Cultivation material for artificial cultivation of Phellinus igniarius, and preparation method of cultivation material

A technology of artificial cultivation and cultivation materials, which is applied in the field of artificial cultivation of Phellinus Phellinus, which can solve the problems of insufficient nutrient supply, difficulty in forming fruiting bodies, and low yield of Phellinus Phellinus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

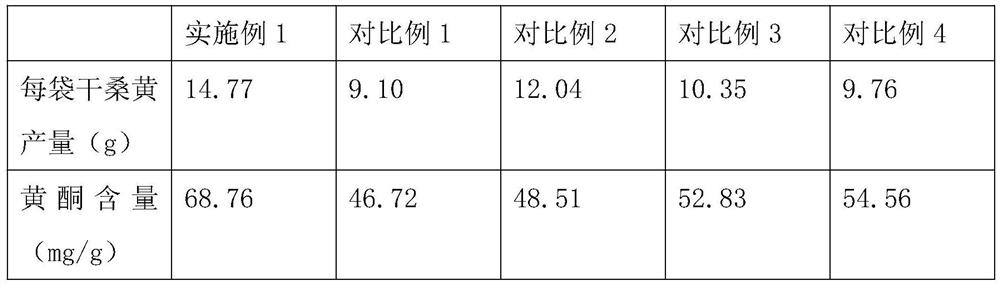

Examples

Embodiment 1

[0025] A preparation method of a cultivation material for artificially cultivating Phellinus Phellinus, comprising the steps of:

[0026] (1) After pulverizing mulberry twigs, cottonseed hulls and bran, mix them evenly according to the mass ratio of 3:1:0.5 to obtain the mixture A;

[0027] (2) The mixture A is adjusted to a water content of 45%, then placed in a steam explosion tank, maintained at a steam pressure of 1 MPa for 6 minutes, then the valve is opened to release the pressure quickly, and the collected material is dried to obtain a mixed mixture. Material B;

[0028] (3) Prepare a liquid medium with grapefruit peel hydrolyzate, yeast powder, peptone, and sucrose as raw materials, insert Acetobacter xylinum equivalent to 4% of the volume of the liquid medium, and at 28°C, pH is 6.2 Mechanically stirred and fermented for 12 days to obtain fermented liquid C, wherein the liquid medium included the following components in mass percent: yeast powder 5%, peptone 4%, sucr...

Embodiment 2

[0033] A preparation method of a cultivation material for artificially cultivating Phellinus Phellinus, comprising the steps of:

[0034] (1) After crushing mulberry twigs, cottonseed hulls and bran, mix them evenly according to the mass ratio of 4:0.5:0.3 to obtain the mixture A;

[0035] (2) adjusting the mixture A to a water content of 40%, then placing it in a steam explosion tank, maintaining it for 10 minutes at a steam pressure of 0.5 MPa, then opening the valve to release the pressure quickly, and drying the collected material to obtain mix B;

[0036] (3) Prepare a liquid medium with grapefruit peel hydrolyzate, yeast powder, peptone, and sucrose as raw materials, insert Acetobacter xylinum equivalent to 3% of the volume of the liquid medium, and at 25 ° C, pH is 6 conditions Mechanically stirred and fermented for 15 days to obtain fermented liquid C, wherein the liquid medium included the following components in mass percent: yeast powder 3%, peptone 2%, sucrose 5%,...

Embodiment 3

[0041] A preparation method of a cultivation material for artificially cultivating Phellinus Phellinus, comprising the steps of:

[0042](1) After pulverizing mulberry twigs, cottonseed hulls and bran, mix them evenly according to the mass ratio of 5:1.5:0.8 to obtain the mixture A;

[0043] (2) adjusting the mixture A to a water content of 50%, then placing it in a steam explosion tank, maintaining it for 5 minutes at a steam pressure of 1.5MPa, then opening the valve to release the pressure quickly, and drying the collected material to obtain mix B;

[0044] (3) Prepare a liquid medium with grapefruit peel hydrolyzate, yeast powder, peptone, and sucrose as raw materials, insert Acetobacter xylinum equivalent to 5% of the volume of the liquid medium, and at 30°C, the pH is 6.5 Mechanically stirred and fermented for 10 days to obtain fermented liquid C, wherein the liquid medium included the following components in mass percentage: 8% yeast powder, 5% peptone, 8% sucrose, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com