Patents

Literature

110results about How to "Add active groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep softening method of thick oil sewage

ActiveCN102815765ASolving the scaling problem of boilers reused in thermal recoveryAvoid badWater/sewage treatment by ion-exchangeWater qualitySewage

The invention relates to a deep softening method of thick oil sewage, which comprises the following steps: preterating thick oil sewage to remove impurities in the thick oil sewage, and carrying out preliminary softening treatment with a macroporous weak acid resin until the pH value of the thick oil sewage reaches 7-9 and the temperature reaches 57-80 DEG C; passing the pretreated thick oil sewage through an adsorption tower or adsorption column filled with a chelating resin at the flow rate of 20-30 BV / h to carry out adsorption treatment; and when the adsorption reaches the leakage point, obtaining the thick oil sewage subjected to deep softening. The method provided by the invention is a treatment process capable of efficiently softening thick oil sewage according to the water quality characteristic of the thick oil sewage; and the method provided by the invention can still be used repeatedly in a thermal recovery boiler without generating scales after saving the silicon removal system.

Owner:PETROCHINA CO LTD

Modification method for improving hygienic performance of superfine fiber synthetic leather base fabric through collagen

ActiveCN103382637AImproved water vapor permeabilityAchieve covalent modificationFibre typesPolymer scienceAcid hydrolysis

The invention relates to a modification method for improving hygienic performance of superfine fiber synthetic leather base fabric through collagen. The superfine fiber synthetic leather base fabric serves as a main body of synthetic leather, and water vapor can not be transferred effectively between fibers and the outside due to a few active groups on the base fabric. According to the modification method, gelatin is hydrolyzed to obtain the collagen; dry superfine fiber synthetic leather base fabric is processed with concentrated sulfuric acid to obtain the superfine fiber synthetic leather base fabric with the acid-hydrolysis modified surface; the extracted collagen is grafted to the processed base fabric for reaction to obtain target products. By the aid of the modification method, the active groups on the surface of the superfine fiber synthetic leather base fabric are effectively increased, covalent modification is performed on the surface of the superfine fiber synthetic leather base fabric through the collagen, the hygienic performance of the superfine fiber synthetic leather base fabric is improved through the collagen, resource utilization of the waste collagen is achieved, and meanwhile, the problem of the poor hygienic performance of the superfine fiber synthetic leather is solved.

Owner:SHAANXI UNIV OF SCI & TECH +1

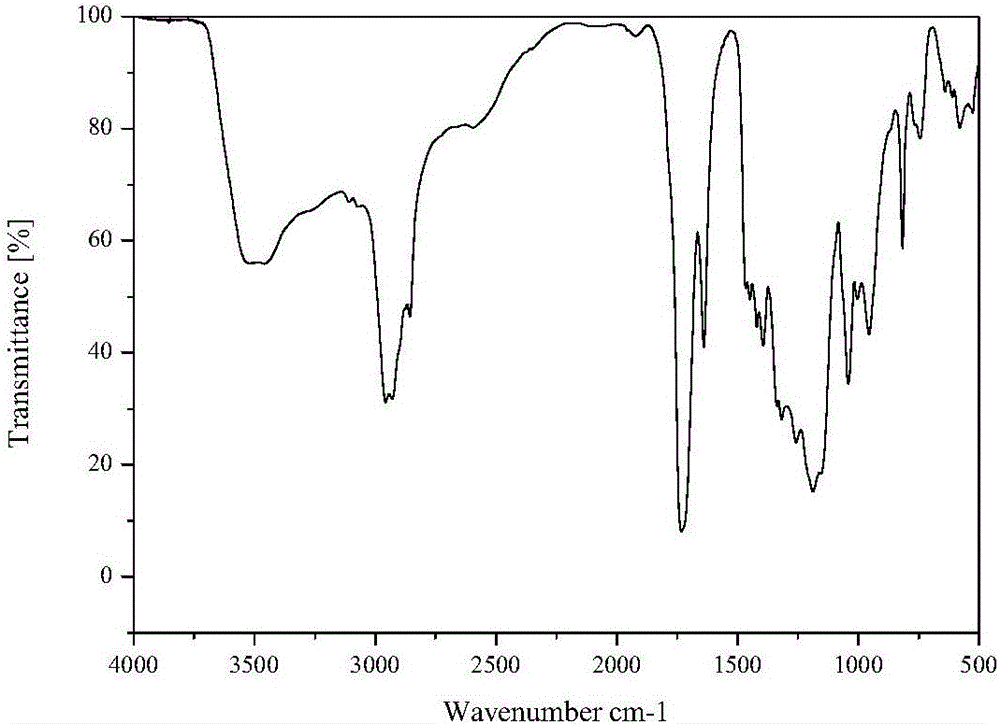

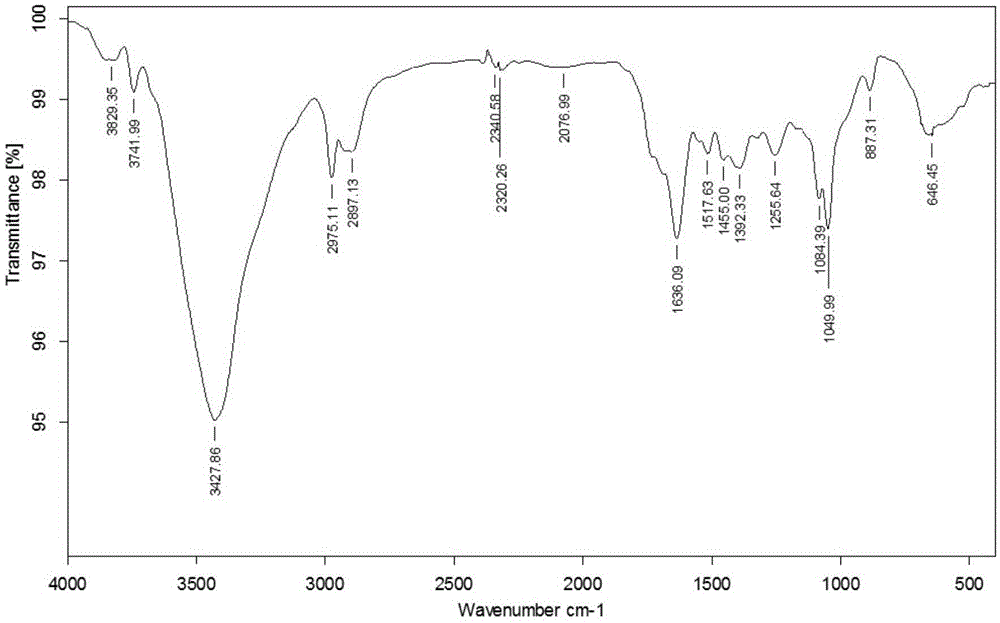

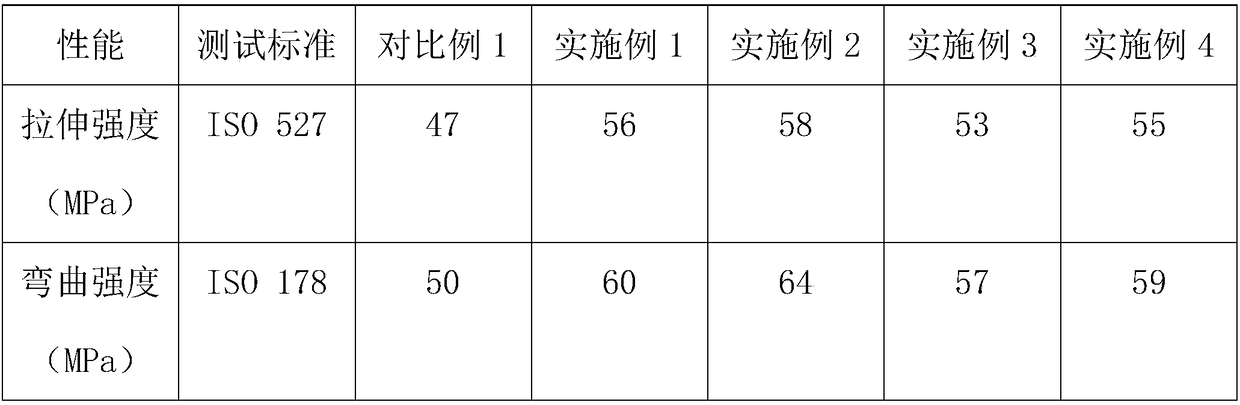

Preparation process of glass fiber composite material

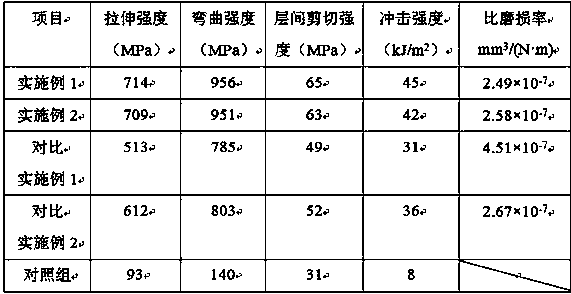

The invention provides a preparation process of a glass fiber composite material. The preparation process comprises the steps of (1) a glass fiber high-temperature treatment process, (2) an acid-alkali etching treatment process, (3) a silane coupling agent treatment process, and (4) preparation of a glass fiber / dicyclopentadiene (DCPD) composite material. According to the process, glass fibers are modified, the treated glass fibers are analyzed by adopting an infrared spectrogram and SEM, and a result shows that the surface structure of the treated glass fibers is changed compared with the untreated glass fibers. The surface of the glass fibers after being treated by the coupling agent is not smooth, active groups are increased, the overall appearance is provided with valleys and attachments adhered on the surface of the glass fibers, and the compatibility of the glass fibers to a matrix can be improved. When the glass fibers are broken in the matrix after being treated by the coupling agent, no obvious interface exists between the fibers and the matrix. The mechanical properties of the composite material can be improved.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

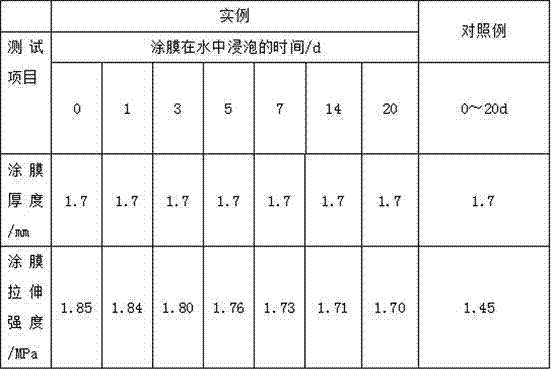

Molybdenum disulfide-modified carbon cloth friction material and preparation method thereof

ActiveCN103450492AAdd active groupsImprove impregnation effectOther chemical processesModified carbonSolvent

The invention discloses a molybdenum disulfide-modified carbon cloth friction material and a preparation method thereof. The method comprises the following steps: firstly, dissolving modified phenolic resin into ethanol to prepare a modified phenolic resin ethanol solution, and then adding nano molybdenum disulfide and padding, so as to prepare suspension impregnation liquid; dipping a piece of carbon cloth for 10-15 minutes by using the suspension impregnation liquid in vacuum impregnation equipment; taking out after the impregnating amount of the resin achieves 15-25%; carrying out thermal curing to obtain the molybdenum disulfide-modified carbon cloth friction material after a solvent volatilizes. The molybdenum disulfide-modified carbon cloth friction material prepared by the method has the characteristics of high dynamic friction coefficient, low attrition rate, and small abrasion on a mating material.

Owner:SHAANXI UNIV OF SCI & TECH

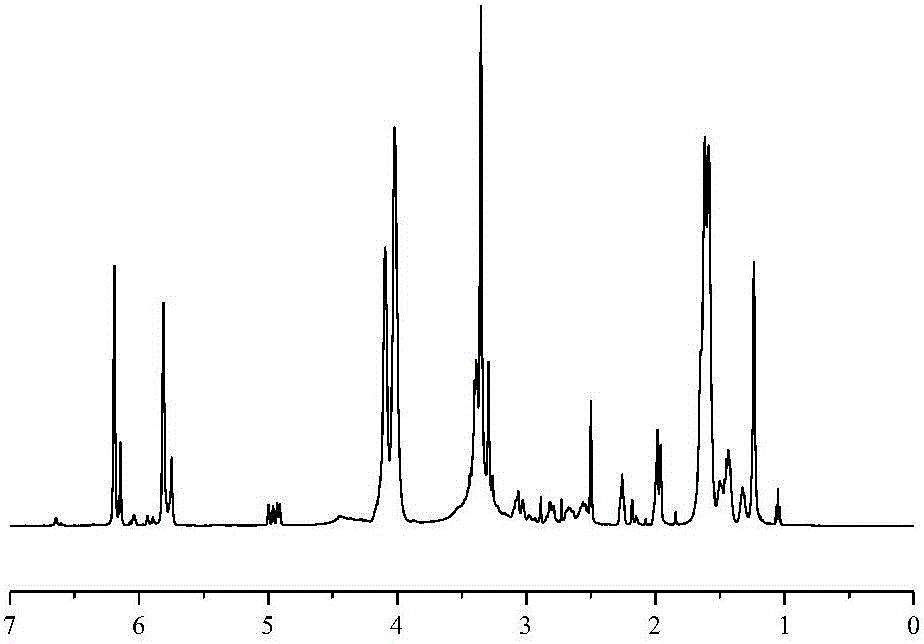

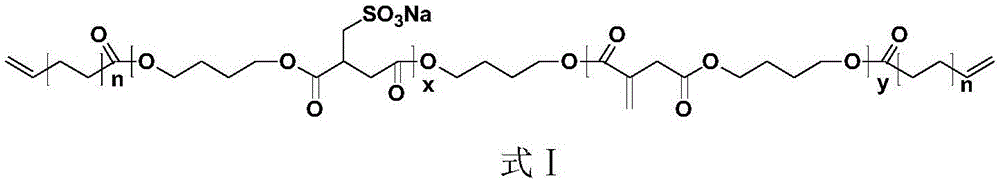

Novel self-emulsifying water-based polyester emulsion and preparation method thereof

ActiveCN106432706ANovel preparation methodWith self-emulsifying functionPolyester coatingsPolyesterPolymer science

The invention provides novel self-emulsifying water-based polyester emulsion and a preparation method thereof. The preparation method includes the following steps that itaconic acid, methyl-butanedioic acid-5-sodium sulfonate and 1,4-butanediol are subjected to condensation polymerization, then terminal hydroxyl water-based polyester-poly(itaconic acid butanediol-co-methyl-butanedioic acid-5-sodium sulfonate butanediol)ester (PBIINa) is obtained, and the PBIINa and terminal olefine acid are heated to 110-160 DEG C under nitrogen protection, and terminal olefine acid modified water-based polyester is obtained after an esterification reaction. The terminal olefine acid modified water-based polyester is dispersed in water, and then the water-based polyester emulsion is obtained. The preparation method of the water-based polyester emulsion is novel and has a self-emulsifying function, an emulsifying agent does not need to be added, organic solvent is not contained, and the water-based polyester emulsion can be used as emulsion coating and has broad market prospects. The steps are simple, operation is convenient, and practicability is high.

Owner:QINGDAO UNIV OF SCI & TECH

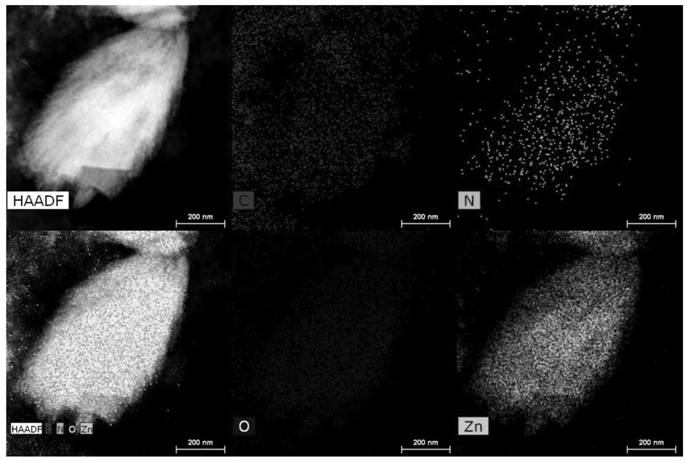

Lignin nitrogen-rich carbon/zinc oxide nanocomposite as well as preparation method and application thereof

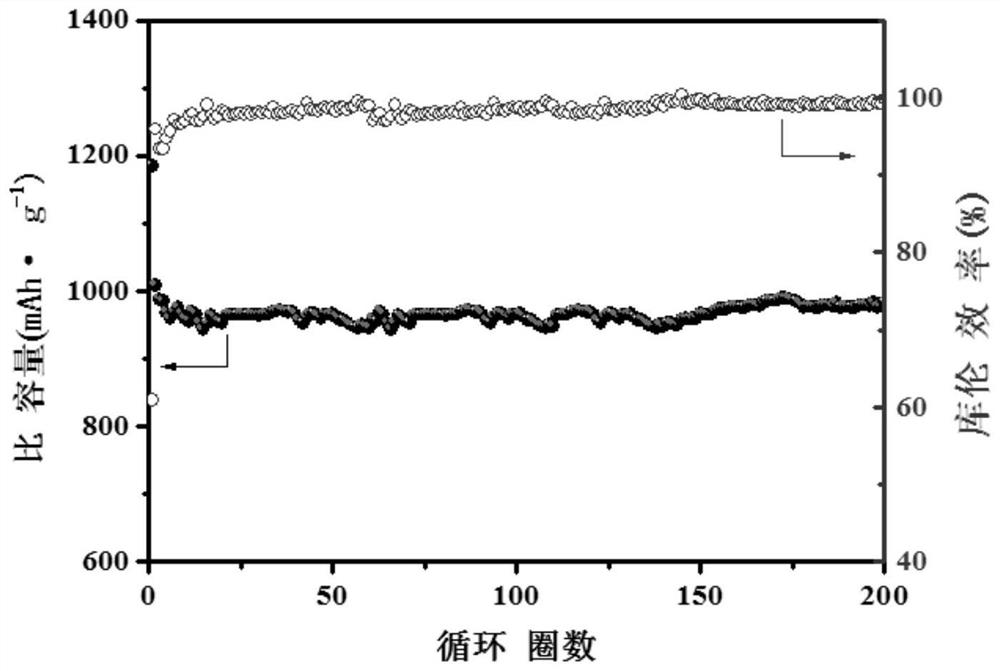

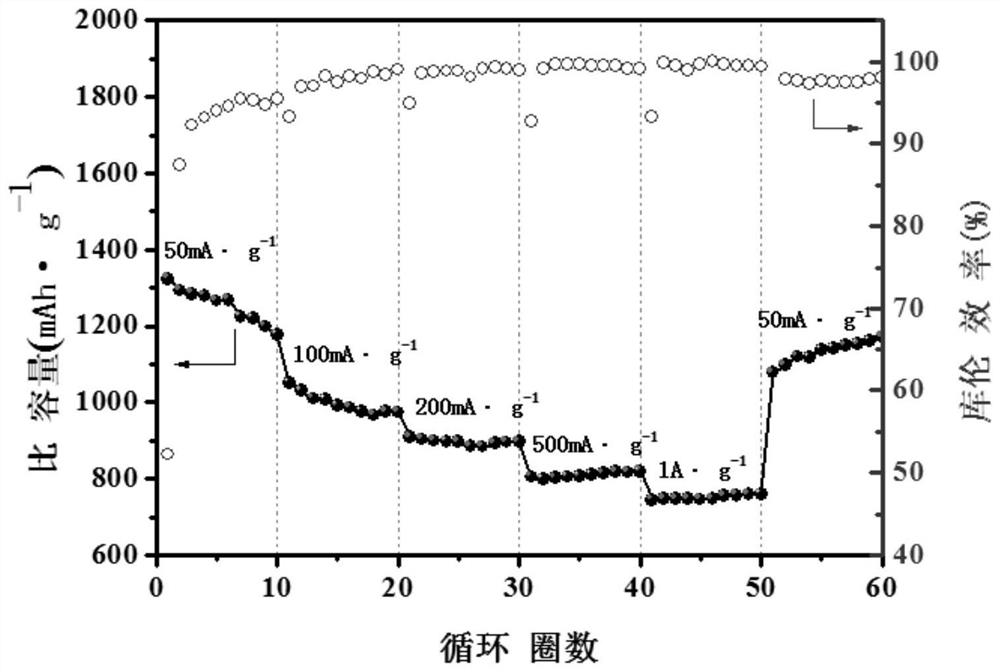

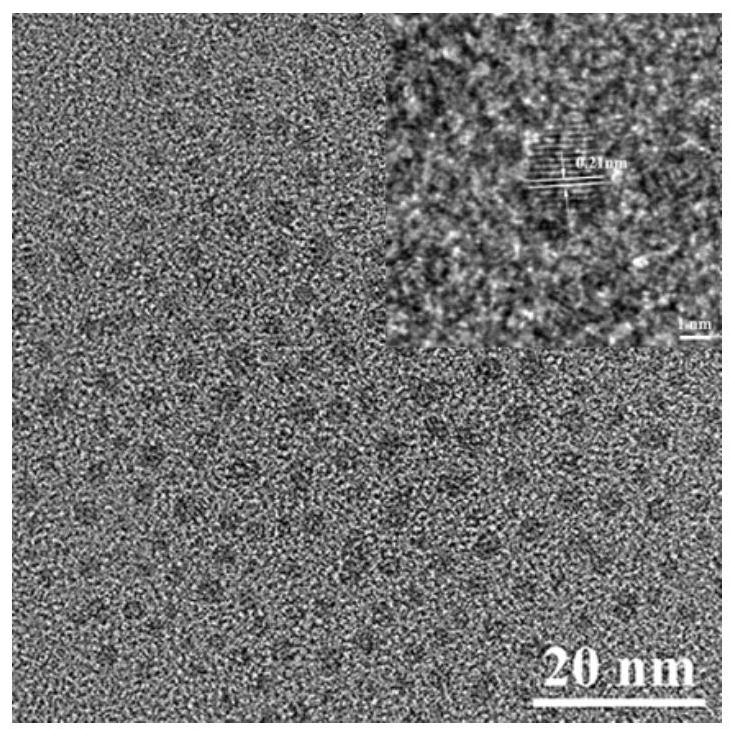

ActiveCN112072086AImprove structural strengthAdd active groupsMaterial nanotechnologyHybrid capacitor electrodesCarbon layerElectrical battery

The invention discloses a lignin nitrogen-rich carbon / zinc oxide nanocomposite as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving ligninin an alkaline solution, carrying out hydrothermal pretreatment, conducting cooling, and adjusting a pH value to 3-5 to obtain an acid-soluble lignin solution; (2) adding a mixed solution of soluble zinc salt and soluble carbonate into the acid-soluble lignin solution, conducting a hydrothermal reaction, then adding hydroxymethylated melamine, and continuing the hydrothermal reaction to obtain a nitrogen-doped lignin / zinc oxide compound; and (3) carbonizing the nitrogen-doped lignin / zinc oxide compound to obtain the lignin nitrogen-rich carbon / zinc oxide nanocomposite. In the obtained composite material, lignin carbon is uniformly doped with the nitrogen element, and the lignin nitrogen-rich carbon uniformly coats the surfaces of zinc oxide particles to form a uniform carbon layer with a continuous structure, so the problems of serious volume expansion and poor conductivity of zinc oxide serving as a lithium ion negative electrode material are solved, and the specific capacity, the initial coulombic efficiency and the rate capability of a lithium ion battery are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

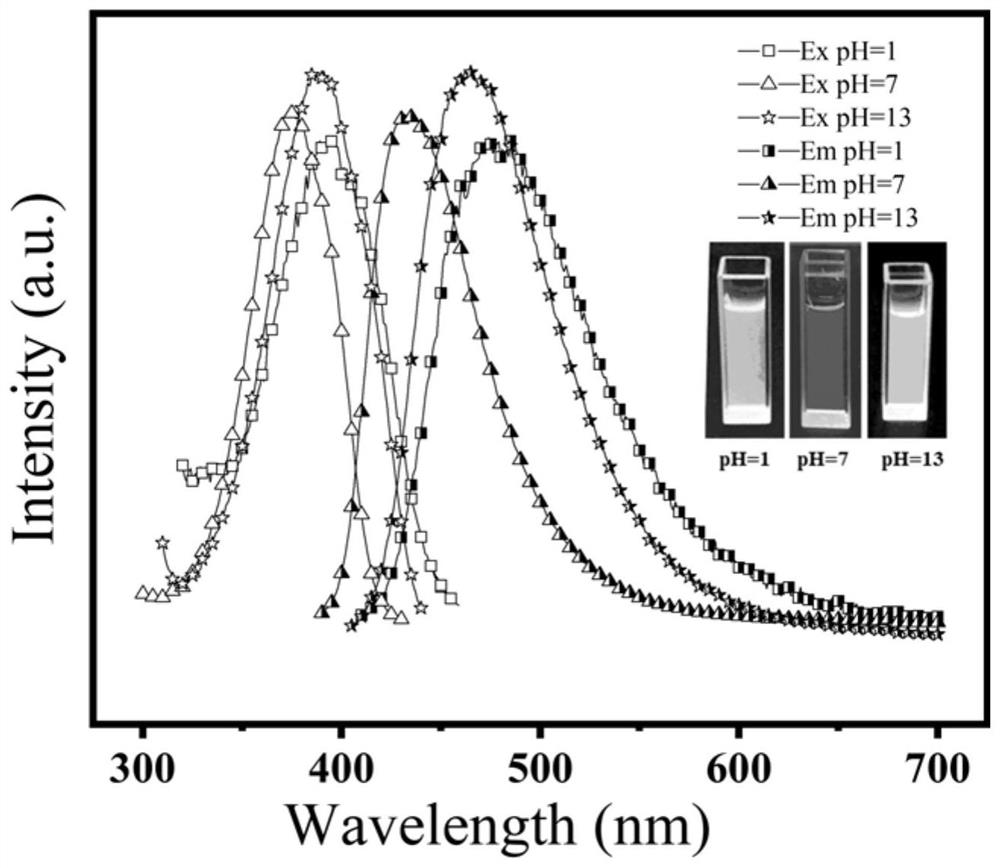

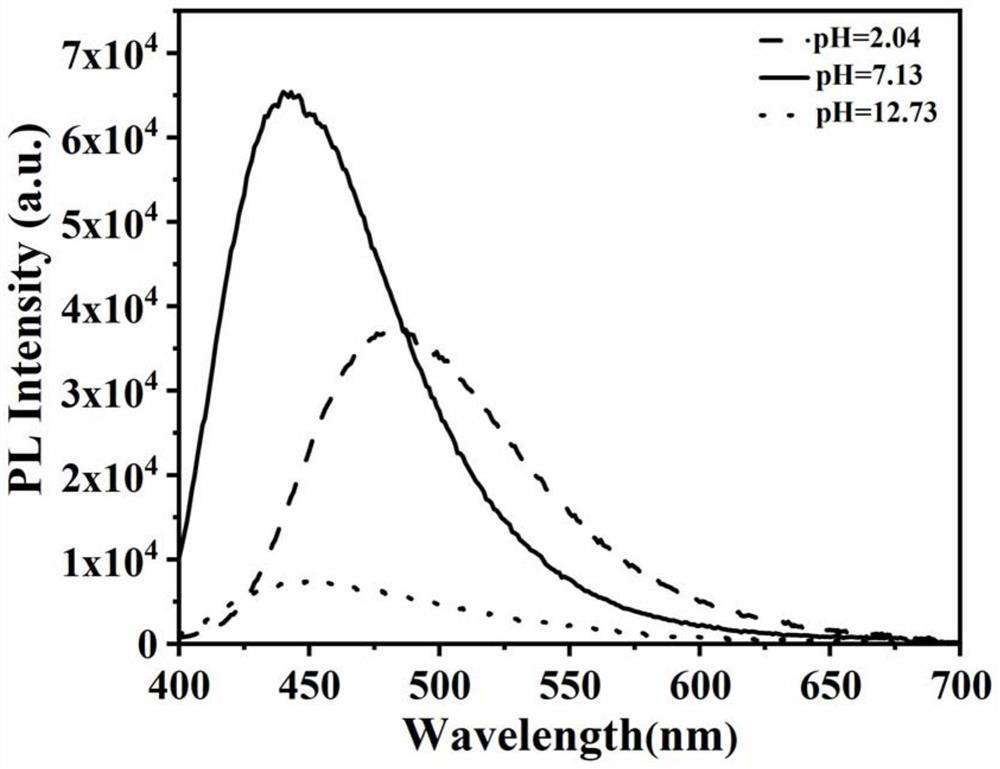

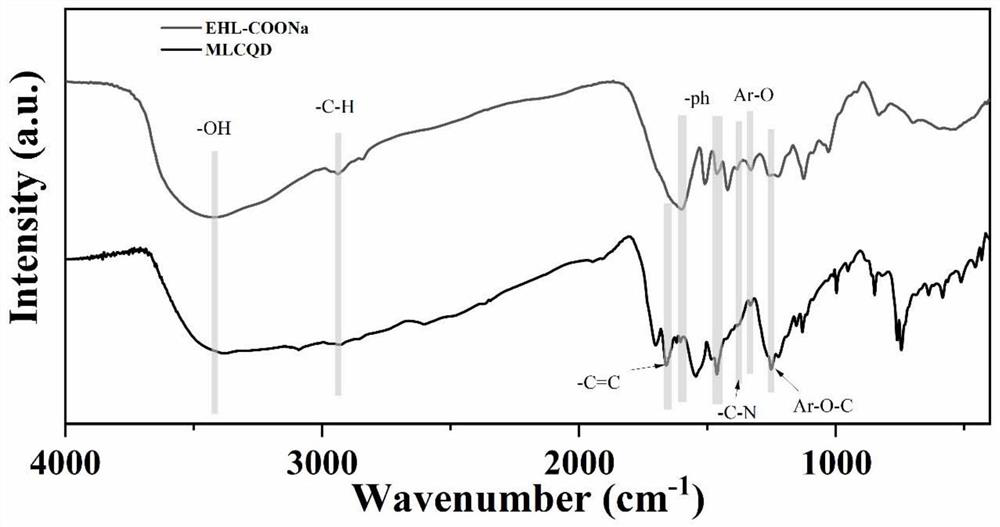

Blue-light and green-light lignin carbon quantum dots with high quantum yield as well as preparation method and application thereof

ActiveCN113025321AWide variety of sourcesLow priceMaterial nanotechnologyNanoopticsCelluloseQuantum yield

The invention belongs to the field of biomass fluorescent nano materials, and particularly relates to a blue-light and green-light lignin carbon quantum dot with high quantum yield as well as a preparation method and application thereof. According to the method, modified lignin and citric acid are subjected to dehydration, polymerization and carbonization to form lignin carbon quantum dots, and the lignin carbon quantum dots are protonated or deprotonated by adjusting the pH value, so that the fluorescent carbon quantum dots emitting blue and green light are obtained. The non-radiative transition process is reduced through heteroatom doping, so that the lignin carbon quantum dots with high quantum yield are obtained, and the absolute quantum yield can reach 59.3% at most. Compared with other non-biomass precursors such as polycyclic aromatic hydrocarbon, lignin is renewable, wide in source, low in price, non-toxic and harmless; Compared with other biomass-based compounds such as cellulose, hemicellulose and lignin, the carbon content is higher, and the biomass-based compound is the only natural polymer containing a large number of conjugated aromatic structures in nature, so that the carbon quantum dots are easier to obtain theoretically.

Owner:GUANGDONG UNIV OF TECH

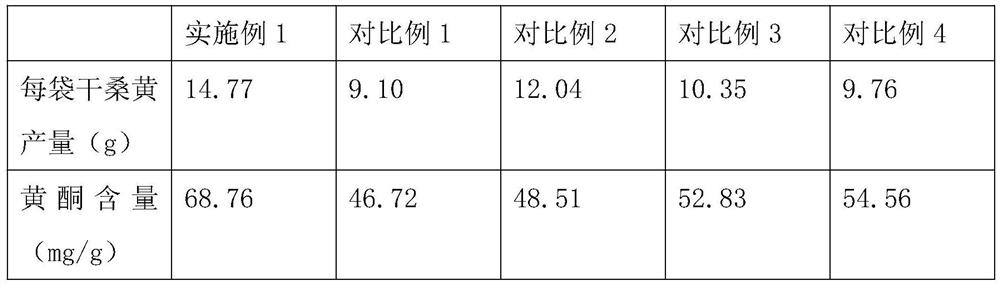

Cultivation material for artificial cultivation of Phellinus igniarius, and preparation method of cultivation material

ActiveCN111972212AIncrease productionHigh densityCultivating equipmentsMushroom cultivationBiotechnologySucrose

The invention discloses a cultivation material for the artificial cultivation of Phellinus igniarius, and a preparation method of the cultivation material. The preparation method comprises the following steps: (1) crushing mulberry twigs, cotton seed hulls and bran and then performing uniform mixing to obtain a mixture A; (2) performing steam explosion treatment on the mixture A to obtain a mixture B; (3) preparing a liquid culture medium with grapefruit peel hydrolysate as a raw material, performing inoculation with Acetobacter xylinum, and performing mechanical stirring and fermentation to obtain a fermentation broth C; (4) uniformly mixing the mixture B, the fermentation broth C, a vermiculite powder and quicklime, and performing microwave expansion treatment to obtain a mixture D; (5)fully dissolving sucrose and potassium dihydrogen phosphate in water to obtain a nutrient solution E; and (6) fully stirring the mixture D and the nutrient solution E uniformly, and then performing pressing to obtain the cultivation material. The cultivation material prepared by the invention not only can provide nutrient components required for the growth of Phellinus igniarius and improve the yield of Phellinus igniarius fruiting bodies, but also can improve the content of active components of Phellinus igniarius and improve product quality.

Owner:岳西县思远生态农业有限公司

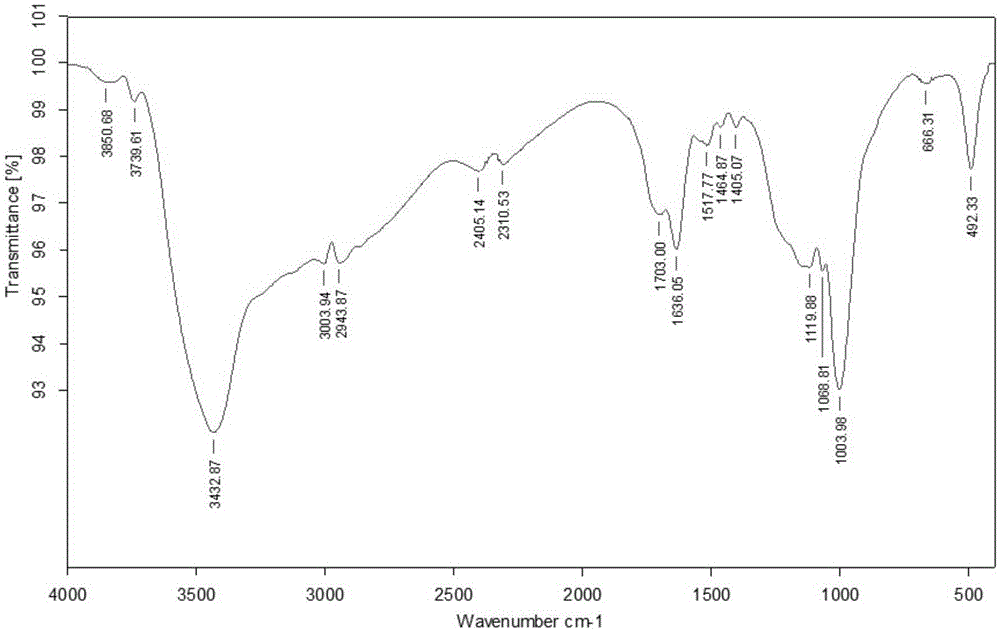

Modification method of corncobs, modified product of corncobs and application of modified product

InactiveCN105597702AAchieve reuseImprove adsorption capacityOther chemical processesWater contaminantsWater bathsRoom temperature

The invention discloses a modification method of corncobs, a modified product of the corncobs and application of the modified product and belongs to the technical field of modified materials. The modification method of the corncobs comprises the following steps: (1) chopping the corncobs and mixing the corncobs with tap water, and mashing; washing and immersing crushed residues with the tap water; removing suspended fine substances and soluble matters; after filtering, drying with air at a room temperature and sieving; (2) uniformly mixing a sieved matter and a phosphoric acid solution, immersing with a water bath and then filtering; (3) drying at 30-70 DEG C and 110-150 DEG C in sequence; (4) washing until the pH value is equal to 7; and (5) drying. With the adoption of the method disclosed by the invention, the reutilization of the agricultural waste corncobs is realized; and active groups on the surfaces of particles can be increased and uneven and porous structures can be formed on the surfaces of the particles, so that the modified material has excellent physical absorption and chemical properties, and the adsorption rate is averagely improved by about 24%-40%.

Owner:FOSHAN UNIVERSITY

Preparation method of wear-resisting polyether-ether-ketone composite material filled and reinforced by calcium carbonate crystal whisker-vermiculite

The invention discloses a preparation method of a wear-resisting polyether-ether-ketone composite material filled and reinforced by calcium carbonate crystal whisker-vermiculite. The method comprisesthe steps of drying polyether-ether-ketone in a vacuum drying oven, loading the dried polyether-ether-ketone, silane-modified nanometer titania, surface-treatment calcium carbonate crystal whisker andsurface modification treatment carbon fiber, and organic intercalated vermiculite in a high-speed mixing machine, stirring and mixing at low speed, loading in a mold, pre-pressing, putting in a furnace, heating for melting, then placing into a press vulcanizer for mould pressing, air cooling, taking out, and annealing to obtain the composite material. Hexadecyl trimethyl ammonium bromide is adopted for carrying out organic intercalation treatment on lamellar vermiculite, so that the interlayer spacing of the vermiculite is increased; the vermiculite and the nanometer titania are compounded tomodify the polyether-ether-ketone, so that the oxidation of the polyether-ether-ketone is delayed, and the thermal and oxidative aging resistance of the polyether-ether-ketone is improved; the nanometer titania has a higher ultraviolet light shielding effect, so that the light aging resistance of the polyether-ether-ketone is improved.

Owner:界首市鑫一龙机械设备购销有限公司

Special paper tube adhesive for paper

InactiveCN107556946ARich porosityEasy to embedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses a special paper tube adhesive for paper and belongs to the technical field of binding agents. The special paper tube adhesive for the paper is prepared by the following steps:stirring and mixing nano silicon dioxide, a silane coupling agent and an ethanol solution and reacting; then filtering, washing and drying to obtain modified nano silicon dioxide; then carrying out ultrasonic dispersion on the modified nano silicon dioxide and absolute ethyl alcohol to obtain a modified nano silicon dioxide dispersed solution; mixing glass fibers and the modified nano silicon dioxide dispersed solution and immersing; then drying the immersed glass fibers until the weight is constant; mixing the immersed glass fibers and a dopamine solution and immersing; then drying the immersed glass fibers until the weight is constant, so as to obtain modified glass fibers; stirring and mixing polyvinyl alcohol, a cyclodextrin derivative and water; then adding polyvinyl acetate emulsion,cellulase, the glass fibers and polystyrene emulsion, and stirring and mixing to obtain the special paper tube adhesive for the paper. The special paper tube adhesive for the paper, which is preparedby the technical scheme, has the characteristics of excellent bonding performance and has a wider application and development field.

Owner:常州市绿意管道有限公司

Preparation method of decolorizing membrane for printing and dyeing wastewater

InactiveCN108404679AGood dispersionImprove stabilitySemi-permeable membranesMembranesFiberChloroacetic acids

The invention discloses a preparation method of a decolorizing membrane for printing and dyeing wastewater. The decolorizing membrane is prepared from copper acetate monohydrate, sodium borate decahydrate, dopamine hydrochloride, 2-bromoisobutyryl bromide, nanometer titanium dioxide, hydrazine hydrate, chitosan, chloroacetic acid, silver nitrate, beta-cyclodextrin, polyacrylic acid and other raw materials. Obtained silver particles are loaded with the chitosan, the beta-cyclodextrin and the like for embedding, and a stable fiber membrane structure is formed by electrospinning and thermal crosslinking. The obtained fiber membrane is impregnated with grafted nano-titanium dioxide, a large number of active sites on the surface of the membrane are used for increasing the reaction contact surface with the wastewater, and then a layer of nano-copper membrane is impregnated and loaded with the copper acetate monohydrate. The process of a reduction reaction is accelerated by the characteristicof rapid electron conduction, and the dye decolorizing speed is increased, so that the obtained decolorizing membrane has high efficiency and high stability, and the defects of the traditional decolorization treatment of the printing and dyeing wastewater are overcome. The preparation method has significant application value in pollution control.

Owner:WUHU EDISON AUTOMATION EQUIP

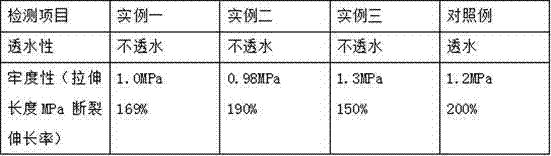

Polymer cement waterproof coating

The invention belongs to the technical field of waterproof coatings, and particularly relates to a polymer cement waterproof coating. According to the polymer cement waterproof coating disclosed by the invention, by using ethyl acrylate, methyl acrylate and the like as basic raw materials, acrylate emulsion is synthesized; in a synthesizing process, the acrylate emulsion is modified by using silicone monomer methyl vinyl dichlorosilane; a silicon-oxygen bond is introduced, so that binding degree between the silicon-oxygen bond and cement is increased, performance and firmness of the membrane is improved; meanwhile, under an effect of Lewis acid, an unsaturated bond is introduced by using maleic anhydride, so that an active group of the emulsion is increased, an effect of the unsaturated bond and calcium ions is increased, water tolerance is further improved, and the photographic property of the emulsion is also improved; by compounding with butanol, the flowability of the membrane in the early stage is improved; by utilizing unrecoverable performance of calcination of kyanite is utilized, pore formation in the cement is carried out, and contact performance of the cement and the emulsion is increased; meanwhile, the emulsion is compounded with o-cresol aldehyde epoxy resin, so that performance of self-curing membrane formation of the coating is increased, and the phenomenon that a curing membrane is easily swelled by water again is avoided.

Owner:常州市宝平不绣钢制品有限公司

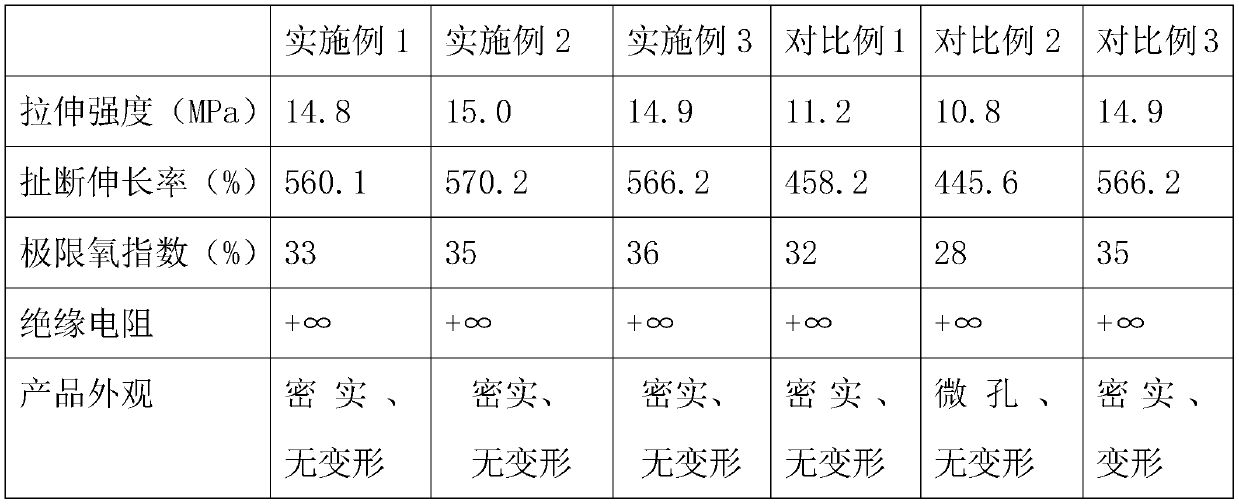

Insulating flame-retardant ethylene-propylene-diene monomer hose composition and preparation method thereof

ActiveCN110240760AMeet mechanical strength requirementsMeet performance requirementsRubber insulatorsAntimony trioxideStearic acid

The invention discloses an insulating flame-retardant ethylene-propylene-diene monomer hose composition which is characterized by comprising the following components in parts by weight: 100 parts of an EPDM (ethylene-propylene-diene monomer) 5890F, 2-6 parts of kaolin, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 2-5 parts of paraffin, 1-3 parts of an anti-aging agent MB, 50-70 parts of carbon black SP6400A, 130-190 parts of a flame retardant, 10-30 parts of paroline, 1-2 parts of sulfur, 10-15 parts of calcium oxide and 1.6-3 parts of an accelerant, wherein the accelerant comprises 0.2-0.5 part of an accelerant TT; and the flame retardant comprises 80-100 parts of aluminum hydroxide, 20-40 parts of zinc borate, 10-20 parts of antimonous oxide and 20-30 parts of decabromodiphenyl ethane. The invention has another purpose of providing a preparation method of the insulating flame-retardant ethylene-propylene-diene monomer hose composition, and on premise that electric insulation and insulation resistance of vulcanized rubber are met, mechanical strength requirements of rubber can be met.

Owner:青岛铁路橡胶厂

An addition of blast furnace slag building inside and outside the wall thermal insulation putty

The invention discloses a method for preparing the inner and outer wall insulation putty of blast furnace slag, which is prepared by the following raw materials: cement, hollow glass beads, tetraethyl orthosilicate, anhydrous ethanol, 1mol / L hydrochloric acid, template agent F127, emulgator OP 10 portions, sodium bicarbonate, silica sol, ammonium persulfate, light sand, titanium dioxide, blast furnace slag, brucite fiber, gypsum, polyethylene glycol fatty acid ester, tourmaline powder, polystyrene prepolymer, sodium alginate, azodiisobutyronitrile and a proper amount of deionized water. The putty powder of this invention has the advantages of low cost, good adhesive property, good abrasion resistance, good washing resistance, and also has anti-cracking, no corrosion, no cracking, environmentally friendly, tasteless, no harm to the human body and so on.

Owner:高绍彬

Method for modifying graphene by aqueous titanate

The invention relates to a method for modifying graphene by aqueous titanate. The method is as below: first dissolving aqueous titanate in water, then adding a graphene powder, and conducting ultrasonic treatment in a magnetic field to obtain a graphene dispersion; conducting distillation or vacuum distillation on the dispersion in the external magnetic field to obtain a graphene concentrated solution; and then drying to obtain aqueous titanate modified graphene. The method uses aqueous titanate for surface modification of graphene, introduces active groups to the graphene surface and avoids the agglomeration of graphene; and active group can significantly improve the dispersion and compatibility of graphene with other materials, and substantially improve the performance of graphene composite. In addition, ultrasonic treatment on the graphene dispersion in magnetic field not only can make the aqueous titanate fully modify the graphene, but also can achieve good stripping effect of graphene under the joint action of the magnetic field and ultrasound; and the method can significantly reduce the usage amount of graphene composite.

Owner:ZHEJIANG TAISUO TECH

A method for improving the dyeing performance of superfine fiber synthetic leather base cloth

ActiveCN103603197BImprove dyeing effectAdd active groupsFibre treatmentDyeing processLeather industryAlkaline protease

The invention relates to a method for improving the dyeing property of superfine fiber synthetic leather base cloth. The method comprises the following steps: adding water into gelatin, stirring to enable the gelatin to expand to obtain a gelatin solution, and adding alkaline protease into the gelatin solution for hydrolysis; adding the superfine fiber synthetic leather base cloth into a rotating drum, and treating the superfine fiber synthetic leather base cloth by acid to obtain surface modified superfine fiber synthetic leather base cloth; adding collagen into the rotating drum, performing graft modification on the collagen with the surface modified superfine fiber synthetic leather base cloth, and reacting to obtain collagen modified superfine fiber synthetic leather base cloth; and adding a dye into the rotating drum to dye the collagen modified superfine fiber synthetic leather base cloth. According to the invention, the superfine fiber synthetic leather base cloth is modified by the collagen, so that the superfine fiber synthetic leather base cloth is covalently modified by the collagen, furthermore, the dyeing performance of the superfine fiber synthetic leather is effectively improved, the dye uptake is up to about 94.21%, and the superfine fiber synthetic leather industry can be favorably developed.

Owner:SHAANXI UNIV OF SCI & TECH

Concrete mortar

The invention discloses concrete mortar and belongs to the field of mortar. The concrete mortar takes lignite as a raw material; the lignite can be pyrolyzed under a high-temperature condition to generate tar and a coke component; the tar has the effect of sticking each component; the coke component can react with hydroxyl silicate in stone material liquid in a system under the catalysis effect ofnano iron powder to generate a silicon carbide framework, so that a reinforcing effect is realized and the toughness of the system is improved; asphalt fibers are oxidized through potassium permanganate so that the adsorption force of the asphalt fibers on nano magnesium oxide is enhanced, and the adsorption performance of the asphalt fibers on silicon dioxide generated by hydrolyzing tetraethylorthosilicate can also be effectively improved; the early age strength of a cement-based grouting material is improved, and the expansion coefficient of the cement-based grouting material can be adjusted through magnesium oxide, so that the cement-based grouting material is not easy to crack after being cured. By adopting the concrete mortar provided by the invention, the problems that common mortar at present is easy to hollow and rack, and the toughness and mechanical property are poor are solved.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

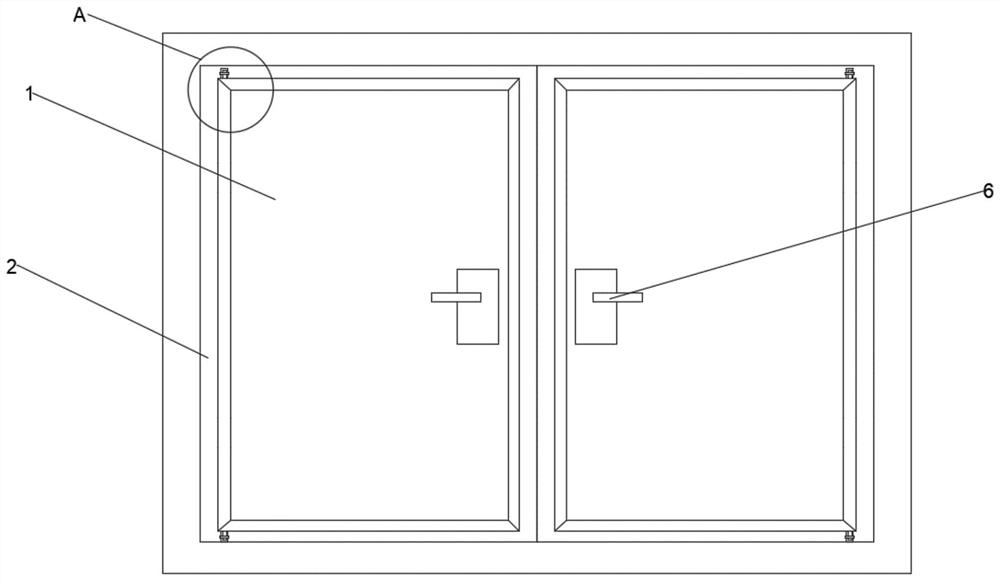

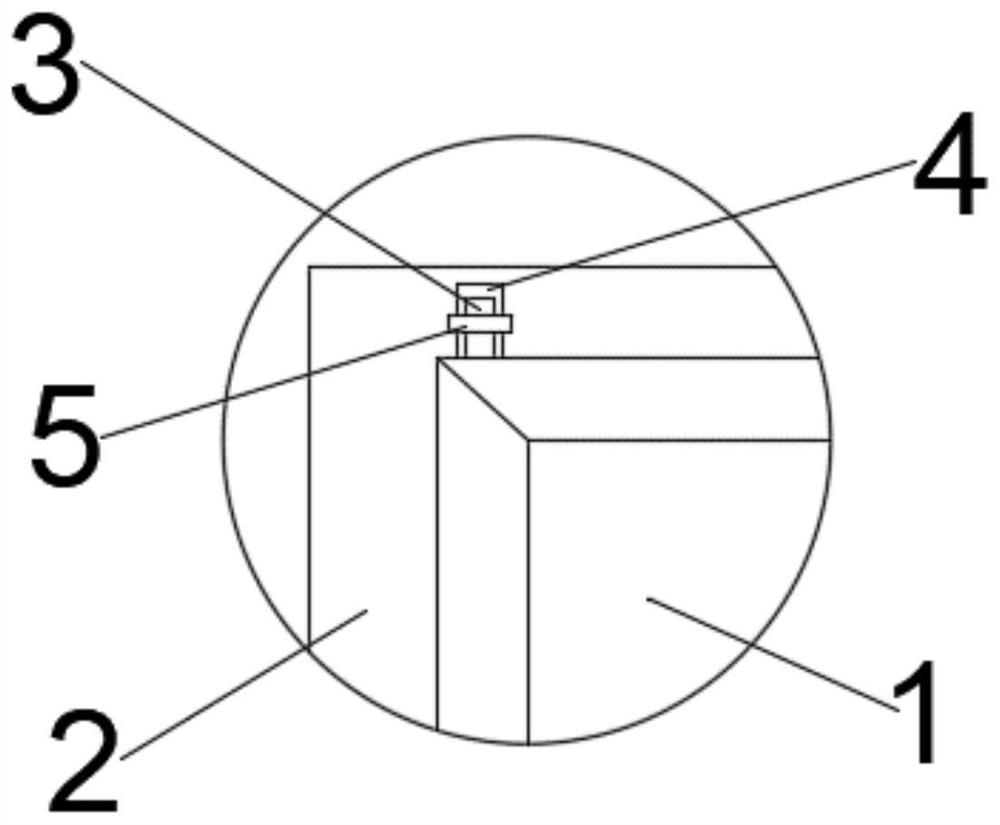

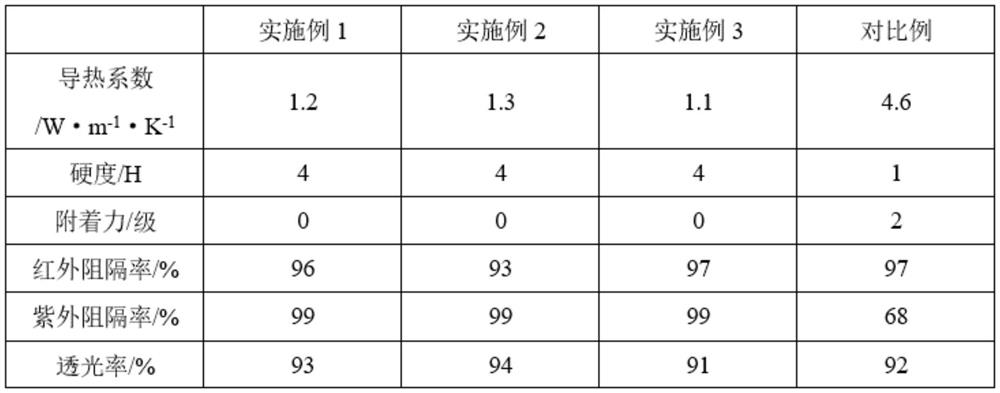

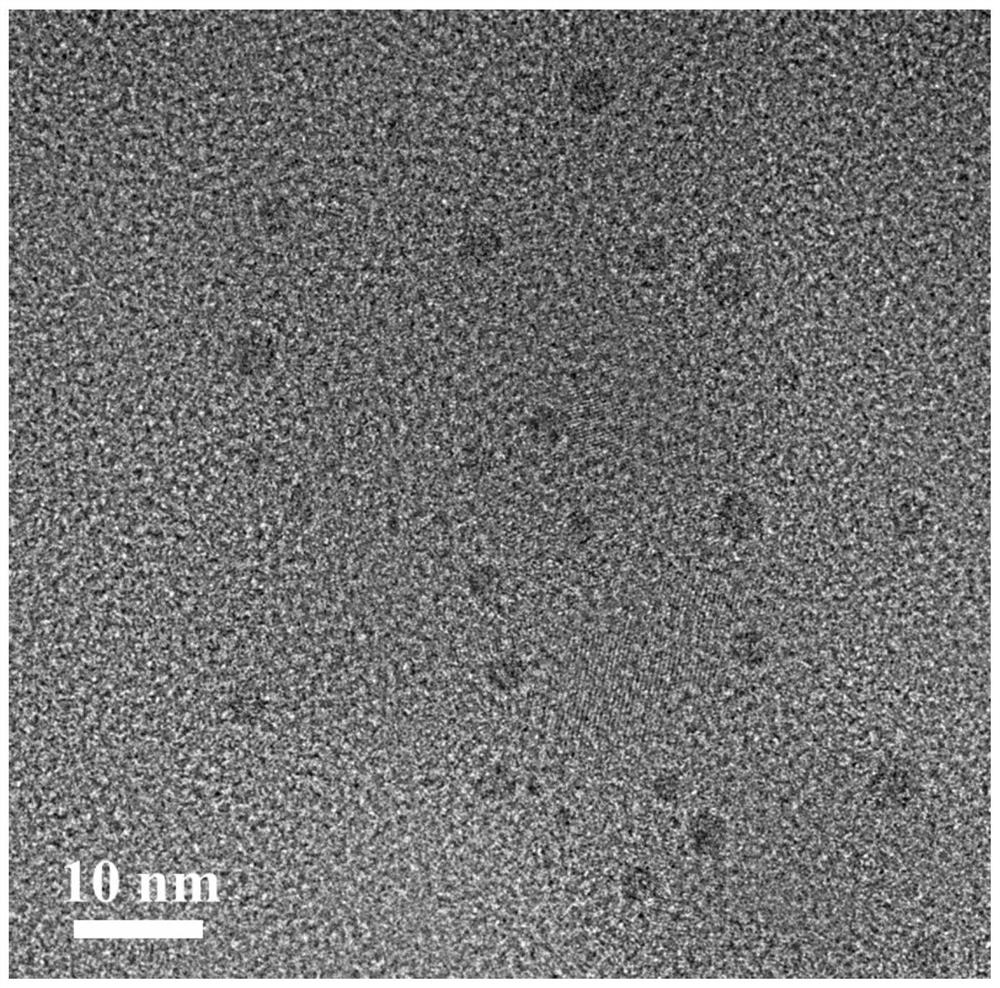

Constant-temperature health door and window

ActiveCN111827835AEnhance thermal insulationGood opticsWing accessoriesGermanium compoundsThermal insulationStructural engineering

The invention relates to the field of doors and windows, in particular to a constant-temperature health door and window comprising a door and window sash and a door and window frame body. Door and window shafts are arranged at the upper end and the lower end of the door and window sash, and the door and window sash is movably connected with the door and window frame body through the door and window shafts. When the door and window need to be moved or replaced, only hinges need to be dismantled, and use can be realized through installation after dismantling without vacuumizing like double-layerglass, and light transmittance is much higher than that of the double-layer glass. The door and window sash is coated with a thermal insulation coating, and the problem of poor thermal insulation performance of an existing door and window is solved. In addition, the edge of the door and window sash is coated with a sealing rubber pad, and the sealing rubber pad can seal the gap between the door and window sash and the door and window frame body after the door and window are closed, so that the thermal insulation effect of the door and window is further enhanced.

Owner:广东福临门世家智能家居有限公司

Method of processing superfine fiber synthetic leather skin-imitated leather

ActiveCN104878599AImprove efficiencyEasy to operateFibre typesDyeing processOxazolidineSodium Bicarbonate Solution

The invention relates to a method for processing superfine fiber synthetic leather skin-imitated leather. Superfine fiber synthetic leather is treated by adopting the traditional means, so that the hygienic property of the superfine fiber synthetic leather can be improved to a certain extent, but excellent performance of dermis can not be achieved. The method comprises the following steps: washing the superfine fiber synthetic leather in an overflow dyeing machine, regulating a pH value by adding a formic acid solution, carrying out crosslinking by adding a crosslinking agent solution, regulating a pH value by adding a sodium bicarbonate solution, finishing filling by adding a retanning agent solution, adding glutaraldehyde, modified glutaraldehyde, oxazolidine or an organic phosphine tanning agent, carrying out secondary fixed crosslinking, finishing fat liquoring by adding a fat-liquoring agent solution, dyeing, regulating a pH value by adding the formic acid solution, adding the crosslinking agent solution, carrying out third time of fixed crosslinking, adding the sodium bicarbonate solution, extracting alkali, washing, exiting the overflow dyeing machine, hanging and drying. According to the method disclosed by the invention, a macromolecular tanning agent is fully fixed among fibers, so that the amount of active group on the surface of a base cloth is increased, and performances, including the water vapor permeability, the hygroscopicity and the drapability, of the superfine fiber synthetic leather base cloth are improved.

Owner:SHAANXI UNIV OF SCI & TECH

Rapid and simple preparation method of lignin-based carbon quantum dots with high quantum yield

The invention belongs to the field of fluorescent carbon quantum dot preparation, and discloses a rapid and simple preparation method of lignin-based carbon quantum dots with a high quantum yield. The method comprises the following steps: firstly, mixing a carbon source consisting of modified lignin and organic acid with a nitrogen source consisting of a nitrogen-containing reagent, adding the mixture into a solvent to obtain a mixed solution, then carrying out ultrasonic treatment on the mixed solution, and finally, carrying out microwave heating on the mixed solution for a period of time to obtain a nitrogen-containing carbon quantum dot mixed solution; and after the reaction is finished, centrifuging, filtering, dialyzing and freeze-drying the mixed solution to obtain carbon quantum dot powder. By adjusting the pH value, the surface groups are protonated or deprotonated, so that the fluorescent carbon quantum dots emitting blue light and green light are obtained. Nitrogen atom doping can stabilize the surface defects of the carbon quantum dots, improve the radiative transition probability and enhance the photoluminescence performance, so that the lignin-based carbon quantum dots with the relative quantum yield as high as 70.77% are obtained.

Owner:GUANGDONG UNIV OF TECH

Preparation method for glass fiber

InactiveCN107032596ASmooth appearanceUniform colorGlass making apparatusMuffle furnaceWork in process

The invention relates to a preparation method for glass fiber. The method comprises the following steps: 1) mixing and fusing raw materials, and wiredrawing to form a crude fiber product; 2) putting the crude fiber product into a muffle furnace, removing water attached to the glass fiber surface, and then performing acid-base immersion cleaning, thereby acquiring a refined glass fiber product; 3) soaking the refined glass fiber product into a NaOH solution and then taking out, washing with distilled water, taking out and dispersing in absolute ethyl alcohol of a coupling agent KH570, regulating pH and dispersing with an ultrasonic meter, thereby acquiring a semi-finished product of glass fiber; 4) removing surface alkali liquor by spraying the surface of the semi-finished product of glass fiber with warm water, then soaking in clean water, and washing with the assistance of a hot water pump till the pH value is less than 6, thereby acquiring a to-be-finished product of glass fiber; 5) performing thermal shaping treatment on the to-be-finished product of glass fiber, and performing gumming, grouting and drying on the surface, thereby acquiring the end product. The preparation method has the advantages of simple structure, low cost and suitability for large-scale industrial manufacturing.

Owner:合肥钢骨玻璃制品有限公司

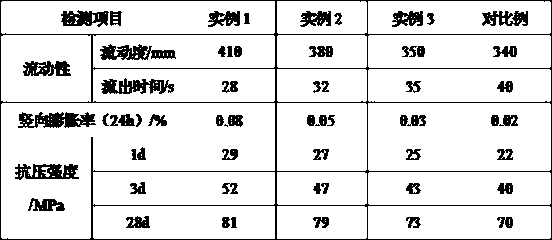

Cement-based grouting material

The invention discloses a cement-based grouting material, and belongs to the technical field of building materials. The cement-based grouting material is prepared according to the following steps: melting asphalt powder, performing high-voltage electrostatic spinningto obtain asphalt raw threads, soaking the asphalt raw threads in a potassium permanganate solution, performing oxidation to obtain oxidized asphalt fibers, mixing nano magnesium oxide, a silane coupling agent and an ethanol solution, performing ultrasonic dispersion, adding the oxidized asphalt fibers, performing mixing under stirring, adding tetraethoxysilane dropwise, performing mixing under stirring, performing filtering, performing washing, performing drying, and performing carbonizing to obtain modified asphalt fibers; mixing aluminum powder and glycerol under stirring, adding wheat gluten powder, performing mixing under stirring, adding water, performing swelling, allowing the obtained material to stand, and performing ultrasonic dispersion to obtain a modified aluminum powder dispersion liquid; and mixing cement, quartz sand, water, a water reducing agent, fly ash, mineral powder, slag, a defoaming agent, a water retaining agent, the modified asphalt fibers and the modified aluminum powder under stirring to obtain the cement-based grouting material. The cement-based grouting material obtained by the technical scheme has the advantages of good fluidity, early-stage strength and expansion performance.

Owner:郭迎庆

Preparation method of saline-alkaline soil bio-conditioner

InactiveCN109134141AImprove water retentionImprove convenienceMagnesium fertilisersBioloigcal waste fertilisersAlkali soilGenipin

The invention belongs to the technical field of soil conditioning and particularly relates to a preparation method of a saline-alkaline soil bio-conditioner. The preparation method includes: using leaf mold having developed pores and rich organics as a raw material, activating the raw material with a surfactant, extruding the activated material with additives, tightly combining the additives and the raw material by adding, allowing sulfur in the additives to form sulfides during pre-charring, retaining the sulfides during extrusion, allowing the sulfides to be well sucked to pre-charred particles through magnetic iron oxide, mixing the sucked sulfides with a mixed biological liquid to well suck and support microbes in the mixed biological liquid, subjecting enzymes and bacteria in the microbes to crosslinking and curing via Genipin, and mixing with additives. The additives help effectively improve water-holding performance of soil, and other auxiliaries help improve the soil conditioning effect.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

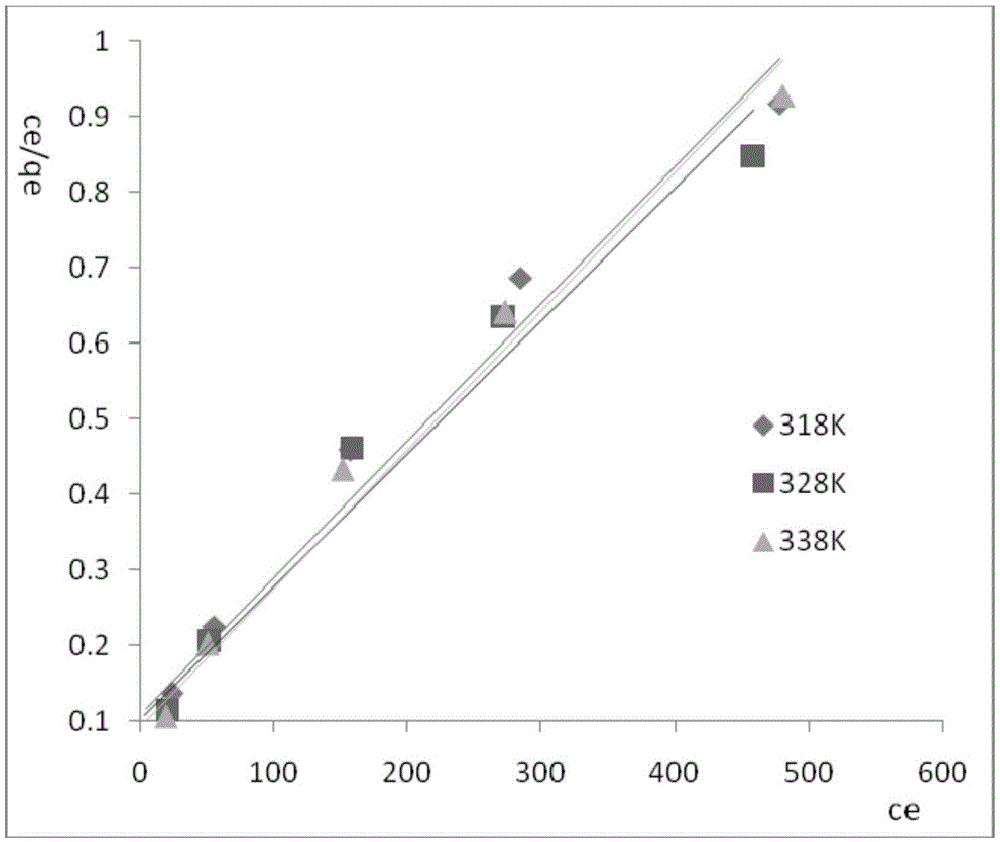

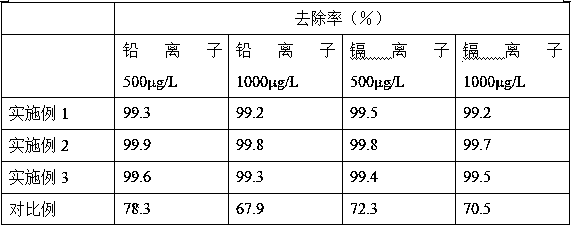

Preparation method of metal ion adsorbent

InactiveCN109126738AHigh porosityImprove adsorption capacityOther chemical processesWater contaminantsCross-linkSorbent

The invention relates to a preparation method of a metal ion adsorbent and belongs to the technical field of adsorbents. According to the preparation method, bamboo is adopted as a carrier, pores in the bamboo are increased through a steam blasting method, an internal structure of the bamboo is destroyed, the adsorption performance is improved, and then the bamboo is put into a carbonization furnace for pre-carbonization; complete carbonization of the interior of the bamboo is avoided through pre-carbonization, internal materials of the bamboo are partially decomposed or degraded, the adsorption and binding capability is improved, and then composite glue and sea mud are added; active substances in the sea mud can be well combined with the composite glue to achieve wrapping of pre-carbonized particles, metal substances in the sea mud are utilized to promote cross-linking in the composite glue for improving the adsorption performance, the composite glue is cross-linked with acrylic acidunder the action of sodium hydroxide, and under the action of N,N-dimethyl amide and sodium hydrosulfide, sulfydryl is added to the surface of the adsorbent, so that the adsorption performance for metal ions is improved.

Owner:张剑

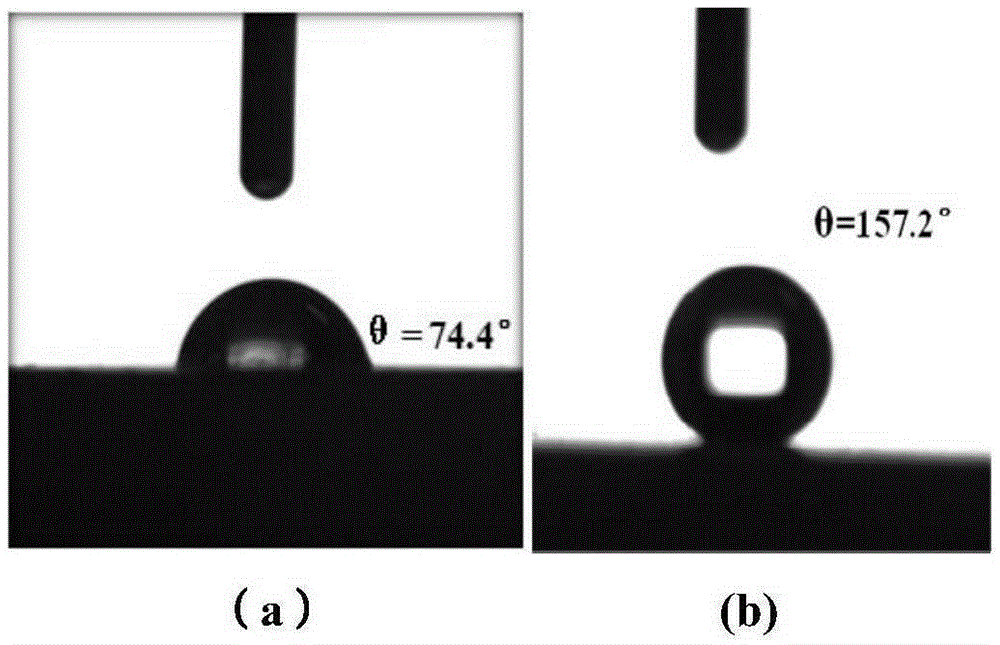

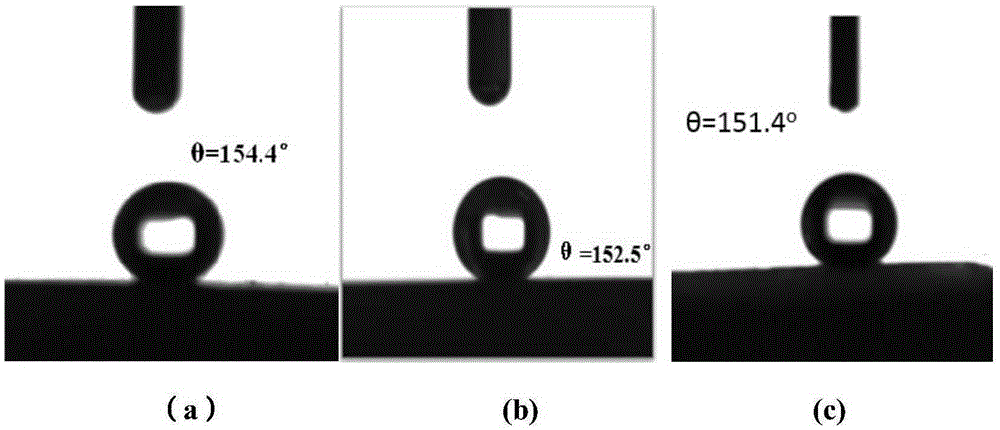

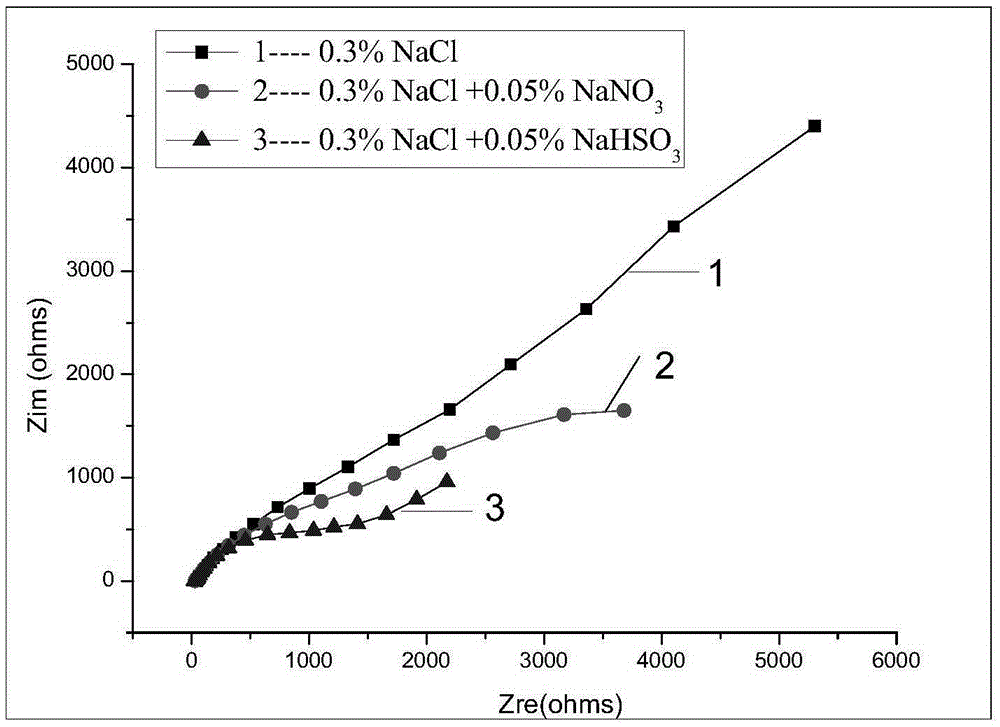

Method for constructing super-hydrophobic film on rusty bronze surface

InactiveCN105386060AImprove bindingThe production process is simple and safeVolatile corrosion inhibitorGas phase

The invention relates to a method for constructing a super-hydrophobic film on a rusty bronze surface. The method mainly aims at preventing further corrosion of bronze ware on the basis that the appearance of a cultural relic is not changed. The method includes the following steps: (1) pretreatment is carried out; (2) active groups on the bronze surface are increased through a volatile corrosion inhibitor; (3) silanization treatment is carried out; and (4) the step (2) and the step (3) are repeatedly executed, and the bronze surface with the super-hydrophobic performance is obtained. According to the method, the colorless and transparent super-hydrophobic film is successfully constructed on the rusty bronze surface through a gaseous phase layer-by-layer self-assembly technology, the manufacturing method is safe, and the surface of a base body is free of damage; by means of the method, the contact angle of the constructed super-hydrophobic surface ranges from 152 degrees to 158 degrees, the good super-hydrophobic performance is shown, and corrosion prevention and self cleaning of the surface of the bronze cultural relic can be achieved; and the super-hydrophobic surface manufactured with the method has the extremely-high stability and durability and is soaked in a high corrosive solution for 90 days, and the good antiseptic property is still shown.

Owner:SHANGHAI MUSEUM +1

Preparation method of composite material for mobile phone shell

The invention discloses a preparation method of composite material for a mobile phone shell, which includes steps of: feeding raw materials into a high-speed mixer, the raw materials comprising, by weight, 82-95 parts of polycarbonate, 33-36 parts of an acrylonitrile-butadiene-styrene copolymer, 15-25 parts of modified carbon fiber, 3-8 parts of a ternary styrene-acrylonitrile-maleic anhydride random copolymer, 2-4 parts of tributyl phosphate, 2-4 parts of EC type brominated epoxy resin, 0.5-1 part of tri(2,4-di-tert-butylphenyl) phosphite, 1-2 parts of pentaerythritol stearate, and 0.5-2 parts of bis(2,6-di-tert-butylphenol), and mixing the components for 3-5 min to obtain a mixture; and performing extrusive granulation to the mixture on a twin-screw extruder to obtain the composite material. The composite material has great comprehensive performance and high strength.

Owner:安徽酷米智能科技股份有限公司

Method for preparing protein filling agent from organic phosphate and chitosan modified keratin

ActiveCN107385124AHigh molecular weightAdd active groupsTanning treatmentPeptide preparation methodsResource utilizationPhosphate

The invention relates to the technical field of leather waste resource utilization, and provides a method for preparing a protein filling agent from organic phosphate and chitosan modified keratin. The method comprises the steps that animal fur is hydrolyzed through an alkali-reducing agent combined method, then, organic phosphate and chitosan are used for modifying obtained keratin, the relative molecular mass of the keratin is increased, and the crosslinking behavior and antibacterial and antifungal properties of the protein filling agent are improved, so that when the protein filling agent prepared by the method for preparing the protein filling agent from the organic phosphate and the chitosan modified keratin is applied to leather making, obtained leather is flat, fine, soft and full in grain surface, bright in color and good in antibacterial and antifungal property.

Owner:XINGYE LEATHER TECH CO LTD

Deep softening method of thick oil sewage

ActiveCN102815765BIncrease surface areaAdd active groupsWater/sewage treatment by ion-exchangeWater qualitySewage

Owner:PETROCHINA CO LTD

Preparation method of glass fiber composite material

InactiveCN108249769AImprove ablation performanceImprove high temperature resistanceGlass making apparatusMolten stateGlycidyl methacrylate

The invention provides a preparation method of a glass fiber composite material. The preparation method comprises the following steps that a, glass powder, selected high filter residue, calcium oxide,magnesium oxide, titanium dioxide, aluminum oxide and silicon dioxide are mixed and smashed, and mixed powder is obtained; b, a substrate material, glycidyl methacrylate, sodium pyrophosphate and pentaerythritol ester are mixed to be uniform and melted to be at a molten state, and a first material is obtained after heat preservation is conducted; c, the mixed powder is added into the first material and melted and stirred, then subjected to fusion wiredrawing, and a crude product is obtained; and d, the crude product is subjected to acidification treatment, treatment is conducted on the crudeproduct by using a silane coupling agent, heat treatment is conducted consecutively, and finally drying is conducted. The prepared glass fiber composite material has good ablation performance, betterhigh temperature resistance, the chemical corrosion resistant property and the elasticity modulus.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com