Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

A super-slump-preserving concrete technology, applied in the field of concrete production, can solve the problems of concrete segregation and bleeding, concrete bleeding, and high cost, and achieve the effects of stable workability retention capability, extended slump retention performance, and water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

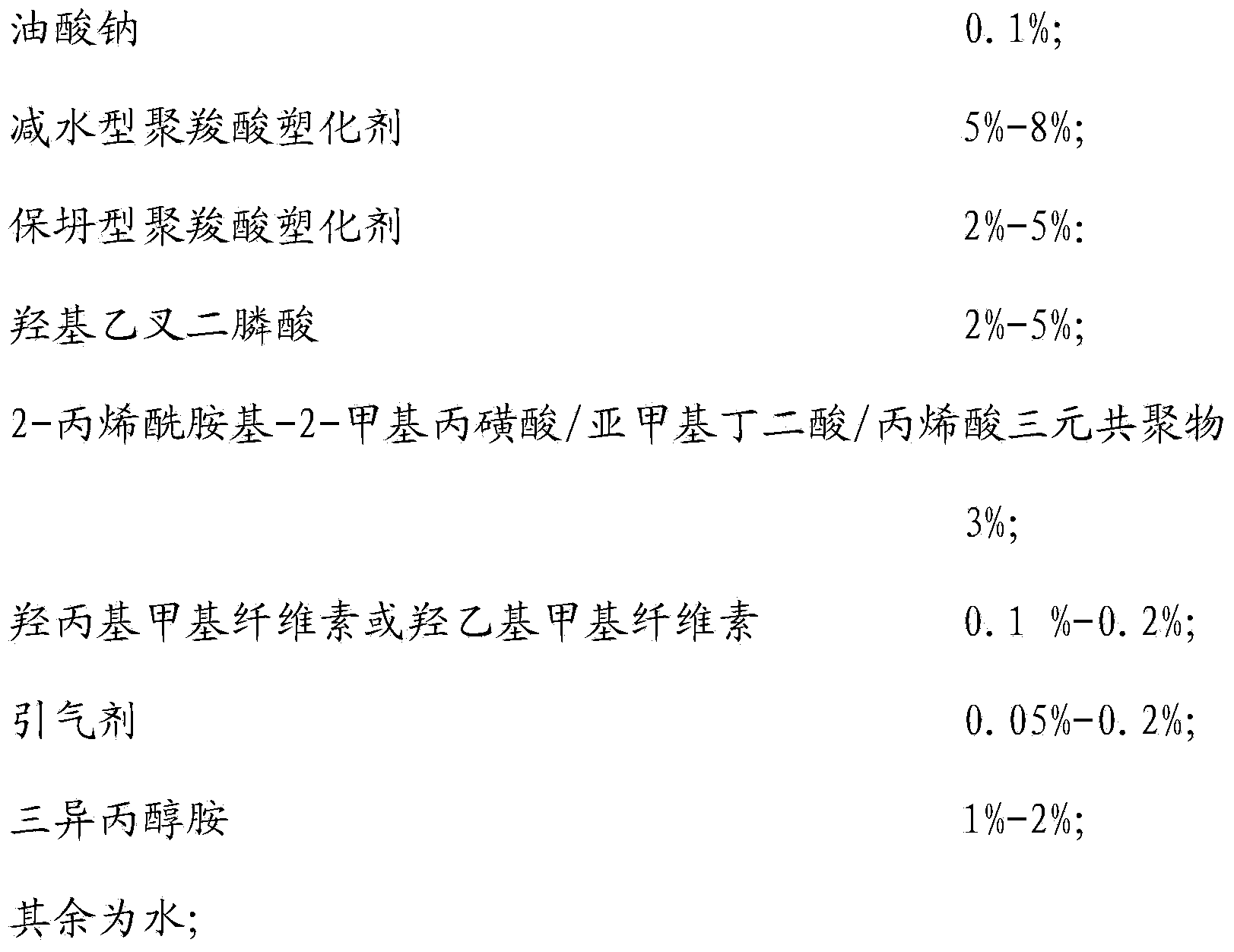

[0047] The ultra-slump-retaining polycarboxylate water-reducer for cast-in-situ pile concrete in this example is called water-reducer 1#, and the dosage when used is 1.5%-2.5% of the cementitious material. The water-reducer is in a liquid state. The percentage of each component in the total mass of the water reducer is as follows based on the mass of the solution with the following predetermined concentration:

[0048]

[0049] The ultra-slump-retaining polycarboxylate superplasticizer 1# of this embodiment was prepared according to the following preparation method:

[0050] Step 1: Raw material preparation

[0051] (1) Dissolving sodium oleate for later use: add 1 part by weight of sodium oleate powder to 9 parts by weight of water at 20-80°C, stir until completely dissolved, and prepare a solution with a concentration of 10% for later use;

[0052] (2) Dissolve hydroxypropyl methylcellulose for later use: add 2 parts by weight of hydroxypropyl methylcellulose to 98 parts b...

Embodiment 2

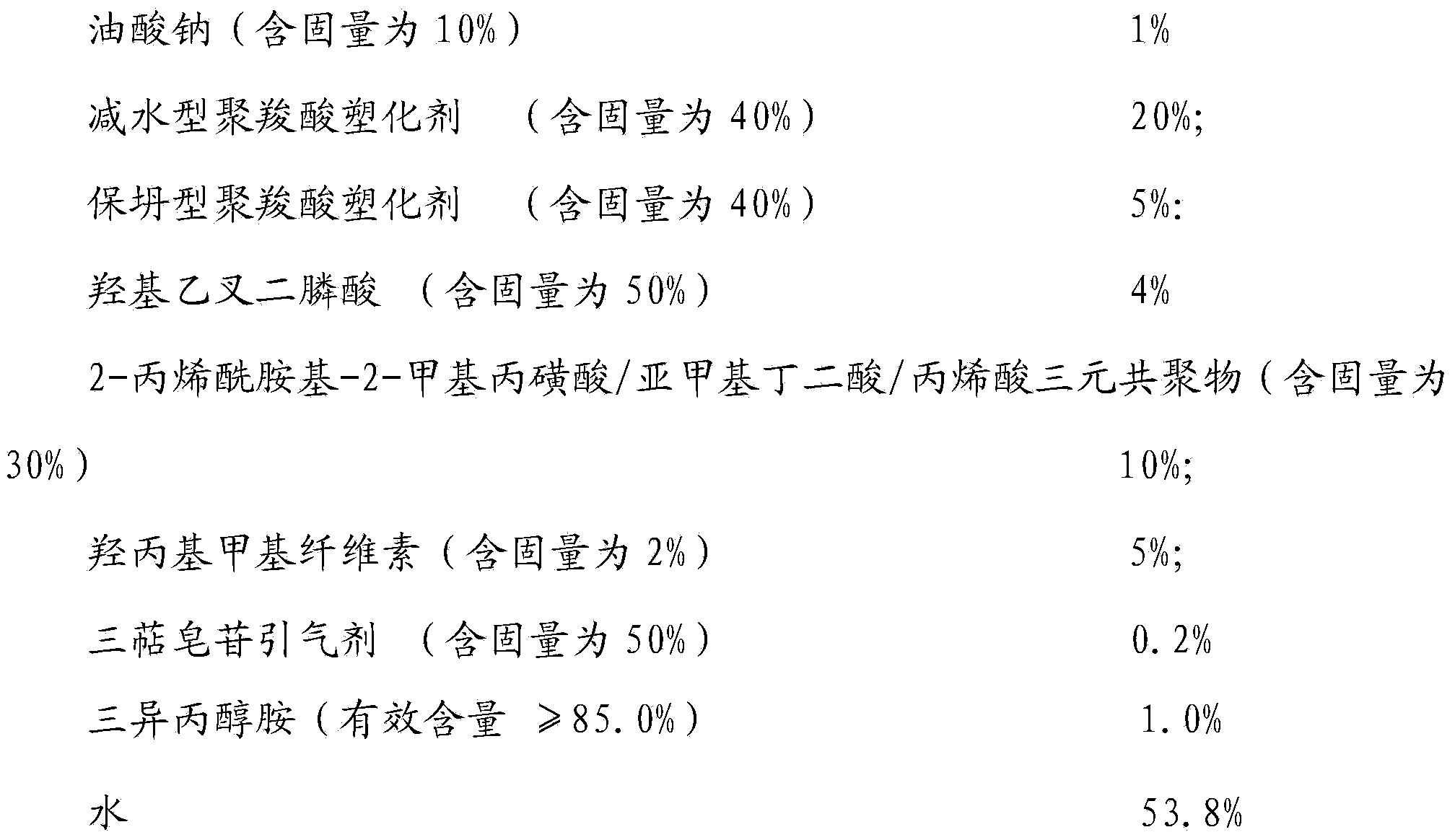

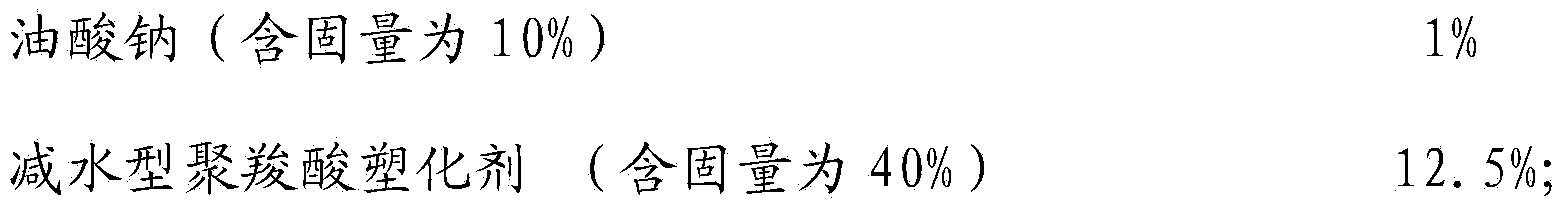

[0057] The ultra-slump-retaining polycarboxylate water-reducer for cast-in-situ pile concrete in this example is called water-reducer 2#, and the dosage when used is 1.5%-2.5% of the cementitious material. The water-reducer is in a liquid state. The percentage of each component in the total mass of the water reducer is as follows based on the mass of the solution with the following predetermined concentration:

[0058]

[0059]

[0060] The ultra-slump-retaining polycarboxylate superplasticizer 2# of this embodiment was prepared according to the following preparation method:

[0061] Step 1: Raw material preparation

[0062] (1) Dissolving sodium oleate for later use: add 1 part by weight of sodium oleate powder to 9 parts by weight of water at 20-80°C, stir until completely dissolved, and prepare a solution with a concentration of 10% for later use;

[0063] (2) Dissolve hydroxyethyl methylcellulose for later use: Add 2 parts by weight of hydroxyethyl methylcellulose t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com