Patents

Literature

82 results about "ACRYLATE TERPOLYMER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

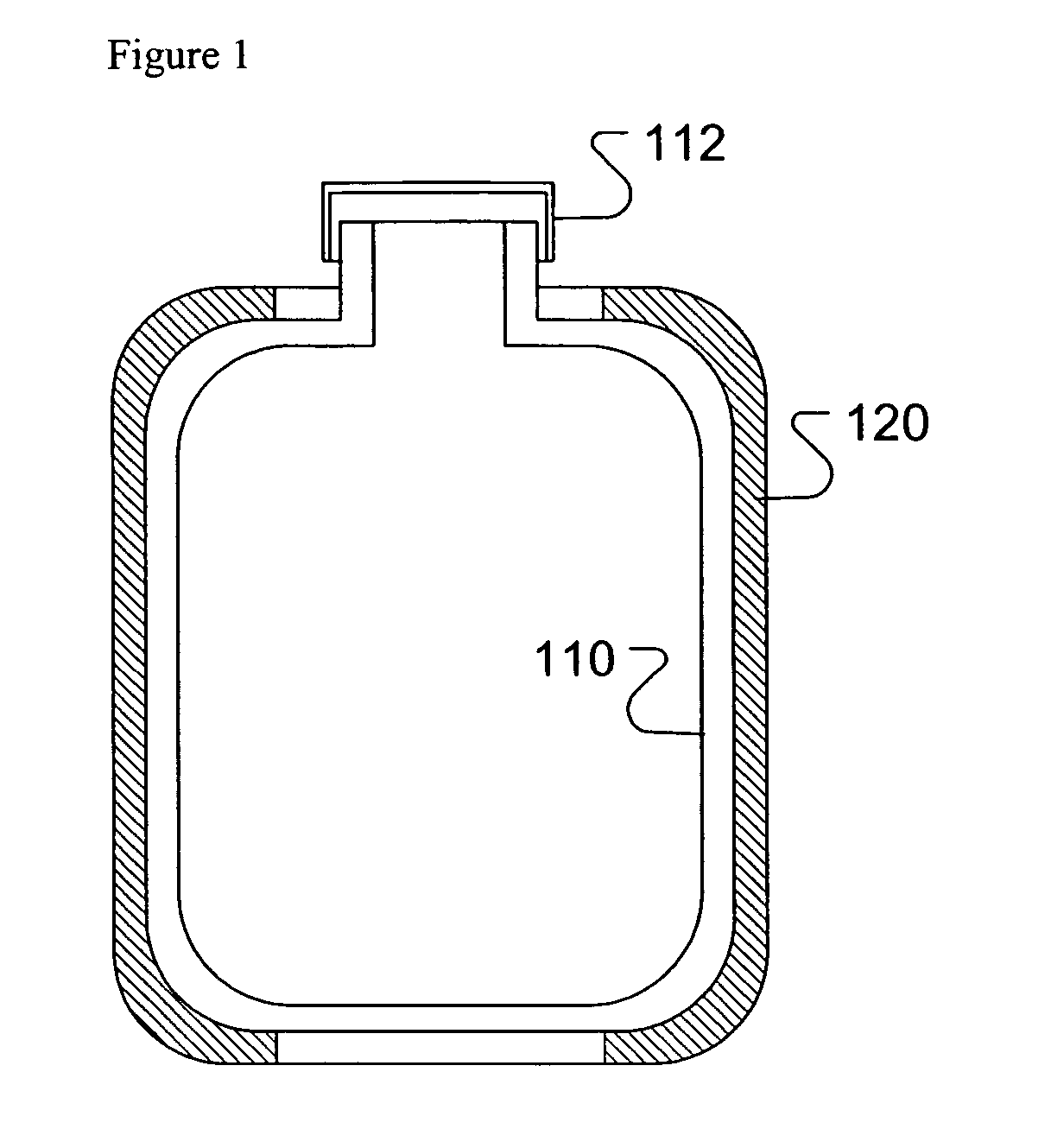

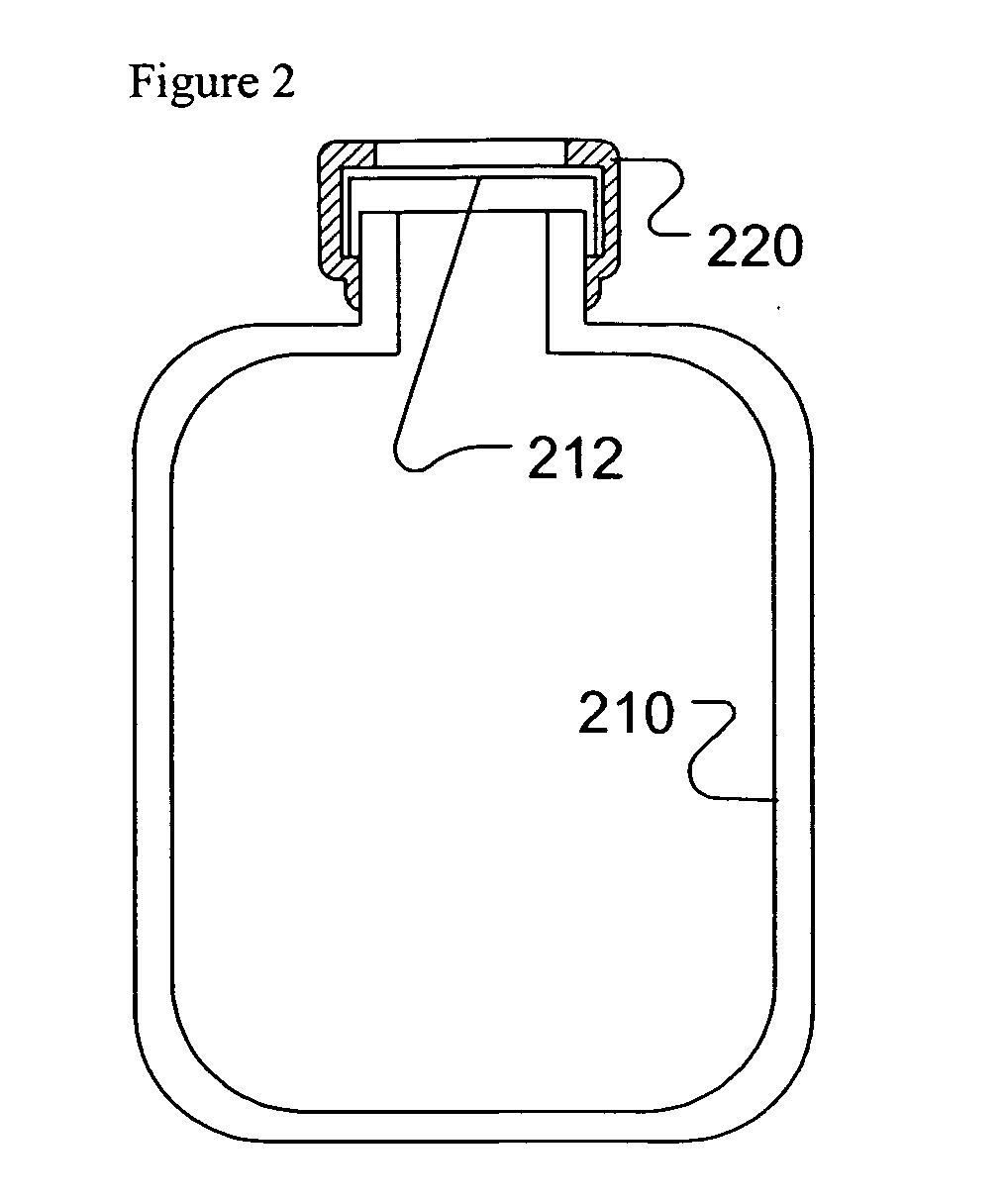

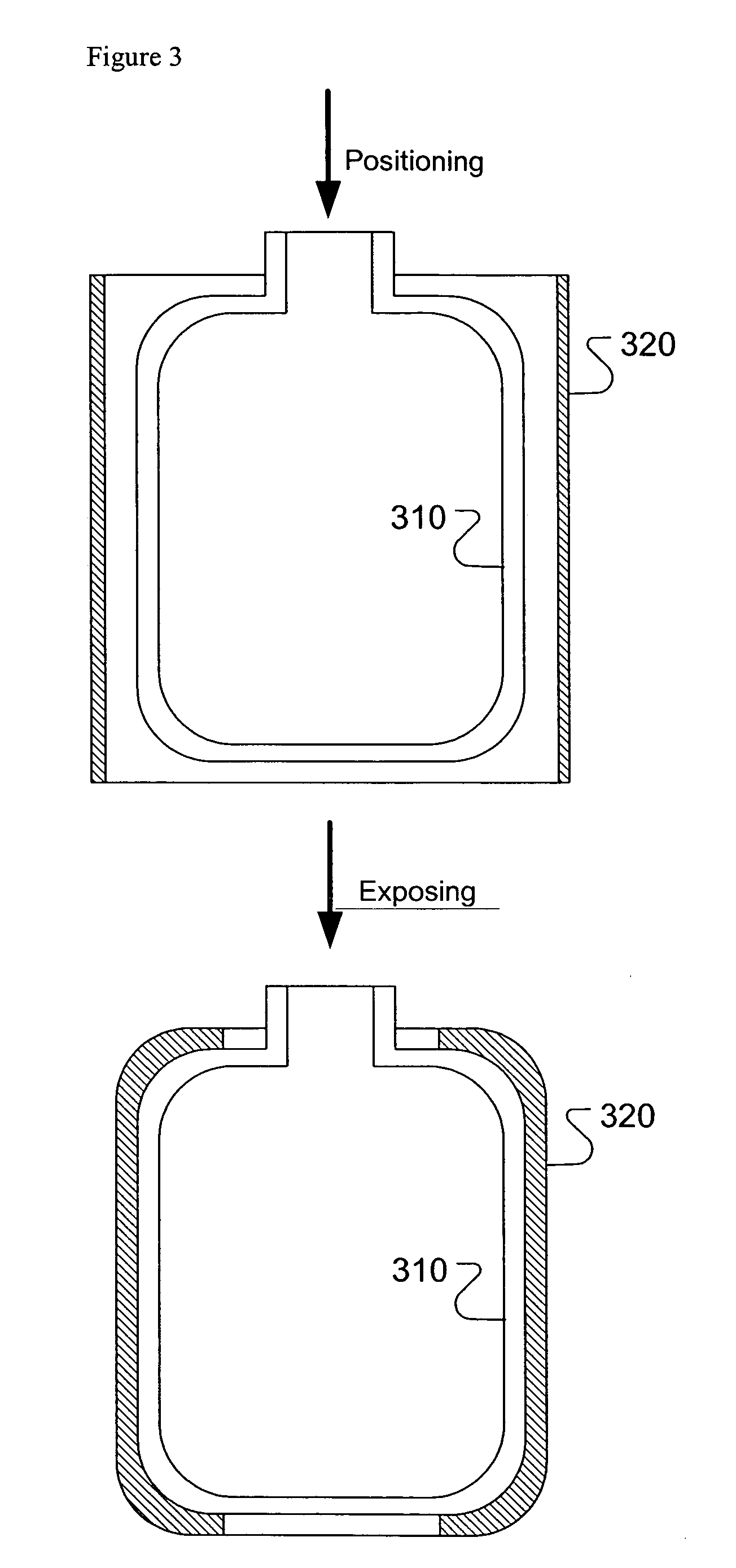

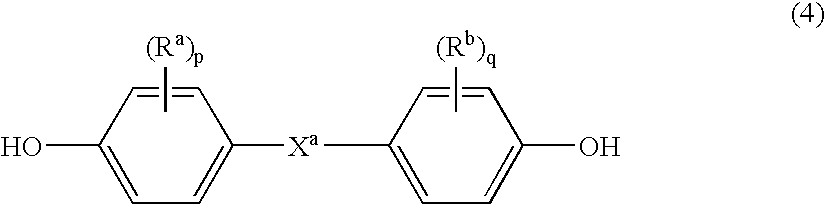

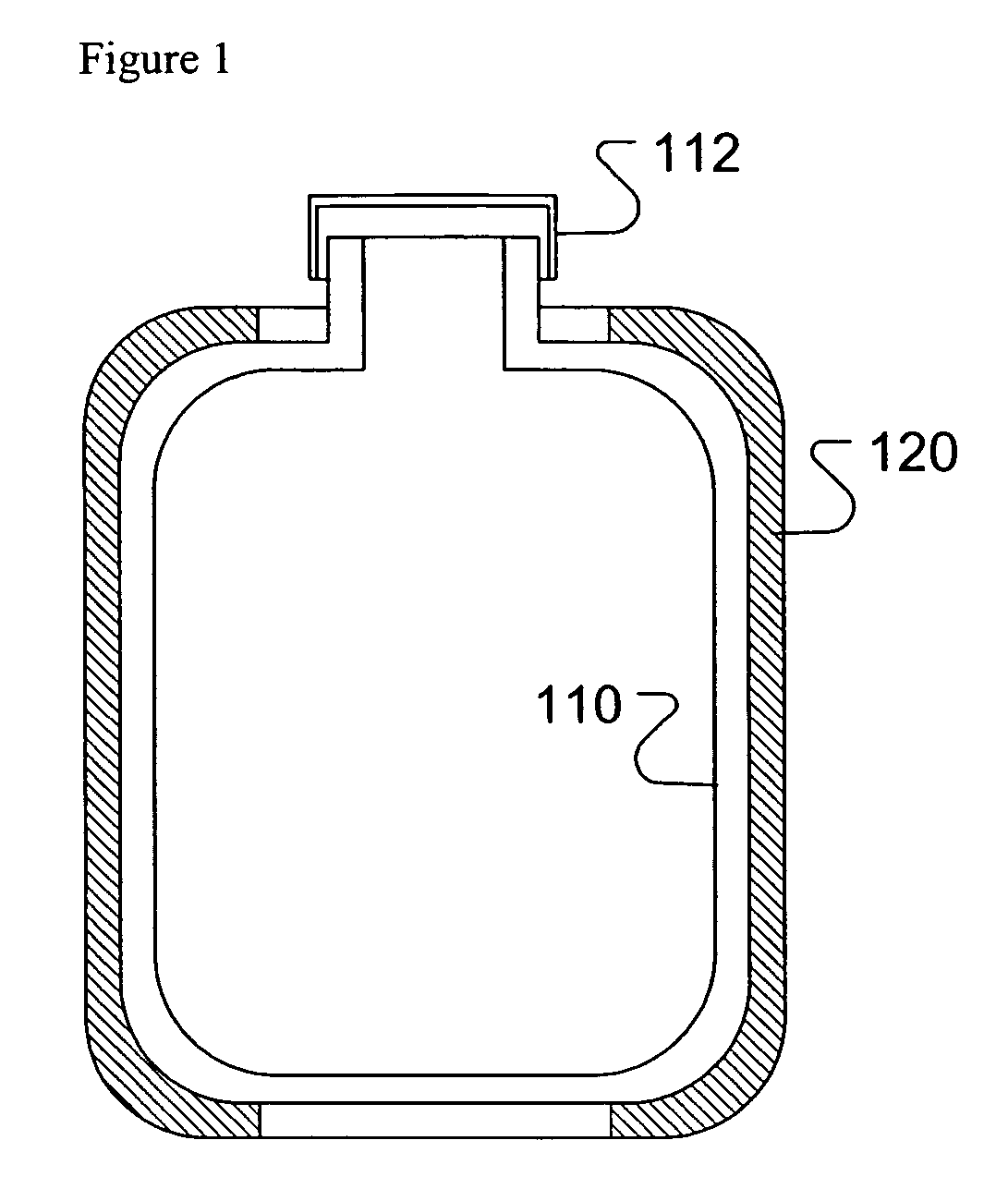

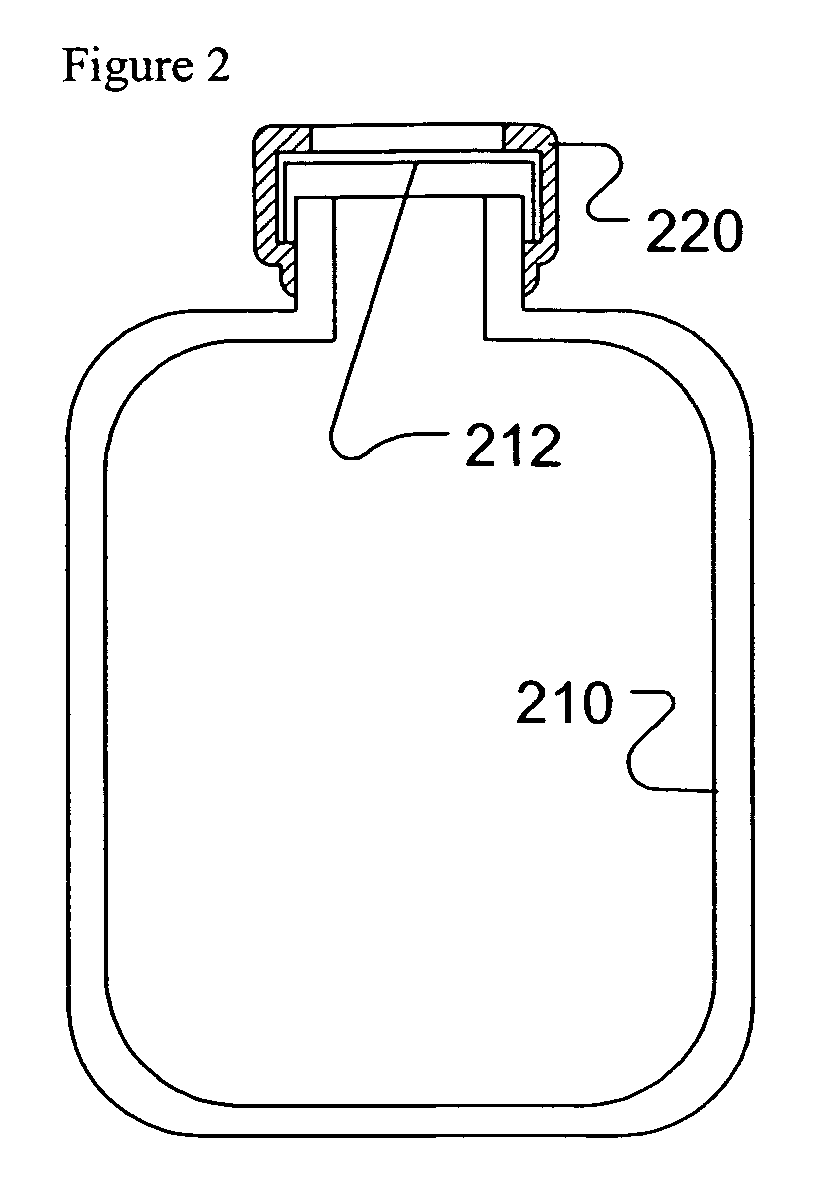

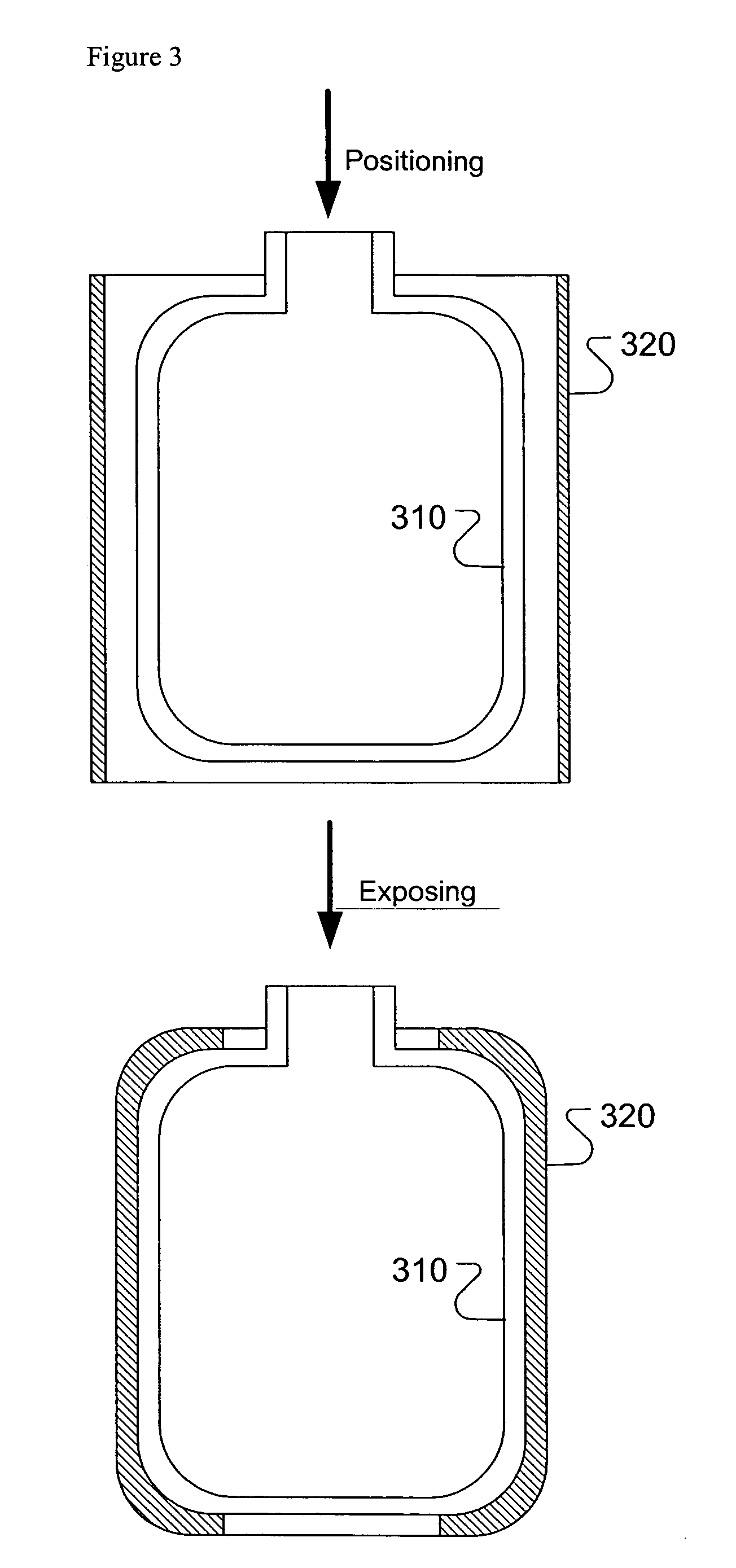

Composition for monovinylrenic-based shrink label films

We disclose a composition comprising (i) a monovinylarene-conjugated diene copolymer and (ii) an acrylate terpolymer. The composition can be in the form of a film. We also disclose a container comprising a container structure and a shrink label in contact with the container structure's exterior surface. We also disclose a method of applying a shrink label to a container structure.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP +1

Low gloss thermoplastic composition, method of making, and articles formed therefrom

A thermoplastic composition comprises a polycarbonate, an acrylonitrile-styrene-acrylate terpolymer, and a low gloss additive, wherein the 60° gloss is measured to be less than or equal to 90 GU according to ASTM D2457. The thermoplastic composition has excellent low gloss performance and mechanical performance. A method of making the thermoplastic composition, and an article comprising the thermoplastic composition are also disclosed.

Owner:SABIC GLOBAL TECH BV

Ethylene copolymer-modified polyamide product

Disclosed are films, tapes, and melt-spun fibers comprising or prepared from a composition comprising (a) at least one polyamide polymer; and (b) from about 0.1 to 20 weight % of at least one ethylene copolymer such as ethylene / vinyl acetate dipolymers, ethylene / vinyl acetate terpolymers, ethylene / alkyl (meth)acrylate dipolymers, ethylene / alkyl (meth)acrylate terpolymers, functionalized ethylene copolymers, ethylene / acid copolymers, and salts thereof. The films, tapes and fibers exhibit improved tensile properties such as tensile strength and elongation at break compared to nonmodified polyamide compositions. Also disclosed are nonwoven textiles comprising or prepared from the oriented melt-spun fibers.

Owner:DOW GLOBAL TECH LLC

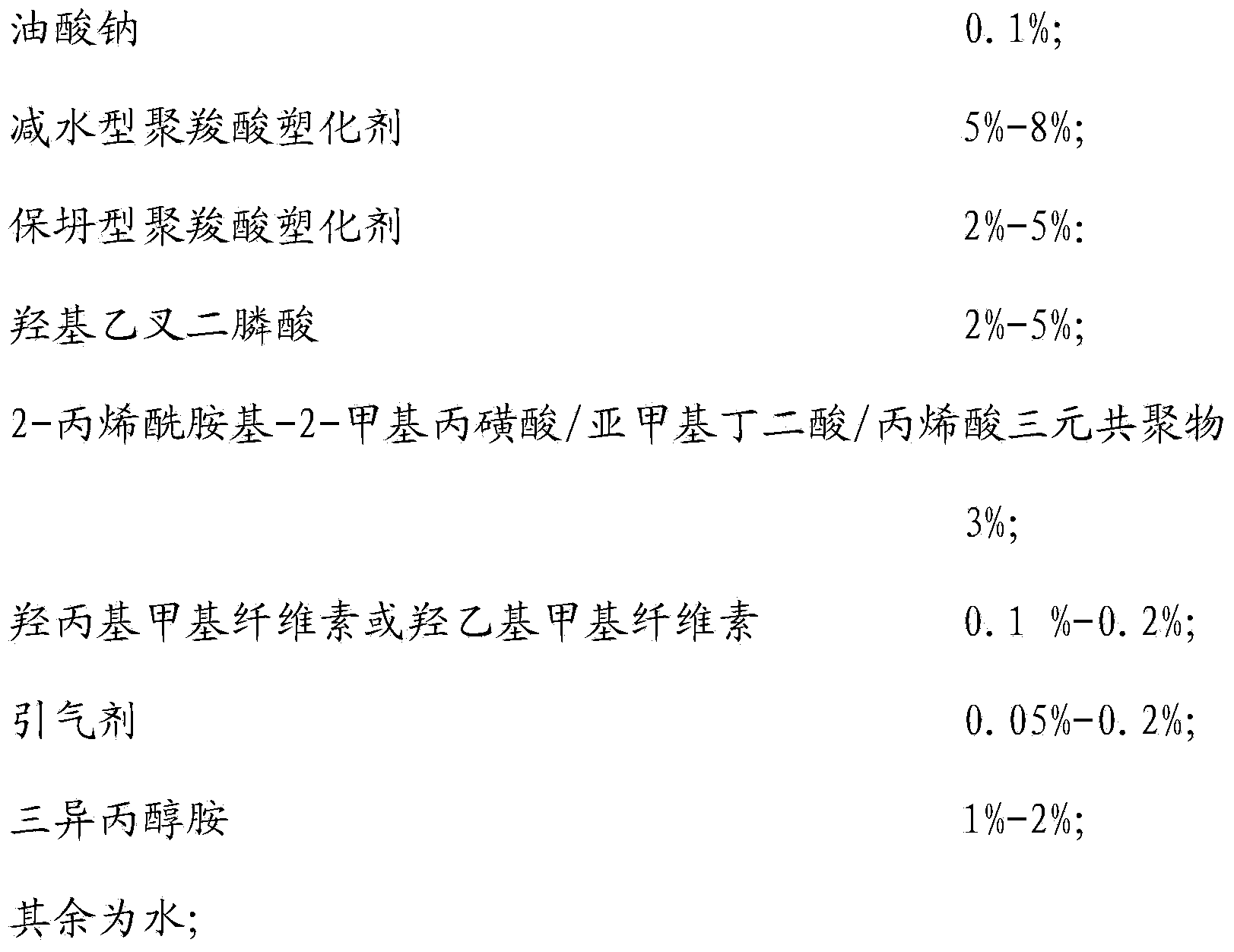

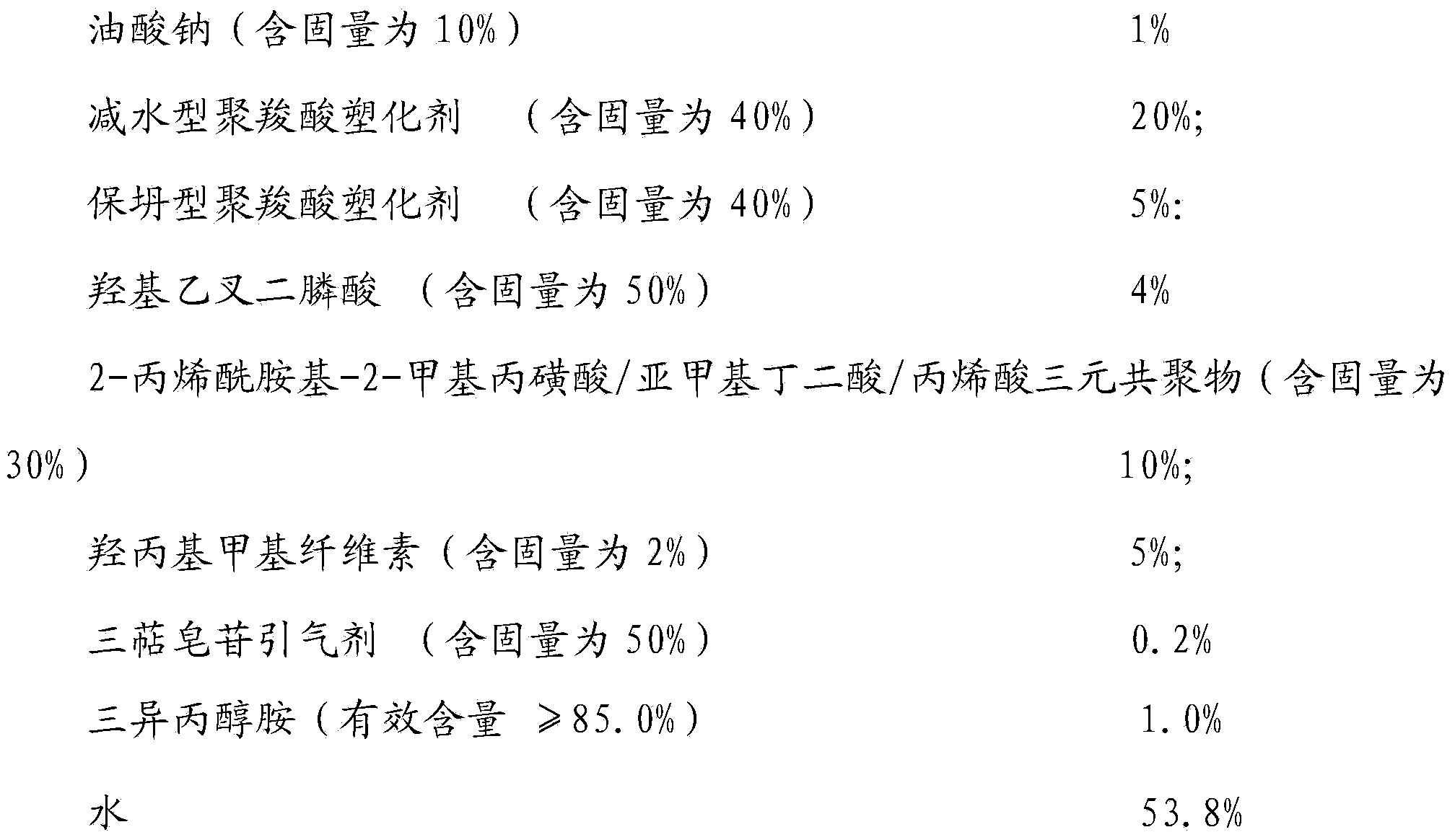

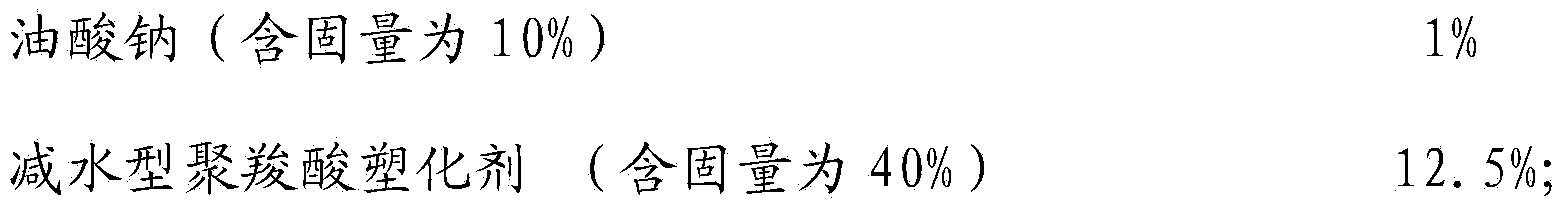

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

Hot melt wetness indicator adhesive composition with controllable color change

InactiveCN1471410AAvoid defectsFilm/foil adhesivesAcid polymer adhesivesAdditive ingredientColor changes

The present invention is directed towards a hot melt wetness indicator composition based on an ethylene-alkylacrylate-acrylic acid terpolymer. The wetness indicator composition comprises the terpolymer, a tackifying resin, a compatible surfactant having a HLB value less than 20 and a pH indicator or a dye that is capable of changing color when insulted with urine, as the primary ingredients. One embodiment of the present invention is to provide a wetness indicator that has excellent heat and environmental stability, improved fastness, vivid color change, easy manufacturing, and easy application. Another embodiment is directed towards a composition having a delayed response and therefore can withstand multiple insults daily.

Owner:ATO FINDLEY

Cleaning implement comprising a modified open-cell foam

A cleaning implement comprises a modified open-cell foam with a density in the range from about 5 to about 1,000 kg / m3 and with an average pore diameter in the range from about 1 μm to about 1 mm, comprising an amount in the range from about 1 to about 2,500% by weight, based on the weight of the unmodified open-cell foam, of at least about one water-insoluble polymer (b), selected from polystyrene, styrene copolymers, polybutadiene, butadiene copolymers, polyvinylesters, polyvinylethers, copolymers from (meth)acrylic acid with at least one (meth)acrylate, and polyurethanes, with the proviso that styrene-acrylonitrile-C1-C10-alkyl (meth)acrylate terpolymers, styrene-butadiene-n-butyl acrylate terpolymers, and styrene-maleic anhydride copolymers are excluded.

Owner:THE PROCTER & GAMBLE COMPANY

Reactive hot melt adhesive

The invention is a reactive hot melt composition which has excellent adhesion and curing properties, and can be formulated into free-flowing pellets or beads, by using an ethylene-acrylic acid copolymer, and athylene-methacrylic acid copolymer, and / or an ethylene-acrylic acid methacrylic acid terpolymer as a component of the composition along with free radical crosslinking initiators. The incorporation of a foaming agent enables the production of compositions which are useful in space-filling applications, (i.e., as so-called "anti-flutter" compositions).

Owner:DOW GLOBAL TECH LLC +1

Ethylene copolymer modified oriented polyester films, tapes, fibers and nonwoven textiles

Disclosed are films, tapes, and melt-spun fibers prepared from a composition comprising (a) at least one polyester polymer and (b) from about 1 to 30 weight % of at least one ethylene copolymer such as ethylene / vinyl acetate dipolymers, ethylene / vinyl acetate terpolymers, ethylene / alkyl (meth)acrylate dipolymers, ethylene / alkyl (meth)acrylate terpolymers, functionalized ethylene copolymers, ethylene / acid copolymers, and salts thereof. The films, tapes and fibers exhibit improved tensile properties such as tensile strength and elongation at break compared to non-modified polyester compositions. Also disclosed are textiles and articles prepared from the fibers described.

Owner:DUPONT POLYMERS INC

Reactive hot melt adhesive

ActiveUS7271202B2Excellent adhesion and curing propertyImprove adhesionAbsorbent padsBaby linensFoaming agentHot melt

The invention is a reactive hot melt composition which has excellent adhesion and curing properties, and can be formulated into free-flowing pellets or beads, by using an ethylene-acrylic acid copolymer, and athylene-methacrylic acid copolymer, and / or an ethylene-acrylic acid methacrylic acid terpolymer as a component of the composition along with free radical crosslinking initiators. The incorporation of a foaming agent enables the production of compositions which are useful in space-filling applications, (i.e., as so-called “anti-flutter” compositions).

Owner:DOW GLOBAL TECH LLC +1

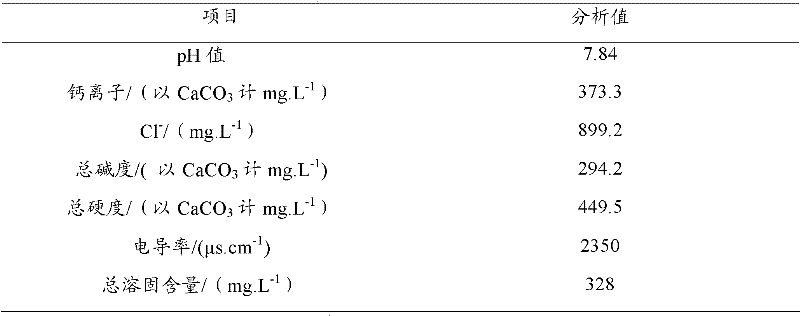

Ascorbic acid phosphorus-free corrosion and scale inhibitor, and preparation method thereof

ActiveCN102225809ADoes not cause eutrophicationWide variety of sourcesScale removal and water softeningGluconatesPollution

The invention discloses an ascorbic acid phosphorus-free corrosion and scale inhibitor which is applicable for treatment of industrial circulating cooling water. The corrosion and scale inhibitor is prepared by compounding a maleic acid compound, an acrylic acid terpolymer, ascorbic acid, a sulfamic acid compound, a zinc salt, a gluconate and distilled water. The ascorbic acid phosphorus-free corrosion and scale inhibitor provided by the present invention provides good corrosion inhibition and scale inhibition effects for carbon steel equipment. The dosage of the phosphorus-free corrosion and scale inhibitor is 20 mg.L<-1> - 50 mg.L<-1> in the industrial circulating cooling water having an alkalinity less than 400 mg.L<-1>, a hardness less than 500 mg.L<-1>, a pH value less than 8.2, a conductance controlled from 0[mu]s.cm<-1>-2400[mu]s.cm<-1>. A plurality of experiment results show that the corrosion and scale inhibitor provides a annual corrosion rate lower than 0.04 mm.a<-1> and a calcium carbonate inhibition rate higher than 98% for the A3 carbon steel. Advantages of the ascorbic acid phosphorus-free corrosion and scale inhibitor and the preparation method are as follows: the discharged waste water during using the corrosion and scale inhibitor does not provide a eutrophic pollution caused by phosphor for water body; the environment is environment-friendly; agent cost for treating each ton of the water is less than 0.12 yuan; the product preparation process is simple.

Owner:WUHAN UNIV OF TECH +1

Polyurethane hot melt adhesives with acrylic copolymers and thermoplastic resins

InactiveCN1437623AMonocarboxylic acid ester polymer adhesivesOther chemical processesSolvent freeCarvacryl acetate

This invention relates to solvent-free moisture curable one-part hot melt polyurethane adhesive or sealant compositions which are solid at room temperature. In one embodiment, the polyurethane adhesive or sealant composition comprises in percentages by weight (a) from about 20 % to about 75 % of a urethane prepolymer; (b) from about 1 % to about 66 % of a reactive, hydroxyl containing, or a nonreactive polymer formed from ethylenically unsaturated monomers; and (c) from about 20 % to about 75 % of a thermoplastic resin. In another embodiment, the polyurethane adhesive or sealant composition comprises, in percentages by weight of the polyurethane composition (a) from about 10 % to about 90 % of a urethane prepolymer; and (b) from about 5 % to about 90 % of a thermoplastic resin which is an ethylene vinylacetate / ethylene acrylate terpolymer.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

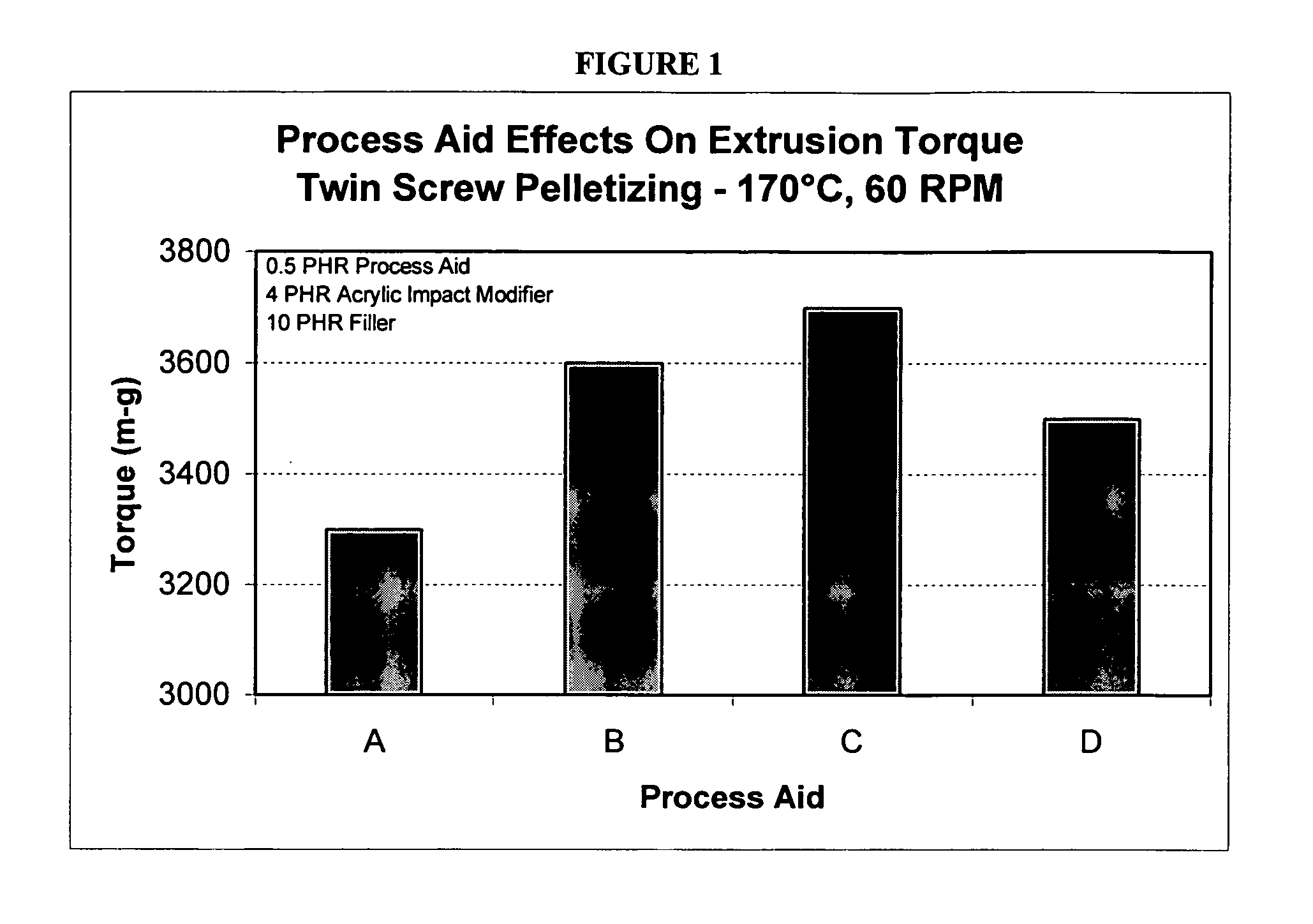

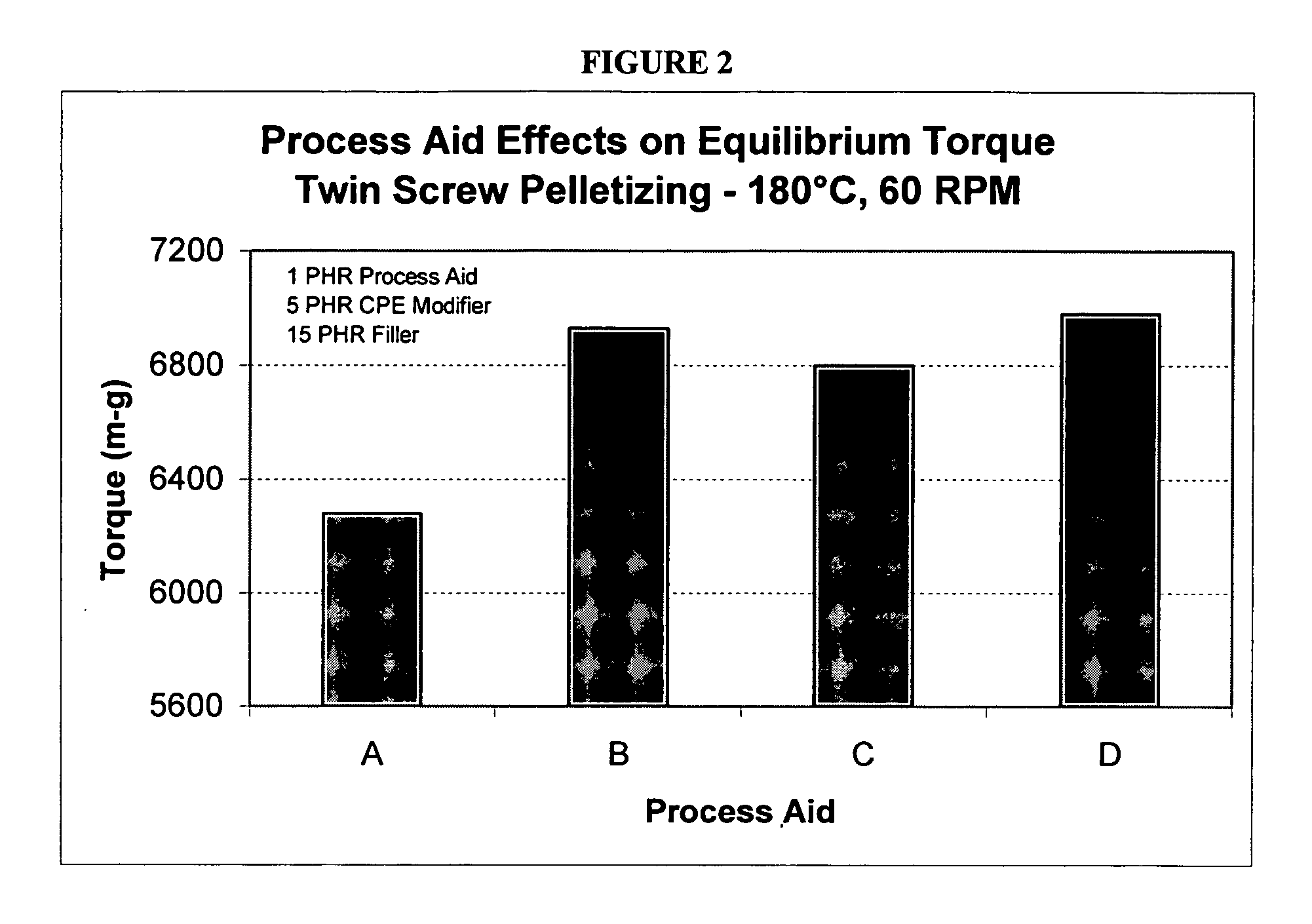

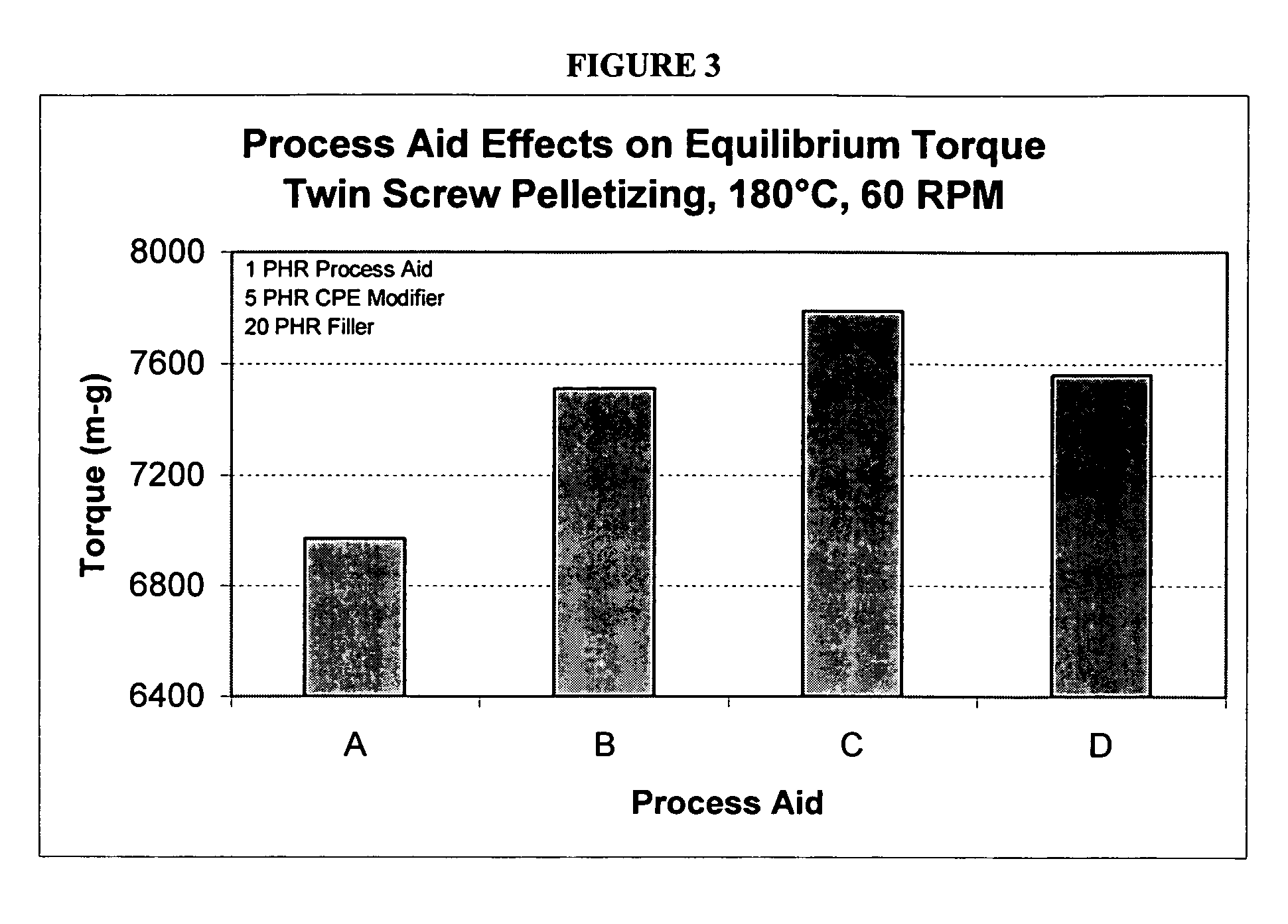

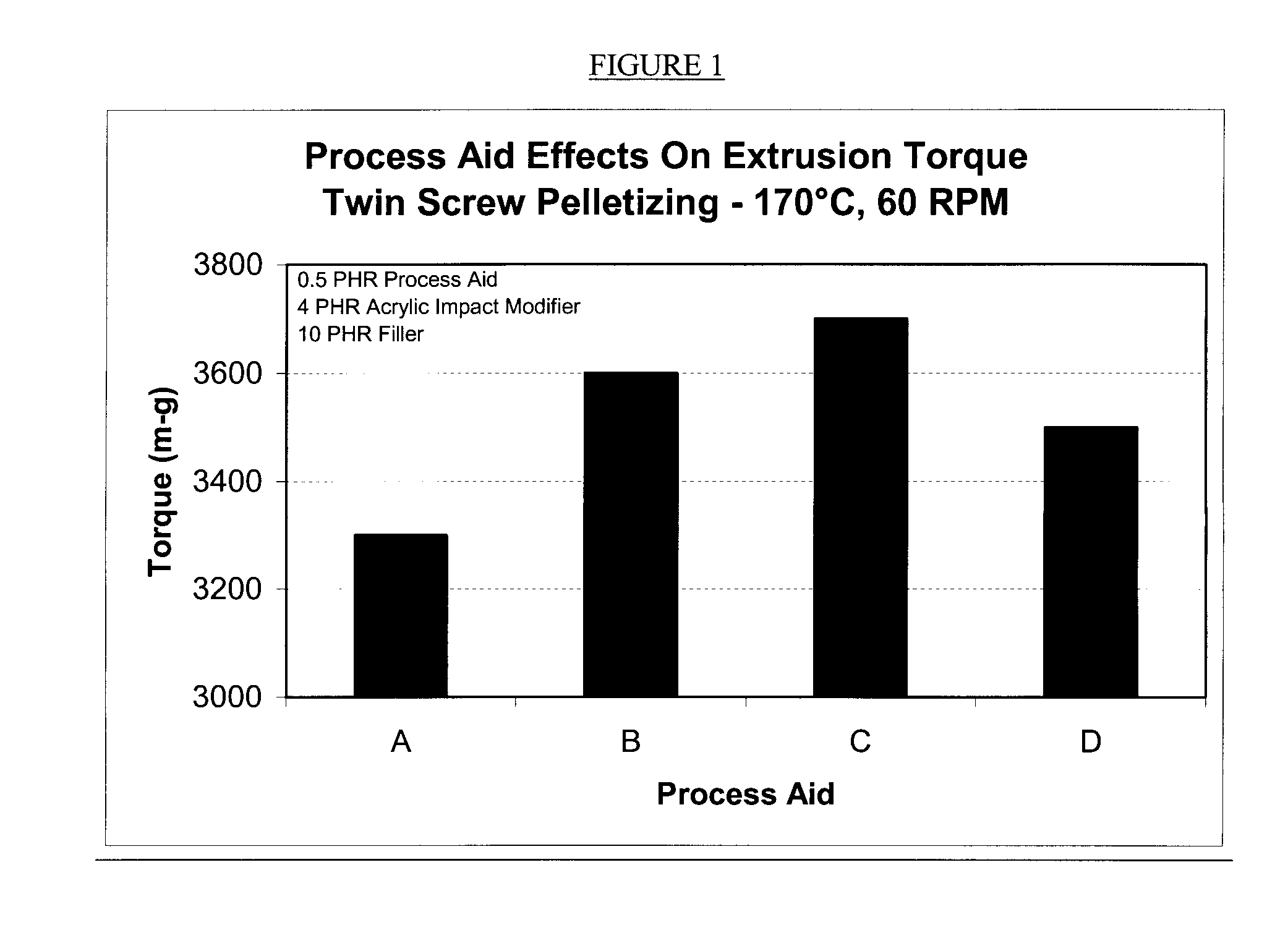

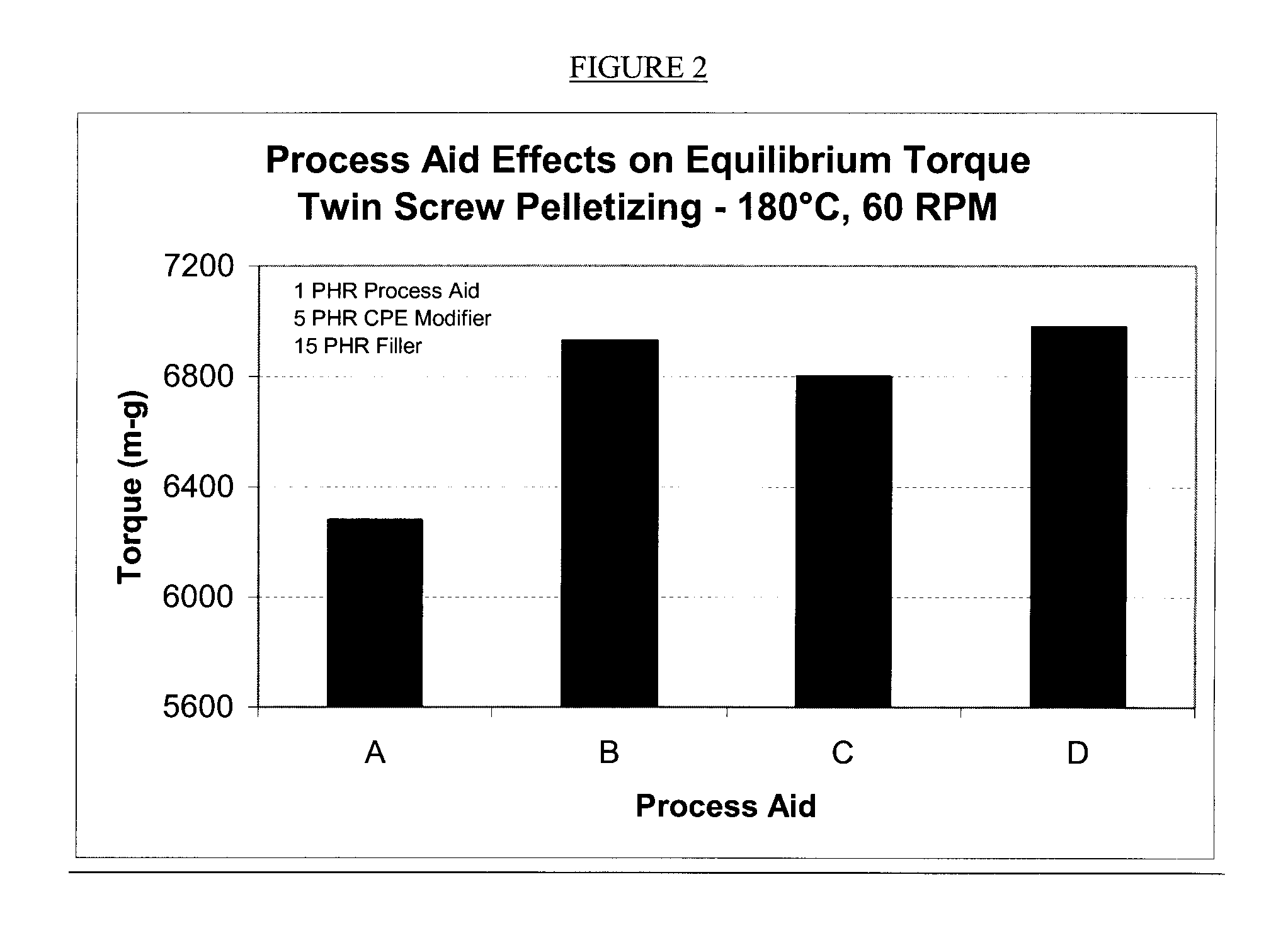

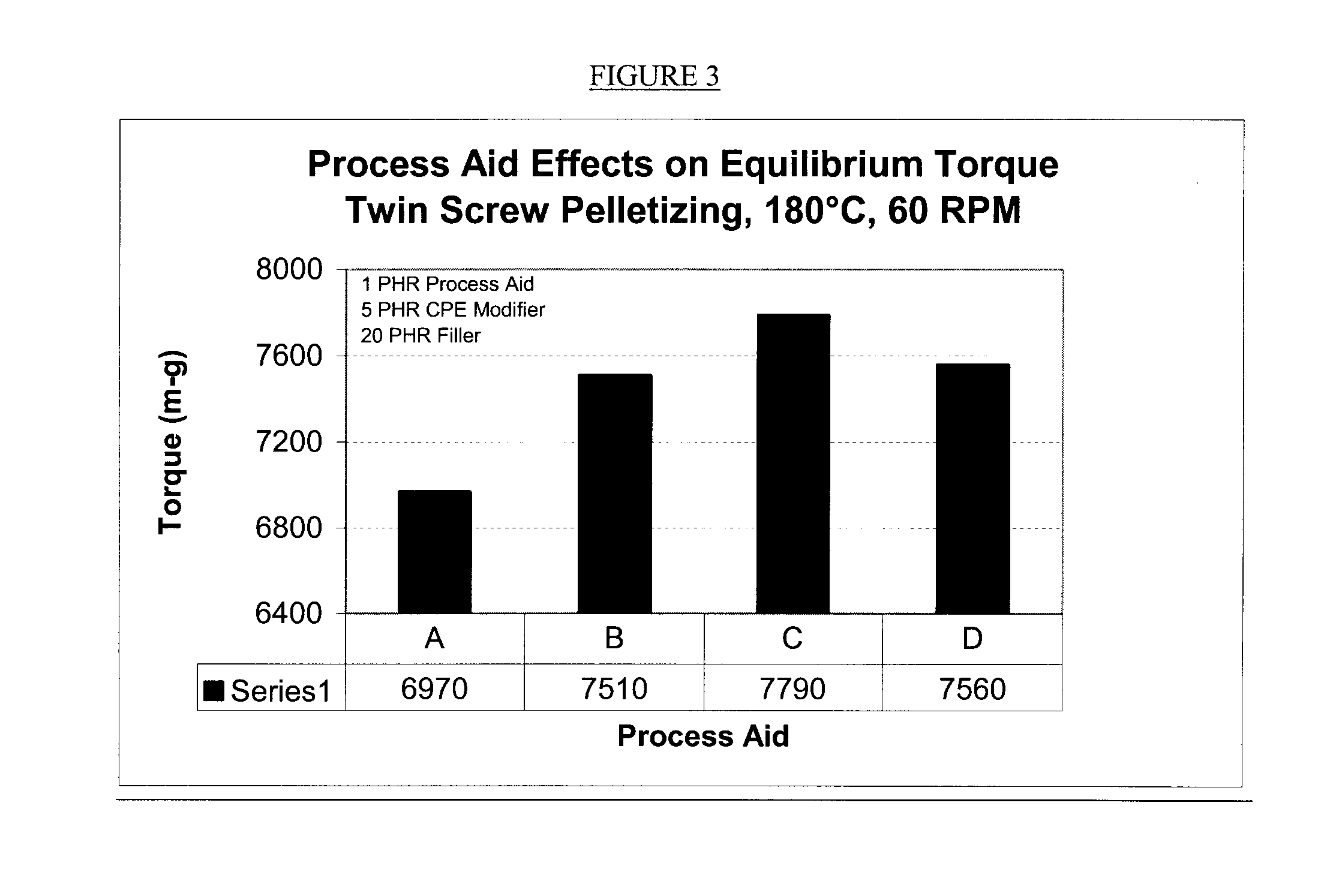

Reduced melt viscosity rigid polyvinylchloride (PVC) composition

ActiveUS20060175728A1Reduce meltingImprove throughputCeramic shaping apparatusProduction rateProcedure Agents

The invention relates to a process aid for use in rigid thermoplastic compositions, and especially in rigid polyvinylchloride (PVC) compositions. The process aid is an acrylic terpolymer of methylmethacrylate, butyl acrylate and styrene at an optimal ratio to produce a significant reduction in melt process viscosity. The resulting reduction in extrusion melt torques enables manufacturers of rigid PVC products to have higher throughput production rates.

Owner:ARKEMA INC

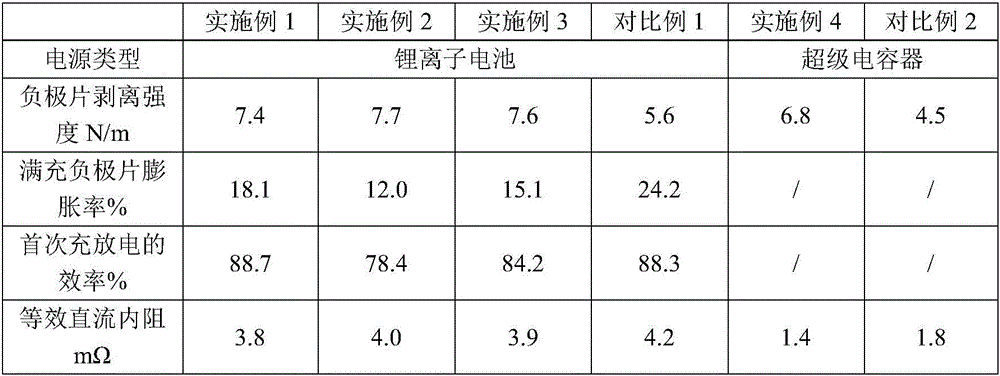

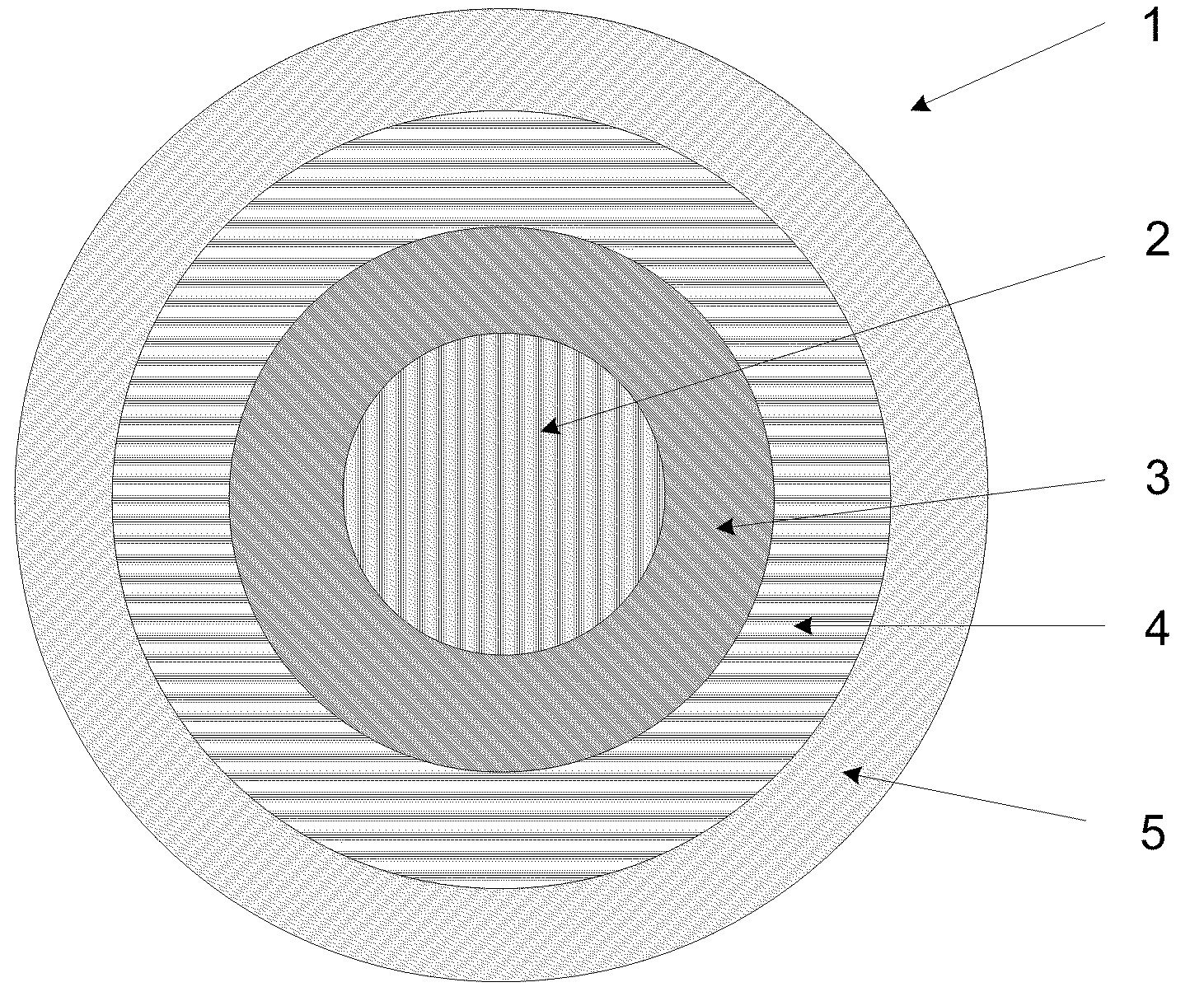

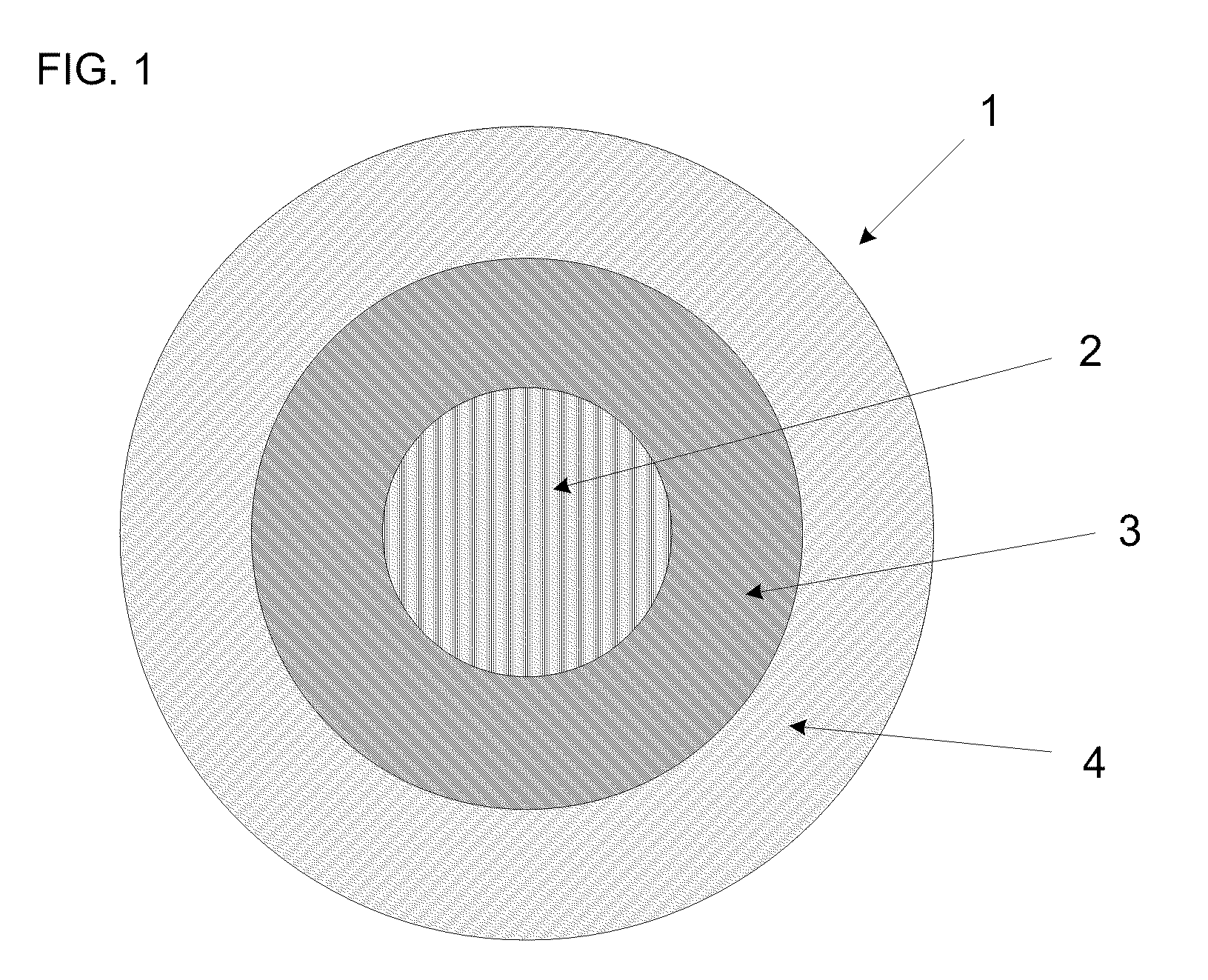

Composite adhesive, pole piece prepared by means of the composite adhesive, preparation method and application thereof

ActiveCN105788887ALower internal resistanceImprove securityCell electrodesHybrid/EDL manufacturePolyvinylidene fluorideACRYLATE TERPOLYMER

The invention relates to a composite adhesive, a pole piece prepared by means of the composite adhesive, a preparation method and an application thereof, wherein the composite adhesive, the pole piece, the preparation method and the application thereof belong to the technical field of energy storage devices. The composite adhesive is composed of the following components by weight: 1-13% of phosphoric acid, 20-45% of polyvinylidene fluoride, 5-9% of phenolic resin, 2-3% of amino resin, 6-11% of polyacrylate, 10-30% of acrylate terpolymer latex, 1-4% of carboxymethylcellulose sodium, 3-17% of polyimide, 2-4% of ethanol and 6-18% of N-methylpyrrolidone. The composite adhesive can reduce the internal resistance of a lithium ion battery or a super-capacitor and settle problems such as electrode powdering and electrode peeling-off caused by size increase of the pole piece. Utilization rate and cycle life of the electrode material are improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Ethylene copolymer-modified polyamide product

Disclosed are films, tapes, and melt-spun fibers comprising or prepared from a composition comprising (a) at least one polyamide polymer; and (b) from about 0.1 to 20 weight % of at least one ethylene copolymer such as ethylene / vinyl acetate dipolymers, ethylene / vinyl acetate terpolymers, ethylene / alkyl (meth)acrylate dipolymers, ethylene / alkyl (meth)acrylate terpolymers, functionalized ethylene copolymers, ethylene / acid copolymers, and salts thereof. The films, tapes and fibers exhibit improved tensile properties such as tensile strength and elongation at break compared to nonmodified polyamide compositions. Also disclosed are nonwoven textiles comprising or prepared from the oriented melt-spun fibers.

Owner:DOW GLOBAL TECH LLC

Ethylene copolymer modified oriented polypropylene

InactiveUS20050203232A1Filament/thread formingMonocomponent polyolefin artificial filamentFiberPolymer science

Disclosed are oriented films, tapes, and melt-spun fibers prepared from compositions comprising (a) at least one polypropylene polymer; and (b) at least one ethylene copolymer such as ethylene / vinyl acetate dipolymers, ethylene / vinyl acetate terpolymers, ethylene / alkyl (meth)acrylate dipolymers, ethylene / alkyl (meth)acrylate terpolymers, functionalized ethylene copolymers, ethylene / acid copolymers, and salts thereof. The films, tapes and fibers exhibit improved tensile properties such as tensile strength and elongation at break compared to nonmodified polypropylene compositions. Also disclosed are woven, nonwoven and knitted textiles prepared from the oriented melt-spun fibers described, and methods for producing slit film fibers of the invention.

Owner:EI DU PONT DE NEMOURS & CO

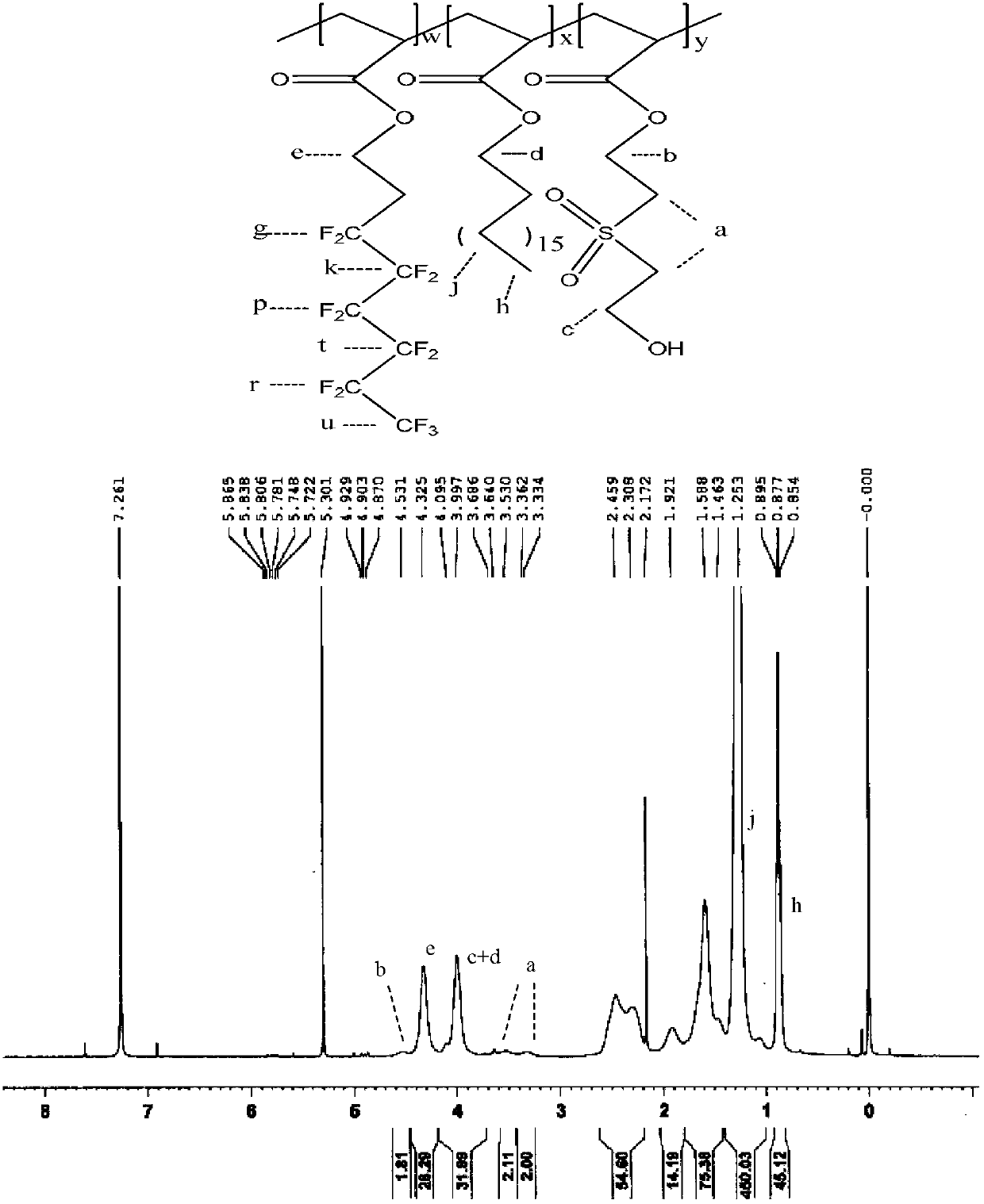

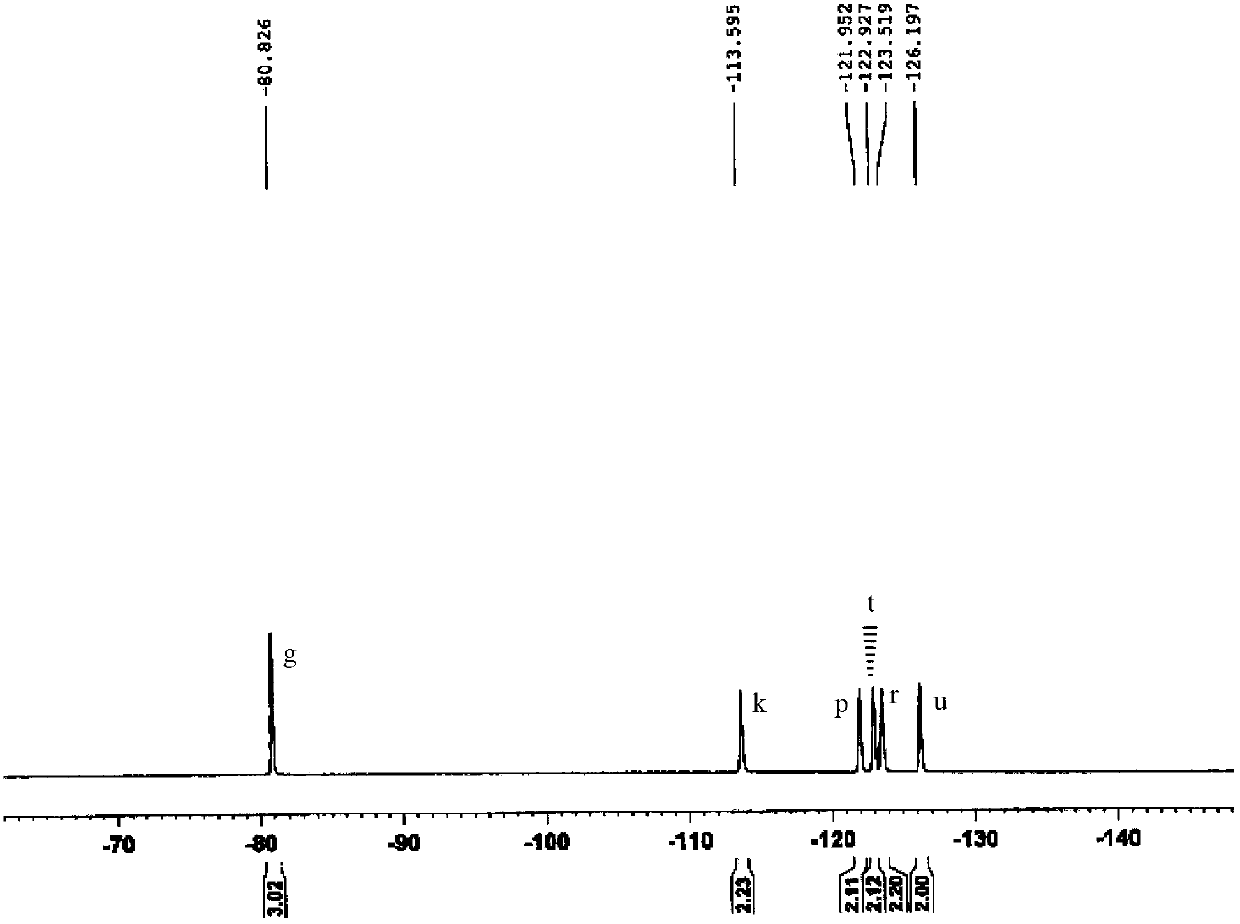

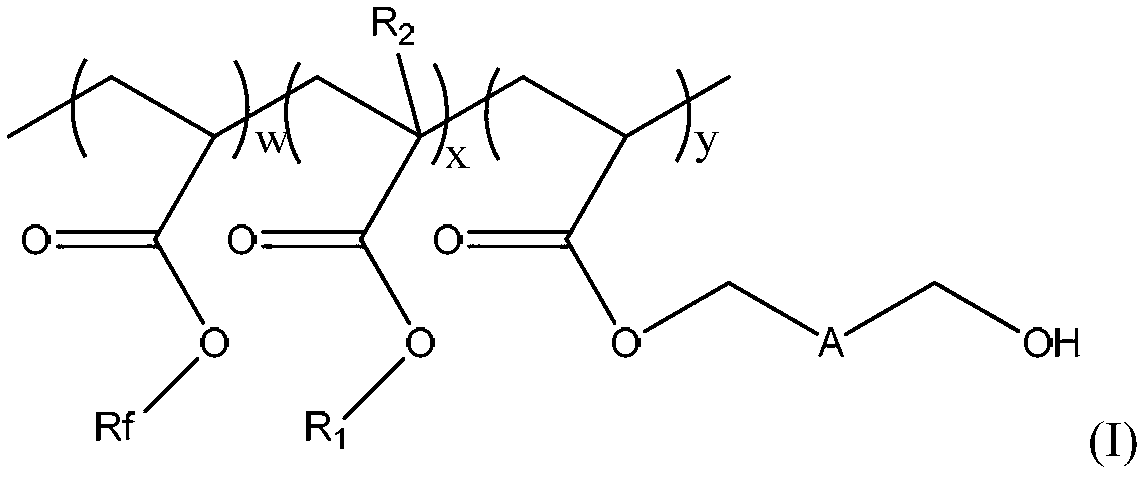

Preparation method of fluorine-containing acrylate terpolymer emulsion

ActiveCN103130950AWater repellent and oil repellentWashableFibre treatmentACRYLATE TERPOLYMERPolymer chemistry

The invention relates to a preparation method of a fluorine-containing acrylate terpolymer emulsion, which comprises the following steps: by taking perfluorohexyl ethyl (methyl) acrylate, high fatty alcohol (methyl) acrylate and a crosslinking monomer as main raw materials, taking persulfate as initiator and using composite emulsifier and a proper amount of co-emulsifier, chain transfer agent and deionized water, performing high-speed shearing at 40 DEG C for 0.5-2 hours, and then performing ultrasonic emulsification for 20-60 minutes to obtain a stable pre-emulsion; and taking part of the pre-emulsion, adding part of the initiator, heating to 50-90 DEG C, reacting for 0.5-1 hours, dropwisely adding the residual pre-emulsion and residual initiator, reacting for 3-6 hours while keeping the temperature, cooling, and regulating the pH value. The prepared emulsion is uniform and stable in particle size and does not contain harmful ingredients such as PFOS / PFOA and the like; and a coated film formed by the emulsion has favorable water repellency and oil repellency.

Owner:SHANDONG UNIV

Golf ball composition

The present invention relates to golf ball having a core and an outer cover layer made from a blend composition of about 1 to about 99 wt % of a block copolymer having no polar functionality; and from about 1 to about 99 wt % (based on the combined weight of Components A and B) of either one or more unimodal acidic polymers; or a bimodal polymer blend composition including a high molecular weight component having a weight average molecular weight, Mw, of about 80,000 to about 500,000 and including one or more ethylene / α,β-ethylenically unsaturated C3-8 carboxylic acid copolymers and / or one or more ethylene, alkyl (meth)acrylate, (meth)acrylic acid terpolymers; and a low molecular weight component having a weight average molecular weight, Mw, of about from about 2,000 to about 30,000 and comprising one or more ethylene / α, β-ethylenically unsaturated C3-8 carboxylic acid copolymers and / or one or more ethylene, alkyl (meth)acrylate, (meth)acrylic acid terpolymers. Also included in the blend is one or more basic metal salts present in an amount to neutralize at greater than or equal to about 30 percent of the acid groups of the acid polymer. The blend composition has a melt index of greater than about 5 g / 10 min, a flexural modulus of from about 500 to about 100,000 psi, a material Shore D hardness of from about 25 to about 70; and the golf ball has a cover layer Shire D hardness as measured on the ball of from about 35 to about 70 and a shear cut resistance of less than about 4.

Owner:TAYLOR MADE GOLF

Composite corrosion and scale inhibitor containing benzotriazole

The invention discloses a composite corrosion and scale inhibitor containing benzotriazole. The corrosion and scale inhibitor is compounded by a maleic acid compound, an acrylic acid terpolymer, a zinc salt, gluconate, a sulfamate compound and benzotriazole; and the composite corrosion and scale inhibitor containing benzotriazole, which is disclosed by the invention, is widely applied and can be used for corrosion and scale inhibitions of devices made of carbon steel, copper and copper alloys. The composite corrosion and scale inhibitor containing benzotriazole has a full phosphate-free formula so that the treated exterior drainage causes no eutrophication pollution to a water body due to phosphorus, and belongs to an environment friendly product; moreover, the composite corrosion and scale inhibitor has the advantages of no need of prefilming equipment before used, operation availability at a normal temperature, stable treatment effect, annual corrosion rate of lower than 0.0240 mm.a-1 to the carbon steel, calcium carbonate resistance rate of more than 98.2%, and very good corrosion and scale inhibiting effect and economic and environmental benefits.

Owner:WUHAN UNIV OF TECH +1

Peelable mask and preparation method thereof

ActiveCN104673140AGood synergyIncrease elasticityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyPolystyrene

The invention provides a peelable mask and a preparation method thereof. The peelable mask has properties of adhesion, elasticity, peeling strength, high-temperature resistance and the like, the film forming condition is simple, a film has properties of high adhesion, elasticity, peeling strength, high-temperature resistance and the like, quick and integral peeling can be realized, no residue exists after peeling, and the peelable mask is significant in high-temperature resistance, non-sticky, anti-fogging and high in chemical reagent resistance. The peelable mask takes a chlorinated polypropylene-ethylene random copolymer, a vinyl chloride-vinyl acetate-acrylate terpolymer, polystyrene-polyurethane-unsaturated polyester resin as well as organosilicone modified acrylate rubber as main film forming matters and takes epoxy resin, cellulose acetate butyrate and blocked polyurethane as auxiliary film forming matters.

Owner:SHENZHEN GLITER PRINTING MATERIALS & EQUIP

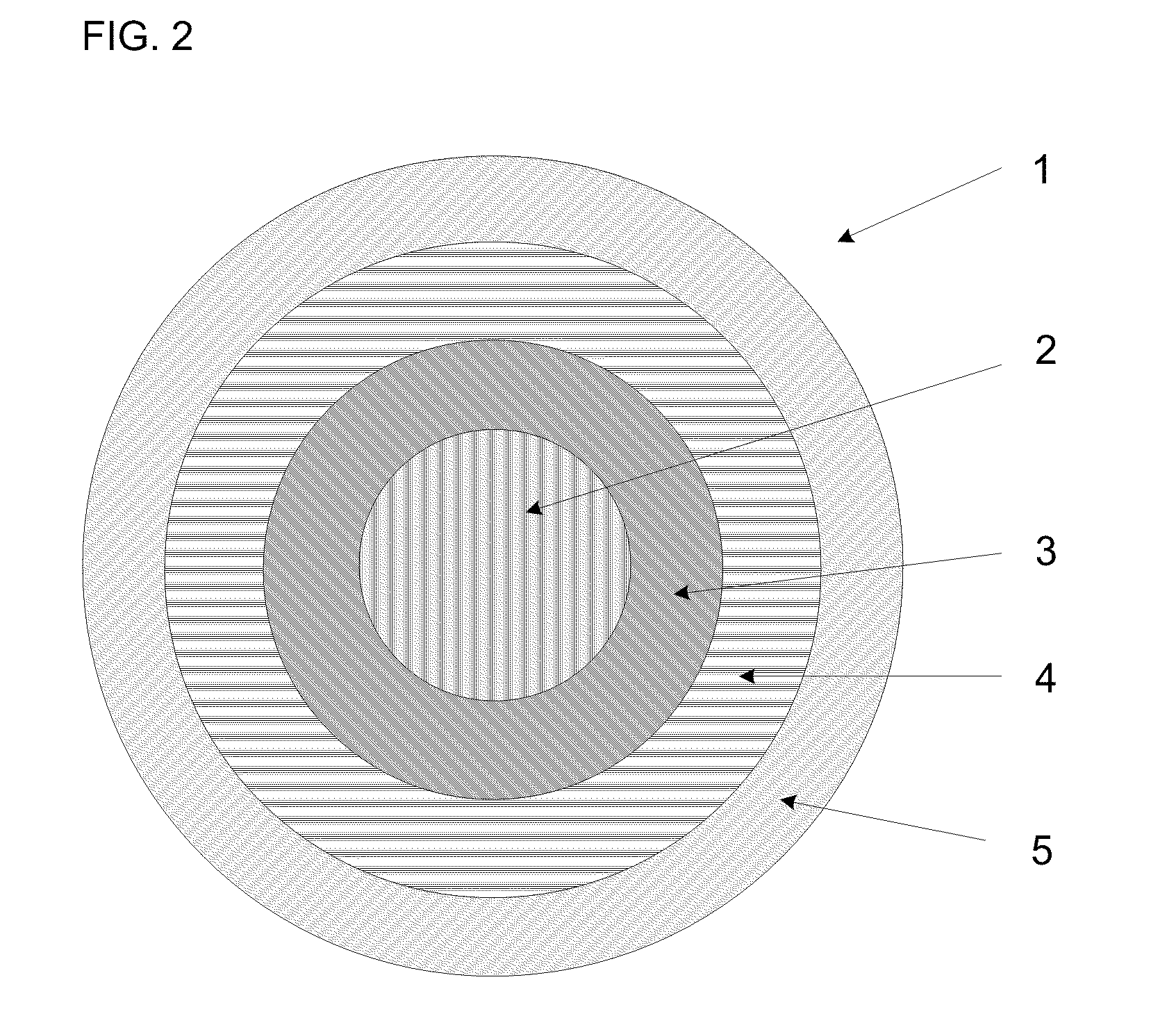

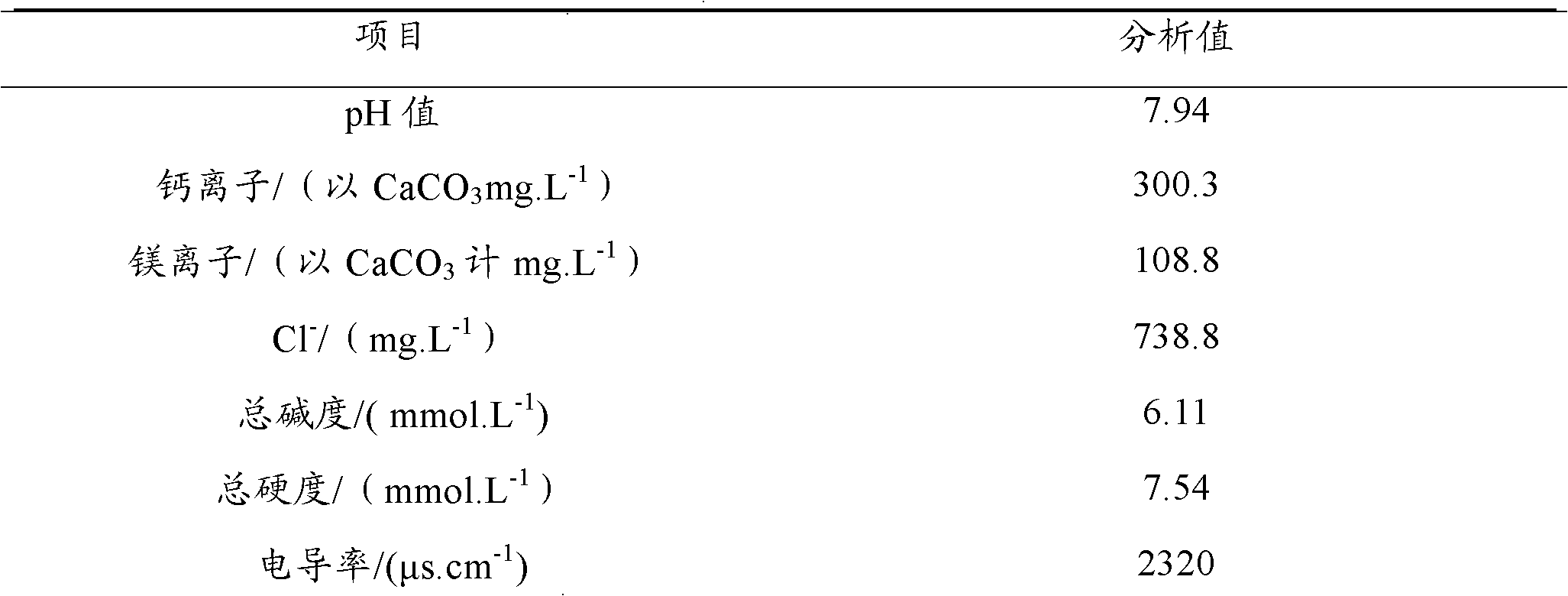

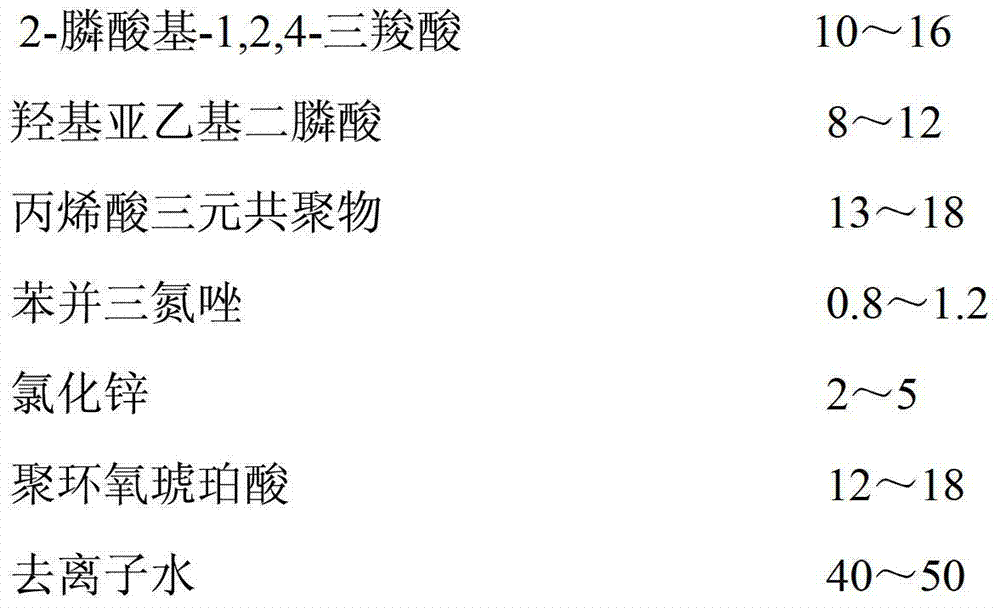

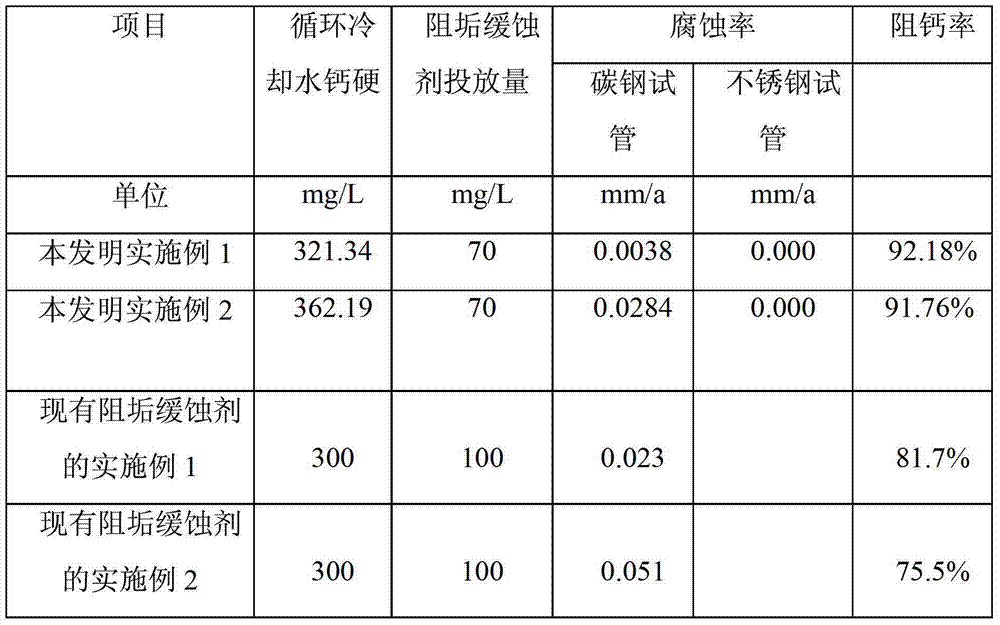

Composite scale and corrosion inhibitor

InactiveCN103241846AGood scale and corrosion inhibitionImprove complexation effectTreatment using complexing/solubilising chemicalsTricarboxylic acidCopolymer

The invention discloses a composite scale and corrosion inhibitor. The inhibitor is characterized by comprising the following main ingredients: 2-phosphono-1,2,4-tricarboxylic acid, hydroxyethylidene-1,1-diphosphonic acid, an acrylic copolymer, benzotriazole, zinc chloride, polyepoxysuccinic acid and deionized water. The inhibitor disclosed by the invention has the following beneficial effects that 2-phosphono-1,2,4-tricarboxylic acid, the hydroxyethylidene-1,1-diphosphonic acid, the acrylic copolymer, benzotriazole, zinc chloride and the polyepoxysuccinic acid of the inhibitor all have good scale and corrosion resistance; and after the above ingredients are compounded according to the weight parts in the formulation of the inhibitor disclosed by the invention, the scale and corrosion resistance effect of the inhibitor is obviously enhanced. The inhibitor disclosed by the invention is suitable for high hardness and high base, and has extremely strong complexing function on carbonate scale. The composite sale and corrosion inhibitor is good in scale and corrosion resistance, low in phosphorus content, and therefore is capable of meeting environment protection requirements. The inhibitor disclosed by the invention not only is suitable for circulating cooling water in a natural gas purification treatment plant, but also is suitable for circuiting cooling water systems in other industries of chemical fertilizer, power, textile and the like, as well as is wide in application range; and acid does not need to be added for regulating PH (Potential of Hydrogen) value.

Owner:北京市龙源科创石油技术有限公司

Composition for monovinylrenic-based shrink label films

We disclose a composition comprising (i) a monovinylarene-conjugated diene copolymer and (ii) an acrylate terpolymer. The composition can be in the form of a film. We also disclose a container comprising a container structure and a shrink label in contact with the container structure's exterior surface. We also disclose a method of applying a shrink label to a container structure.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP +1

Ethylene copolymer modified oriented polyester films, tapes, fibers and nonwoven textiles

Disclosed are films, tapes, and melt-spun fibers prepared from compositions comprising (a) at least one polyester polymer; and (b) from about 1 to 30 weight % of at least one ethylene copolymer such as ethylene / vinyl acetate dipolymers, ethylene / vinyl acetate terpolymers, ethylene / alkyl (meth)acrylate dipolymers, ethylene / alkyl (meth)acrylate terpolymers, functionalized ethylene copolymers, ethylene / acid copolymers, and salts thereof. The films, tapes and fibers exhibit improved tensile properties such as tensile strength and elongation at break compared to nonmodified polyester compositions. Also disclosed are textiles and articles prepared from the fibers described.

Owner:EI DU PONT DE NEMOURS & CO

Gelled material for improving properties of fly ash-based inorganic polymer and preparation method thereof

InactiveCN101823847AConducive to large-scale resource utilizationReduce pollutionSolid waste managementSodium metasilicateMechanical property

The invention discloses a gelled material for improving mechanical properties of a fly ash-based inorganic polymer and a preparation method thereof. The gelled material comprises the following raw materials: 1,350 grams of fly ash, 150 grams of silicon powder, 225 or 300 grams of sodium metasilicate and 307 or 264 grams of water, wherein the ratio of the summation of the water and crystal water in the Na2SiO2.9H2O to the summation of the fly ash and the silicon powder is equal to 0.29; the weight of a styrene-butyl acrylate-acrylic acid terpolymer resin emulsion is 0.5 to 3 percent of that of the fly ash and the silicon powder; the sodium metasilicate is used for exciting the binary combination of the fly ash and the silicon powder; or the terpolymer resin emulsion is doped into the binary combination of the fly ash and the silicon powder excited by the sodium metasilicate to prepare the gelled material at the room temperature. The optimal compression strength during the 28-day age of the gelled material is increased by 16.08 MPa compared with that of the fly ash-based inorganic polymer, and the rupture strength during the 28-day age of the gelled material is increased by 3.32 MPa. The doping of the terpolymer resin emulsion can significantly improve the mechanical properties of the fly ash-based gelled material. The gelled material is prepared in an environment-friendly mode which needs no heating, does not cause three-waste discharge and has a simple process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Reduced melt viscosity rigid polyvinylchloride (PVC) composition

ActiveUS7572862B2Reduce meltingImprove throughputCeramic shaping apparatusProduction rateProcedure Agents

The invention relates to a process aid for use in rigid thermoplastic compositions, and especially in rigid polyvinylchloride (PVC) compositions. The process aid is an acrylic terpolymer of methylmethacrylate, butyl acrylate and styrene at an optimal ratio to produce a significant reduction in melt process viscosity. The resulting reduction in extrusion melt torques enables manufacturers of rigid PVC products to have higher throughput production rates.

Owner:ARKEMA INC

Ethylene copolymer modified oriented polypropylene

InactiveCN1926177AFilament/thread formingMonocomponent polyolefin artificial filamentFiberPolymer science

The present invention discloses oriented films, tapes and melt-spun fibers prepared from compositions comprising (a) at least one polypropylene polymer; and (b) at least one ethylene copolymer, such as ethylene / acetic acid Vinyl ester dimer, ethylene / vinyl acetate terpolymer, ethylene / alkyl (meth)acrylate dimer, ethylene / alkyl (meth)acrylate terpolymer, functionalized ethylene copolymer compounds, ethylene / acid copolymers and their salts. The films, tapes and fibers exhibit improved tensile properties, such as tensile strength and elongation at break, compared to unmodified polypropylene compositions. Also disclosed are woven, nonwoven, and knitted fabrics prepared from the oriented melt-spun fibers, as well as methods of producing the slit film fibers of the present invention.

Owner:EI DU PONT DE NEMOURS & CO

Modified acrylonitrile-styrene-acrylate terpolymer resin, and preparation method and product thereof

ActiveCN103059228ALow costImprove self-cleaning functionSynthetic resin layered productsASA-polymerAcrylonitrile

The invention provides a modification method of an acrylonitrile-styrene-acrylate terpolymer resin, which comprises the following steps: under ammonolysis reaction conditions, carrying out first contact on the acrylonitrile-styrene-acrylate terpolymer resin with diamine to obtain the contacted acrylonitrile-styrene-acrylate terpolymer resin; and under amide generation reaction conditions, carrying out second contact on the contacted acrylonitrile-styrene-acrylate terpolymer resin with an alkyl carboxylic acid solution. The invention also provides a modified acrylonitrile-styrene-acrylate terpolymer resin obtained by the method and a product prepared from the modified acrylonitrile-styrene-acrylate terpolymer resin. The modified acrylonitrile-styrene-acrylate terpolymer resin provided by the invention has excellent self-cleaning function.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of non-phosphate environment-friendly scale-resistant dispersing agent

InactiveCN106145396AInhibitor copolymerGood scale resistanceScale removal and water softeningWheat starchChemistry

The invention discloses a preparation method of a phosphorus-free environment-friendly scale inhibitor dispersant and belongs to the technical field of scale inhibitor dispersants. The present invention first utilizes wheat starch to prepare amylose, carries out copolymerization reaction with amylose, maleic anhydride and acrylic acid to obtain amylose-maleic anhydride-acrylic acid terpolymer, and terpolymer, polyaspartic acid acid, sodium lignosulfonate and other complexing agents and deionized water, and stir and mix evenly to obtain a scale inhibitor dispersant. The scale inhibitor dispersant prepared by the present invention is economical, environmentally friendly, and efficient, and can not only inhibit calcium carbonate scale, sulfuric acid scale The copolymer of calcium scale and calcium phosphate scale, and also inhibits the copolymer of zinc scale, iron scale, silicon scale and other scales. It has good scale inhibition effect, prevents the generation of scale, and can fully disperse the scale deposited in the water system. , environmentally friendly and biodegradable.

Owner:丁玉琴

Polyurethane hot melt adhesives with acrylic copolymers and thermoplastic resins

InactiveCN1244606CMonocarboxylic acid ester polymer adhesivesOther chemical processesSolvent freeCarvacryl acetate

This invention relates to solvent-free moisture curable one-part hot melt polyurethane adhesive or sealant compositions which are solid at room temperature. In one embodiment, the polyurethane adhesive or sealant composition comprises in percentages by weight (a) from about 20 % to about 75 % of a urethane prepolymer; (b) from about 1 % to about 66 % of a reactive, hydroxyl containing, or a nonreactive polymer formed from ethylenically unsaturated monomers; and (c) from about 20 % to about 75 % of a thermoplastic resin. In another embodiment, the polyurethane adhesive or sealant composition comprises, in percentages by weight of the polyurethane composition (a) from about 10 % to about 90 % of a urethane prepolymer; and (b) from about 5 % to about 90 % of a thermoplastic resin which is an ethylene vinylacetate / ethylene acrylate terpolymer.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Cleaning implement comprising a modified open-cell foam

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com