Alkali-free oil displacement agent with high temperature resistance and high salinity and preparation method thereof

A technology with high salinity and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unfavorable environmental protection, non-environmental protection, high cost, etc., and achieve environmental protection and strong salt resistance , The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

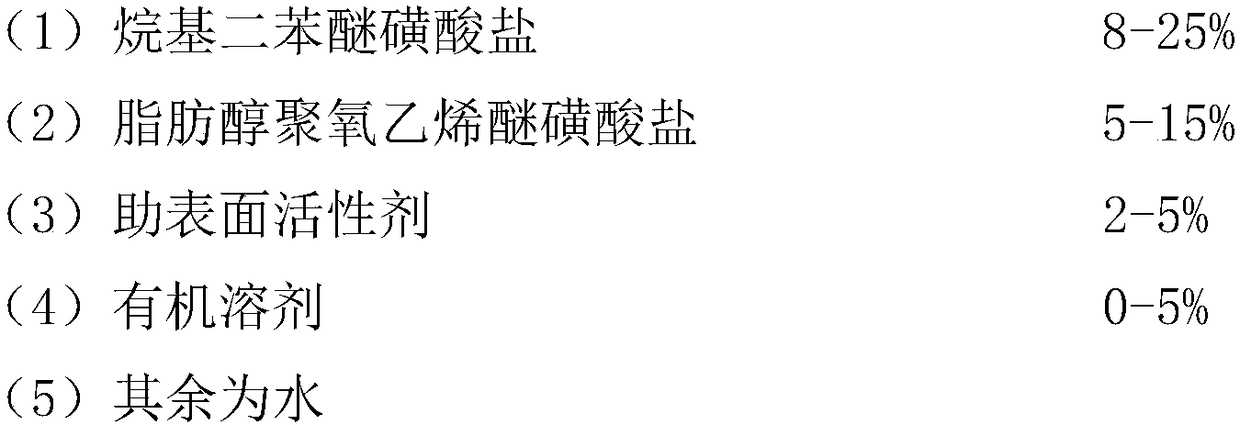

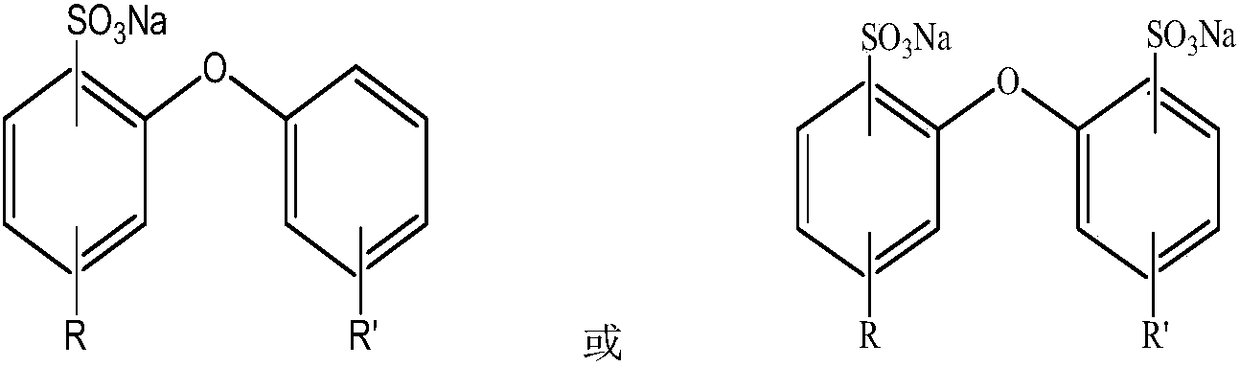

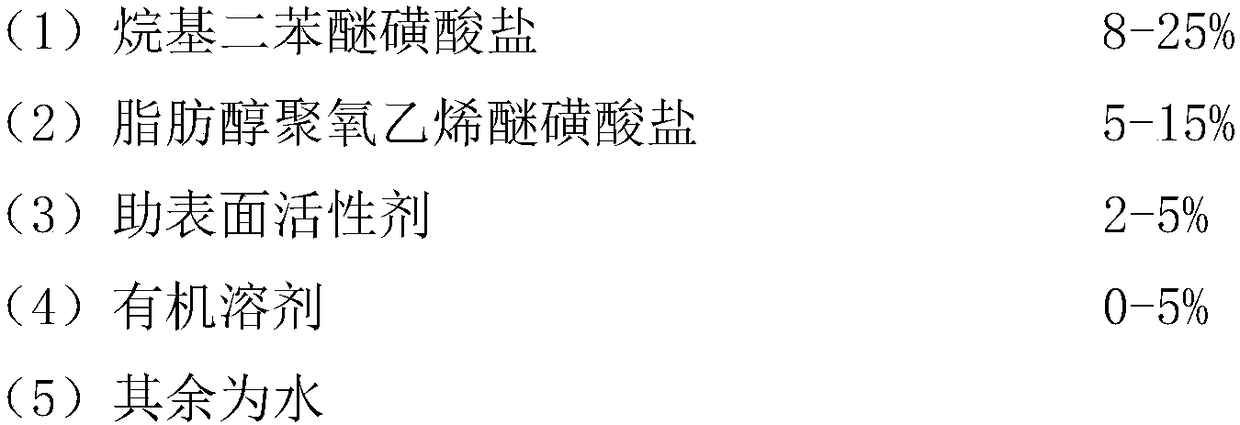

Method used

Image

Examples

Embodiment 1

[0030] Oil displacement agent composition: 8wt% alkyl diphenyl ether sulfonate (m=12, n=0), 15wt% fatty alcohol polyoxyethylene ether sulfonate (m=8, n=3), 1wt% α-olefin sulfonate (AOS), 1 wt% of AEO-7, and the rest is water.

[0031] Preparation steps:

[0032] (1) At room temperature, add alkyl diphenyl ether sulfonate (m=12, n=0) and fatty alcohol polyoxyethylene ether sulfonate (m=8, n=3) into the reactor and stir.

[0033] (2) Add 1 / 2 of the total amount of water into the reactor, and continue stirring for 15 minutes.

[0034] (3) Add co-surfactants AOS and AEO-7 and stir for 30 minutes.

[0035] (4) Finally, add the remaining water and stir well to obtain the oil displacing agent.

[0036] The water is formation water with total salinity of 180000mg / L and total calcium and magnesium ions of 10000mg / L.

[0037] Add the oil displacement agent prepared above into the formation water, stir evenly, and prepare a solution with an active substance concentration of 1.2 g / L. ...

Embodiment 2

[0040] Oil displacement agent composition: 14wt% alkyl diphenyl ether sulfonate (m=10, n=10), 5wt% fatty alcohol polyoxyethylene ether sulfonate (m=12, n=5), 1wt% HABS, 3wt% AEO-7, 5wt% ethanol, and the rest is water.

[0041] Preparation steps:

[0042] (1) At room temperature, add alkyl diphenyl ether sulfonate (m=10, n=10) and fatty alcohol polyoxyethylene ether sulfonate (m=12, n=5) into the reactor and stir.

[0043] (2) Add 1 / 2 of the total amount of water into the reactor, and continue stirring for 30 minutes.

[0044] (3) Add ethanol, co-surfactant HABS and AEO-7, and stir for 30 minutes.

[0045] (4) Finally, add the remaining water and stir well to obtain the oil displacing agent.

[0046] Formation water is the formation water with total salinity of 150000mg / L and total calcium and magnesium ions of 8400mg / L.

[0047] Add the oil displacement agent prepared above into the formation water, stir evenly, and prepare a solution with an active substance concentration...

Embodiment 3

[0050] Oil displacement agent composition: 25wt% alkyl diphenyl ether sulfonate (m=16, n=0), 5wt% fatty alcohol polyoxyethylene ether sulfonate (m=14, n=7), 2wt% IOS, 2wt% AEO-9, 3wt% ethanol, and the rest is water.

[0051] Preparation steps:

[0052] (1) At room temperature, add alkyl diphenyl ether sulfonate (m=16, n=0) and fatty alcohol polyoxyethylene ether sulfonate (m=14, n=7) into the reactor and stir.

[0053] (2) Add 1 / 2 of the total amount of water into the reactor, and continue to stir for 20 minutes.

[0054] (3) Add ethanol, co-surfactant IOS and AEO-9, and stir for 30 minutes.

[0055] (4) Finally, add the remaining water and stir well to obtain the oil displacing agent.

[0056] The water is formation water with total salinity of 150000mg / L and total calcium and magnesium ions of 8400mg / L.

[0057] Add the oil displacement agent prepared above into the formation water, stir evenly, and prepare a solution with an active substance concentration of 1.2 g / L.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com