Composite filtering material and applications thereof

A composite filtration and substrate technology, applied in filtration and separation, dispersed particle filtration, synthetic resin layered products, etc., can solve the problems of reducing filtration resistance, low specific surface area of blanking materials, poor filtration efficiency, etc., and achieves less cleaning times. , The effect of good dust collection efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

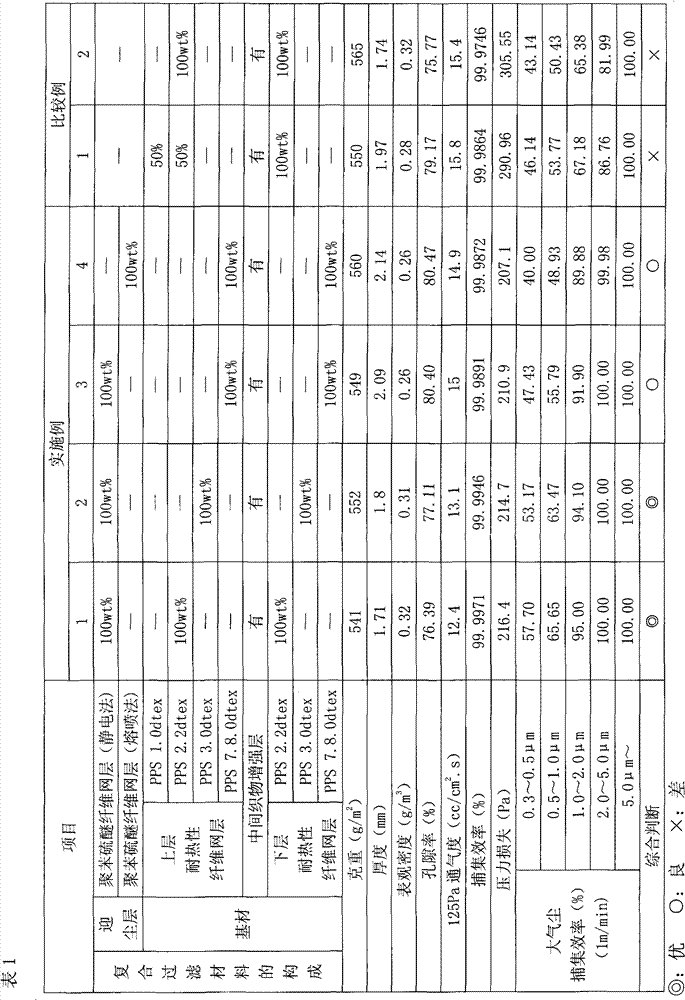

Embodiment 1

[0040] Spray the polyphenylene sulfide spinning liquid onto the upper surface of the following substrate by electrospinning to form polyphenylene sulfide fibers with an average diameter of 400 nm, and then make them pile up into a dust-repellent layer with an average pore diameter of 3 μm.

[0041] The preparation method of the base material that constitutes the composite filter material of the present invention is as follows: adopt the PPS staple fiber of denier 2.0dtex (13.8 μm of average fiber diameter), length 51mm to make warp direction density 36 / 2.54cm, weft density 15 / The 2.54cm plain weave fabric is used as the middle fabric reinforcement layer, and then the upper and lower layers are laminated at 190g / m 2 The staple fiber net layer of weight per unit area, the upper and lower two layers of staple fiber net layer are all made of 100wt% fineness 2.2dtex (fiber average diameter 14.5 μ m), after the PPS staple fiber with a length of 51mm is opened and carded. 50 pcs / cm ...

Embodiment 2

[0044] The polyphenylene sulfide spinning solution is sprayed onto the upper surface of the following substrates by electrospinning to form polyphenylene sulfide fibers with an average diameter of 600nm, and then pile them into polyphenylene sulfide with an average pore diameter of 4.2μm Fiber web layer, the prepared fiber web layer is used as the dust-receiving layer of the composite filter material of the present invention.

[0045] The difference between the preparation method of the base material constituting the composite filter material of the present invention and embodiment 1 is that the upper and lower two layers of short fiber web layers of the base material are all made of 100wt% fineness 3.0dtex (fiber mean diameter 16.9 μm), length 51mm After the PPS staple fiber is opened and carded, it is cut at 50 fibers / cm 2 It is obtained by needle punching at a needle density, and then the intermediate fabric reinforcement layer and the above-mentioned upper and lower layers...

Embodiment 3

[0048] The polyphenylene sulfide spinning liquid is sprayed onto the upper surface of the following substrates by electrospinning to form polyphenylene sulfide fibers with an average diameter of 800 nm, and then pile them into polyphenylene sulfide with an average pore diameter of 6.5 μm Fiber web layer, the prepared fiber web layer is used as the dust-receiving layer of the composite filter material of the present invention.

[0049] The difference between the preparation method of the base material that constitutes the composite filter material of the present invention and embodiment 1 is that the upper and lower two layers of short fiber web layers of the base material are all made of 100wt% fineness 7.8dtex (the average fiber diameter is 27.2 μm), and the length After the 76mm PPS staple fiber is opened and carded, the 2 It is obtained by needle punching at a needle density, and then the intermediate fabric reinforcement layer and the above-mentioned upper and lower layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com