Preparation method of fluorine-containing acrylate terpolymer emulsion

An acrylate terpolymer and acrylate technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of high cost of initiators and emulsifiers, unfavorable for large-scale popularization and application, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

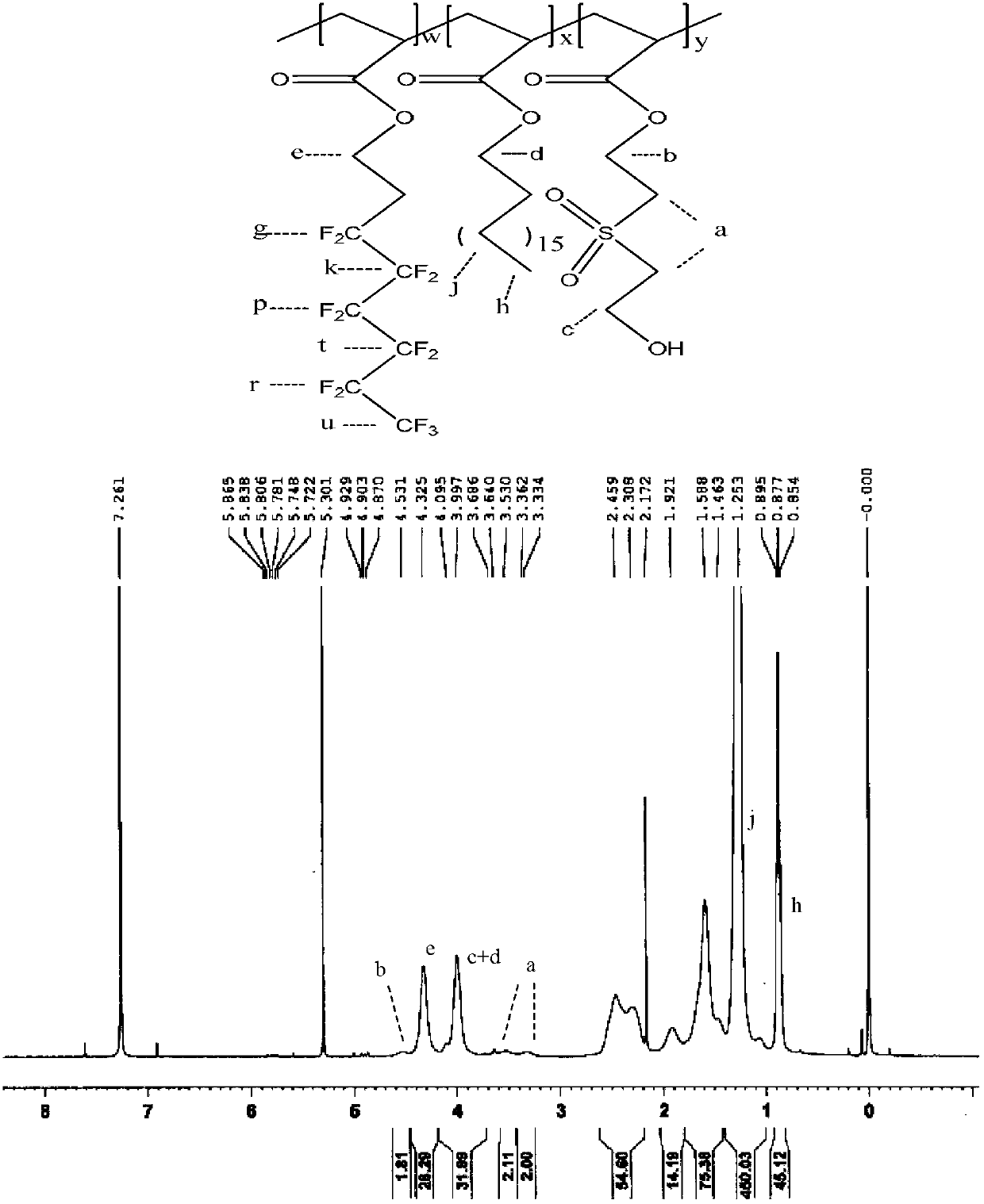

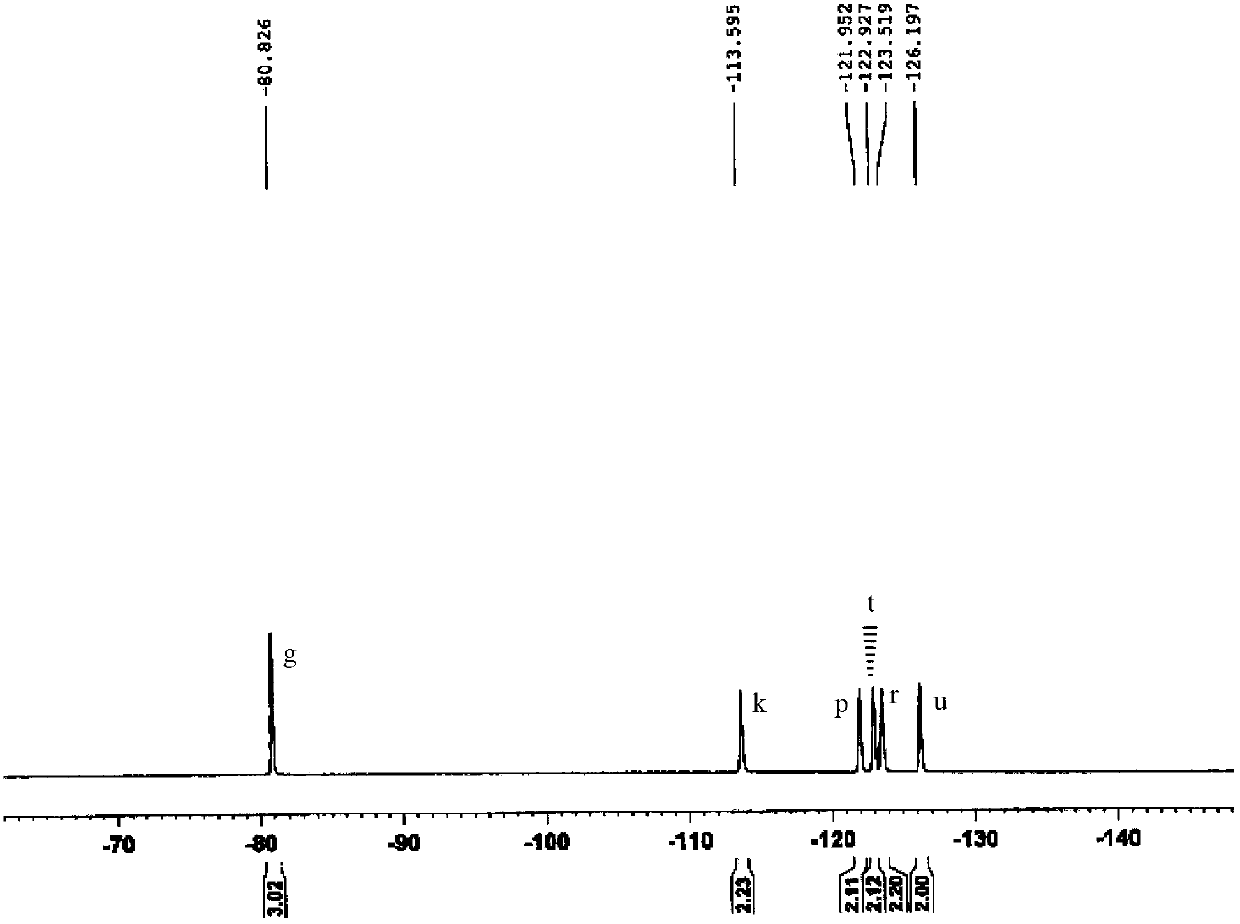

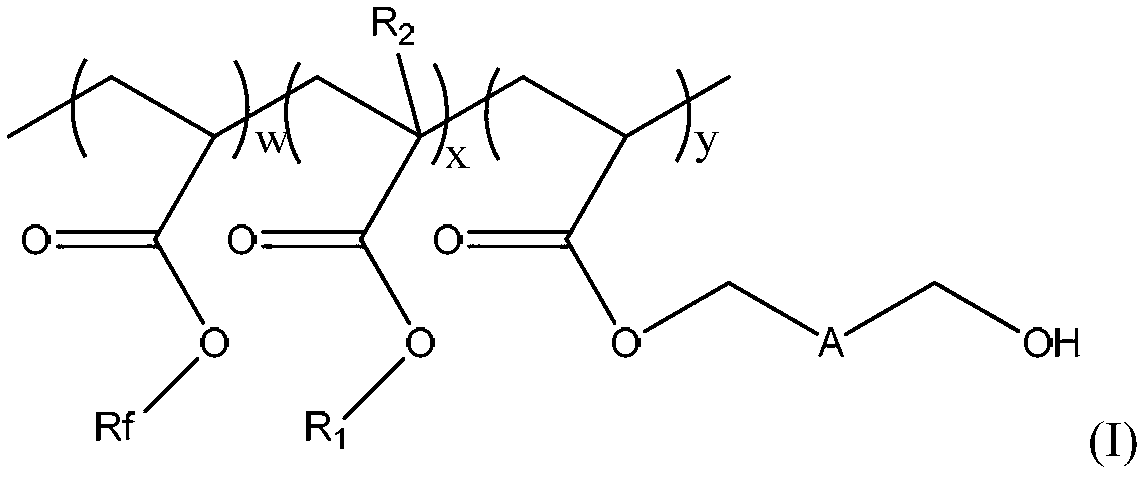

[0047] (1) Add 35ml of deionized water, 10ml of acetone, 4.55g of perfluorohexyl ethyl acrylate, 9.30g of stearyl acrylate, 2-((2-hydroxyethyl)sulfonyl)ethyl acrylate into a 100ml reaction bottle Esters 1.20g, OP-10 (non-ionic surfactant) 0.46g, anionic surfactant sodium dodecyl sulfate 0.25g, dodecyl mercaptan 0.10g, high-speed shearing at 40°C for 1h, then ultrasonic emulsification After 0.5h, a milky white pre-emulsion was obtained.

[0048] Take 0.11 g of the initiator ammonium persulfate, dissolve it in 10 ml of deionized water, and prepare a solution for later use.

[0049] (2) In a 100ml reaction vessel equipped with stirring, reflux condenser, thermometer, and constant pressure dropping funnel, pass nitrogen protection, add 1 / 2 mass of pre-emulsion prepared in step (1) and 1 / 3 mass The initiator was heated to 80°C to react, and blue fluorescence appeared after 1 hour of reaction, then the remaining pre-emulsion and initiator were added dropwise, and the addition was c...

Embodiment 2

[0051] (1) Add 35ml of deionized water, 10ml of acetone, 6.07g of perfluorohexyl ethyl acrylate, 7.67g of lauryl acrylate, and 2-((2-hydroxyethyl)sulfonyl)ethyl acrylate into a 100ml reaction bottle in sequence 1.36g, OP-100.46g, anionic surfactant sodium lauryl sulfate 0.26g, dodecyl mercaptan 0.072g, high-speed shearing at 40°C for 1h, and ultrasonic emulsification for 30min to obtain a milky white pre-emulsion.

[0052] Take 0.11 g of the initiator ammonium persulfate, dissolve it in 10 ml of deionized water, and prepare a solution for later use.

[0053] (2) The heating reaction temperature is 83° C., and other conditions are the same as (2) in Example 1.

Embodiment 3

[0055] (1) Add 35ml of deionized water, 10ml of acetone, 4.55g of perfluorohexyl ethyl acrylate, 9.35g of stearyl acrylate, 2-((2-hydroxyethyl)sulfonyl) ethyl acrylate into a 100ml reaction bottle 1.44g of ester, 0.49g of NP-400, 0.30g of cationic surfactant cetyltrimethylammonium bromide, 0.062g of dodecyl mercaptan, high-speed shearing at 40°C for 1h, and ultrasonic emulsification for 35min to obtain milky white pre-emulsion.

[0056] Take 0.090 g of initiator ammonium persulfate, dissolve it in 10 ml of deionized water, and prepare a solution for later use.

[0057] (2) The reaction device, operation steps and other conditions are the same as (2) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com