Air filter and manufacturing method thereof

An air filter, filter technology, used in chemical instruments and methods, filtration separation, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

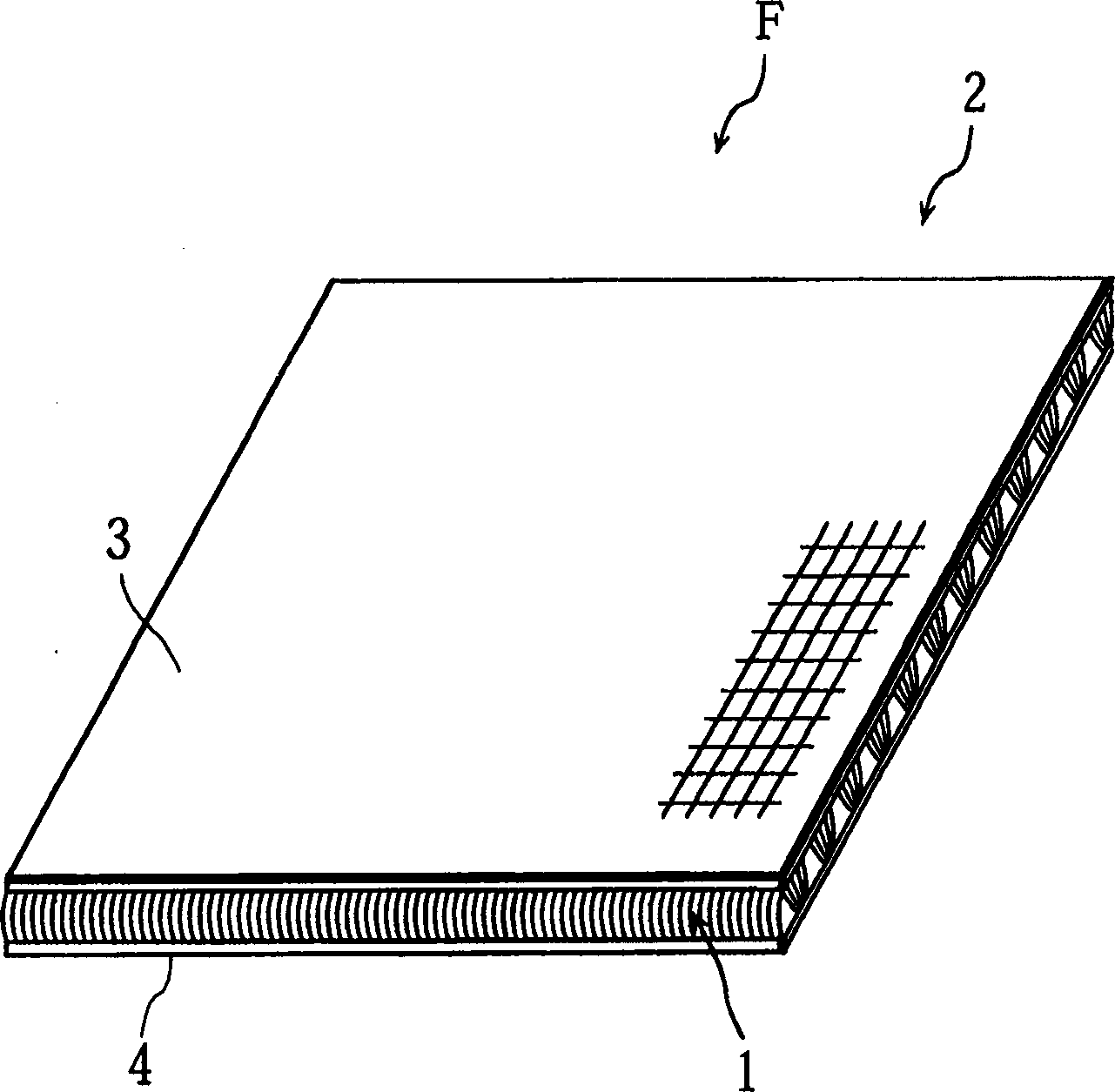

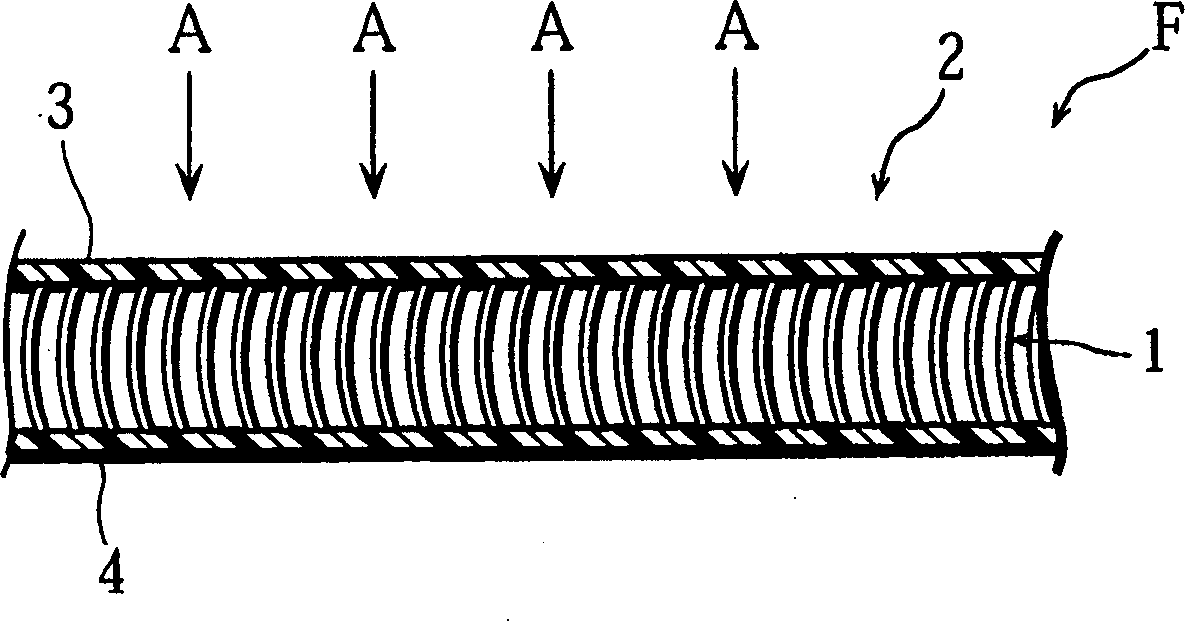

[0034] In the front view, two rectangular air filters (such as Figure 1 to 3 Said) as Example 1 and Example 2. Table 1 shows the dust collection efficiency of the air filter F. In Table 1, 0.3 μm, 0.5 μm, and 1.0 μm all indicate the size of dust (average diameter of particles).

[0035] Pressure loss Pa

Dust collection efficiency %

0.3μm

0.5μm

1.0μm

Example 1

3

12.25

19.80

32.81

Example 2

3

9.86

21.00

34.31

[0036] In addition, the two rectangular air filters with corrugated honeycomb structure of Comparative Example 1 and Comparative Example 2 have a front view size of 300mm×350mm, and the width between the two concave portions of the first member 26 of the circular waveform The size W is 3.6 mm, and the height H between two adjacent flat second parts 27 is 2 mm. Table 2 shows the dust collection efficiency of the air filter F. In Table 2, 0.3 μm, 0.5 μm, and 1.0 μm al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com