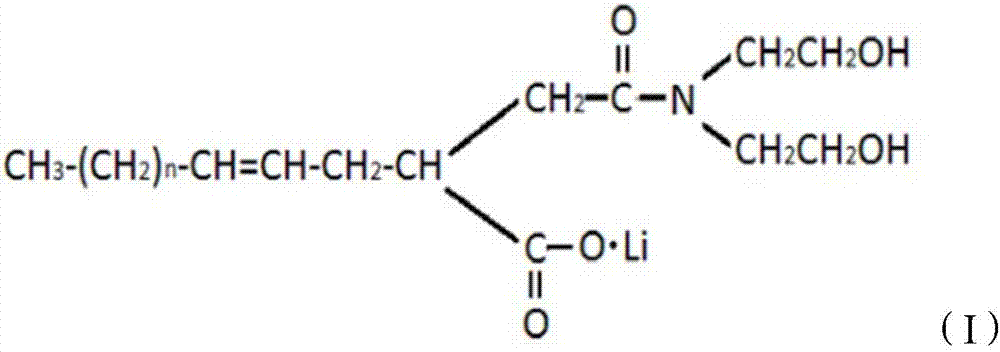

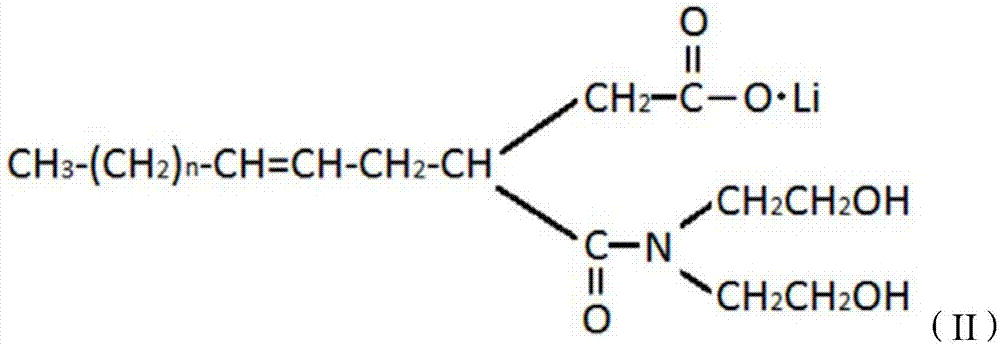

Lithium salt compound and preparation method thereof

A compound and lithium salt technology, applied in the field of lithium salt compounds and their preparation, can solve the problems of environmental protection and rust prevention of extreme pressure agents, and achieve the effects of excellent mechanical stability, cost reduction and rust prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

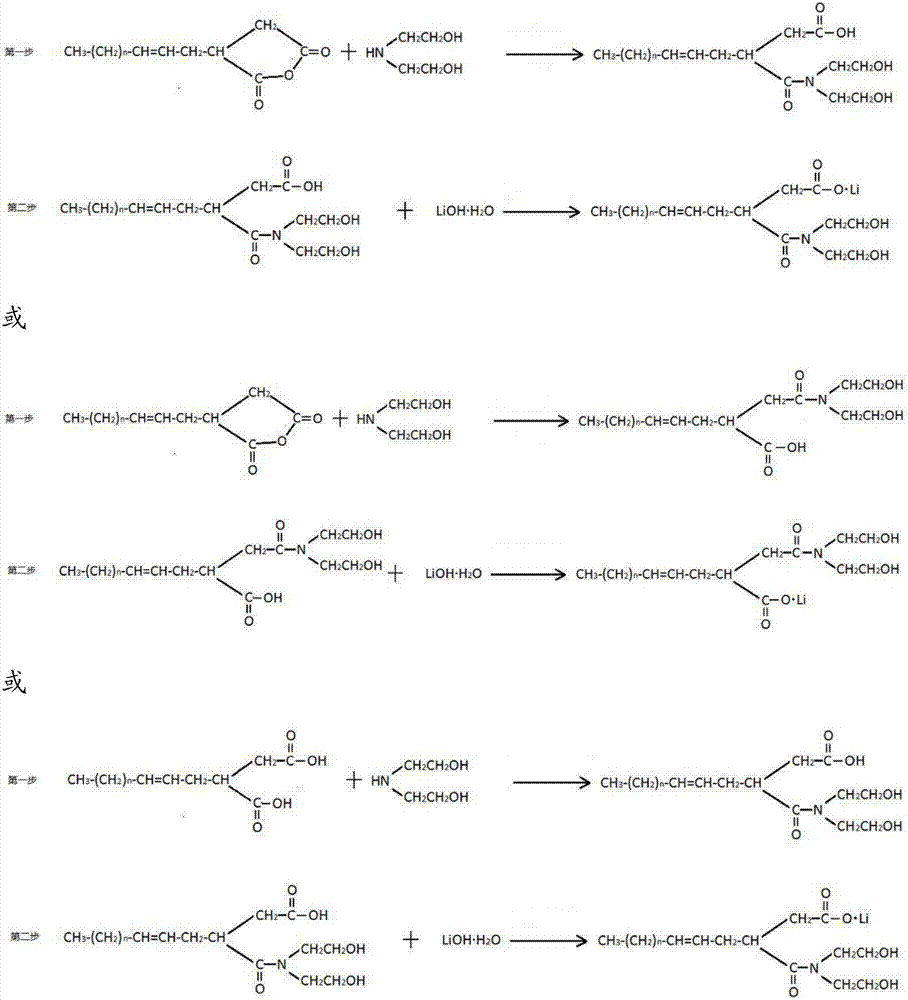

Method used

Image

Examples

Embodiment 1

[0033] 1), put 50 parts by weight of dodecenyl succinic anhydride into a heated and stirred 100L stainless steel reactor and preheat to 80°C;

[0034] 2), put 1 weight part of catalyst A (a mixture of hexahydropyridine and diethylenetriamine in a mass ratio of 1:1) into the preheated reactor and stir and mix evenly;

[0035] 3) Slowly put 35 parts by weight of diethanolamine into the reactor for reaction, control the flow rate during the feeding process, put in 17.5 parts by weight of diethanolamine in the first 5 minutes, raise the reaction temperature to 100-105°C, and then feed the The valve is closed, and the remaining 17.5 parts by weight control the flow rate at 0.5 parts by weight / min to slowly flow into the reactor, the reaction temperature is controlled at 103°C, and the reaction is kept for 1 hour;

[0036] 4) Titrate the contents of the reaction kettle for acid value detection until the acid value stops falling after 10 minutes between two times. When the acid valu...

Embodiment 2

[0040] 1), put 65 parts by weight of dodecenyl succinic acid into a heated and stirred 100L stainless steel reactor and preheat to 80 degrees;

[0041] 2), put 2.5 parts by weight of catalyst A (a mixture of hexahydropyridine and diethylenetriamine in a mass ratio of 1:1) into a preheated reactor and stir and mix evenly;

[0042] 3) Slowly put 35 parts by weight of diethanolamine into the reactor for reaction, control the flow rate during the feeding process, put in 17.5 parts by weight of diethanolamine in the first 5 minutes, raise the reaction temperature to 140°C, and then close the feed valve, The remaining 17.5 parts by weight control the flow rate at 0.5 parts by weight / min and slowly flow into the reactor, the reaction temperature is controlled at 145°C, and the reaction is kept for 1 hour;

[0043] 4) Titrate the contents of the reaction kettle for acid value detection until the acid value stops falling after 10 minutes between two times. When the acid value is 153mg...

Embodiment 3

[0047] 1), put 60 parts by weight of dodecenyl succinic anhydride into a heated and stirred 100L stainless steel reactor and preheat to 80 degrees;

[0048] 2), put 0.5 parts by weight of catalyst A (a mixture of hexahydropyridine and diethylenetriamine in a mass ratio of 1:1) into a preheated reactor and stir and mix evenly;

[0049] 3) Slowly put 35 parts by weight of diethanolamine into the reactor for reaction, control the flow rate during the feeding process, put in 17.5 parts by weight of diethanolamine in the first 5 minutes, raise the reaction temperature to 100-105°C, and then feed the The valve is closed, and the remaining 17.5 parts by weight control the flow rate at 0.5 parts by weight / min to slowly flow into the reactor, the reaction temperature is controlled at 103°C, and the reaction is kept for 1 hour;

[0050] 4) Titrate the contents of the reaction kettle for acid value detection until the acid value stops falling after 10 minutes between two times. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com