Method for constructing super-hydrophobic film on rusty bronze surface

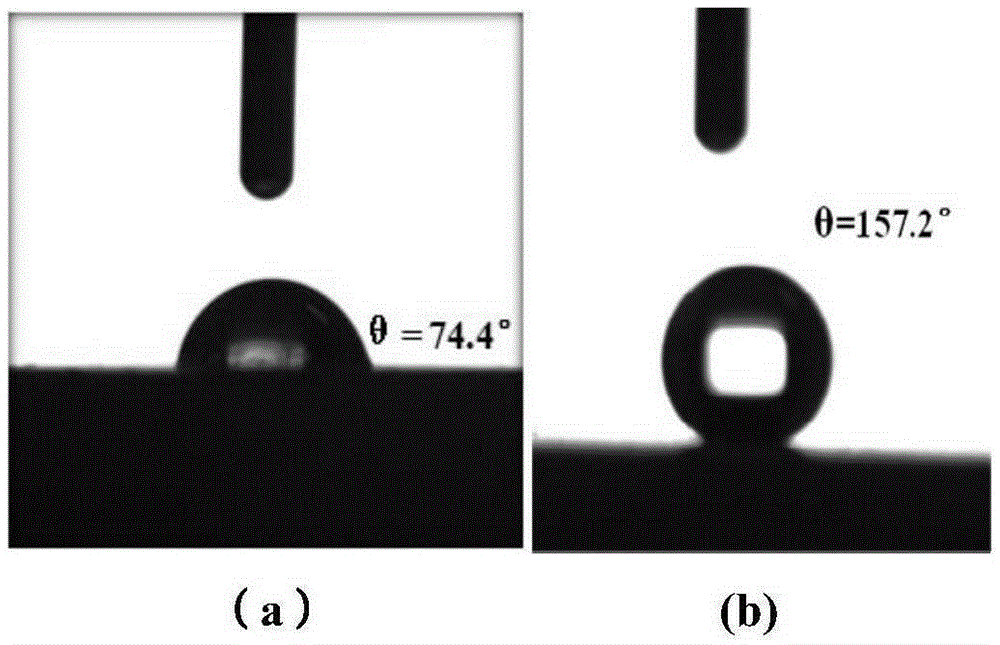

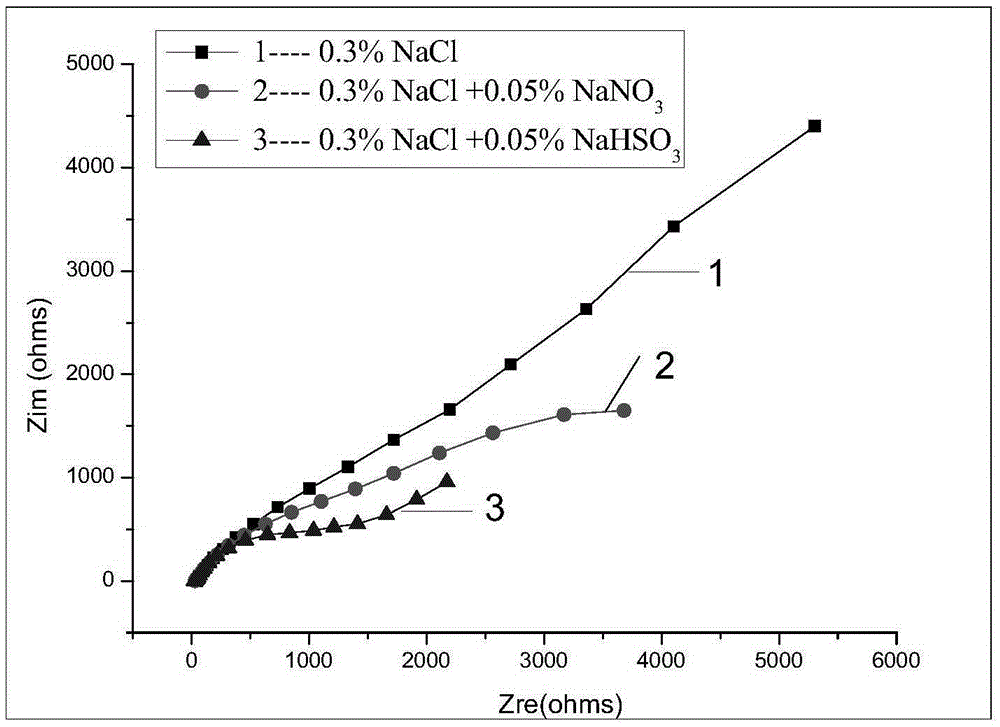

A super-hydrophobic, bronze technology, applied in the field of constructing a super-hydrophobic film on the surface of rusted bronze, can solve problems such as inapplicability to the surface of cultural relics, and achieve the effects of high durability, anti-corrosion, self-cleaning performance, high stability, and simple and safe preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

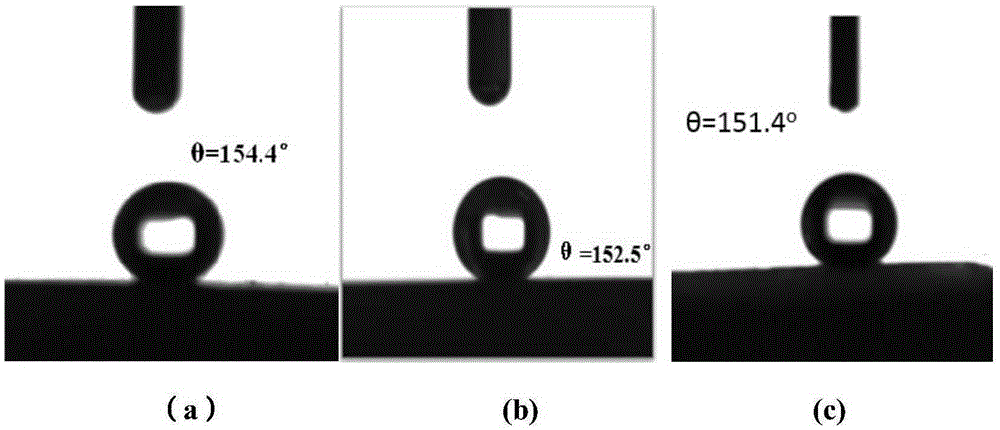

Embodiment 1

[0026] Use a soft brush to gently brush the surface of the rusty bronze, and then repeatedly blow the surface with dry nitrogen to remove dust, particles and harmful powdery rust on the bronze surface;

[0027] The pretreated bronze was hung in an atmosphere box, 10.0% benzotriazole, 5.0% 1-phenyl-5-mercaptotetrazolium, 3.0% 2-mercaptobenzoxazole, 2.0% 2-mercaptobenzimidazole, the balance is a solvent ethanol composite gas phase corrosion inhibitor solution placed at the bottom of the atmosphere box, nitrogen gas is passed through the microporous diffuser for 120 minutes to vaporize; pre-film at 20-30 ° C for 72 hours , followed by nitrogen gas for 60 minutes to blow off the corrosion inhibitor and ethanol molecules attached to the surface;

[0028] 5.0% of tridecafluorooctyltriethoxysilane, 5.0% of heptadecafluorodecyltriethoxysilane, 2.0% of 4-methyl-tridecafluorodecyltriethoxysilane, the balance The fluorosilane solution that is ethanol solvent is placed at the bottom of t...

Embodiment 2

[0031] Use a soft brush to gently brush the surface of the rusty bronze, and then repeatedly blow the surface with dry nitrogen to remove dust, particles and harmful powdery rust on the bronze surface;

[0032] The pretreated bronze was hung in an atmosphere box, 2.0% benzotriazole, 1.0% 1-phenyl-5-mercaptotetrazolium, 1.0% 2-mercaptobenzoxazole, 1.0% 2-Mercaptobenzimidazole, the balance is solvent ethanol composite vapor phase corrosion inhibitor solution placed at the bottom of the atmosphere box, nitrogen gas is passed through the microporous diffuser for 40 minutes to vaporize; pre-film at 20-30°C for 48 hours , followed by nitrogen gas for 40 minutes to blow off the corrosion inhibitor and ethanol molecules attached to the surface;

[0033] 1.0% of tridecafluorooctyltriethoxysilane, 1.0% of heptadecafluorodecyltriethoxysilane, 1.0% of 4-methyl-tridecafluorodecyltriethoxysilane, the balance The fluorosilane solution that is ethanol solvent is placed at the bottom of the a...

Embodiment 3

[0036] Use a soft brush to gently brush the surface of the rusty bronze, and then repeatedly blow the surface with dry nitrogen to remove dust, particles and harmful powdery rust on the bronze surface;

[0037]Suspend the pretreated bronze in the atmosphere box, add 5.0% benzotriazole, 5.0% 1-phenyl-5-mercaptotetrazolium, 5.0% 2-mercaptobenzoxazole, 1.0% 2-Mercaptobenzimidazole, the balance is a solvent ethanol composite vapor phase corrosion inhibitor solution placed at the bottom of the atmosphere box, and nitrogen gas is passed through a microporous diffuser for 90 minutes to vaporize; pre-film at 20-30°C for 24 hours , followed by nitrogen gas for 40 minutes to blow off the corrosion inhibitor and ethanol molecules attached to the surface;

[0038] 1.0% of tridecafluorooctyltriethoxysilane, 5.0% of heptadecafluorodecyltriethoxysilane, 2.0% of 4-methyl-tridecafluorodecyltriethoxysilane, the balance The fluorosilane solution as an ethanol solvent is placed at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com