Mine dedusting apparatus

A technology for dust removal equipment and mines, which is applied in the fields of removing smoke and dust, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of inability to achieve equipment dust removal, poor dust removal effect, and low dust removal efficiency, achieve good dust removal effect, and improve dust collection. The effect of high efficiency and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

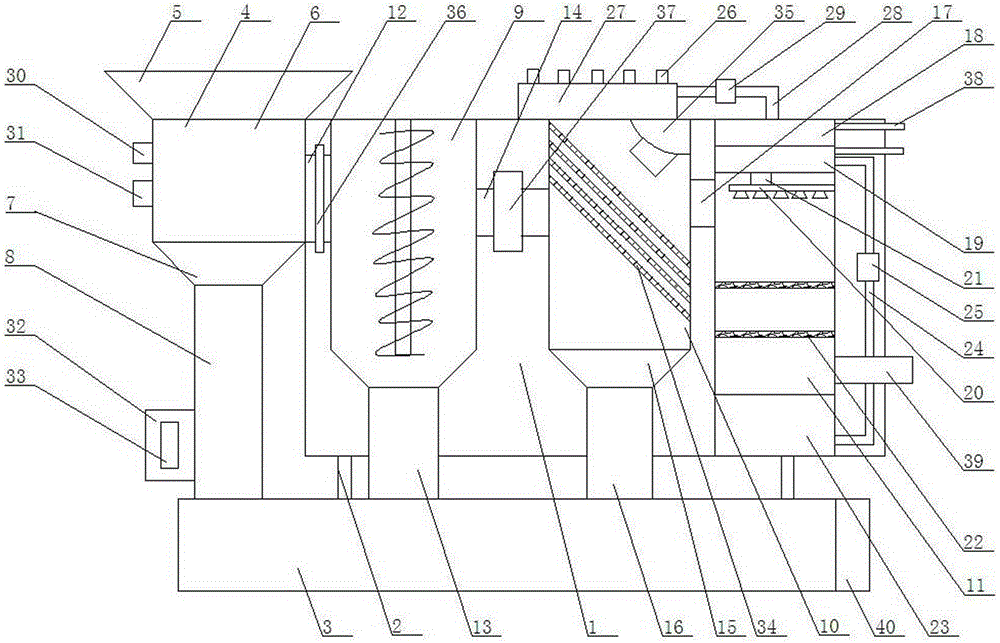

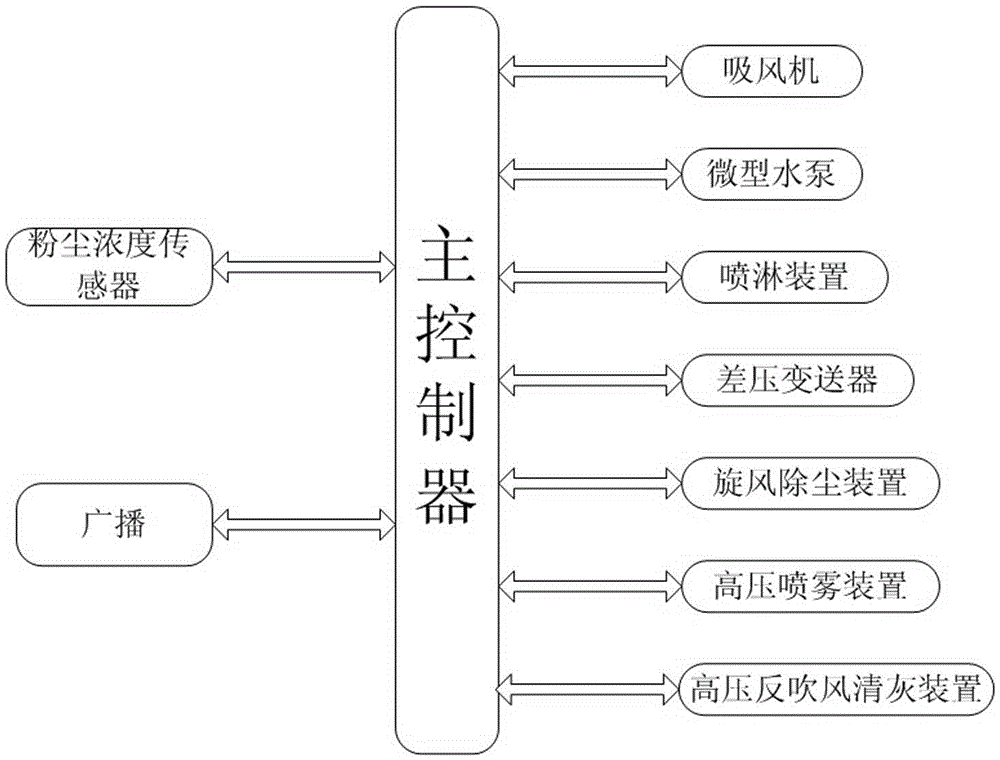

[0024] Such as figure 1 As shown, a mine dust removal equipment includes an outer box 1, a bracket 2, an ash discharge chamber 3, and a dust collection device 4. The left end of the outer box 1 is equipped with a dust collection device 4, and the dust collection device 4 is installed On the left side of the top of the ash discharge chamber 3, the top of the ash discharge chamber 3 supports the upper outer box body 1 through the left and right rows of brackets 2; the dust collection device 4 is composed of a dust collection nozzle 5, a dust collection chamber 6, a first The ash outlet 7 and the ash outlet pipe 8 are composed, the dust collecting nozzle 5 is installed on the top of the dust collection chamber 6, the lower end of the dust collection chamber 6 is connected to the first ash outlet 7, and the lower end of the first ash outlet 7 is connected to the ash outlet pipe 8. The ash outlet pipe 8 is connected to the ash discharge chamber 3 at the lower end; the inside of ...

Embodiment 2

[0026] Such as figure 1 As shown, the dust concentration sensor 30 and the radio 31 are installed on the left wall of the dust collection chamber 6 .

Embodiment 3

[0028] Such as figure 1 As shown, a control box 32 is installed on the left wall of the ash outlet pipe of the dust collecting device 4, and a main controller 33 using an AT89S52 single-chip microcomputer is arranged inside the control box 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com