Dust discharging system of V-CUT board-splitting machine

A technology of V-CUT and board splitting machine, which is applied in the field of PCB board manufacturing, can solve problems such as the impact on the health of product quality operators, the impact on PCB board processing quality, and the health hazards of operators, and achieve a simple structure and meet the requirements of production automation control Requirements, energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

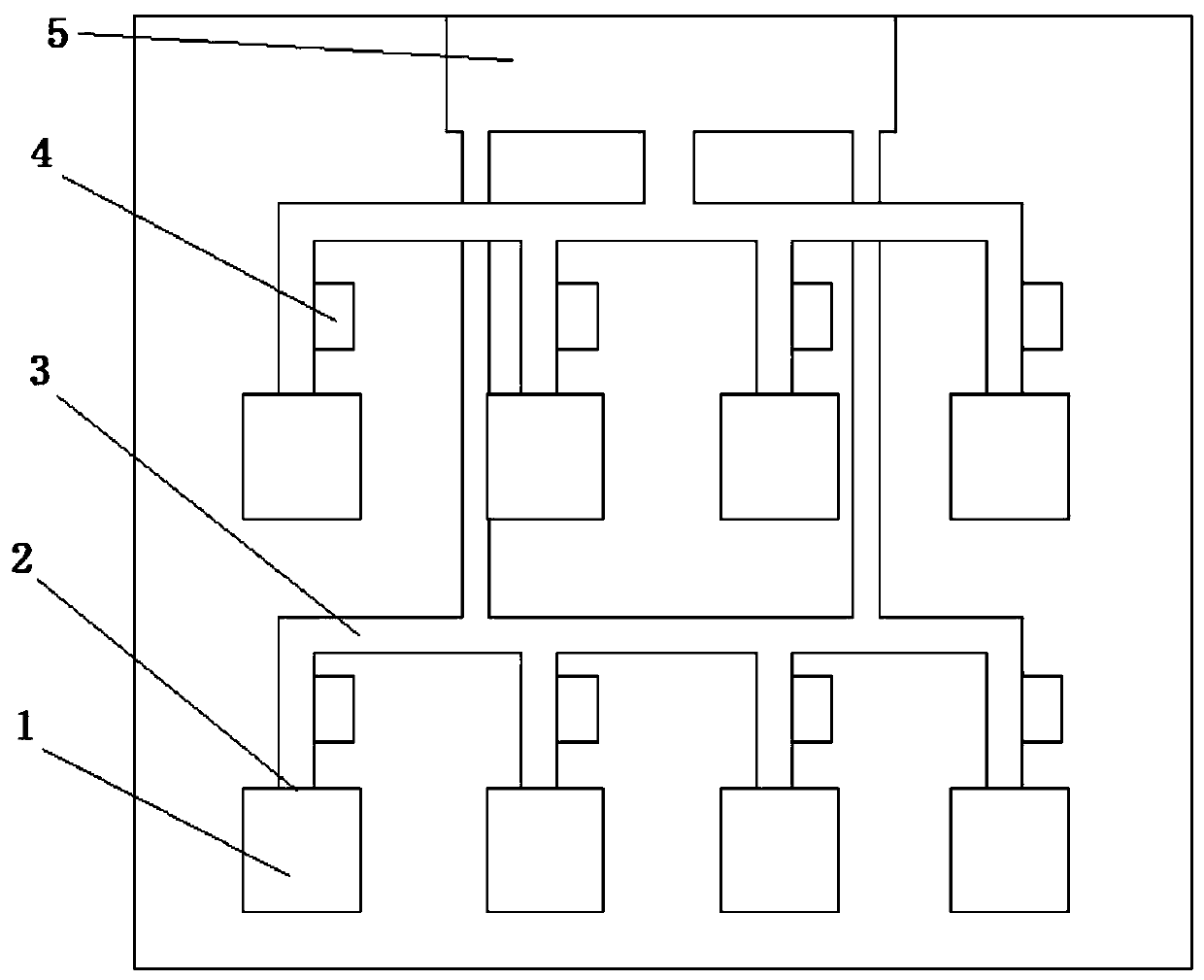

[0015] Referring to the accompanying drawings, a V-CUT splitter 1 dust discharge system of the present invention includes more than one V-CUT splitter 1, dust collection port 2, dust collection pipeline 3, central dust collector 5 and external control host , the dust collection port 2 is set on each V-CUT splitter 1, the other end of the dust collection port 2 is connected to the central dust collector 5 through the dust collection pipe 3, the V-CUT splitter 1, the central dust collector 5. Connect with external control host.

[0016] The present invention arranges a central dust collector 5 in the operating area, and the central dust collector 5 is a high-power dust collector in the prior art, which can satisfy the dust collection effect of air dust within a certain range. Can achieve the effect of saving energy consumption.

[0017] As a further improvement, the present invention also includes a sub-dust collector 4, which is connected to the dust-collecting pipeline 3 of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com