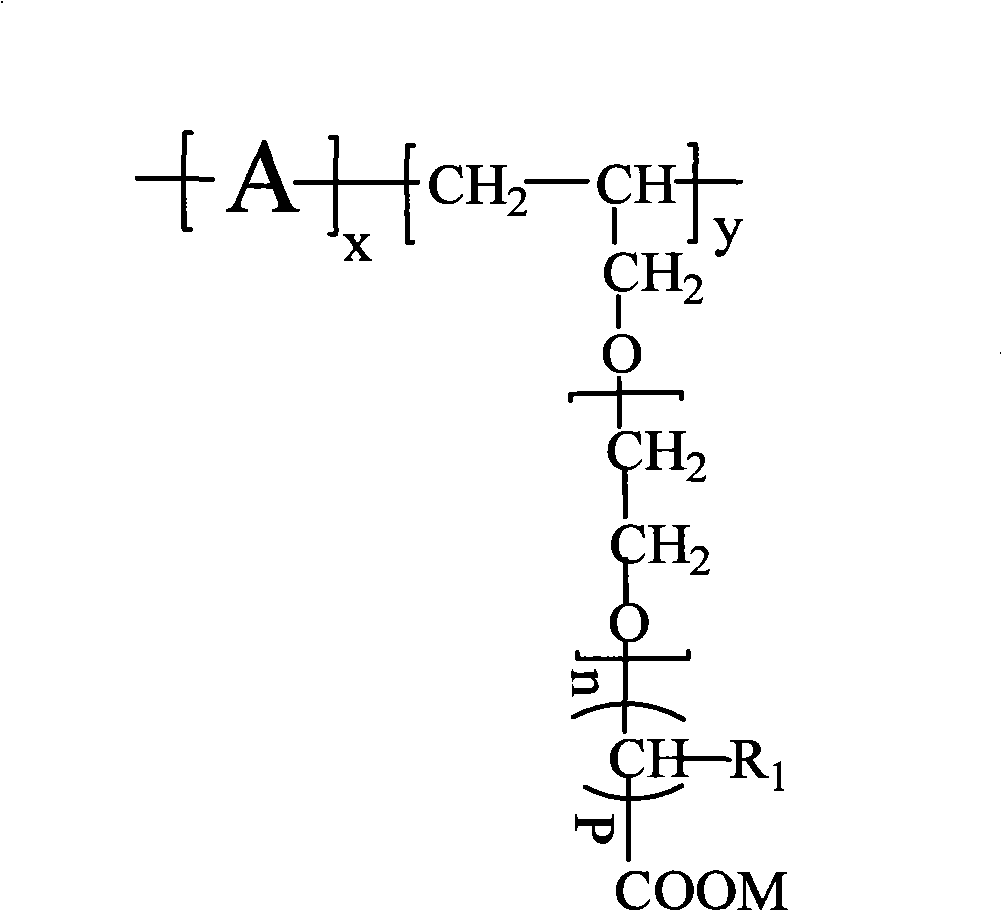

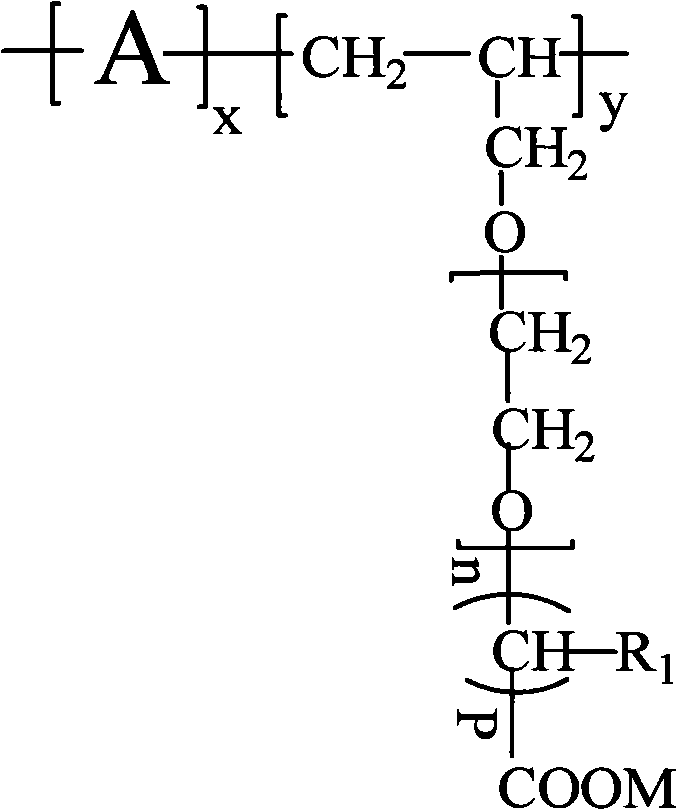

Phosphate-free polyether scale inhibitor and preparation method thereof

A technology of antiscalant and polyether, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve secondary pollution, difficult inorganic waste salt, poor scaling performance, etc. problem, to achieve the effect of good compatibility and high inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of phosphorus-free polyether scale inhibitor of the present invention is:

[0025] Based on the quality of allyl polyethylene glycol monoether, add allyl polyethylene glycol monoether and solid inorganic base 0.5 to 2 times the mass of allyl polyethylene glycol monoether into the reaction kettle, 2 Under atmosphere, after basification at 20-120°C for 1-5 hours, add lactone with 0.5-2 times the mass of allyl polyethylene glycol monoether, and react at 30-150°C for 2-8 hours; adjust and control the temperature at 50°C- After 95°C, add 0.2 to 5 times the mass of allyl polyethylene glycol monoether and distilled water with 0.1 to 5 times the mass of allyl polyethylene glycol monoether, and mix well Add dropwise an inorganic initiator aqueous solution with a concentration of 5% to 60% by mass. The amount of the inorganic initiator added is 0.01 to 0.5 times the mass of allyl polyethylene glycol monoether, and the dripping is completed in 0.5 to 5 hours...

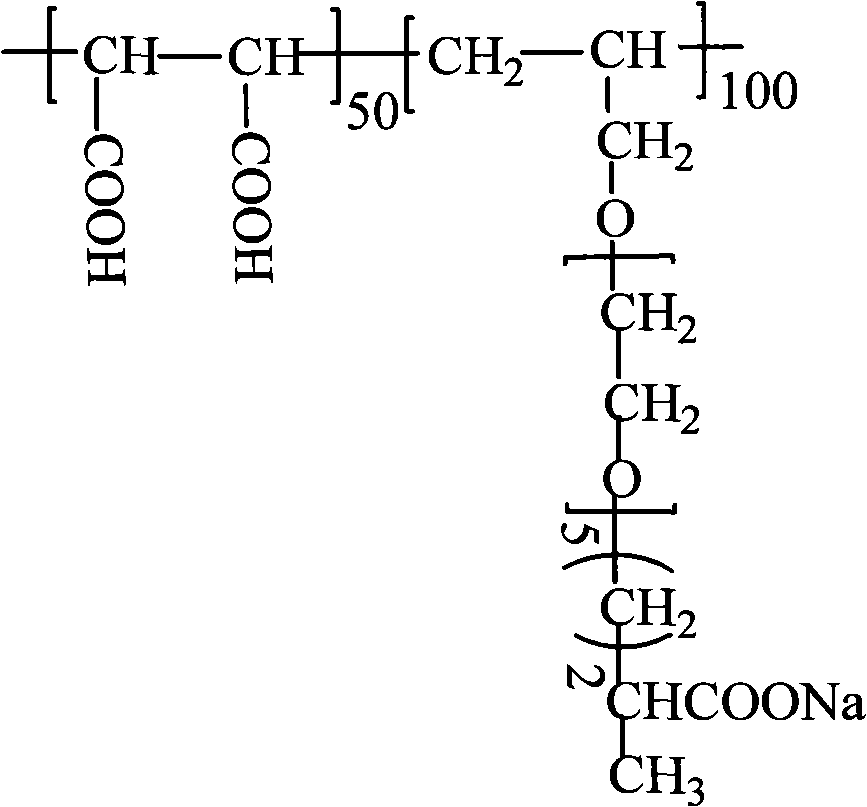

example 1

[0026] Example 1: Add 100g allyl polyethylene glycol monoether and 80g NaOH to an N2-protected reaction kettle, after alkalinizing at 50°C for 2h, add 120gγ-butyrolactone and react at 80°C for 6h, add 150g distilled water, and simultaneously 80g of maleic anhydride (dissolved in 150g of distilled water) and 6g of sodium persulfate (dissolved in 50g of distilled water) were added dropwise, and after the addition was completed, the reaction was continued at 80°C for 3h, and after cooling down to room temperature, a phosphorus-free polyether barrier was obtained. Detergent (APEX).

[0027] The Ca of the obtained APEX antiscalant 3 (PO 4 ) 2 The rate is 99.87%.

example 2

[0028] Example 2: Add 150g of allyl polyethylene glycol monoether and 140g of NaOH to a reaction kettle protected by N2, after alkalization at 60°C for 3h, add 160g of gamma-nonalactone and react at 60°C for 8h, add 200g of distilled water, At the same time, 60g of methacrylic acid (dissolved in 100g of distilled water) and 5g of potassium persulfate (dissolved in 50g of distilled water) were added dropwise respectively. After the addition, the temperature was raised to 90°C, and the reaction was continued for 5h. After cooling down to room temperature, no Phosphopolyether antiscalant (APEX).

[0029] The Ca of the obtained APEX antiscalant 3 (PO 4 ) 2 The rate is 99.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com