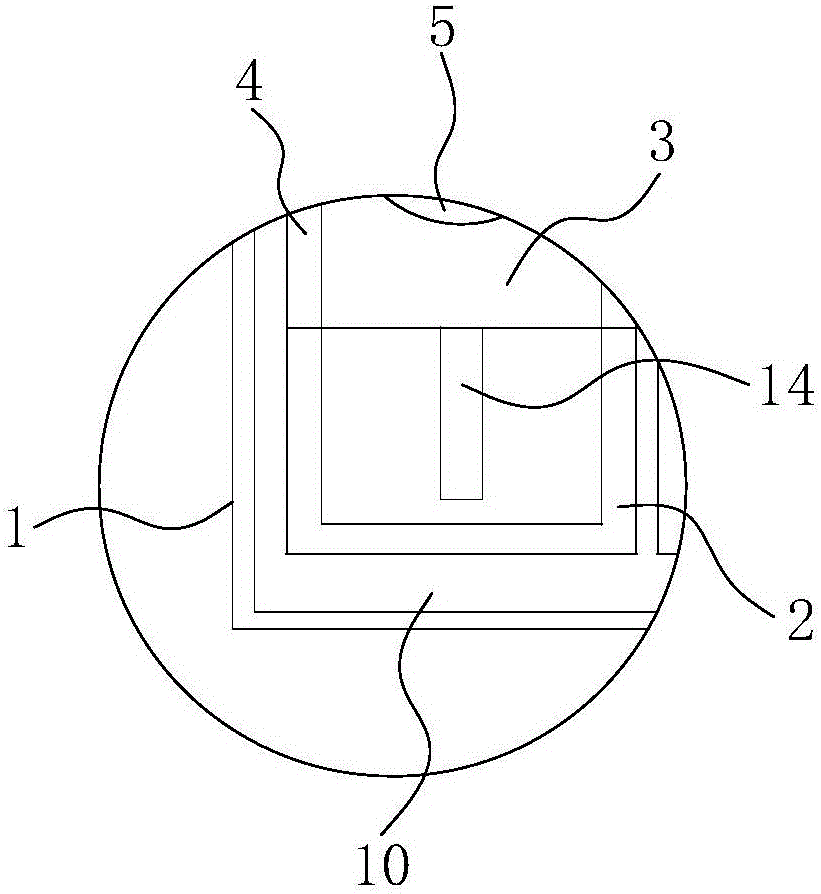

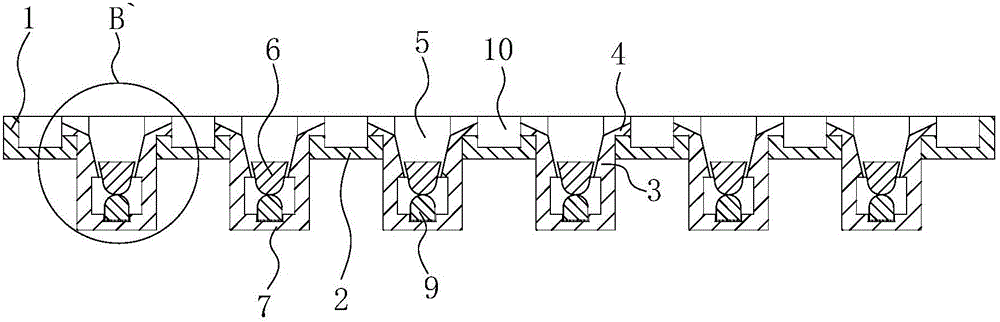

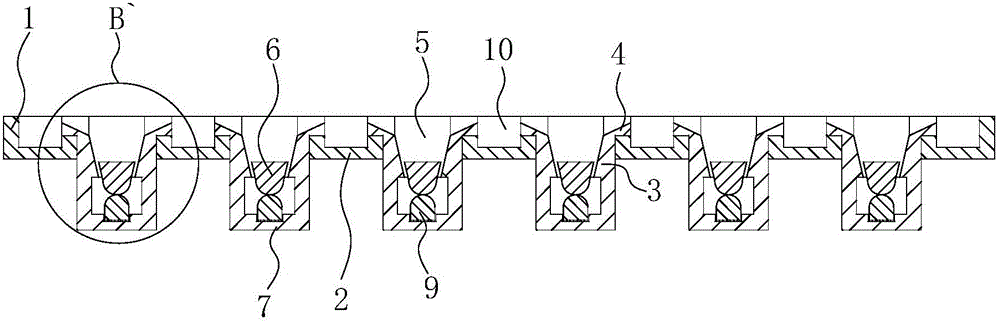

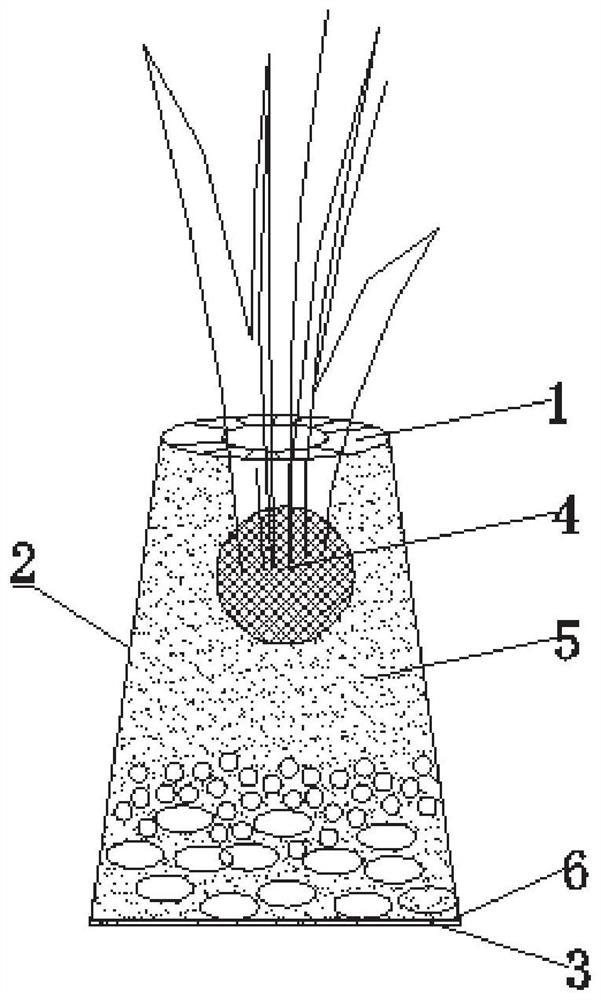

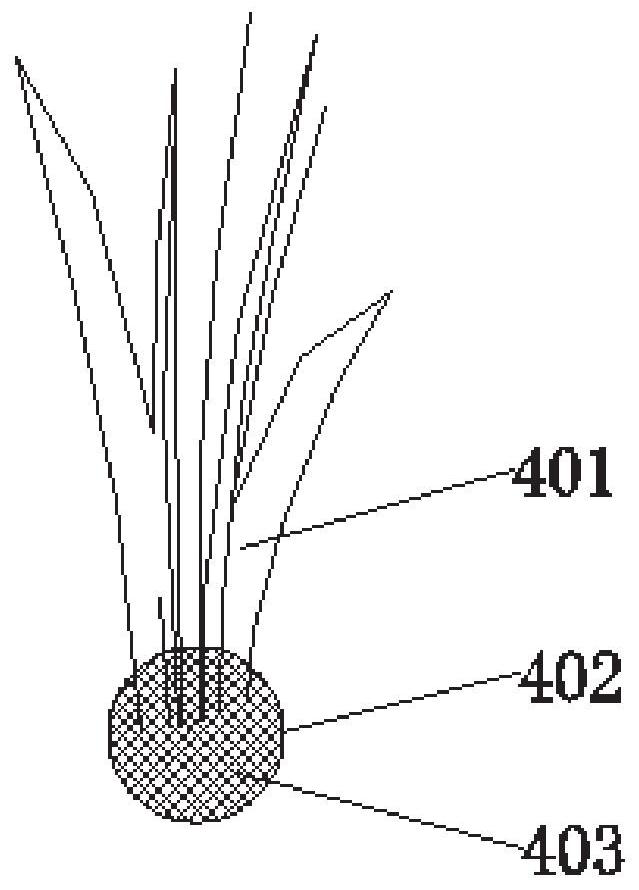

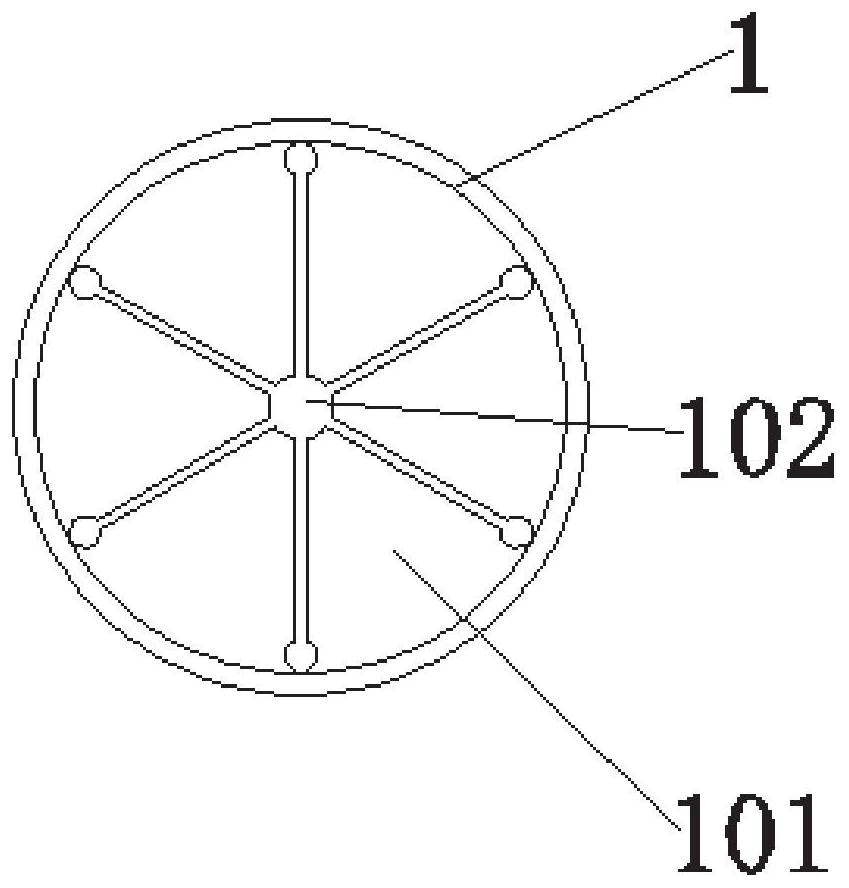

Submerged plant seed throwing cup capable of increasing survival rate

PendingCN112425417AEasy to makeThe planting process is convenient and safeCultivating equipmentsReceptacle cultivationEcologyEcological environment

The invention discloses a submerged plant seed throwing cup capable of increasing the survival rate. The cup comprises a cup body, planting filler and a submerged plant, wherein the cup body is composed of a deformable cup opening, a cup structure and a hollow cup bottom, the submerged plant is placed in the cup body from the deformable cup opening, the root of the submerged plant is wrapped witha planting soil ball, the planting soil ball is wrapped with a cotton thread in a winding mode, a plant fiber net is laid above the hollowed cup bottom, the planting filler is laid above the plant fiber net, the planting filler comprises stone, ceramsite and planting matrix soil which are sequentially laid from bottom to top, the particle size of the stone, the particle size of the ceramsite and the particle size of the planting matrix soil are sequentially reduced, and gaps between the stone and the ceramsite are also filled with the planting matrix soil. The cup is simple in structure, convenient to use and low in cost, the problem that roots of submerged plants are difficult to attach under hard and aerobiotic substrate conditions can be effectively solved, the planting survival rate ofthe submerged plants is greatly increased, all used materials are natural degradable environment-friendly substances, and the ecological environment of target water bodies such as lakes, reservoirs and the like can be protected.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

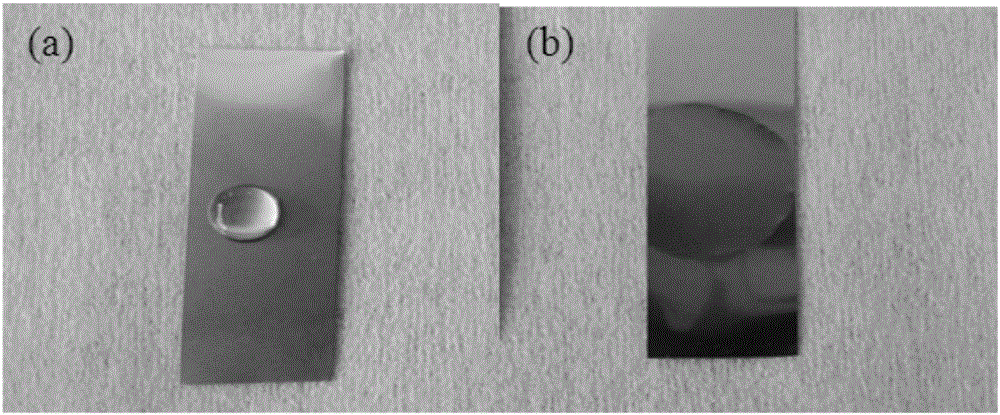

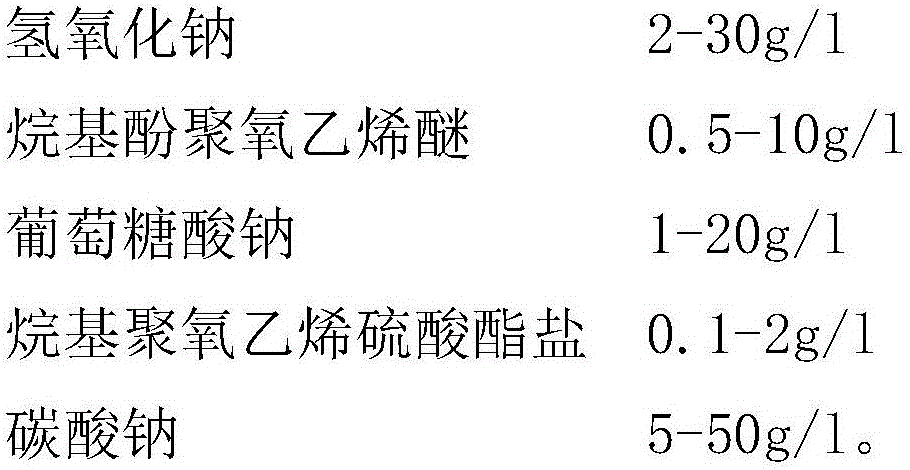

Water-based cleaning agent applied to cleaning hastelloy alloy strips and ultrasonic cleaning method

The invention discloses a water-based cleaning agent applied to cleaning hastelloy alloy strips. The formula of the water-based cleaning agent comprises: 2 to 30g / l of sodium hydroxide, 0.5 to 10g / l of alkylphenol polyoxyethylene ether, 1 to 20g / l of sodium gluconate, 0.1 to 2g / l of alkyl polyoxyethylene sulfate, and 5 to 50g / l of sodium carbonate. The water-based cleaning agent provided by the invention effectively overcomes the defects that an organic solvent is high in cost and harmful to people and livestock, and is simple in process, easy to manage, environmentally friendly, pollution-free, high in efficiency and low in power consumption; and the cleaning temperature ranges from 30 DEG C to 60 DEG C. The cleaning effect is evaluated and compared by adopting a Ramis CIA cleanliness inspection system, so that the detection can be carried out quickly and sensitively; and in addition, a cleaning fluid can be reused after being filtered, so that the service life is prolonged.

Owner:SUZHOU NEW MATERIAL INST

Non-phosphorus washing auxiliary detergent and manufacture method thereof

InactiveCN103131554ADoes not cause eutrophicationImprove build performanceOrganic detergent compounding agentsEpoxyPtru catalyst

The invention discloses non-phosphorus washing auxiliary detergent and a manufacture method of the non-phosphorus washing auxiliary detergent. The non-phosphorus washing auxiliary detergent is a copolymer of epoxy itaconic acid sodium with low molecular weight and 2,3-epoxy propanesulfonic acid sodium. The manufacture method includes that firstly itaconic acid is neutralized through sodium hydroxide solutions to form itaconic acid sodium solutions and then catalyzed and oxidized through sodium tungstate and hydrogen peroxide to produce exopy itaconic acid sodium solutions; secondly epoxy chloropropane and sodium hydrogen sulfite react to produce 3-chrorine-2 hydroxy propanesulfonic acid sodium, and under an alkaline condition, 2,3-epoxy propanesulfonic acid sodium is produced in a cyclized mode; thirdly under the action of the alkaline condition and the catalysts, the epoxy itaconic acid sodium and the 2,3-epoxy propanesulfonic acid sodium carry out cycle opening copolymerization reaction; and ultimately by means of purification of cation exchange resin, the copolymer of the epoxy itaconic acid sodium and the 2,3-epoxy propanesulfonic acid sodium is obtained. The copolymer has good resultant force and dispersion force for calcium ions, has good biodegradability and is efficient and environment-friendly non-phosphorus washing auxiliary detergent.

Owner:GUANGDONG UNIV OF TECH

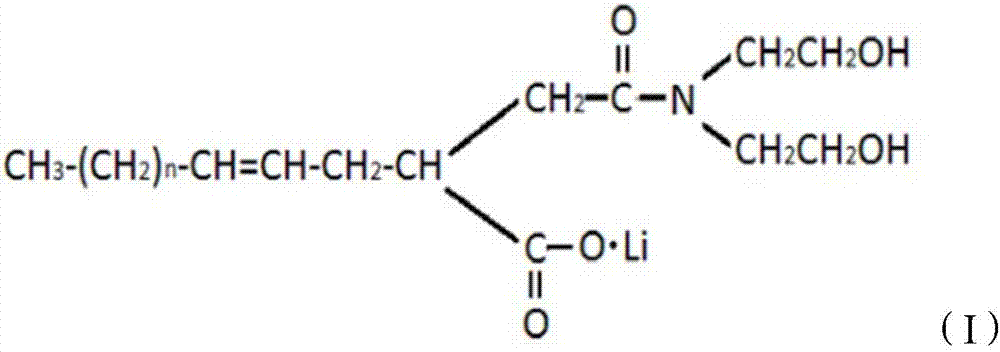

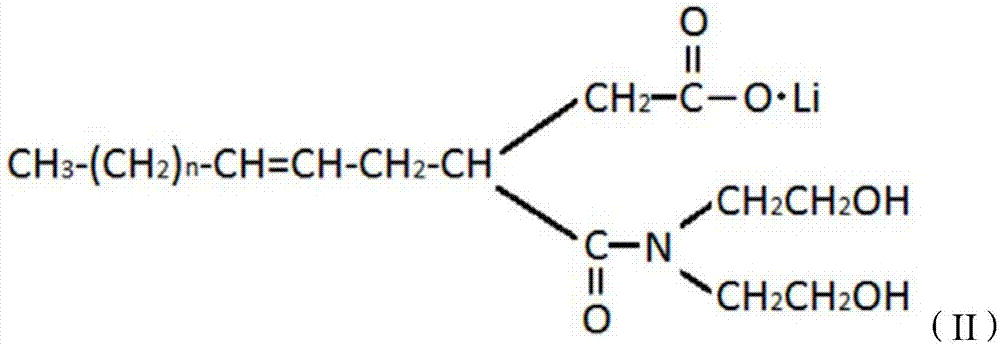

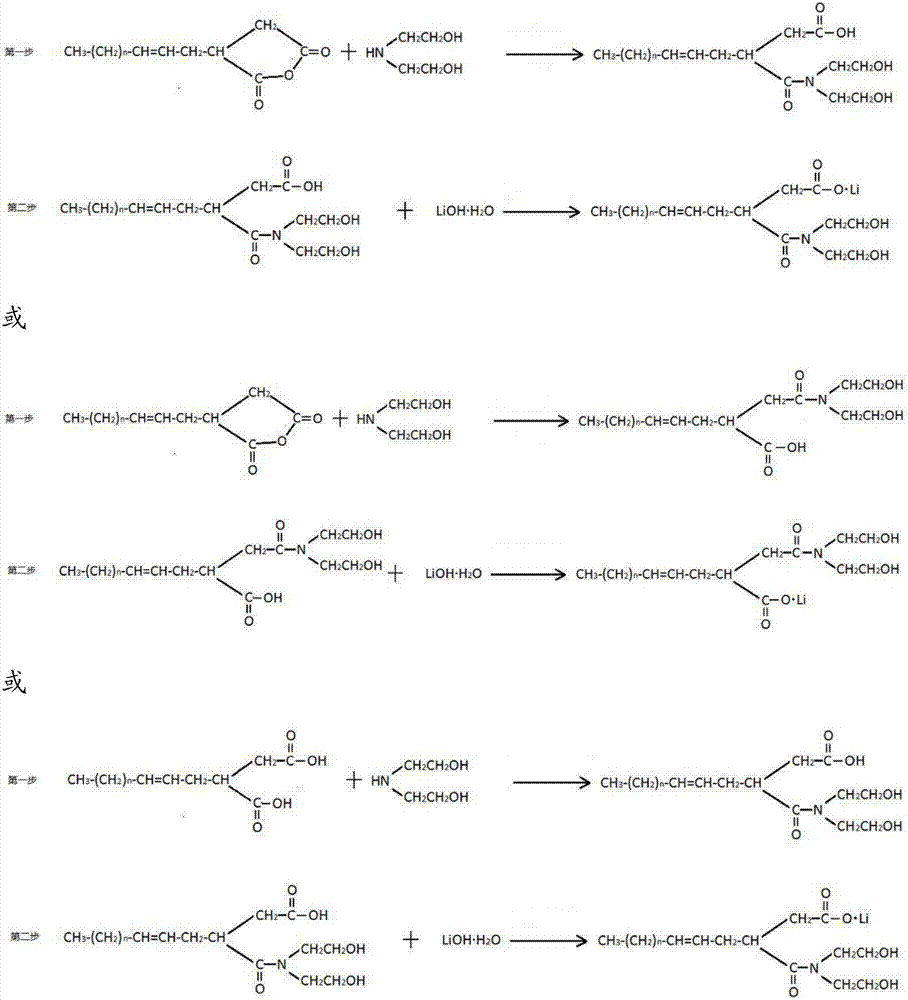

Lithium salt compound and preparation method thereof

ActiveCN106892834AGood mechanical stabilityImprove rust resistanceOrganic compound preparationCarboxylic acid amides preparationEutrophicationMetal working fluid

The invention belongs to the field of metal processing and particularly relates to a lithium salt compound and a preparation method of the lithium salt compound. The invention discloses the lithium salt compound which is obtained through the reaction of an acid compound, diethanol amine and lithium hydroxide monohydrate. The lithium salt compound solves the technical problems that a metal working fluid is not environmentally friendly and the anti-rust property and the extreme pressure property are not excellent in the prior art. The provided lithium salt compound does not contain phosphorus, does not cause eutrophication of a water body, and reduces the cost for wastewater treatment of a user; in addition, the pH value of the compound is 8-9, most of bacteria do not grow within the pH range, then the service cycle of the lithium salt compound is prolonged, and the problems of injuries of the human body and corrosion of the machine caused by excessive low pH value are also avoided; and besides, the lithium salt compound has an excellent anti-rust property and an excellent extreme pressure property on the basis of environmental friendliness.

Owner:德旭新材料(广州)股份有限公司

Bactericidal algicide, and preparation method thereof

InactiveCN107347910ASpectrum efficientStrong peeling and penetrating powerBiocideDisinfectantsCompound organicChlorine dioxide

The invention discloses a bactericidal algicide. The bactericidal algicide comprises, by weight, 18 to 25 parts of a quaternary ammonium salt cationic surfactant, 4 to 5 parts of a natural organic polymer, 5 to 8 parts of chlorine dioxide, 1 to 2 parts of a composite organic amine, 4 to 6 parts of a dispersing agent, 8 to 12 parts of a zinc salt, and 150 to 250 parts of deionized water. The bactericidal algicide possesses scale inhibition and corrosion delaying functions; the above ingredients are harmonious; synergistic effect of the ingredients is achieved; spectrum efficiency is high; drug effect lasts long; and stripping permeability is high.

Owner:SICHUAN AOHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method for degradable slow-release scale inhibitor

InactiveCN105439295AGood anti-scaling effectSimple preparation stepsWaste water treatment from bathing facilitiesTreatment using complexing/solubilising chemicalsWater bathsEutrophication

The invention relates to a preparation method for a degradable slow-release scale inhibitor, and belongs to the technical field of scale inhibitor preparation. The preparation method comprises the steps that maleic acid is added into deionized water, after heating in a water bath and cooling are performed, an aqueous ammonia solution is added, heating is performed to increase the temperature, and stirring, drying and cyclodehydration are performed to obtain a yellow solid; the yellow solid is added into distilled water, heating is performed to increase the temperature, and titration and hydrolysis are performed with a sodium hydroxide solution; after the color of the solution is changed into reddish brown, heating is stopped, and natural cooling and standing are performed; filtering is performed, collected filtrate is added into absolute methanol, and precipitation is performed; filtering is performed, filtrate is collected, evaporated and dried, and a granular scale inhibitor is prepared; the granular scale inhibitor is mixed with substances such as a gelatin solution, standing and defoaming are performed, drying is performed, and then the scale inhibitor is prepared. The preparation method has the advantages that when the prepared degradable slow-release scale inhibitor is put into an environment needing scale inhibition, the scale inhibitor is easy to decompose, friendly to the environment and good in scale inhibiting effect, cannot cause water eutrophication and does not need to be massively put due to the slow-release effect of the scale inhibitor.

Owner:雷春生

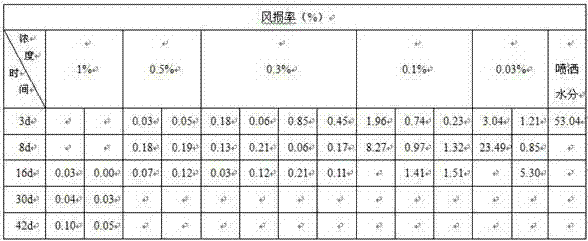

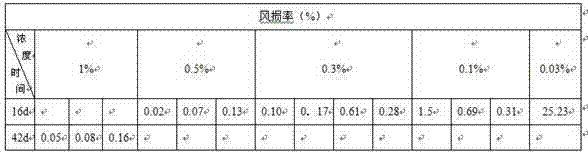

Multi-functional biological high-efficiency dust suppressant, and preparation process and application method thereof

ActiveCN103923608AReduce wind loss rateEasy to produce at room temperatureOther chemical processesDust removalPROPYLENE GLYCOL BUTYL ETHERDiethylene glycol

The invention relates to the technical field of dust suppression, and particularly relates a multi-functional biological high-efficiency dust suppressant, and a preparation process and an application method thereof. The multi-functional biological high-efficiency dust suppressant comprises the following components in percentage by weight: 5-10 percent of water-soluble polyvinyl alcohol, 5-10 percent of fatty alcohol-polyoxyethylene ether, 10-15 percent of dipropylene glycol mono butyl ether, 0.1-0.2 percent of dowcorning organic silicon 120A, 0.1-0.2 percent of dodecyl dimethyl benzyl ammonium chloride and 1-5 percent of diethylene glycol butyl ether. The dust suppressant is formed by composition of multi-functional high-molecular polymer, crosslinking degree molecules in the polymer form a mesh structure, various ion groups exist among molecules, a relatively strong affinity is generated among ions due to large electric density, particle dust can be quickly captured and firmly adsorbed, and the multi-functional biological high-efficiency dust suppressant has strong dust suppressing and dust proofing effects.

Owner:东莞优诺电子焊接材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com