Scale and corrosion inhibitor for power cycling water system

A scale and corrosion inhibitor, power cycle technology, applied in descaling and water softening, complex/solubilizer treatment, water/sludge/sewage treatment, etc., can solve problems affecting the safe, stable and economical operation of thermal power equipment in power plants , thermoelectric equipment scaling, increased deposits and other problems, to improve the effect of scale and corrosion inhibition, low production cost, and enhance the effect of scale inhibition and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

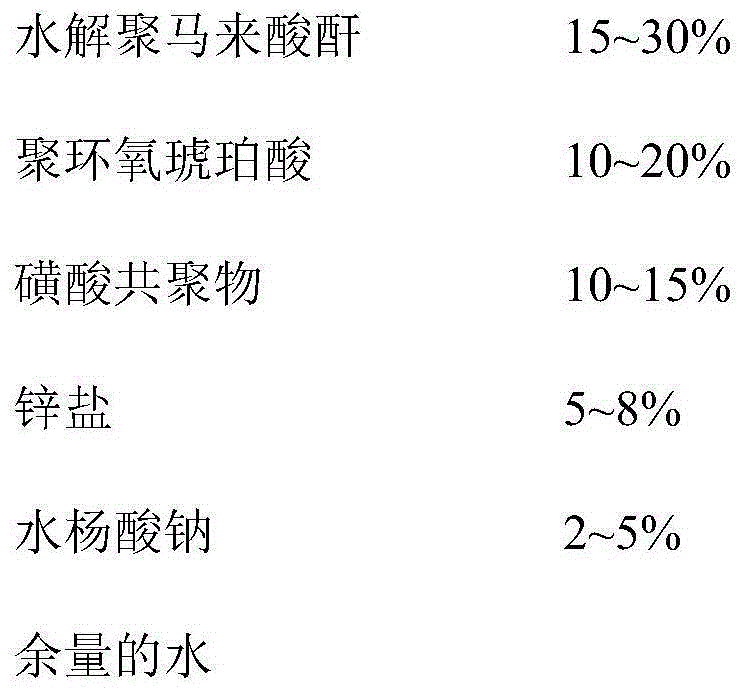

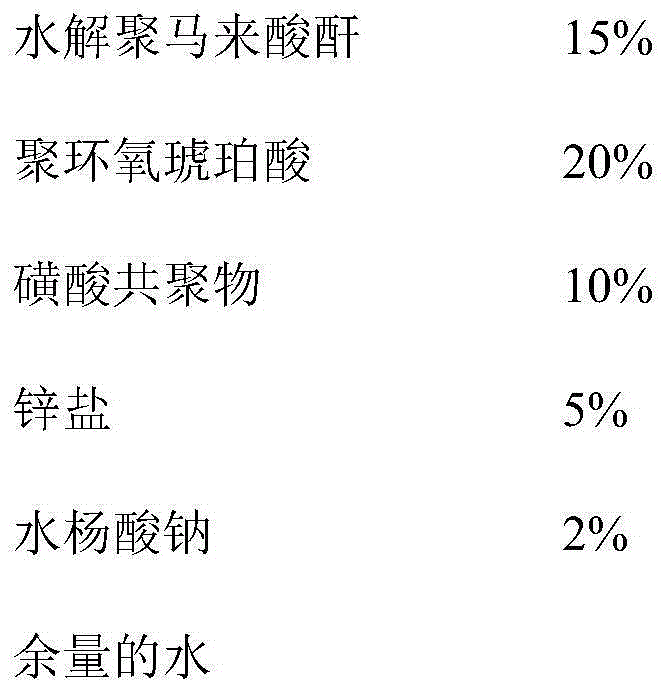

[0020] Embodiment 1: a kind of antiscaling and corrosion inhibitor for electric power circulating water system of the present invention, its batching weight percentage is made up of:

[0021]

[0022] Among them, the molecular weight of hydrolyzed polymaleic anhydride is greater than or equal to 5500, the sulfonic acid copolymer is AA / AMP copolymer, and the zinc salt is zinc sulfate monohydrate or zinc sulfate heptahydrate.

[0023] The steps of the preparation method of the present invention are:

[0024] (1) Add zinc salt and water into the reaction kettle and stir at normal temperature to fully dissolve the zinc salt, then add polymaleic anhydride and stir for 20 minutes;

[0025] (2) Add epoxy succinic acid and sulfonic acid copolymer in the reactor and stir for 30 minutes;

[0026] (3) Finally, add sodium salicylate into the reaction kettle and stir to get the product evenly.

Embodiment 2

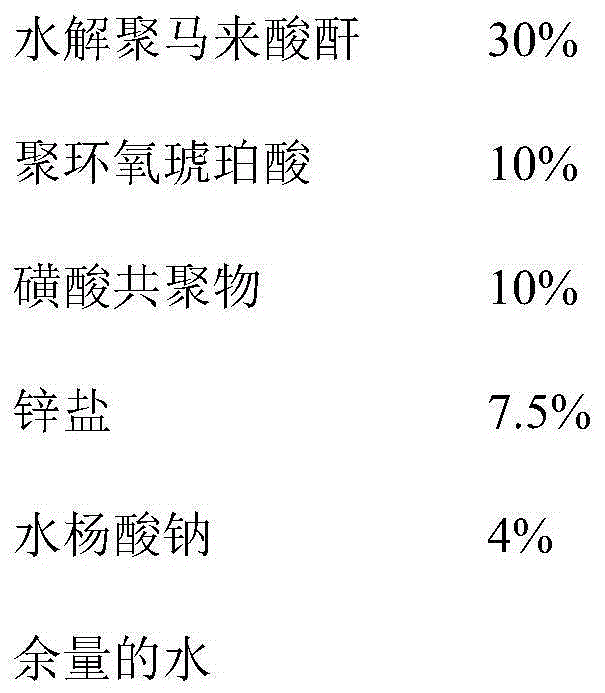

[0027] Embodiment 2: a kind of antiscaling and corrosion inhibitor for electric power circulating water system of the present invention, its batching weight percentage is made up of:

[0028]

[0029] Among them, the molecular weight of hydrolyzed polymaleic anhydride is greater than or equal to 5500, the sulfonic acid copolymer is AA / AMP copolymer, and the zinc salt is zinc sulfate monohydrate or zinc sulfate heptahydrate.

[0030] The steps of the preparation method of the present invention are:

[0031] (1) Add zinc salt and water into the reaction kettle and stir at normal temperature to fully dissolve the zinc salt, then add polymaleic anhydride and stir for 40 minutes;

[0032] (2) Add epoxy succinic acid and sulfonic acid copolymer in the reactor and stir for 30 minutes;

[0033] (3) Finally, add sodium salicylate into the reaction kettle and stir to get the product evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com