Short-fluorine-chain fabric finishing agent as well as preparation method and application thereof

A technology of fabric finishing agent and short fluorine chain group, which is applied in the field of short fluorine chain fabric finishing agent and its preparation, can solve the problems of reducing surface energy, bioaccumulation teratogenicity, etc., and achieve good film-forming properties and thermal stability High, easy-to-operate and implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

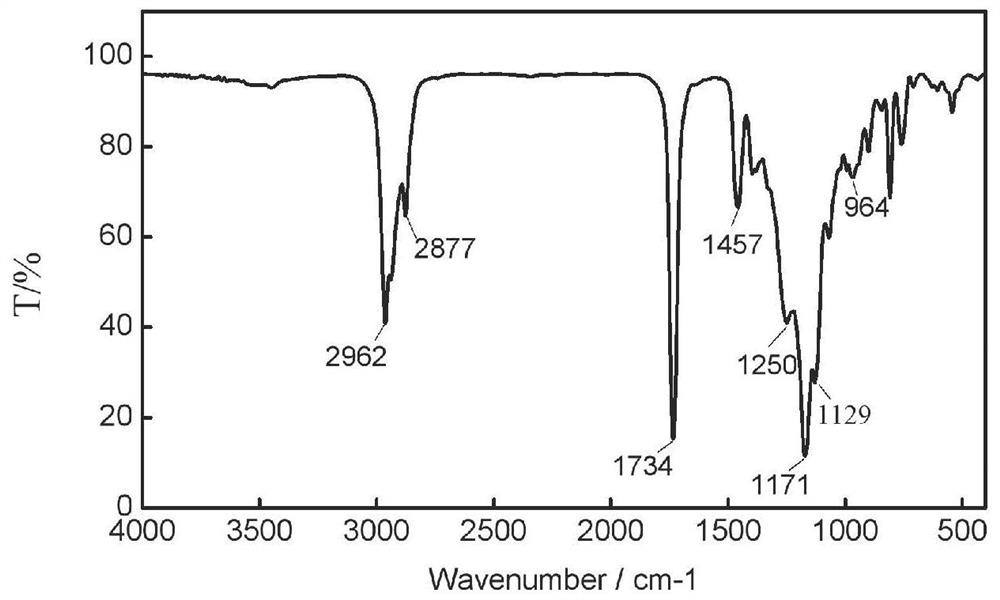

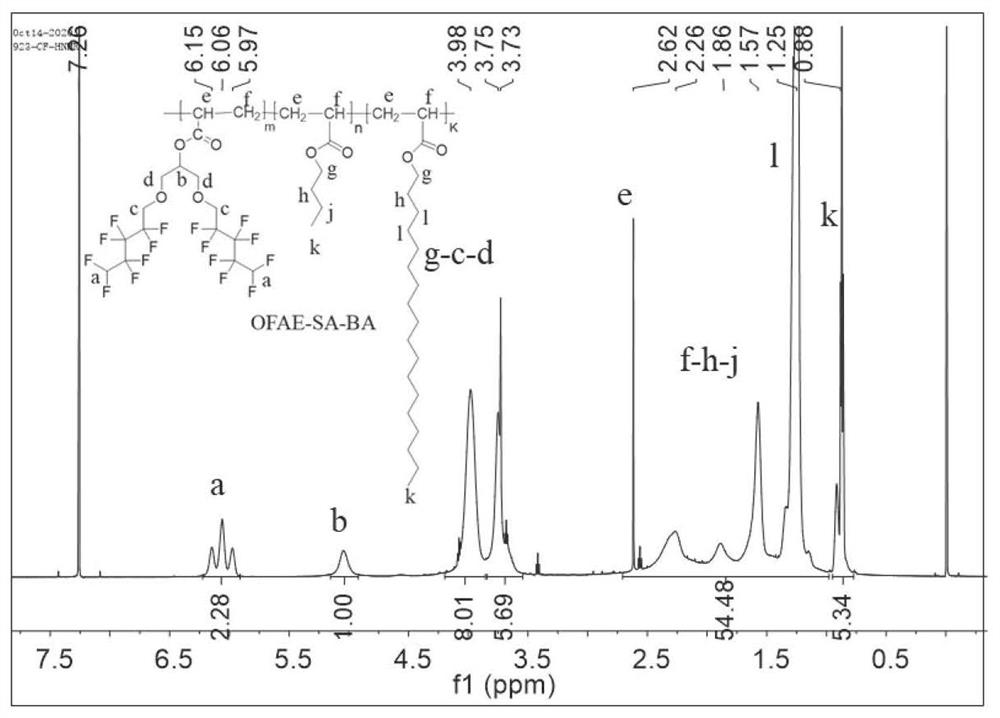

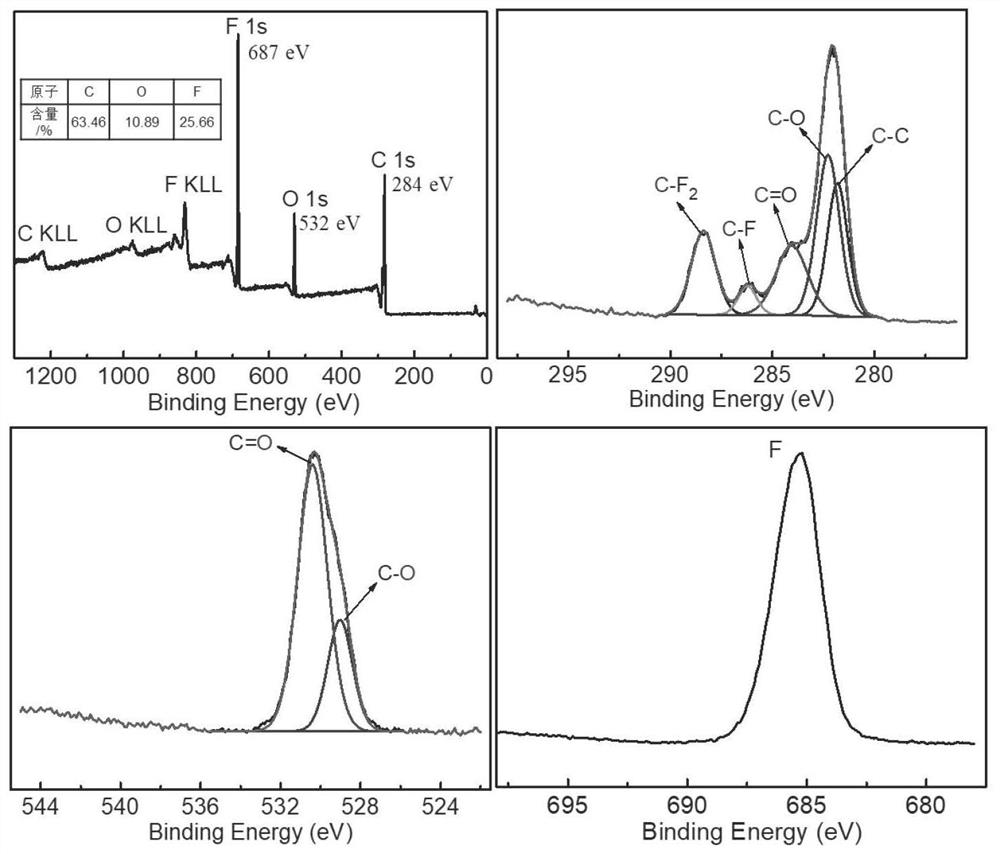

[0033] The preparation of short fluorine chain fabric finishing agent OFAE-SA-BA, the synthetic route is as follows:

[0034]

[0035] The preparation steps are as follows:

[0036] S11. Remove water and oxygen from the reaction flask. Under nitrogen protection, in a 100mL dry three-necked flask, stearyl acrylate (3.18g, 9.8mmol), butyl acrylate (0.63g, 4.9mmol), 2, 3-Bisoctafluoropentyloxy-1-acrylate (5.6g, 24.5mmol) and AIBN (0.15g, 1.6%) were sequentially added into 20mL THF, and stirred at room temperature for 30 minutes.

[0037] S12. The reaction temperature was gradually increased to 64° C., and the reaction was continued for 16 hours, and the reaction solution was transparent and thick. After diluting with 50ml of ethyl acetate, it was slowly dropped into a mixed solvent of methanol and water (200 / 200 (V / V)) with a pipette under vigorous stirring, and a white solid was precipitated. The mixed solvent of methanol and water was washed several times, and dried in vac...

Embodiment 2

[0043]Synthesis of Short Fluorine Chain Fabric Finishing Agent (OFIA-HA-HM):

[0044] S11, remove water and oxygen from the reaction bottle, under the protection of nitrogen, in a 100mL dry three-necked bottle, weigh 0.164gAIBN in N 2 Add 20mL of tetrahydrofuran under protection and stir to obtain an initiator solution. Weigh 7.92g of bis-octafluoropentyloxy-isopropylisopropyl acrylate, 3.23g of hexadecyl acrylate, and 0.20g of hydroxyethyl methacrylate, and add into 20mL tetrahydrofuran, and mix the three monomers evenly, and stir at room temperature for 30 minutes.

[0045] S12, the monomer mixed solution in N 2 Under protection, drop dropwise into the initiator solution equipped with a condenser, thermometer, and stirrer, stir on a magnetic stirrer at a speed of 600r / min for 15min at room temperature, start to heat the oil bath to 64°C, and keep it warm for 24h. It is transparent and thick. After diluting with 50ml of ethyl acetate, it was slowly dropped into a mixed sol...

Embodiment 3

[0048] Finishing agent OFAE-SA-BA prepared in Example 1 is applied to the finishing process and performance of cotton fabrics

[0049] Prepare OFAE-SA-BA into a solution with a concentration of 30g / L, soak the cotton fabric for 30min, after two dipping and two padding, the excess rate is 80%, prebake at 80°C for 3min, bake at 160°C for 3min, wash with water, After soaping and water washing, the fabric can be water- and oil-repellent finished.

[0050] Such as Figure 5 As shown, under this process, the contact angle of cotton fabric to water can reach 151.1°. Such as Image 6 As shown, the contact angle of cotton fabric to liquid paraffin reaches 76.8°, the water repellency grade is 90 points, the oil repellency grade is 1 grade, and the static pressure resistance can reach 190.4mmH 2 O, the softness level is 4.8, and the whiteness value is 199.4, which basically has no effect on the performance of cotton fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com