Alkali-free fluorine-free liquid accelerator and preparation method thereof

An accelerator and liquid technology, applied in the field of concrete admixtures, can solve the problems of large dosage, low stability and poor coagulation effect, and achieve the effects of small skin erosion, good stability and no loss of strength in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

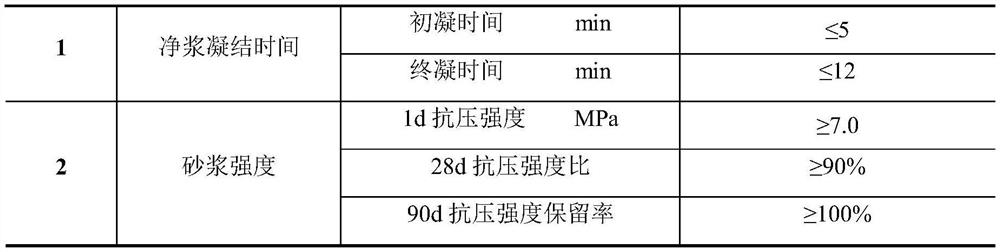

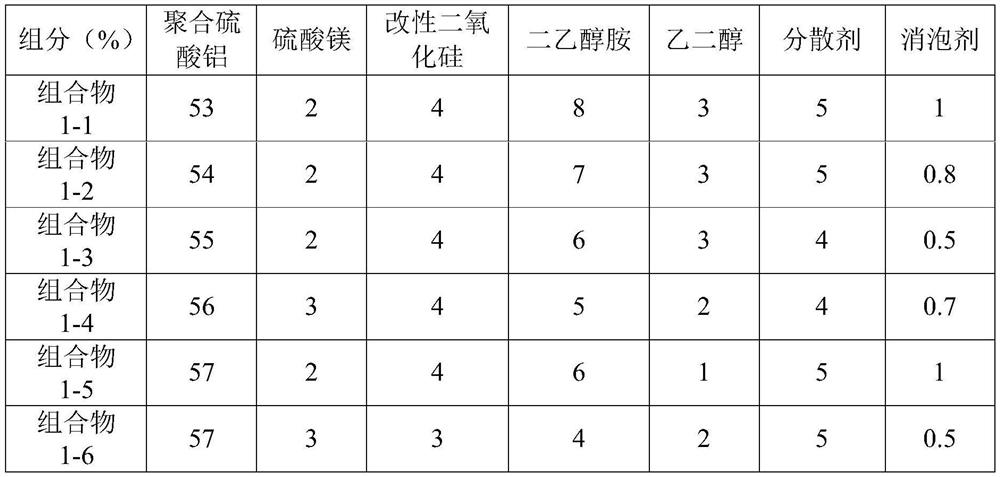

[0054] Present embodiment 1 provides 6 groups of preferred liquid quick-setting agent formulation compositions, and composition total amount is 100%, and balance is water, as shown in table 2:

[0055] The proportioning ratio of each quick-setting agent of table 2

[0056]

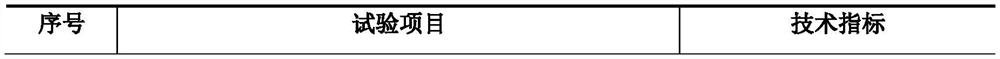

[0057] The above-mentioned 6 groups of compositions were tested for the technical performance index requirements of the quick-setting agent, and the test object was the benchmark cement, and the dosage was 7%; the test results are shown in Table 3 below:

[0058] Table 3 Performance Test Summary

[0059]

Embodiment 2

[0061] This embodiment is the research optimization of the conditions in the preparation method of the quick-setting agent formula

[0062] The key point in the preparation and synthesis of liquid accelerators is to solve the solubility of accelerator components, especially for liquid accelerators that use aluminum-based compounds as accelerator components. Due to the low solubility of aluminum sulfate at room temperature, the purpose of synthetic process control is to promote the dissolution of aluminum sulfate and maintain the content of aluminum ions in the solution for a long time, so as to exert the effect of accelerator and meet the setting time and early strength technology Require. Therefore, choosing an appropriate synthesis process is the basic premise for preparing a qualified liquid accelerator.

[0063] Through the research on the reaction conditions, it is found that in addition to the ratio between the components of the compound product, the synergy between the...

Embodiment 3

[0076] A method for an alkali-free and fluorine-free liquid quick-setting agent, comprising the steps of:

[0077] Step 1: Heat the water to 40°C, put in half of the polyaluminum sulfate, and continue stirring at a speed of 140r / min for 8 minutes, continue to put in the remaining polyaluminum sulfate, and stir to dissolve;

[0078] Step 2: keep the temperature and rotational speed constant, dropwise add diethanolamine to carry out the complexation reaction for 12 minutes;

[0079] Step 3: Keep the temperature and rotation speed constant, add ethylene glycol dropwise for complexation reaction for 15 minutes;

[0080] Step 4: Keep the temperature and rotation speed constant, put in the remaining compound components and stir for 8 minutes, stop stirring, let the solution stand, and let the solution cool down to room temperature naturally to obtain the quick-setting agent #1, and control the total heat preservation Time 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com