Ascorbic acid phosphorus-free corrosion and scale inhibitor, and preparation method thereof

A technology of ascorbic acid and phosphorus-free corrosion inhibition, which is applied in the fields of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of reducing the corrosion rate, blocking the action of the primary battery, and reducing the corrosion current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

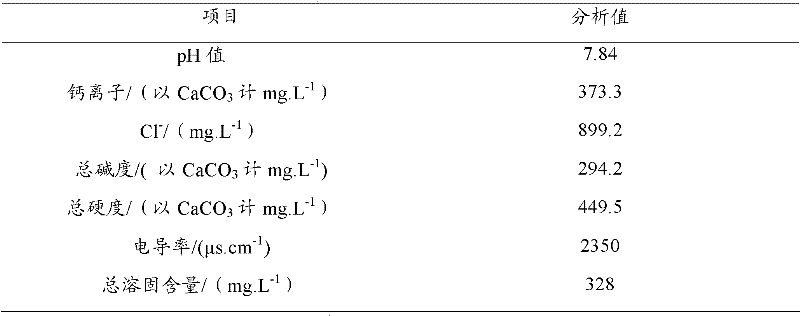

Image

Examples

Embodiment 1

[0027] Preparation of Ascorbic Acid Phosphorus-Free Corrosion and Scale Inhibitor

[0028] The material is taken according to the following composition mass percentages, hydrolyzed polymaleic acid 15%-20%, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 10%-15%, ascorbic acid 0.6%-1%, aminosulfonic acid 0.5% to 1%, zinc nitrate or zinc sulfate 10% to 15%, D-sodium gluconate 10% to 15%, the rest is distilled water, and then hydrolyzed polymaleic acid, acrylic acid-2-acrylamide-2-methyl Propanesulfonic acid, ascorbic acid, sulfamic acid, zinc nitrate or zinc sulfate, D-sodium gluconate or D-potassium gluconate, and distilled water are added to the container in the above order and stirred for 0.5h to 1h. The product is obtained when the mixture is clear and free of insoluble impurities.

Embodiment 2

[0030] Prepare 100g of ascorbic acid phosphorus-free corrosion and scale inhibitors, preparation process: get 50% hydrolyzed polymaleic acid 16.8g, 30% acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 11g, ZnSO 4 .7H 2 Add 12g of O, 12.8g of sodium D-gluconate, 0.7g of ascorbic acid, 0.8g of sulfamic acid, and the rest in distilled water into a clean and dry beaker, and stir evenly to obtain the product.

Embodiment 3

[0032] Prepare 100g of ascorbic acid phosphorus-free corrosion and scale inhibitors, preparation process: get 50% hydrolyzed polymaleic acid 16.8g, 30% acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 12g, ZnSO 4 .7H 2 Add 11.5g of O, 13.4g of sodium D-gluconate, 0.7g of ascorbic acid, 0.7g of sulfamic acid, and the rest in distilled water into a clean and dry beaker, and stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com