Patents

Literature

64 results about "Methylenebutanedioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

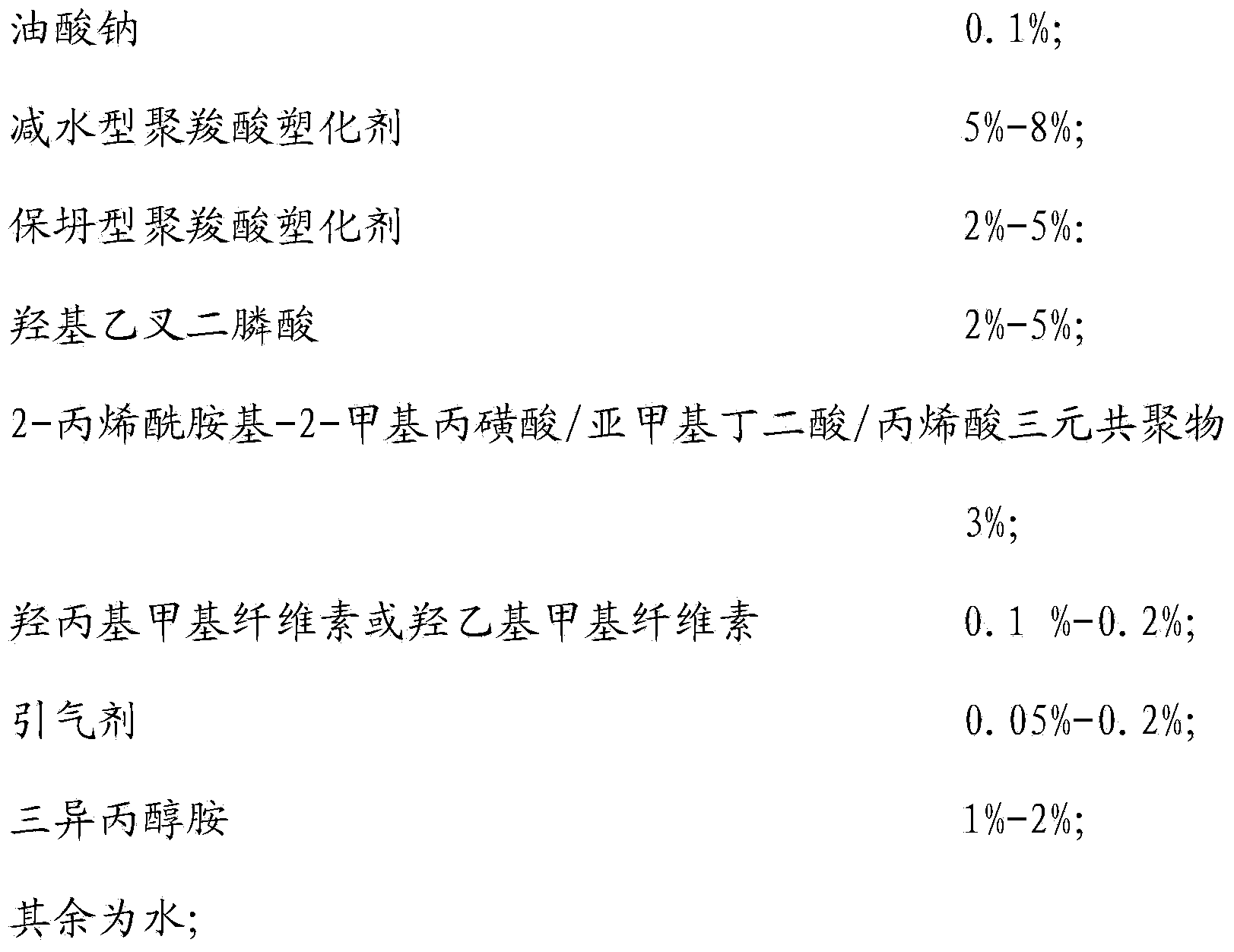

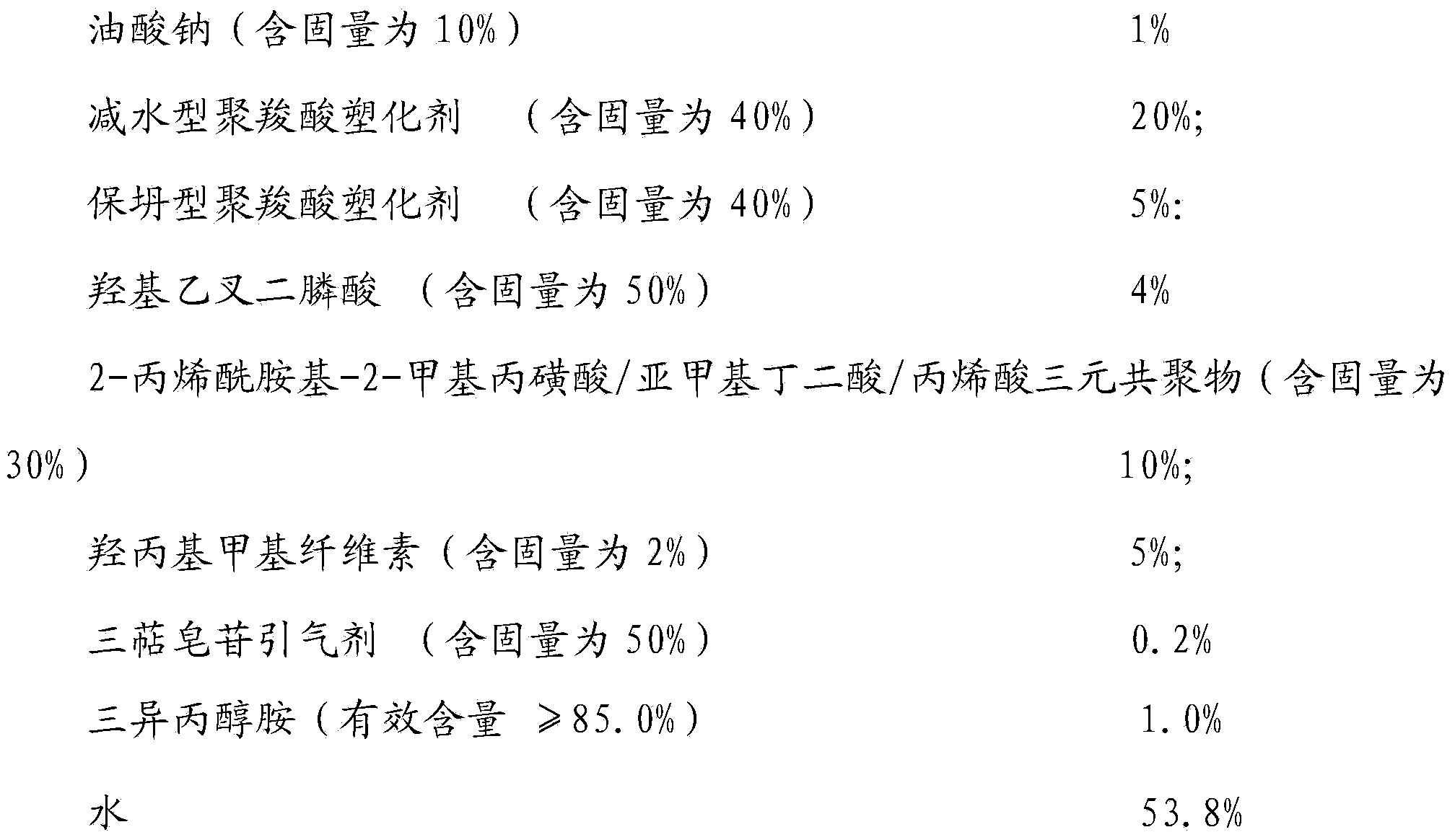

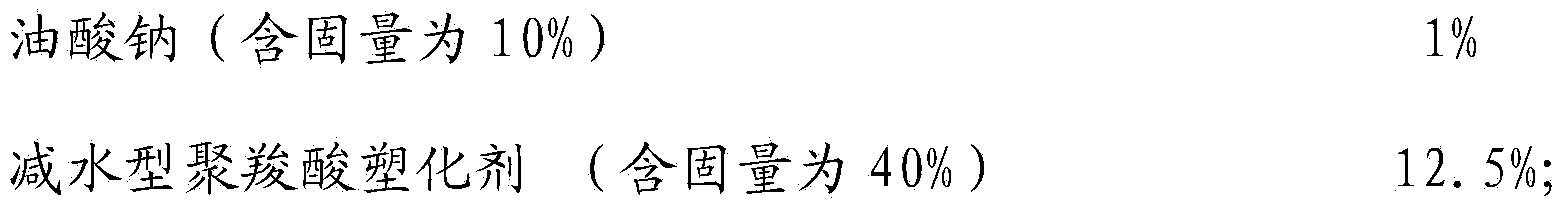

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

Functional silk non-woven xysma and producing process thereof

InactiveCN1552972AImprove insulation effectIncrease elasticityDe-gumming silkNon-woven fabricsCross-linkEmulsion

Functional silk non-woven wadding is prepared from natural silk, plant resin emulsion and inorganic nano bactericidal. The said emulsion is of self cross-linked anion resin, co-polymerized from acrylic diester, arylonitrile itaconic acid and N hydroxy acrylamide as cross-linking agent. The ratio of emulsion : silk is 100: (1.5-5.0) by dry weight. Silver ion nano bactericidal is also added into the wadding with the ratio of the bactericidal : silk is 100: (0.5-15.0). The product is soft and light, moisture-absorbing and gas permeable, high thermal insulation, elastic, water washing resistance, safety and usable widely.

Owner:丁永华

Color-photosensitive aqueous polyurethane emulsion for textiles and preparation method thereof

ActiveCN102199877AExcellent photochromic effectImprove performanceFibre treatmentButanedioic acidPropanoic acid

The invention discloses a color-photosensitive aqueous polyurethane emulsion for textiles and a preparation method thereof; the product comprises the following raw materials in parts by weight: 100 parts of polyatomic alcohol polymer, 70 to 100 parts of polyisocyanates monomer, 5 to 12 parts of micromolecular polyatomic alcohol, 10 to 20 parts of dihydromethyl propionic acid, 7 to 15 parts of dimethylene-butanedioic acid derivative, 9 to 21 parts of neutralizer, 20 to 35 parts of N-methylpyrrolidone or acetone, 490 to 600 parts of deionized water, 2 to 23 parts of diamine chain extender, 2 to 12 parts of tungstic oxide and 1 to 4 parts of assistant. The preparation method of the product comprises the following steps of: reacting the polyisocyanates monomer with the polyatomic alcohol polymer to generate a prepolymer, adding the micromolecular polyatomic alcohol, the dihydromethyl propionic acid and the dimethylene-butanedioic acid derivative for chain extension, adding the N-methylpyrrolidone or acetone and the neutralizer, and reacting so as to disperse to the deionized water, adding the diamine chain extender for chain extension, and finally adding the tungstic oxide and the assistant so as to obtain the product.

Owner:ZHEJIANG LUOXING IND CO LTD

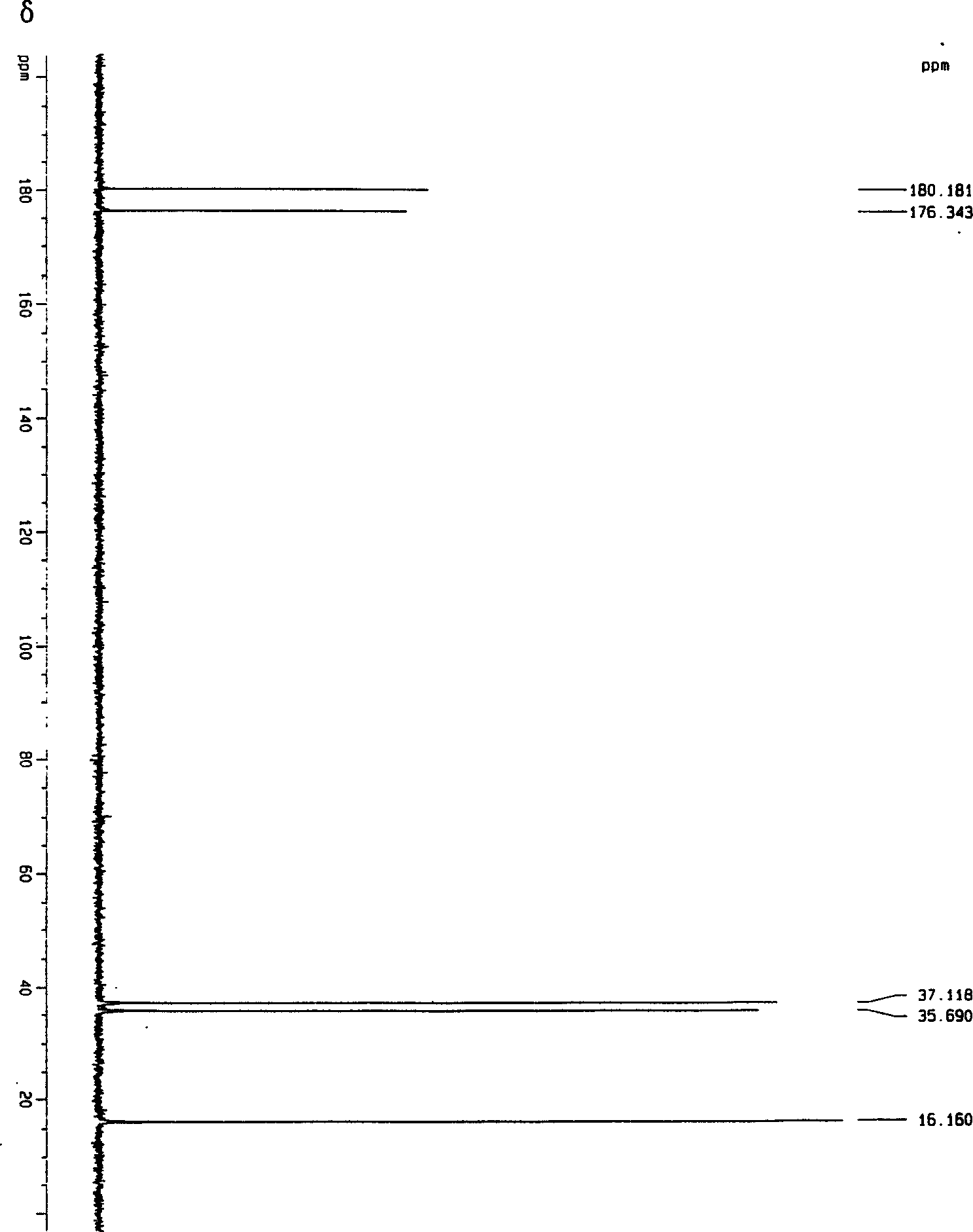

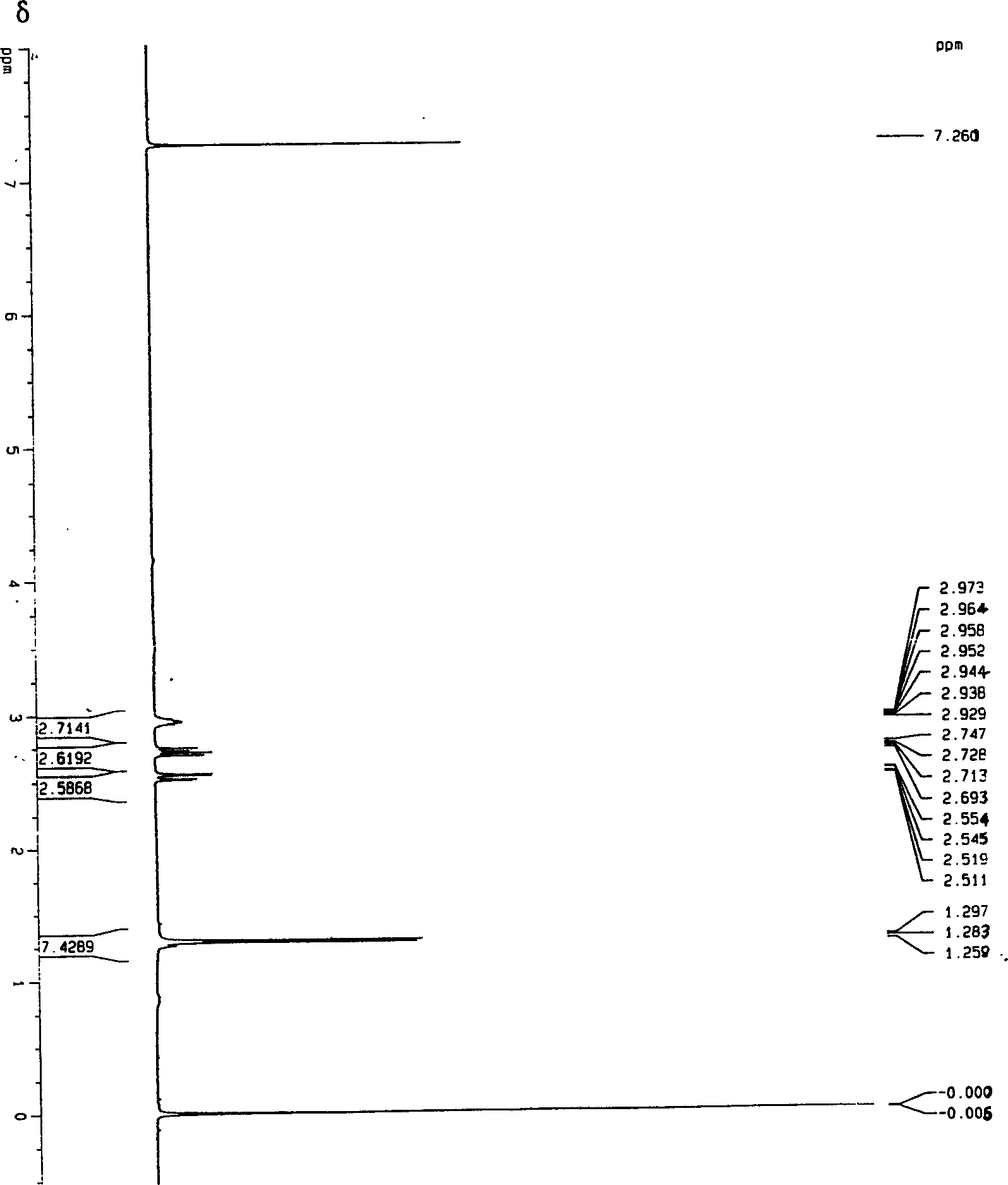

Catalytic synthesis process of methyl succinic acid

InactiveCN1609089AEasy to purifyEfficient purificationCarboxylic preparation by ozone oxidationItaconic acidRoom temperature

The present invention is catalytic synthesis process of methyl succinic acid. The present invention adopts Pd / C catalyst and itaconic acid as material to synthesize methyl succinic acid through liquid phase hydrogenation in certain mixed solvent. The reaction is completed at 10-80 deg.c; and the coarse product is purified through re-crystallization inside cold ethyl ether to reach methyl succinic acid content over 99 %. The said preparation process has mild reaction condition, short reaction time, high itaconic acid conversion rate of 98-99 % and high selectivity of 99 %.

Owner:FUDAN UNIV

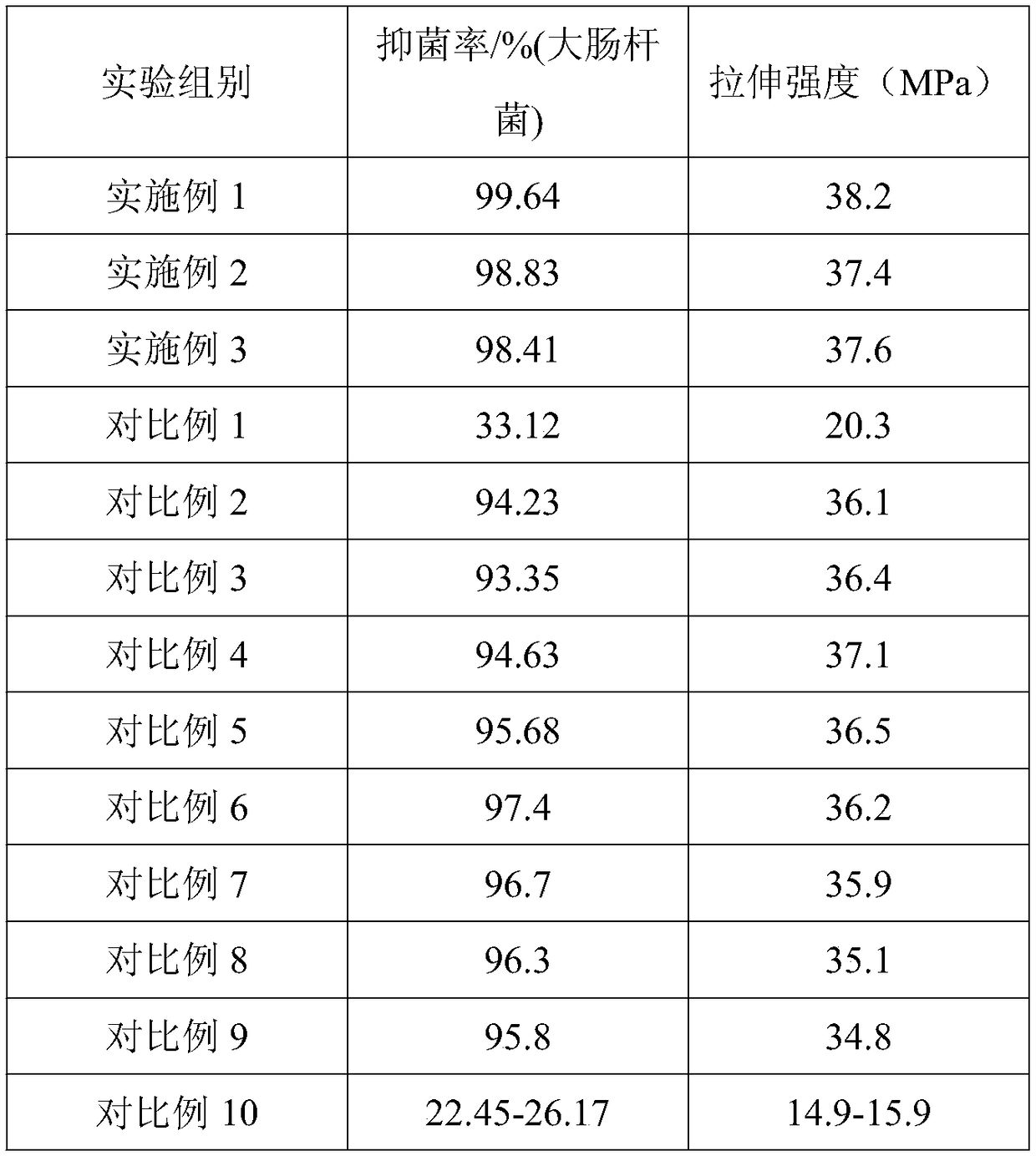

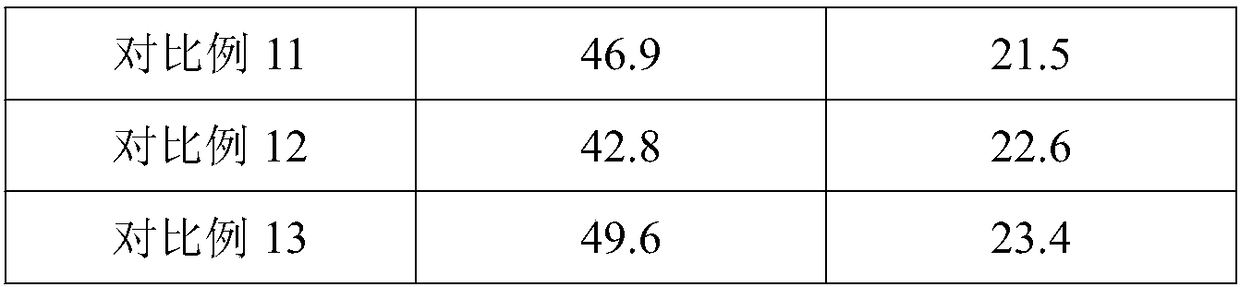

Polymer water-absorbent resin for diapers and preparation method thereof

InactiveCN108485267AImprove antibacterial propertiesImprove toughnessPotassium persulfatePolymer science

The invention discloses polymer water-absorbent resin for diapers and a preparation method thereof. The polymer water-absorbent resin for diapers comprises the following raw materials: bisphenol A type polysulfone resin, polycarbonate, polylactic acid, bamboo charcoal fiber, carbon nano-tube, silane coupling agent KH-560, acrylic acid, N,N-methylene bisacrylamide, potassium persulfate, sodium sulfite, methylene succinic acid, sodium hydroxide, kelp, acrylamide, a modified antibacterial auxiliary agent and a toughening modification auxiliary agent. The polymer water-absorbent resin for diapersis prepared by the steps of preparing a base material, preparing a modified material, and then mixing the base material and modified material. The polymer water-absorbent resin for diapers, provided by the invention, has excellent antibacterial and toughness properties.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

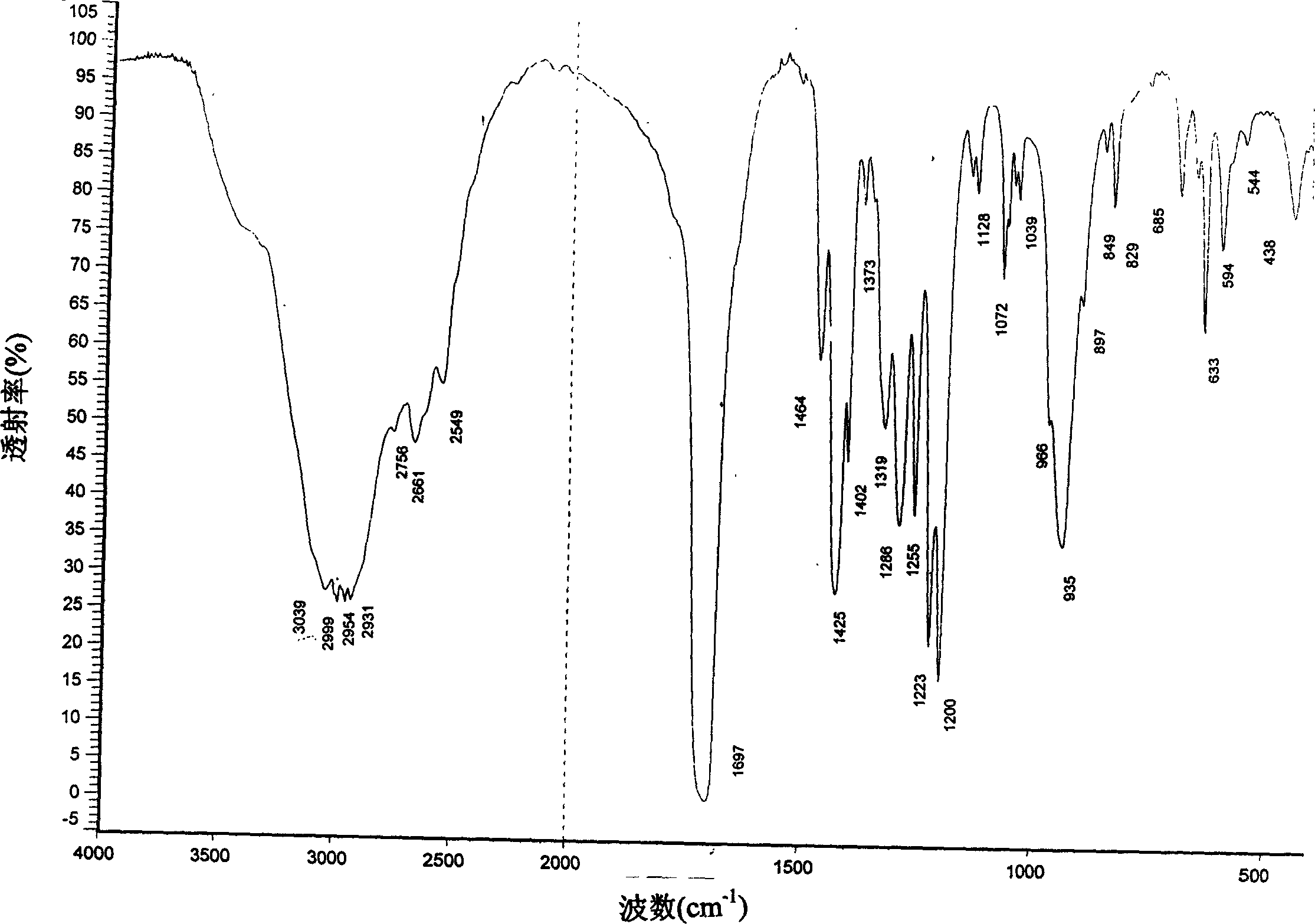

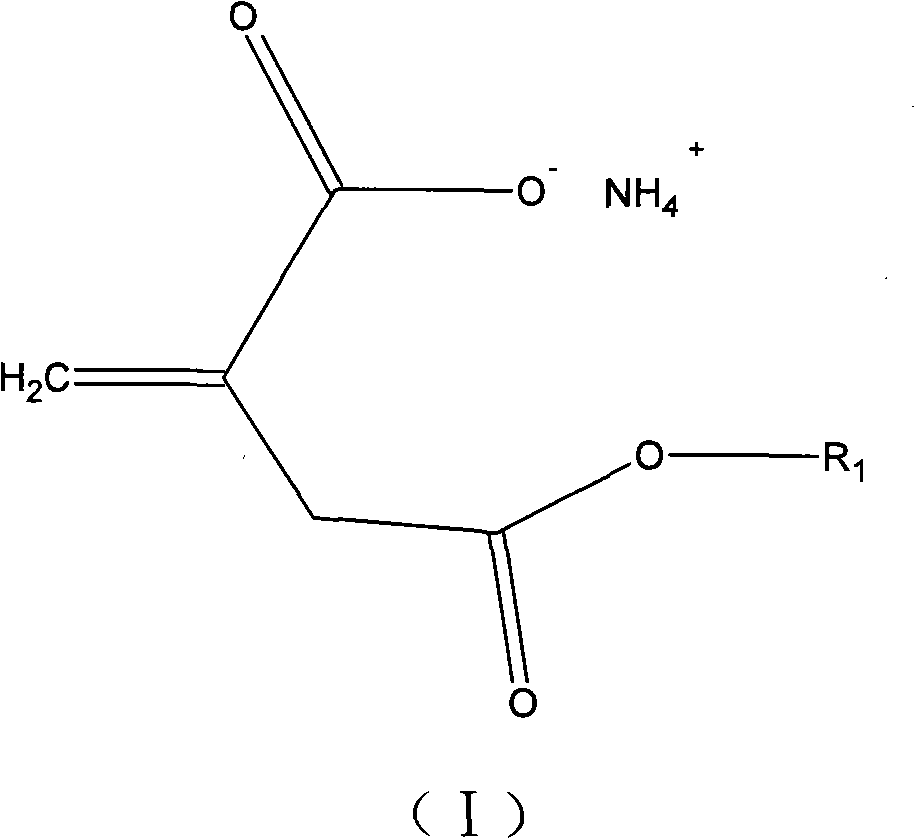

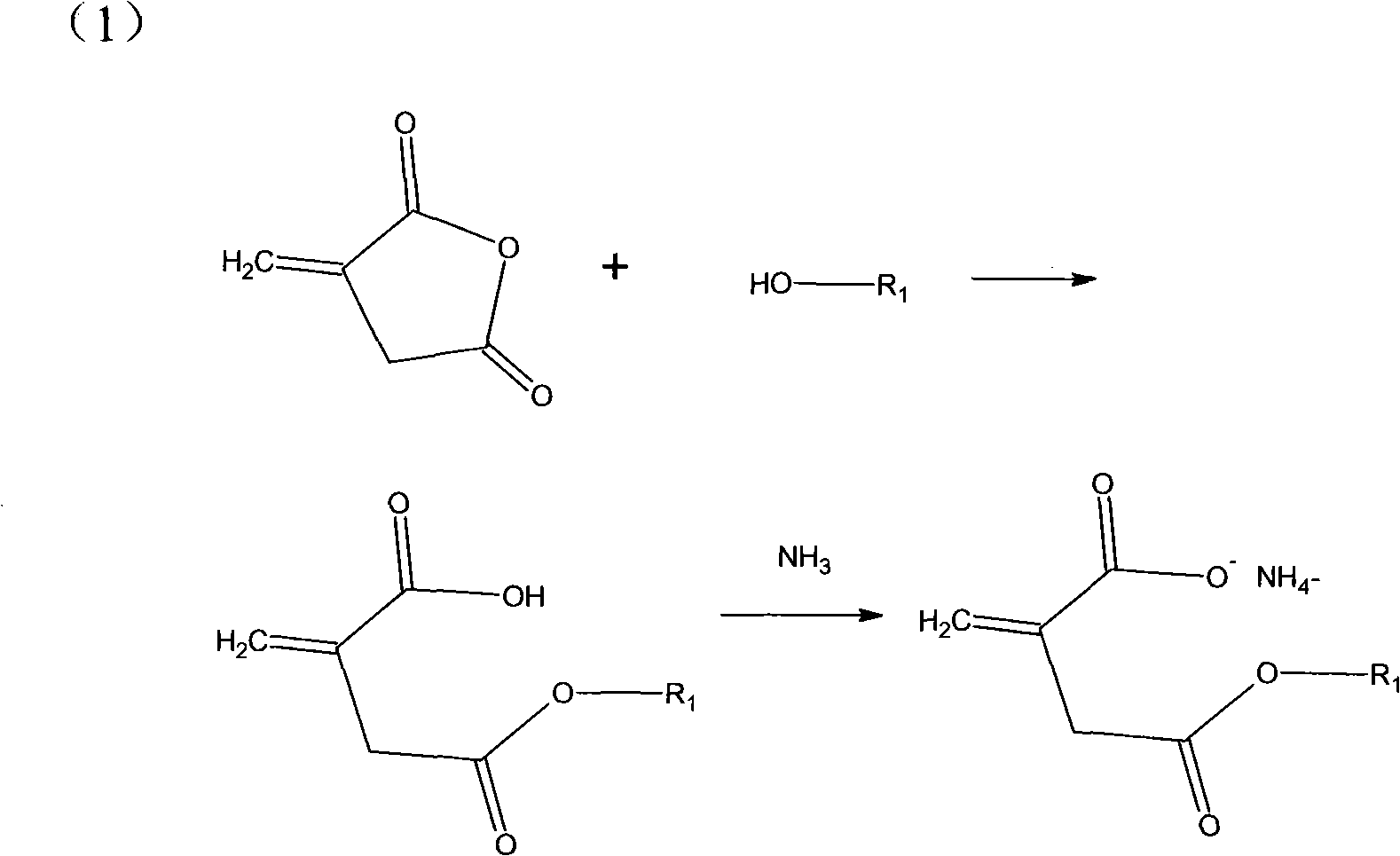

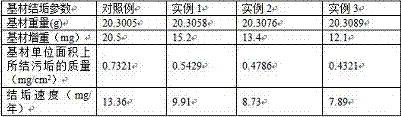

Itaconic acid derivant for copolymerization of acrylonitrile

ActiveCN101768078AStrong process controllabilityOrganic compound preparationCarboxylic acid esters preparationItaconic acidAcrylonitrile

The invention discloses an itaconic acid derivant for copolymerization of acrylonitrile. The structural general formula (I) of the itaconic acid derivant is as follows: in the formula (I), R1 is alkyl. The itaconic acid derivant with both ester-base and ammonio is adopted as a comonomer for the acrylonitrile and the conventional ternary polymerization is replaced, so that the controllability of a copolymer is improved. The itaconic acid derivant is used for preparing high-performance PAN raw silks. In the copolymer of the acrylonitrile and the itaconic acid derivant, the mass ratio of the acrylonitrile is within 90 to 99.99%, and the mass ratio of the itaconic acid derivant is within 0.01 to 10%. The number-average molar mass of the copolymer is within 1 to 1 million.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation method for compound corrosion-inhibiting scale inhibitor

InactiveCN107265676AAdd active groupsAvoid reunionSpecific water treatment objectivesScale removal and water softeningEpoxyMagnesium salt

The invention relates to a preparation method for a compound corrosion-inhibiting scale inhibitor, which belongs to the technical field of chemical engineering. According to the preparation method, amino acid as a material is epoxy-modified to add molecular active groups, so that the formation of calcium and magnesium salt can be inhibited, moreover, metal ions are complexed, consequently, a scale inhibition effect is achieved, and the scale inhibitor can also be prevented from being agglomerated; reaction is then carried out with itaconic acid monomer as a material, so that homopolymer is produced, and the two carboxyl groups in the homopolymer which are connected to double bonds can enhance the scale inhibition property, dispersibility and metal corrosion inhibition property of the scale inhibitor; chitosan is then used for coating; when the scale inhibitor gets into water, the chitosan can slowly swell, so that substances therein pass through the holes of the chitosan to get into the water, consequently, the scale inhibitor can be continuously released, and the scale inhibition time is prolonged. The scale inhibitor prepared by the preparation method has a good scale inhibition effect, and also has the characteristic of slow release, so the scale inhibitor does not need to be added in a large amount.

Owner:常州环际商贸有限公司

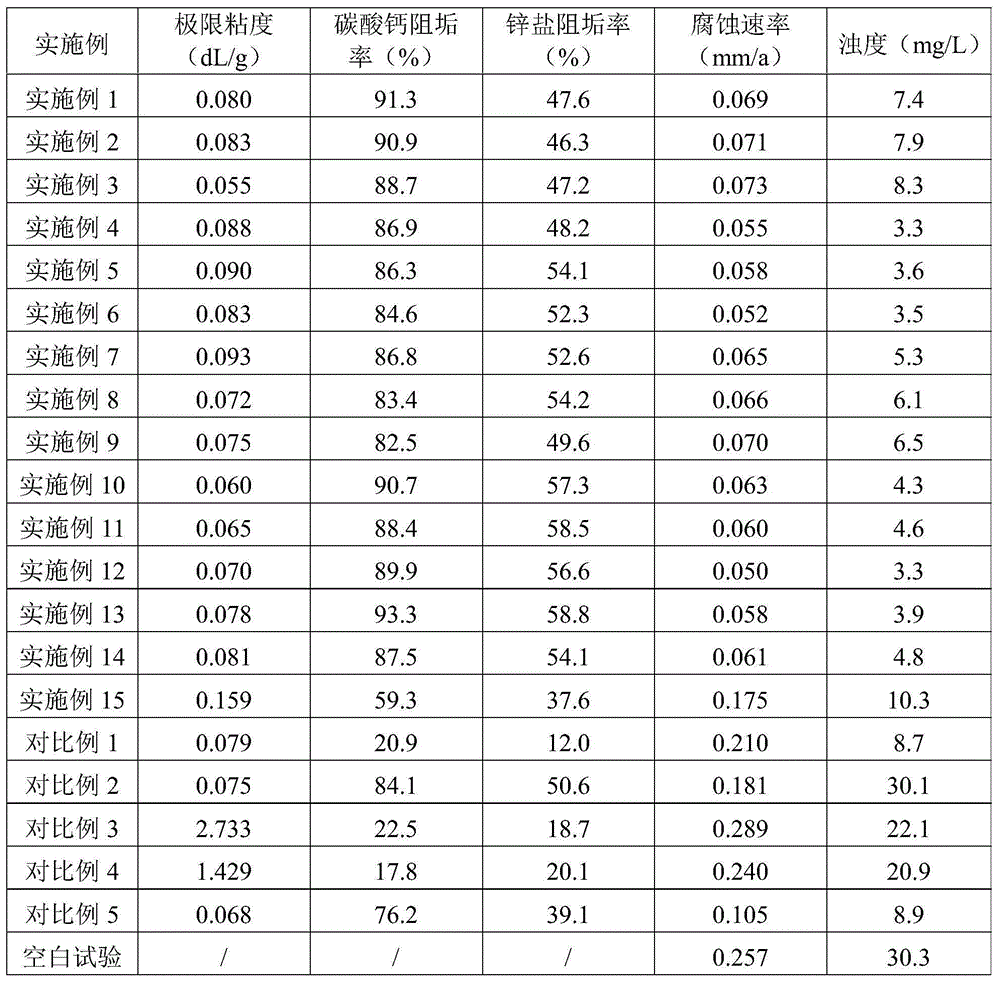

Phosphorus-free water treatment agent, and preparation method and application thereof

ActiveCN105984964AGood flocculation effectGood scale and corrosion inhibitionScale removal and water softeningCarboxylic acidEthyl acrylate

The invention discloses a phosphorus-free water treatment agent, a preparation method for the phosphorus-free water treatment agent, and an application of the phosphorus-free water treatment agent in treatment of circulating water. The phosphorus-free water treatment agent is prepared from dimethyldiallylammonium chloride, unsaturated carboxylic acid and acrylate by polymerization, wherein the phosphorus-free water treatment agent has a limiting viscosity of 0.05 to 0.16 dL / g; the unsaturated carboxylic acid is selected from acrylic acid, maleic acid, methacrylic acid or itaconic acid; and the acrylate is selected from methyl acrylate, ethyl acrylate or hydroxypropyl acrylate. The preparation method for the phosphorus-free water treatment agent comprises the following steps: mixing monomers, an initiator and a molecular weight regulator in a manner of dropwise adding at 50 to 95 DEG C, and after dropwise adding is completed, continuing to carry out a reaction at 75 to 95 DEG C for 1 to 4 h, wherein the monomers are the dimethyldiallylammonium chloride, unsaturated carboxylic acid and acrylate. The phosphorus-free water treatment agent provided by the invention has good scale and corrosion inhibition effects, and has good flocculation effects on suspended matters in the circulating water at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

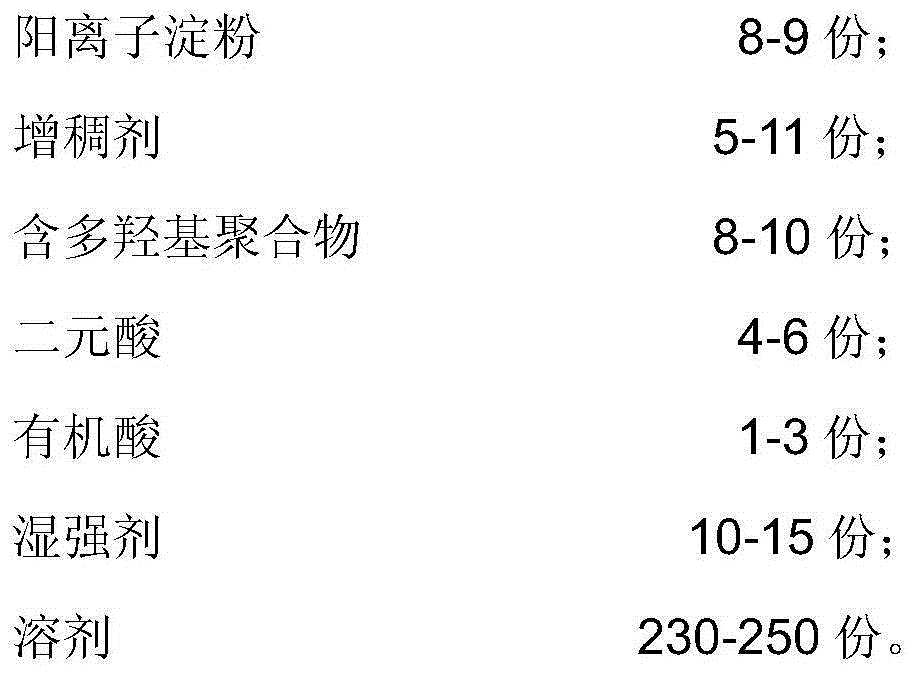

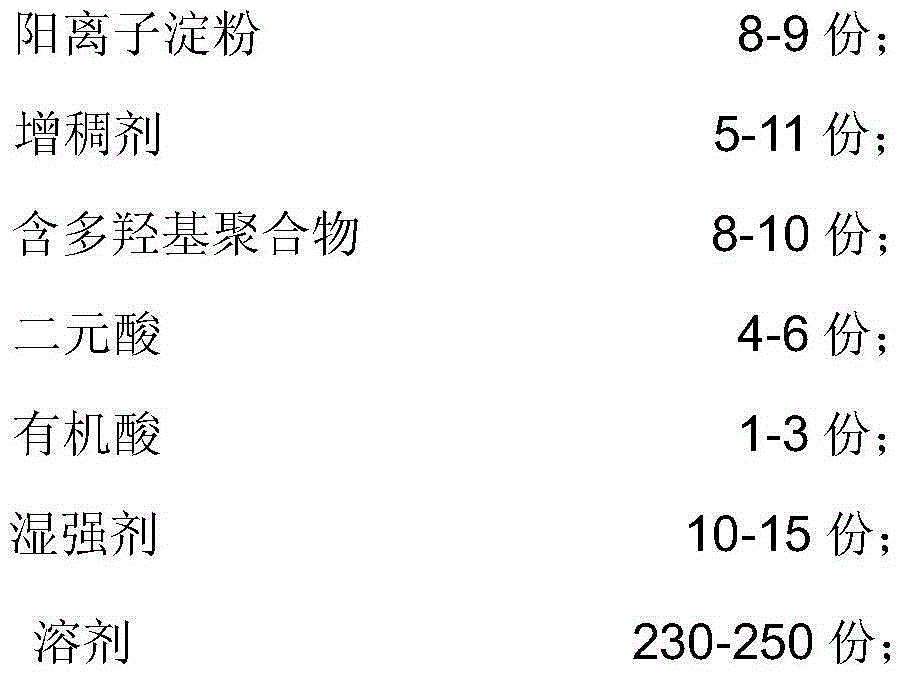

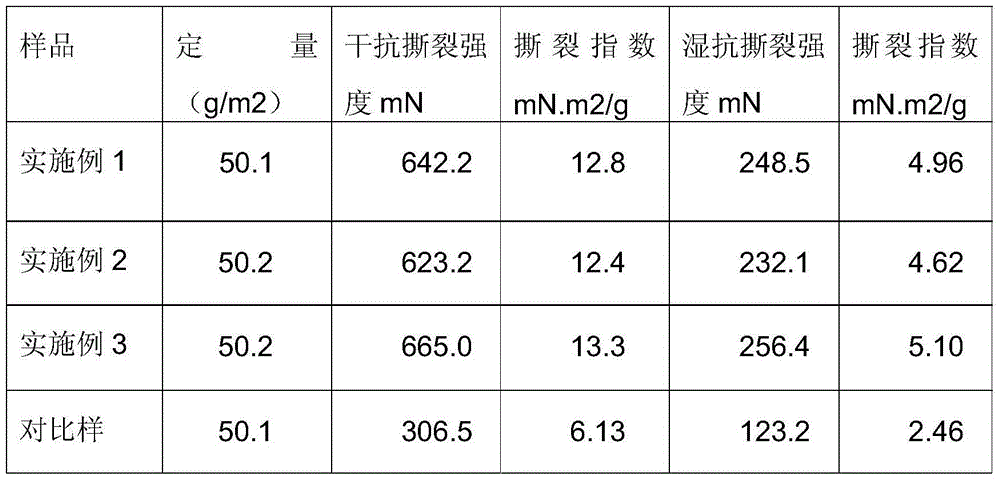

Tearing strength reinforcing agent for papermaking and preparation method of tearing strength reinforcing agent

InactiveCN105568761AHigh tear strengthHigh strengthReinforcing agents additionPaper/cardboardPolyvinyl alcoholPapermaking

The invention discloses a tearing strength reinforcing agent for papermaking and a preparation method of the tearing strength reinforcing agent. The method comprises the steps of mixing guar gum, galactomannan gum, cationic starch, polyvinyl alcohol, acetic acid, polyamideimide epichlorohydrin, methylene succinic acid (itaconic acid) and the like, and carrying out compounding, stirring and other steps so as to prepare the reinforcing agent. According to the tearing strength reinforcing agent prepared by adopting the method provided by the invention, the performance is greatly improved, the solid content is 14.5-16.5%, and the viscosity is 20-35 cps; the tearing strength reinforcing agent is added at the wet part, the tearing strength of paper can be greatly improved, and the paper is endowed with good wet strength and dry strength.

Owner:DSSUN NEW MATERIAL SHANDONG

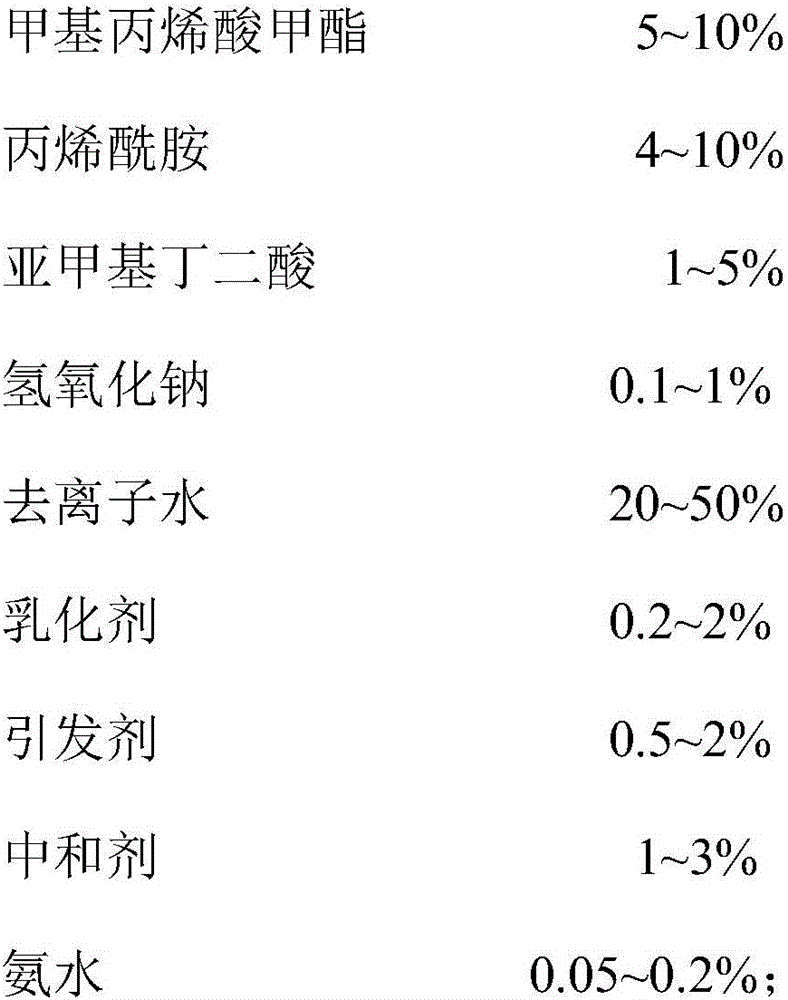

Paper-plastic compound adhesive and preparation method thereof

ActiveCN106479407AImprove stabilityReduce the impact of stabilityEster polymer adhesivesAdhesiveSuccinic acid

The invention belongs to the technical field of adhesives and particularly relates to a paper-plastic compound adhesive. The paper-plastic compound adhesive is prepared from the following components in percentage by weight: 15%-35% of butyl acrylate, 10%-20% of vinyl acetate, 5%-10% of methyl methacrylate, 4%-10% of acrylamide, 1%-5% of methylene succinic acid, 0.1%-1% of sodium hydroxide, 20%-50% of deionized water, 0.2%-2% of an emulsifier, 0.5%-2% of an initiator, 1%-3% of a neutralizing agent and 0.05%-0.2% of aqueous ammonia. The invention further provides a preparation method of the paper-plastic compound adhesive. Compared with the prior art, on the one hand, the added initiator is non-toxic and high in initiation efficiency, and the added neutralizing agent has a relatively small effect on the system stability, so that the prepared adhesive has relatively high stability; on the other hand, the components in the adhesive cooperate with one another, and the adhesive strength of the adhesive is improved.

Owner:东莞市冠力胶业有限公司

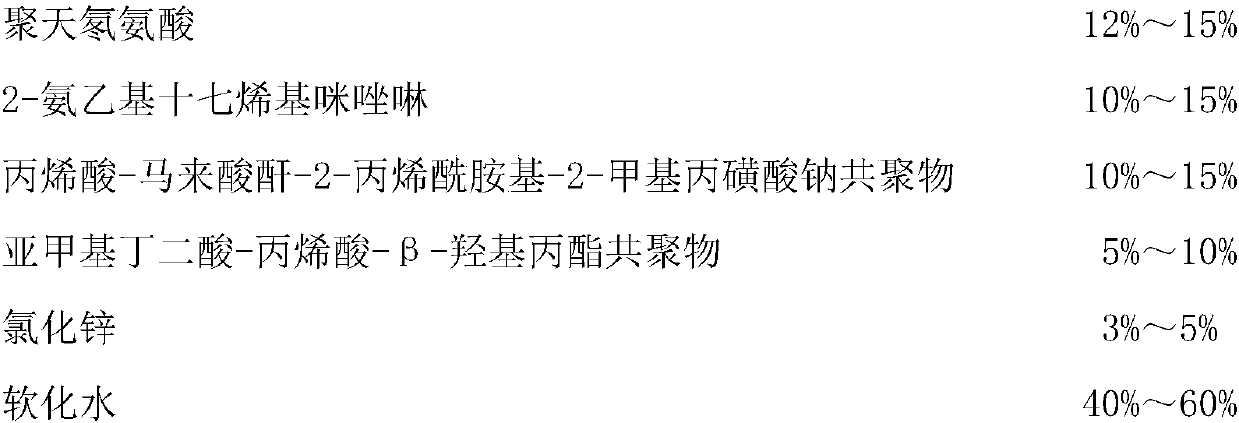

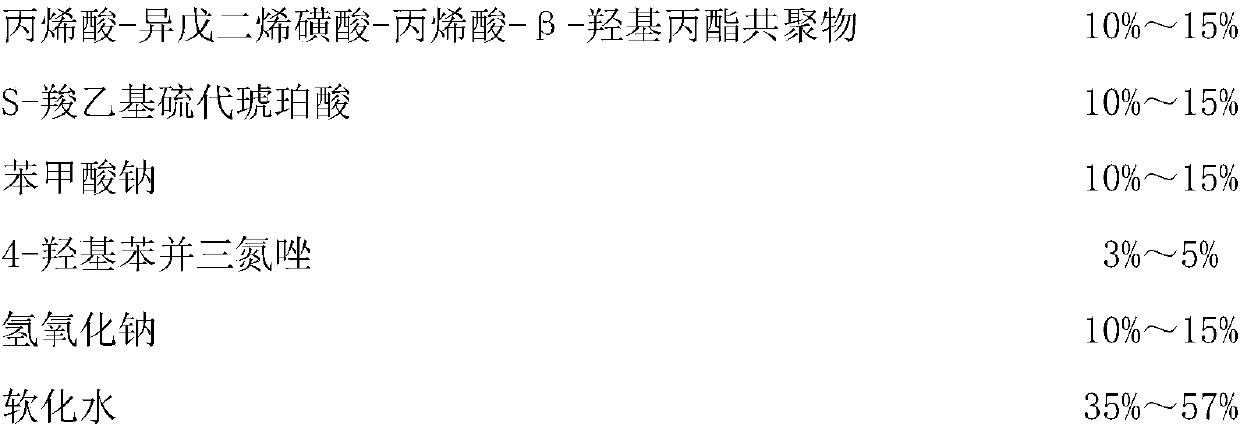

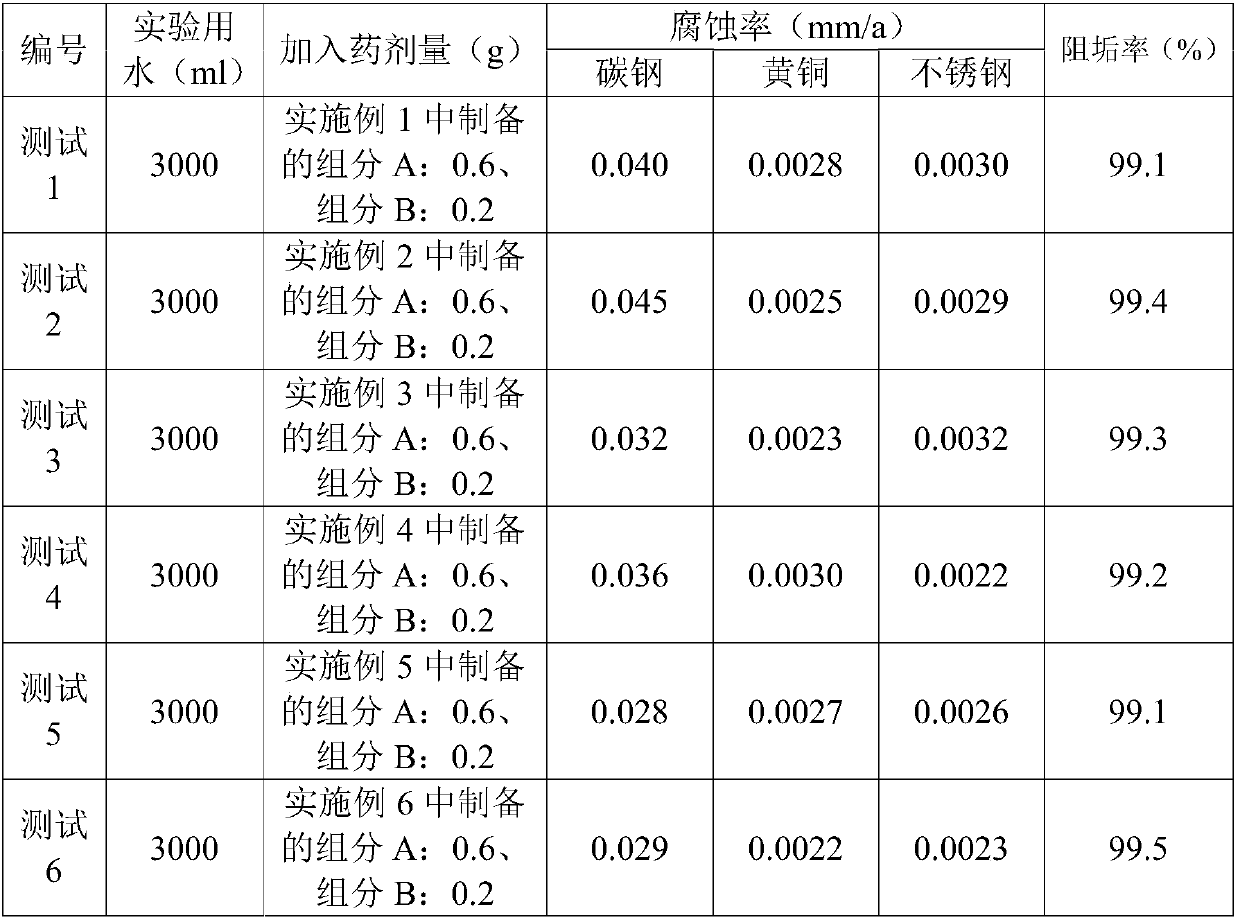

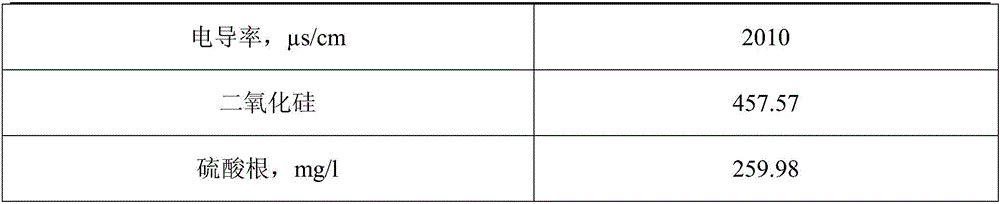

Corrosion and scale inhibitor for circulation cooling water system with desalted seawater as replenishing water

InactiveCN107698041ANot easy to decomposeImprove stabilitySeawater treatmentTreatment using complexing/solubilising chemicalsWater desalinationSoftened water

The invention discloses a corrosion and scale inhibitor for a circulation cooling water system with desalted seawater as replenishing water. The corrosion and scale inhibitor comprises a component A and a component B, wherein the component A comprises 12-15% of polyaspartic acid, 10-15% of 2-aminoethyl-heptadecene imidazoline, 10-15% of an acrylic acid-maleic anhydride-2-acrylamide-2-methyl sodiumsulfonate copolymer, 5-10% of a itaconic acid-acrylic acid-beta-propylparaben copolymer, 3-5% of zinc chloride and 40-60% of softened water; the component B comprises 10-15% of an acrylic acid-isoprene sulfonic acid-acrylic acid-beta-propylparaben copolymer, 10-15% of S-carboxyalkylthiosuccinic acid, 10-15% of sodium benzoate, 3-5% of 4-phenol benzotriazole, 10-15% of sodium hydroxide and 35-57%of softened water; the mass ratio of the component A to the component B is 3:1. The corrosion and scale inhibitor disclosed by the invention is good in corrosion and scale inhibition property, the water resource is saved, and the service life of equipment is prolonged.

Owner:TIANJIN ZHENGDA SCI &TECH CO LTD +2

Phosphorus-free water treatment agent, and preparation method and application thereof

ActiveCN105984965AGood flocculation effectGood scale and corrosion inhibitionScale removal and water softeningCarboxylic acidCorrosion

The invention discloses a phosphorus-free water treatment agent, a preparation method for the phosphorus-free water treatment agent, and an application of the phosphorus-free water treatment agent in treatment of circulating water. The phosphorus-free water treatment agent is prepared from dimethyldiallylammonium chloride and unsaturated carboxylic acid by polymerization, wherein the phosphorus-free water treatment agent has a limiting viscosity of 0.05 to 0.15 dL / g; and the unsaturated carboxylic acid is one or more selected from the group consisting of acrylic acid, maleic acid, methacrylic acid or itaconic acid. The preparation method for the phosphorus-free water treatment agent comprises the following steps: mixing monomers, an initiator and a molecular weight regulator in a manner of dropwise adding at 50 to 95 DEG C, and after dropwise adding is completed, continuing to carry out a reaction at 75 to 95 DEG C for 1 to 4 h, wherein the monomers are the dimethyldiallylammonium chloride and unsaturated carboxylic acid. The phosphorus-free water treatment agent provided by the invention has good scale and corrosion inhibition effects, and has good flocculation effects on suspended matters in the circulating water at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wear-resistant curable coating for walls

The invention discloses a wear-resistant curable coating for walls. The wear-resistant curable coating is prepared from the following raw materials, by weight, 2.5-4.3 parts of polyvinyl butyral, 2.1-3.4 parts of sodium hexametaphosphate, 0.8-1.5 parts of acrylic polyol, 5.6-7.2 parts of 12-hydroxystearic acid, 4.5-6.6 parts of tetramethylammonium chloride, 1.2-1.5 parts of methylenesuccinic acid, 0.3-0.7 part of a filling material, 0.3-0.5 part of a dispersant and 0.1-0.2 part of a mildew preventive. The ultraviolet-proof wear-resistant curable coating has advantages of high production efficiency, low energy consumption, low cost and the like. By the use of the coating, a paint film obtained has characteristics of good appearance, excellent scratch resistance, wear resistance and excellent solvent resistance. In addition, an aqueous colored coating combination contains no volatile organic compounds or has low content of volatile organic compounds, has low environmental pollution performance and can be used as an environmental protection material.

Owner:QINGDAO DESHENGTAI CONSTR INSTALLATION ENG

Anti-static phosgene modified polyacrylonitrile carbon fiber

InactiveCN102465360AStrong impact resistanceImprove wear resistancePolyurea/polyurethane coatingsElectrically-conductive paintsCarbon fibersAcrylonitrile

The invention discloses an anti-static phosgene modified polyacrylonitrile carbon fiber which is characterized by being prepared through the steps of: uniformly mixing 180 parts of acrylonitrile, 10 parts of methyl acrylate and 10 parts of itaconic acid, adding an azo initiator of 1 part of dimethyl 2,2'-azobis(2-methylpropionate) and 1 part of 1-((cyano-1-methylethyl)azo)formamide for carrying out polymerization reaction to produce an polyacrylonitrile base carbon fiber precursor; and modifying the polyacrylonitrile base carbon fiber precursor through COCl2 by adopting an immersion method. An anti-static coating obtained by using the carbon fiber in the invention as an anti-static additive has better tensile property, impact resistance, wear resistance and corrosion resistance, and also has better anti-static property.

Owner:XIAOJIAN TECH DALIAN

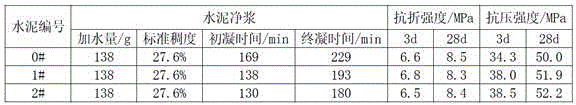

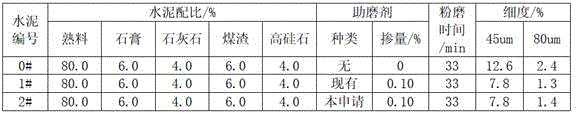

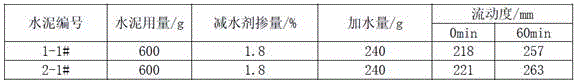

Grinding aid for improving compatibility of cement and water reducing agent

The invention relates to the technical field of cement grinding aids, in particular to a grinding aid for improving compatibility of cement and a water reducing agent. The grinding aid is prepared from, by weight, 20%-25% of diethanolisopropanolamine, 10%-15% of inorganic salt, 20%-30% of itaconic acid industrial effluent and the balance water. In use of the grinding aid, cement hydration can be decelerated, and cement paste is high in fluidity relatively and conducive to actions of the water reducing agent; since itaconic acid is binary unsaturated carboxylic acid, the itaconic acid is easier to compatible to a polycarboxylic water reducing agent according to the principle that the similar substances are more likely to be dissolved by each other, and a polymerization reaction between the itaconic acid and excessive macromonomers in the polycarboxylic water reducing agent can be realized under appropriate conditions to increase effective components of the polycarboxylic water reducing agent, so that effectiveness in use of the water reducing agent is improved. Therefore, compatibility of cement and the concrete water reducing agent is improved on the premise that grinding efficiency and cement strength are almost unchanged.

Owner:安徽海螺材料科技股份有限公司 +1

Preparation method of superabsorbent resin rich in plant nutrients

The invention discloses a preparation method of superabsorbent resin rich in plant nutrients, belonging to the field of resin production. The preparation method comprises the steps of firstly, pretreating potatoes; then, adding monopotassium phosphate and urea into the potatoes to prepare powder; next, preparing a homogeneous-phase monomer mixed solution from 2-itaconic acid and a crosslinking agent; dissolving the prepared powder into distilled water, pasting under microwave heating, and slowly and dropwise adding the mixed solution after pasting; and finally, dropwise adding an ammonium persulfate water solution into a reaction system to carry out polymerization reaction, and smashing into particles to obtain the superabsorbent resin rich in plant nutrients. Compared with different resins, the superabsorbent resin prepared by using the preparation method not only has favorable water absorption and retention properties, but also is rich in plant nutrients including nitrogen, phosphorus and potassium, can be widely applied to agriculture and forestry aspects and is environmentally friendly; in addition, the preparation method is simple in production process and low in cost.

Owner:雷春生

Non-aldehyde low-temperature adhesive

The invention relates to an aldehyde-free low-temperature adhesive and belongs to the technical field of textile printing. The aldehyde-free low-temperature adhesive is characterized in that the adhesive is prepared from raw materials in weight portion: 65 to 75 portions of deionized water, 0.2 to 0.3 portion of fatty alcohol polyethenoxy ether ammonium sulfate salt, 0.8 to 0.9 portion of fatty alcohol polyethenoxy ether, 0.4 to 0.6 portion of methylene-succinic acid, 1 to 2 portions of glycidyl methacrylate, 15 to 18 portions of acrylic ester, 3 to 5 portions of styrene, 5 to 6 portions of acrylate and 0.02 portion of ammonium peroxydisulfate. A product is suitable for printing and coloring pure cotton, polyester cotton and other knitting fabrics and belongs to anionic / nonionic acrylate self-crosslinking latex. The aldehyde-free low-temperature adhesive has the characteristics that the adhesive can self crosslink at low temperature, need no high-temperature roasting and can reach properties of high fastness, high dry resistance and wet rubbing; and the aldehyde-free low-temperature adhesive has the highest level of environmental protection and does not contain APEO, phthalate and other prohibited chemicals.

Owner:SHANDONG JINLU CHEM

Scale inhibiting-dispersing agent for reverse osmosis membrane and preparation method thereof

ActiveCN106000112AReduce dosageEasy to transportSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEtherReverse osmosis

The invention belongs to the technical field of water treatment and in particular relates to a scale inhibiting-dispersing agent for a reverse osmosis membrane and a preparation method thereof. The scale inhibiting-dispersing agent is characterized by being prepared from the following components in percentage by weight: 10 percent to 45 percent of 2-methylenesuccinic acid-hydroxy-propyl acrylate copolymer, 24 percent to 55 percent of polyepoxysuccinic acid, 10 percent to 35 percent of polyethylene glycol monoallyl ether and 5 percent to 10 percent of 2,4-diaminotoluene. The scale inhibiting-dispersing agent for the reverse osmosis membrane, provided by the invention, is a 8-time concentrated solution; the dosage is effectively reduced and the scale inhibiting-dispersing agent does not contain environmentally harmful components including phosphorus and the like; membrane pollution problems caused by a deposition problem on the reverse osmosis membrane, caused by various types of insoluble salts, can be effectively solved; the invention further provides the preparation method of the scale inhibiting-dispersing agent.

Owner:INLEN CHEM TECH

Modified calcium carbonate and preparation method thereof

InactiveCN106752091AGood dispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsTributyl citratePoly(butylene succinate)

The invention discloses modified calcium carbonate and a preparation method thereof. The modified calcium carbonate is prepared from, by weight, 90-110 parts of calcium carbonate, 6-10 parts of diacetone acrylamide, 8-10 parts of poly(butylene succinate), 6-8 parts of methylene succinic acid, 2-4 parts of disodium methylene dinaphthalene sulfonate, 1-3 parts of dibutyltin maleate, 2-4 parts of polyaluminum chloride, 2-4 parts of mica powder, 4-6 parts of nano TiO2, 5-7 parts of deionized water, and 7-9 parts of both acetyl tributyl citrate and dioctyl terephthalate, wherein the weight part ratio of the acetyl tributyl citrate to the dioctyl terephthalate is 6-8:1. The modified calcium carbonate has good dispersibility and is improved in various mechanical performances, which may be related to the weight part ratio of the acetyl tributyl citrate to the dioctyl terephthalate; when the weight part ratio of the acetyl tributyl citrate to the dioctyl terephthalate is 6-8:1, the modified calcium carbonate has optimum performances.

Owner:何淑琼

Viscosity reduction type polycarboxylic acid water reducer and preparation method thereof

ActiveCN113278144AGood viscosity reduction effectLess restraintSolid waste managementButanedioic acidPolyethylene glycol

The invention belongs to the field of concrete admixtures and relates to a viscosity reduction type polycarboxylic acid water reducer which is prepared from the following raw materials: polyethylene glycol, maleic anhydride, methylene succinate, methylene succinic acid, a chain transfer agent and an initiator. A preparation method of the viscosity reduction type polycarboxylic acid water reducer comprises the following steps: weighing polyethylene glycol, adding maleic anhydride, performing a reaction, and uniformly mixing polyethylene glycol maleate with a chain transfer agent, an initiator and deionized water to obtain a mixed substrate; mixing methylene succinate, methylene succinic acid and deionized water to obtain a mixed solution A; mixing hexamethylphosphoric triamide and deionized water to obtain a mixed solution B; and dropwise adding the mixed solution A and the mixed solution B into the mixed substrate. By adding the methylene succinate and the methylene succinic acid, the water reducer has better water reducing property and viscosity reducing property. The hexamethylphosphoric triamide is added, so that the viscosity reduction performance of the water reducer is better.

Owner:北京金隅节能科技有限公司 +3

Anti-ultraviolet wear-resistant curable coating

The invention discloses an anti-ultraviolet wear-resistant curable coating which is prepared from the following raw materials in parts by weight: 2.5-4 parts of a photosensitive initiator, 2-3 parts of nano-zirconium oxide, 0.8-1.5 parts of acrylic polyol, 5.6-7.2 parts of carbamate, 4.5-6.6 parts of vinyl acetate maleate, 1.2-1.5 parts of itaconic acid, 0.35-0.78 part of a filler, 0.3-0.5 part of a dispersant and 0.1-0.2 part of a mildew-proof agent. The anti-ultraviolet wear-resistant curable coating disclosed by the invention can obtain an aesthetic and high-performance coated film by performing spraying construction once; in comparison with a traditional way of coating twice or three times, the anti-ultraviolet wear-resistant curable coating has the advantages of high production efficiency, low energy consumption, low cost and the like, the obtained coated film has the characteristics of great appearance, excellent resistance to scratching, wear resistance and solvent resistance and the like; and in addition, a water-based colored coating composition has the advantages of no or a relatively low content of volatile organic compounds and little environmental pollution, and can be used as an environment-friendly material.

Owner:QINGDAO DESHENGTAI CONSTR INSTALLATION ENG

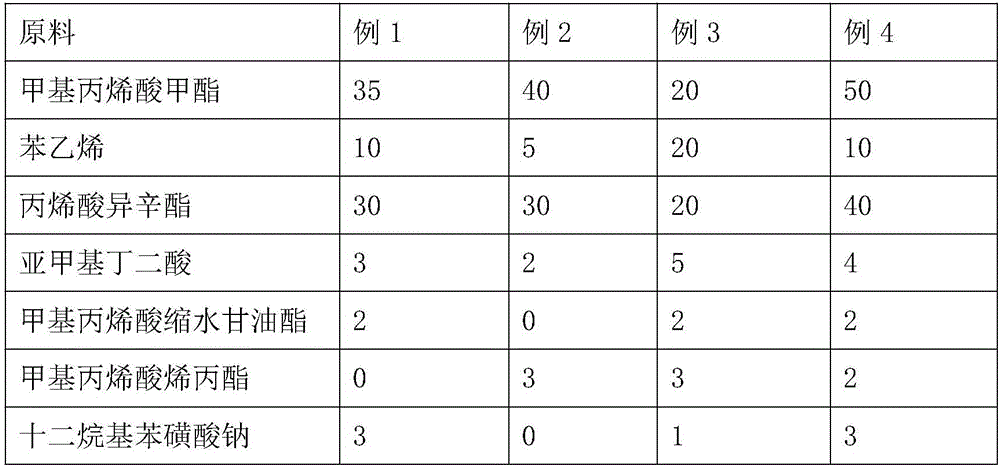

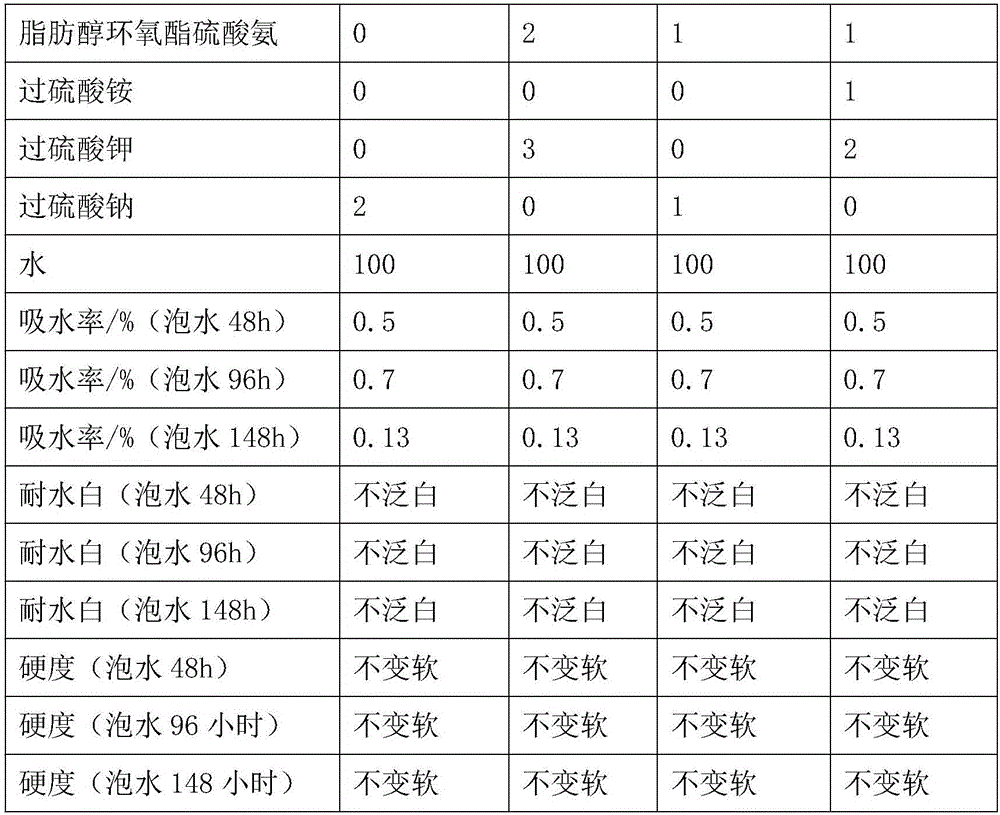

Low-water-absorptivity stone-like coating emulsion and preparation method thereof

The invention discloses low-water-absorptivity stone-like coating emulsion and a preparation method thereof, and belongs to the technical field of building coatings. The low-water-absorptivity stone-like coating emulsion is prepared from the following raw materials in parts by weight: 20 to 50 parts of methyl methacrylate, 5 to 20 parts of styrene, 20 to 40 parts of ethylhexyl acrylate, 2 to 5 parts of a functional monomer, 2 to 5 parts of a crosslinking monomer, 2 to 4 parts of an emulsifier, 1 to 3 parts of persulfate and 100 parts of water. The functional monomer is itaconic acid; the crosslinking monomer is at least one of glycidyl methacrylate and allyl methacrylate; the emulsifier is at least one of sodium dodecyl benzene sulfonate and ammonium fatty alcohol epoxy ester sulfate. The low-water-absorptivity stone-like coating emulsion disclosed by the invention has the characteristics of low water absorptivity, water white resistance and high hardness.

Owner:成都巴德富科技有限公司

Styling gel

InactiveCN103445981AExcellent adhesionAvoid deformationCosmetic preparationsHair cosmeticsSuccinatesMethylenebutanedioic acid

The embodiment of the invention discloses styling gel which comprises the following components in mass ratio: PVP / VA (Poly Vinyl Pyrrolidone / Vinyl Acetate), acrylic acid, methylene succinate, triethanolamine, de-ionized water and appropriate essence. The styling gel disclosed by the invention is good in adhesion, not easy to deform, good in styling effect and long in styling lasting time.

Owner:广东柏亚化妆品有限公司

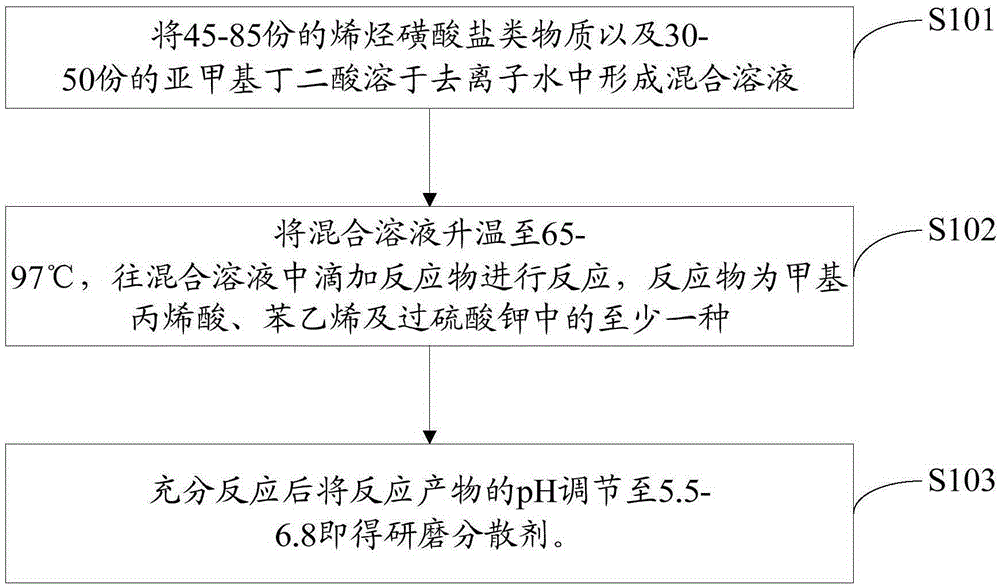

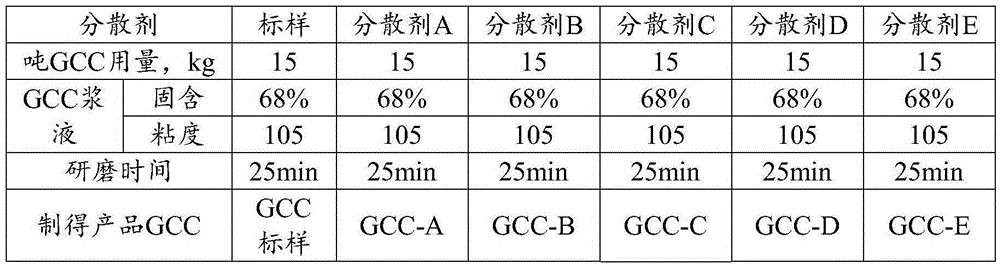

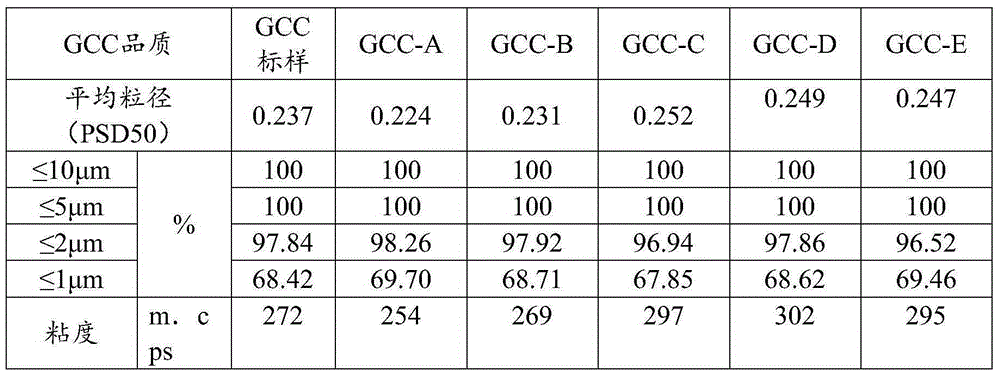

Preparation method and application of grinding and dispersing agent

InactiveCN105254806AGood dispersionExcellent optical propertiesPigment treatment with macromolecular organic compoundsPigment physical treatmentPotassium persulfateItaconic acid

The invention discloses a preparation method and application of a grinding and dispersing agent. The preparation method of the grinding and dispersing agent comprises the following steps of dissolving 45 to 85 parts of olefin sulphosalts materials and 30 to 50 parts of itaconic acid into deionized water to form a mixed solution; warming the mixed solution to be 65 to 97 DEG C; dropwise adding a reactant into the mixed solution to react, wherein the reactant is at least one of methacrylic acid, styrene and potassium persulfate; adjusting pH of a reaction product to be 5.5 to 6.8 after fully reacting so as to obtain the grinding and dispersing agent. Through the method, the GCC grinding efficiency can be improved, the ground GCC grain size is smaller, and the granulometric distribution interval is narrower.

Owner:GOLD EAST PAPER JIANGSU

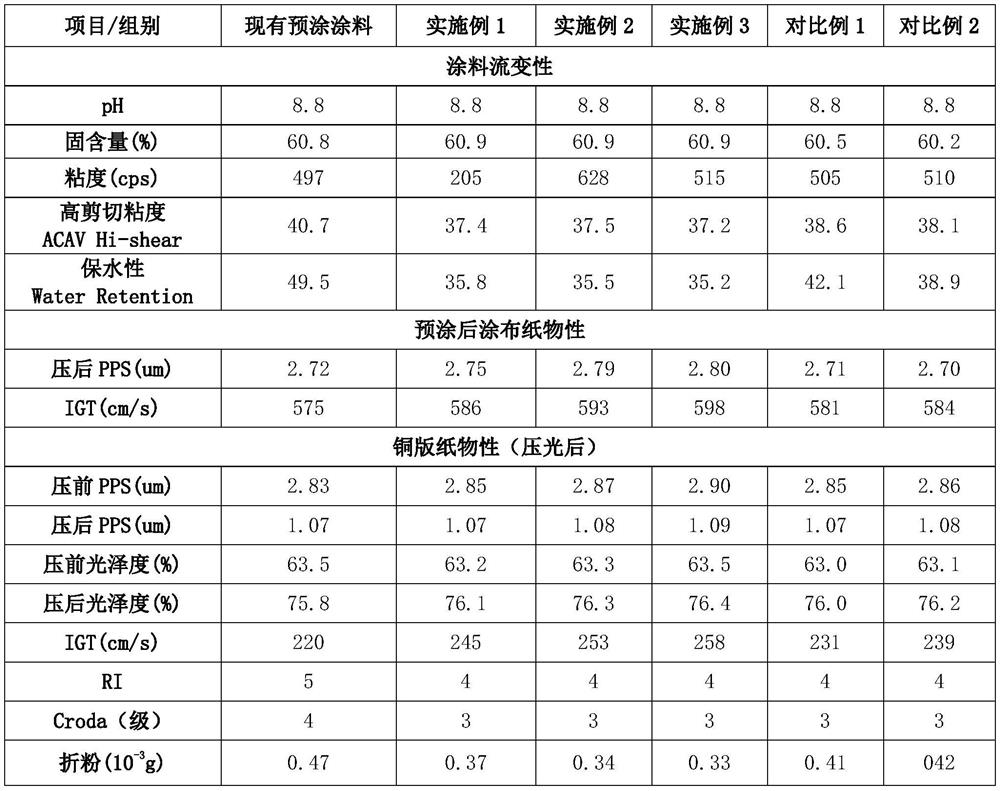

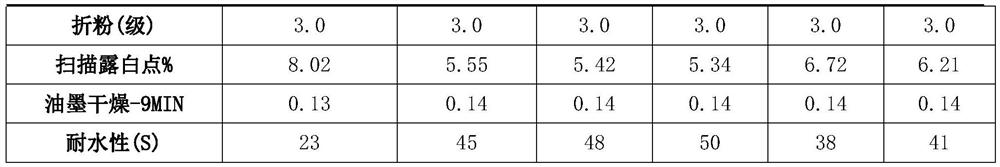

A kind of biological latex for coating, pre-coating paint and preparation method thereof

ActiveCN108677610BEasy to degradeImprove rheologyPaper/cardboardPulp material addition processesBiotechnologyAmylase

The invention provides coating biological latex, precoating paint and a preparation method of precoating paint. The biological latex is prepared from the following raw materials of starch, amylase anda biological intermediate, wherein the biological intermediate is prepared from the following raw materials of itaconic acid, polypropylene glycol and hydrogen peroxide. Compared with the existing paint, the precoating paint prepared by the biological latex disclosed by the invention has a good rheological property and a better water retention capacity; furthermore, the precoating paint has lowerand stabler high shear viscosity, so that a large high-speed paper machine has good operation performance. In addition, after the precoating paint disclosed by the invention is coated, the physical property of finished paper is obviously improved; IGT of the finished paper is remarkably improved, water resistance of the finished paper is obviously improved, and coated paper has better printing performance. The coated paper is suitable for a high-speed printing machine, layering and bubbling in a printing process are avoided, and the light spot phenomenon after printing is avoided.

Owner:HAINAN JINHAI PULP & PAPER

Novel power plant cooling water scale inhibitor corrosion inhibitor

InactiveCN109110931AAvoid badReduce vacuumSpecific water treatment objectivesScale removal and water softeningCooling towerCooling effect

The invention discloses a novel power plant cooling water scale inhibitor corrosion inhibitor. The novel power plant cooling water scale inhibitor corrosion inhibitor is prepared from the following raw materials: acrylic acid, methyl acrylate, cis-butenedioic acid, 2-itaconic acid, ammonium persulfate and sodium hydrogen sulfite. Compared with the prior art, the novel power plant cooling water scale inhibitor corrosion inhibitor has the following advantages: in the prior art, the scaling problem of the power plant cooling water system cannot be thoroughly solved, which results in the scaling of the system; the scaling of a power plant steam condenser directly increases the terminal temperature difference and decreases the vacuum degree, and the power generation cost is increased; after anoil cooler is scaled, the temperature of a whole lubricating oil system is high, and the scaling of an air cooler influences the air cooling temperature; the scaling of a cooling tower filler influences the cooling effect of a cooling tower; the problems in the prior art increase the power generation cost of a power plant and influence the operation stability of the power plant; Zhongrui 863 scale-inhibition corrosion inhibitor thoroughly solves the scaling problem of the power plant cooling system, and the power plant cooling system is operated at an optimum state; and the power generation cost is maximally reduced, the stable operation time can be prolonged, and the scales do not need to be cleaned after the power failure.

Owner:天津中瑞水处理剂有限公司

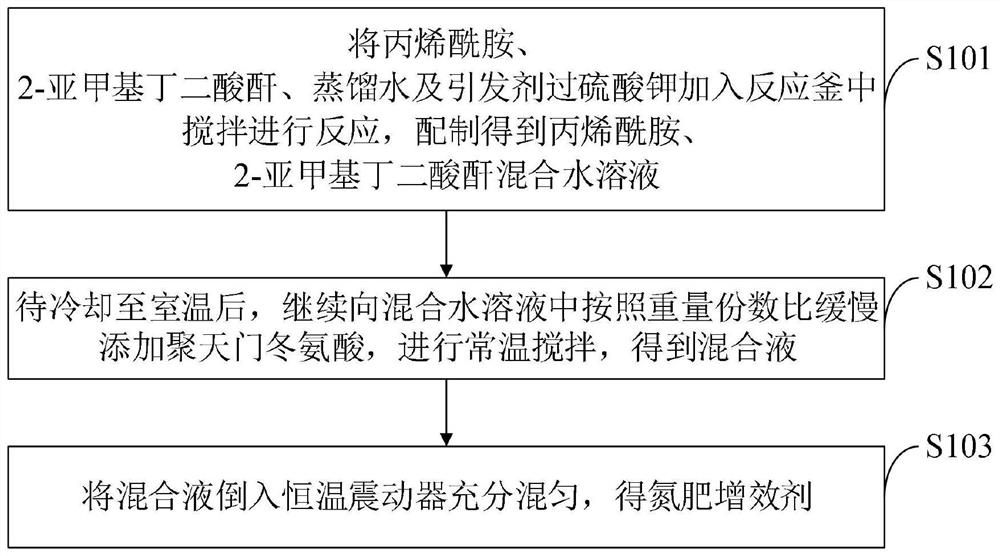

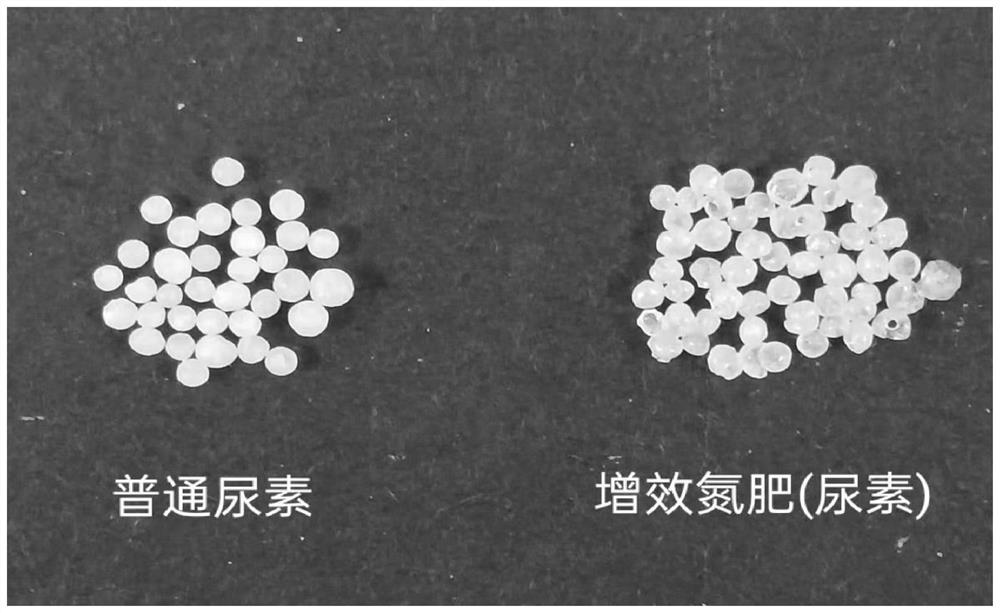

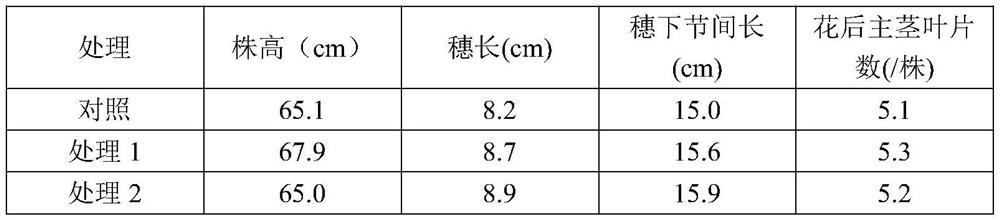

Nitrogen fertilizer synergist, preparation method and application

PendingCN114538995ASolve the problem of volatilitySolve the leaching of nitrogen fertilizerAgriculture gas emission reductionSolid/semi-solid fertilisersPotassium persulfateMeth-

The invention belongs to the technical field of fertilizers, and discloses a nitrogen fertilizer synergist, a preparation method and application, the nitrogen fertilizer synergist comprises the following components in parts by weight: 15-20 parts of polyaspartic acid, 10-15 parts of 2-methylene succinic anhydride, 5-7.5 parts of acrylamide, 0.2-0.6 part of potassium persulfate, and 800-1200 parts of distilled water; the preparation method of the nitrogen fertilizer synergist comprises the following steps: weighing the raw material components in parts by weight, carrying out a dissolution reaction in a reaction kettle, and fully and uniformly mixing the mixed solution through a constant-temperature vibrator to obtain the nitrogen fertilizer synergist. The effective component polyaspartic acid of the nitrogen fertilizer synergist disclosed by the invention has good ion adsorbability and biodegradability; after being copolymerized with 2-methylene succinic anhydride and acrylamide, the compound is coated on the surfaces of fertilizer particles to form a protective film, so that the volatilization of a nitrogen fertilizer and the leaching and runoff loss of the nitrogen fertilizer can be reduced, the slow release effect of the fertilizer is achieved, the growth and development of crops are promoted, and the yield and the utilization efficiency of the fertilizer are improved.

Owner:QINGDAO AGRI UNIV

Color-photosensitive aqueous polyurethane emulsion for textiles and preparation method thereof

ActiveCN102199877BExcellent photochromic effectImprove performanceFibre treatmentButanedioic acidPropanoic acid

Owner:ZHEJIANG LUOXING IND CO LTD

Method for preparing dispersing agent for coating by naphthalenesulfonate wastewater

The invention discloses a method for preparing a dispersing agent for a coating by naphthalenesulfonate wastewater, and belongs to the field of preparation of dispersing agents for coatings. The method comprises the following steps: filtering the naphthalenesulfonate wastewater to remove impurities, mixing and refluxing with itaconic acid, and removing dissolved impurities in the wastewater; reacting with the substances of acetic ether and the like under the action of a palladium catalyst to prepare a coarse dispersing agent for the coating; and adding a surfactant to mix evenly through pH adjustment, so as to prepare the dispersing agent for the coating. The method has the beneficial effects that the preparation method is simple; a hydrophilic group of the obtained dispersing agent for the coating is firmly combined on the particle surface with relatively low polarity or non-polarity; and a lipophilic group has enough carbon chain length, can generate an enough steric-hinerance effect in a water-based dispersion system, and has good solubility and associativity in water.

Owner:嘉兴泰格高新材料股份有限公司

Processing technology of water-base gravure ink copolymer emulsion

InactiveCN101575396BMeet environmental protection requirementsReduce usageMonocarboxylic acid ester polymer adhesivesInksWater basedCarvacryl acetate

The invention discloses a processing technology of a water-base gravure ink copolymer emulsion, the method of the processing technology comprises the following steps: first mixing allyloxy hydroxypropy sulfonate sodium with water, adding a certain amount of mixed solution consisting of vinyl acetate, tertdecanoic acid ethenyl ester, itaconic acid, hydroxyethyl acrylate and dodecyl mercaptan, heating the solution up to 60-70 DEG C, then adding a certain amount of ammonium persulfate aqueous solution for reaction to the temperature of 78-82 DEG C, starting dropwise adding the remaining mixed solution when the reflux stops, adding the ammonium persulfate aqueous solution every one-hour addition, adding the remaining ammonium persulfate aqueous solution upon the ending of the addition for heatpreservation at the temperature of 90-95 DEG C, and then cooling to prepare the emulsion. The material is mainly used for preparing a water-base gravure ink binder that is applied to tipping paper. On the one hand, the prepared binder saves a large amount of food, and on the other hand reduces the use of organic solvents, thereby effectively avoiding the defects that the organic solvent is inevitably combustible and explosive, pollutes environment and jeopardizes health of production worker, and the environment-friendly requirements of the binder are met.

Owner:毛仕龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com