Preparation method for compound corrosion-inhibiting scale inhibitor

A technology of corrosion and scale inhibitor and initiator, applied in chemical instruments and methods, descaling and water softening, bathing facility wastewater treatment, etc. Increase and increase the effect of scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

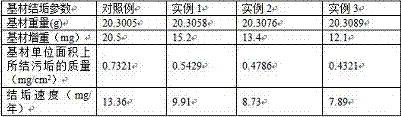

example 1

[0023] First weigh 20g of glutamic acid and add it to a three-necked flask with a thermometer and a reflux device, move the flask into a heat-collecting thermostatic stirrer, control the temperature of the stirrer at 40°C, and the speed of the stirrer at 220r / min, and then add Add 220mL of water to the flask, stir and mix for 15min, then add 15% sodium hydroxide solution to adjust the pH to 10.8, add 25mL epichlorohydrin dropwise to the flask while stirring, control the dropping time for 30min, and dropwise Afterwards, heat up to 60°C, stir and react for 4 hours, then add 300mL of absolute ethanol to mix and stir for 20min, filter, obtain the filtrate and spray dry to obtain epoxy-modified amino acid, take 12g of methylene succinic acid, 50mL of iso Propanol and 3g tert-butyl hydroperoxide were added to the beaker, the beaker was placed in a water bath, the temperature was controlled at 90°C, and the magnetic stirring reaction was carried out for 3h. After the reaction was comp...

example 2

[0025] First weigh 15g of glutamic acid and add it to a three-necked flask with a thermometer and a reflux device, then move the flask into a heat-collecting thermostatic stirrer, control the temperature of the stirrer at 30°C, and the speed of the stirrer at 200r / min, and then pour it into the flask Add 200mL of water to the flask, stir and mix for 10min, then add 15% sodium hydroxide solution to adjust the pH to 10.5, add 20mL of epichlorohydrin dropwise to the flask while stirring, control the dropping time to 25min, and dropwise Afterwards, heat up to 50°C, stir and react for 3 hours, then add 200mL of absolute ethanol to mix and stir for 15min, filter, obtain the filtrate and spray dry to obtain epoxy-modified amino acid, take 8g of methylene succinic acid, 40mL of iso Propanol and 1g of tert-butyl hydroperoxide were added to the beaker, the beaker was placed in a water bath, the temperature was controlled at 80°C, and the reaction was carried out with magnetic stirring fo...

example 3

[0027] First weigh 17g of glutamic acid and add it to a three-necked flask with a thermometer and a reflux device, move the flask into a heat-collecting constant temperature stirrer, control the temperature of the stirrer at 35°C, and the speed of the stirrer at 210r / min, and then add Add 210mL of water to the flask, stir and mix for 12min, then add 15% sodium hydroxide solution to adjust the pH to 10.7, add 22mL of epichlorohydrin dropwise to the flask while stirring, control the dropping time to 27min, and the dropwise addition is completed Afterwards, heat up to 55°C, stir and react for 4 hours, then add 250mL of absolute ethanol to mix and stir for 17min, filter, obtain the filtrate and spray dry to obtain epoxy-modified amino acid, take 10g of methylene succinic acid, 45mL of iso Propanol and 2g tert-butyl hydroperoxide were added to the beaker, the beaker was placed in a water bath, the temperature was controlled at 85°C, and the magnetic stirring was carried out for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com