Golf ball composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

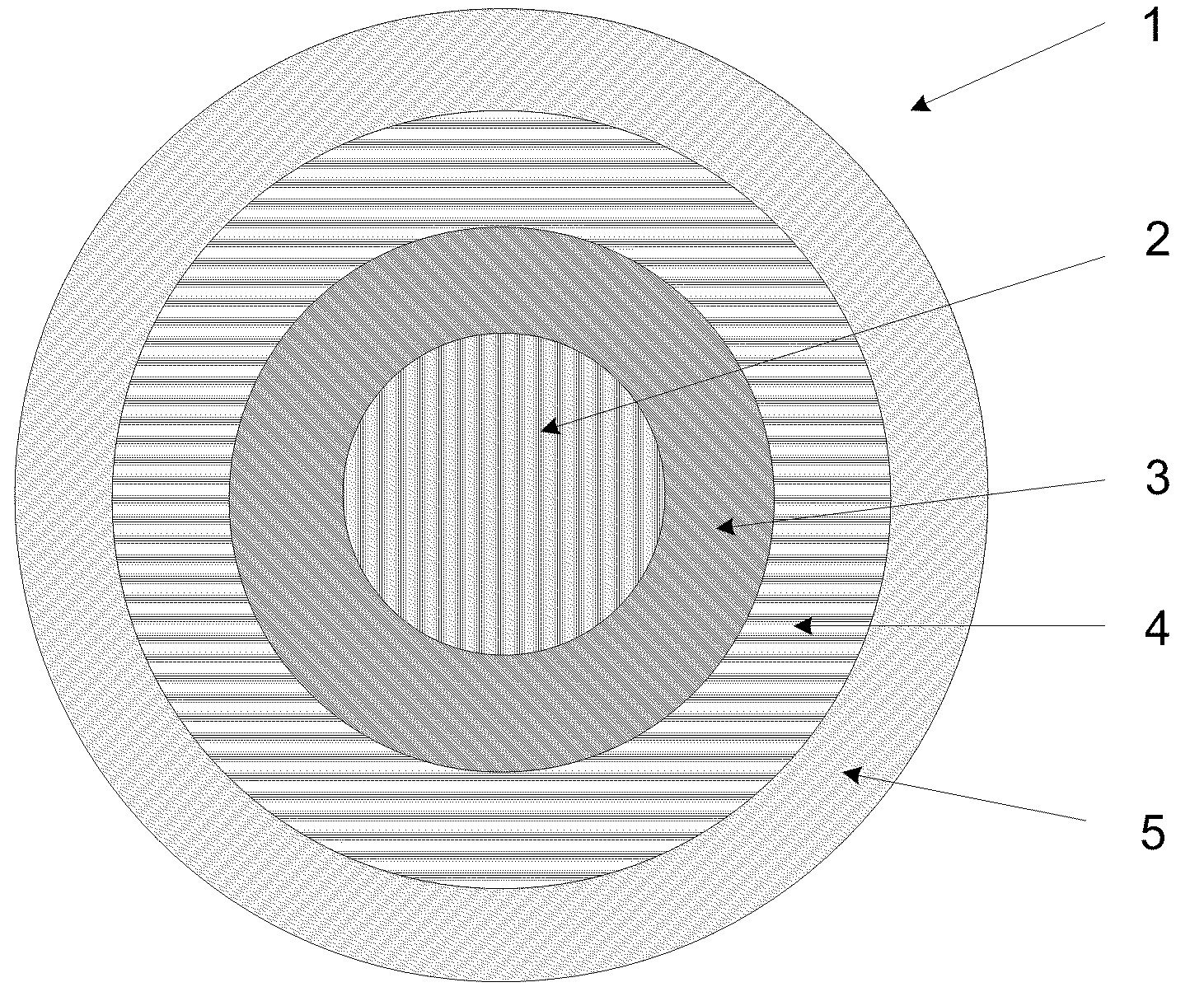

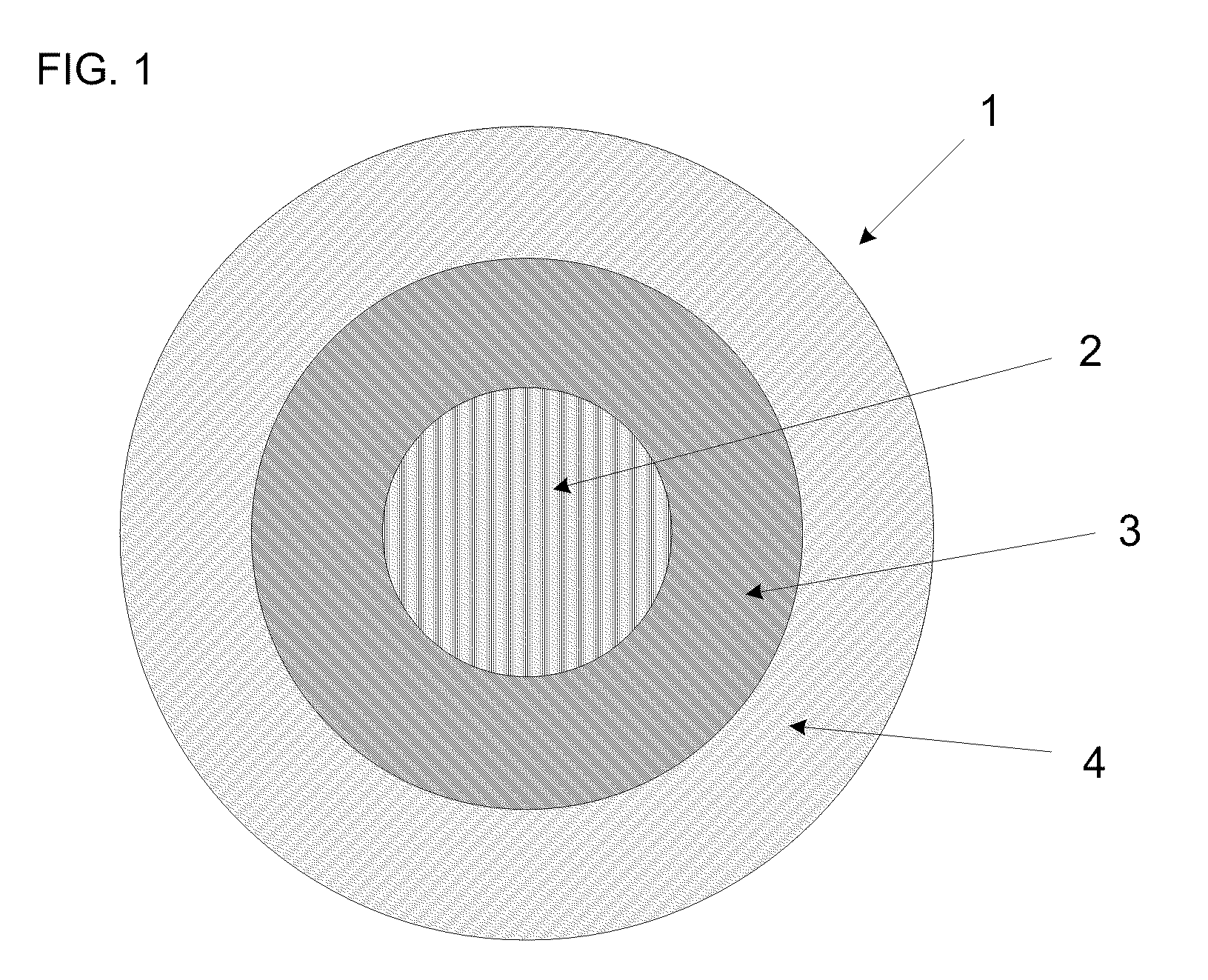

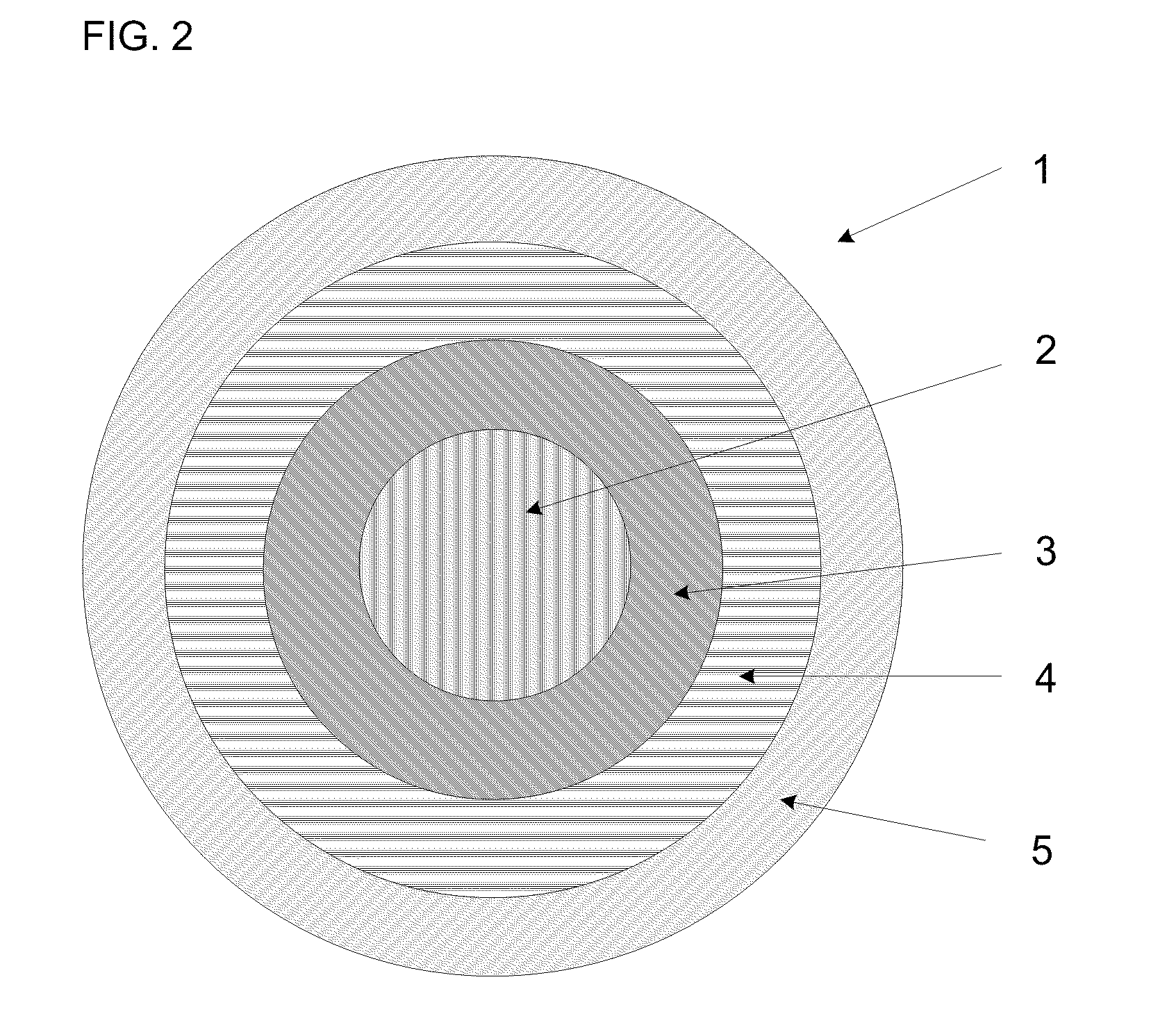

Image

Examples

examples

[0176]Examples of the invention are given below by way of illustration and not by way of limitation.

[0177]The following materials were used to prepare the Examples and Comparative Example:

[0178]Septon 52002 is an SEPS block copolymer commercially available from the Kuraray Group.

[0179]Kraton G1726M is an SEBS block copolymer commercially available from Kraton Polymers LLC.

[0180]AX3410 ethylene-methyl acrylate-glycidyl methacrylate resin from Atofina Chemical.

[0181]Toprene K9156T is an SEBS block copolymer commercially available from Korea Kumho Petrochemical Co., Ltd.

[0182]Septon Hg 252 is an SEEPS block copolymer with one termination is modified into hydroxyl group commercially available from the Kuraray Group.

[0183]Nucrel 2906 is an ethylene / methacrylic acid copolymer commercially available from Du Pont

[0184]Primacor 5980 is an ethylene / acrylic acid copolymer commercially available from Dow Chemical.

[0185]Escor 5200 is an ethylene / acrylic acid copolymer commercially available from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com