Polyurea grease composition and preparation method thereof

A technology of polyurea-based grease and composition, which is applied in the field of novel polyurea-based grease composition and its preparation, and can solve problems such as poor mechanical stability, low water absorption capacity, and unsatisfactory indicators of steel mesh oil and water leaching loss. , achieve excellent water resistance, increase thickening ability, and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

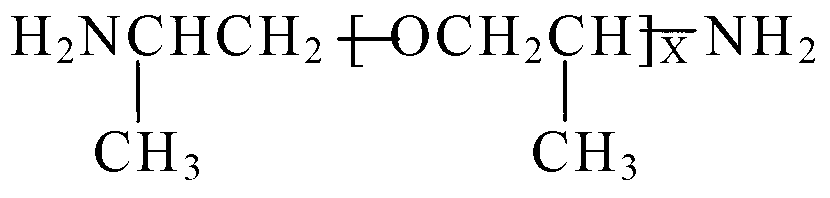

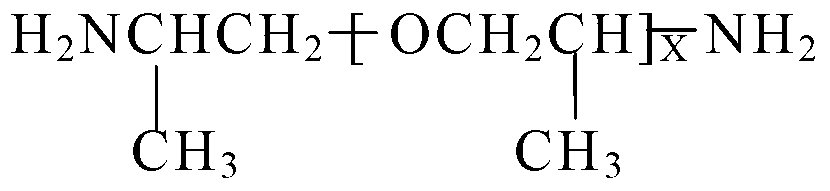

Method used

Image

Examples

Embodiment 1

[0038]Add 300 parts of 150BS base oil (Jiangsu Yinglong Petrochemical Co., Ltd., the same below) and 21.7 parts of 4,4'-diisocyanatodiphenylmethane WANNATE MDI-100 (Wanhua Chemical Group Co., Ltd. , the same below), stirring and heating to 70°C for dissolution, and at the same time, 19 parts of octadecylamine (Nanjing Jinlong Chemical Group Co., Ltd., the same below), 8.2 parts of Aniline (Shandong Haihua Co., Ltd., the same below), and 3.2 parts of polyetheramine D230 (Huntsman Corporation, Inc, the same below), were dissolved at 70°C. When the stirring speed is about 80r / min, quickly put the mixed solution in the reaction kettle into the fat-making kettle, stir the reaction and raise the temperature to 110°C, add the remaining 100 parts of base oil 150BS, continue to heat up to 150°C, and keep the temperature constant Stir for 30 minutes, lower the temperature and cool down, and homogenize out of the kettle to obtain grease composition I.

Embodiment 2

[0046] Add 260 parts of PAO40 base oil SpectraSyn40 (ExxonMobil Chemical Company, the same below) to the fat making kettle, add 20.7 parts of 4,4'-diisocyanatodiphenylmethane WANNATE MDI-100, stir and heat up to 70°C Dissolve, and add 22.2 parts of hexadecylamine (Nanjing Jinlong Chemical Group Co., Ltd.), 6.6 parts of p-toluidine (Shandong Haihua Co., Ltd.), 2.6 parts of polyether in another reaction kettle with 180 parts of SpectraSyn40 Amine D230, dissolved at 70°C. When the stirring speed is about 80r / min, quickly put the mixed solution in the reaction kettle into the fat-making kettle, stir the reaction and raise the temperature to 110°C, add the remaining 100 parts of base oil SpectraSyn40, continue to heat up to 150°C, and keep the temperature constant Stir for 50 minutes, lower the temperature and cool down, and homogenize out of the kettle to obtain grease composition V.

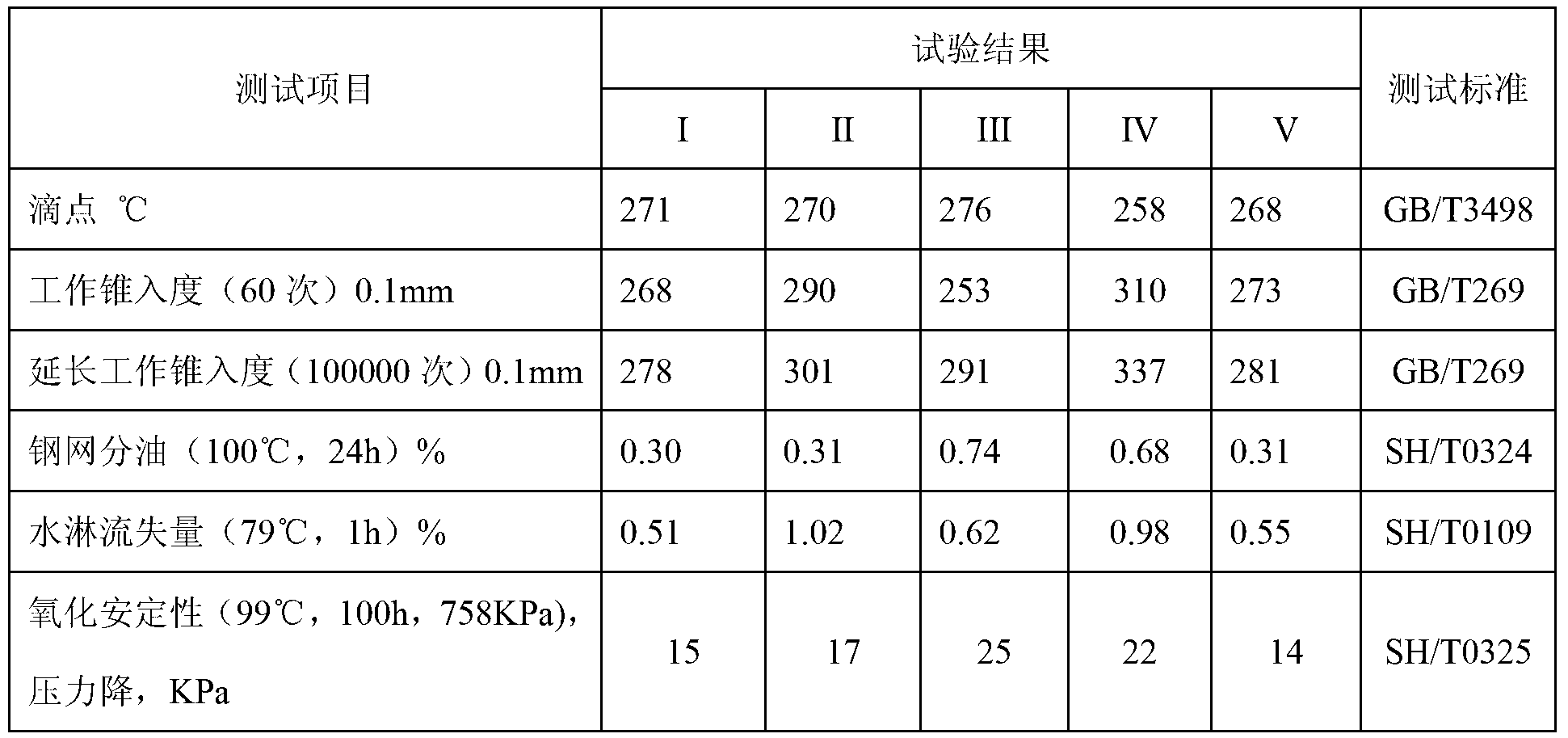

[0047] The above polyurea-based grease compositions I, II, III, IV and V were tested for perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com