Patents

Literature

271 results about "Acetobacter xylinum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetobacter xylinum is a non-pathogenic mesophile identified by A.J Brown in 1886 due to its ability to produce cellulose [1].

Compound probiotics fermented Chinese herbal medicine active health care liquid and preparation method thereof

ActiveCN103027231AAntioxidantHigh food and medicinal valuePre-extraction tea treatmentFood preparationMetaboliteCoronary heart disease

The invention provides compound probiotics fermented Chinese herbal medicine active health care liquid and a preparation method thereof. The health care liquid is prepared by the following raw materials: folium ginkgo, gingko pollen, fructus lycii, tea leaves, bacillus natto, saccharomyces cerevisiae, lactobacilli, acetobacter xylinum, bifidobactirium, white granulated sugar, brown sugar, defatted soy flour, honey, oligosaccharide, sodium chloride, deionized water and the like. The compound probiotics fermented Chinese herbal medicine active health care liquid integrates disease treatment and health care functions of several single products, contains Chinese herbal medicine active ingredients with the functions of preventing and treating hyperlipidemia, hyperglycemia and hypertension, preventing tumors and cancers, enhancing memory, protecting livers, improving immunity, preventing and treating coronary heart diseases, and also contains probiotics groups and metabolic products of the probiotics groups which can regulate balance in the stomach and intestines, resist aging, prolong the life, facilitate digestion, expel toxin for beauty, and prevent and treat thrombi, constipation and diarrhea. The health care liquid integrates health care and treatment, is very wide in market prospect, and conforms to the existing medical viewpoint of people that the prevention, health care, treatment and recovery are combined.

Owner:湖南现代资源生物科技有限公司

Method for fermented-producing bacteria cellulose with pineapple peel juice by two-step method

InactiveCN101671708AEasy to produceReduce manufacturing costMicroorganism based processesFermentationMicrobiologyTwo step

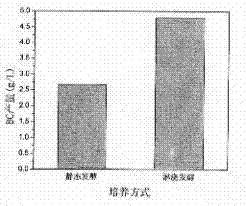

The invention discloses a method for fermented-producing bacteria cellulose with pineapple peel juice by a two-step method. In the method, two stages, including multiplication of acetobacter xylinum and fermented production of bacteria cellulose, are separated from each other, sterile air is ceaselessly fed in at 22 to 28 DEG C in the process of fermentation and acetobacter xylinum is cultivated for 24 to 72 hours under 100 to 200rpm stirring, at this moment, the viable count of acetobacter xylinum is 10<8> to 10<9>cfu / ml, cells are subject to multiplication culture of bacteria to be in a synchronous growth period as far as possible, and the cells are then subject to shallow tray static cultivation in a fermentation medium for fresh juice of the pineapple peel so as to result in bacteria cellulose with the yield more than 17.5g / L. The method greatly shortens the production period of bacteria cellulose, makes full use of the pineapple peel and protects environmental, and in addition, the produced bacteria cellulose is compact and uniform in texture.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing bacteria cellulose with association of activity and inertia

InactiveCN101319242AIncrease productionSimple processMicroorganism based processesFermentationBiotechnologyDry weight

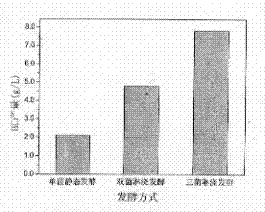

The invention discloses a method for preparing bacterial cellulose by dynamic and static combination, which is characterized in that: an acetobacter xylinum strain is taken and inoculated into a seed culture medium, is inoculated into a seeding tank for amplification culture for 12 to 36h according to 4 to 16 percent of inoculum concentration after the shaking culture by a shaking table at a temperature of between 25 and 31 DEG C and a rotating speed of between 100 and 180rpm for 12 to 48h, is inoculated into a productive tank to be cultured for 12 to 36h, and is packaged separately and then undergoes tray culture for 3 to 10 days at a culture temperature of between 25 and 31 DEG C to produce a finished product, a crude cellulose membrane. The method has simple process, the output is apparently improved, and the output of the bacterial cellulose produced by the method is high up to 13.6g / L (dry weight).

Owner:许春元 +1

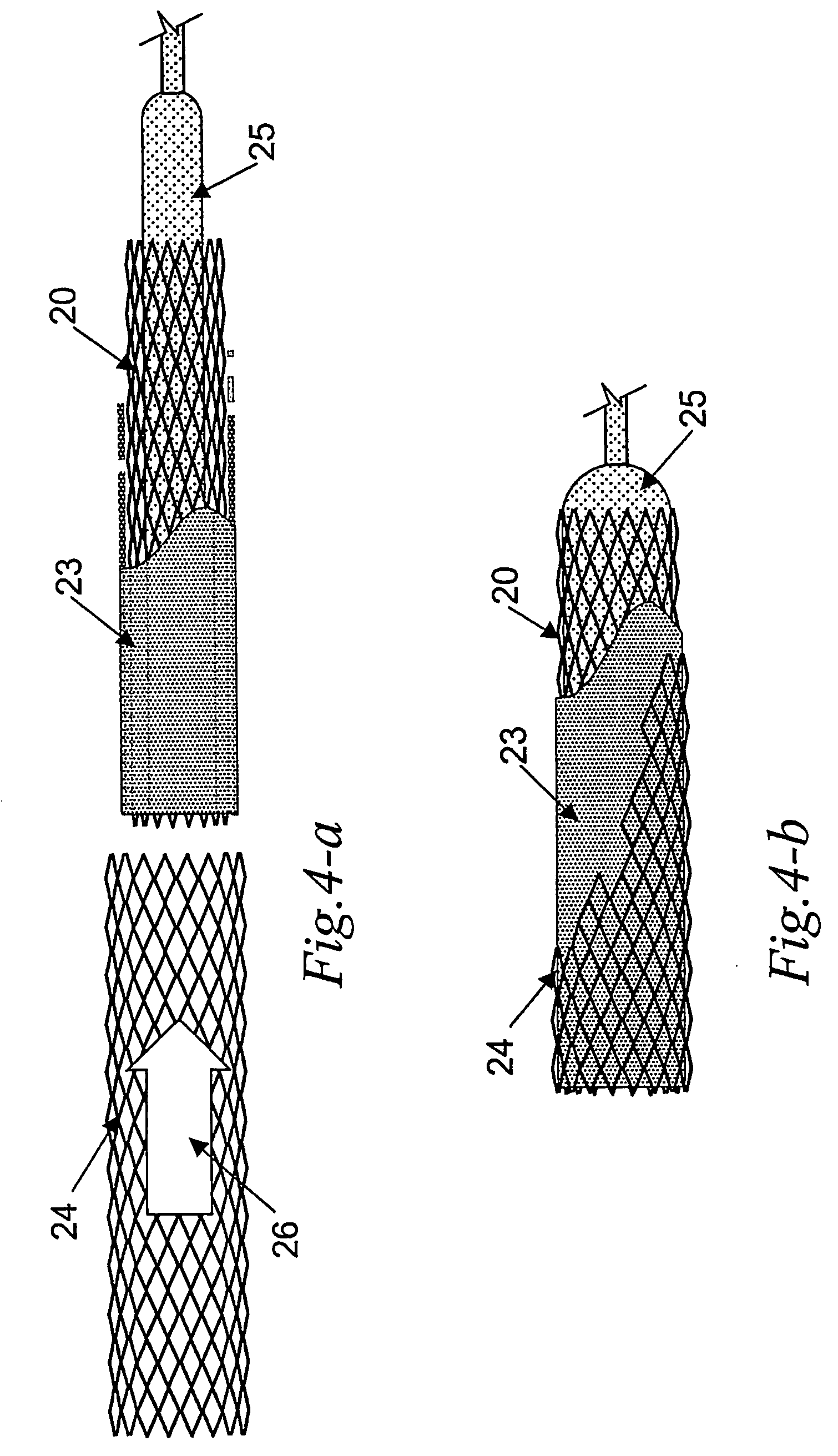

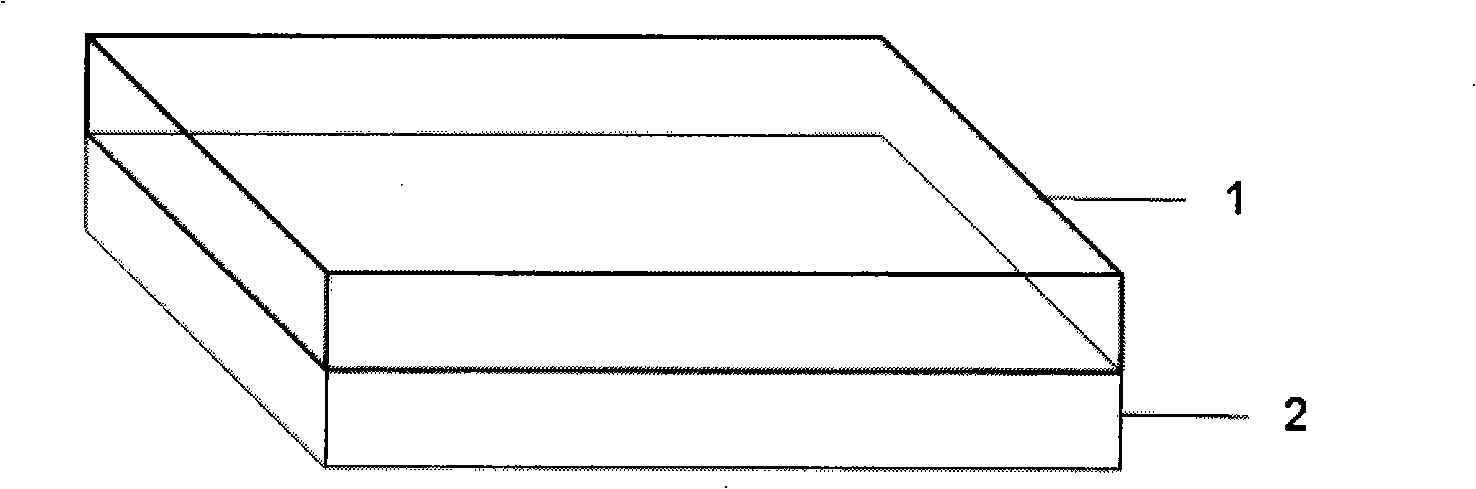

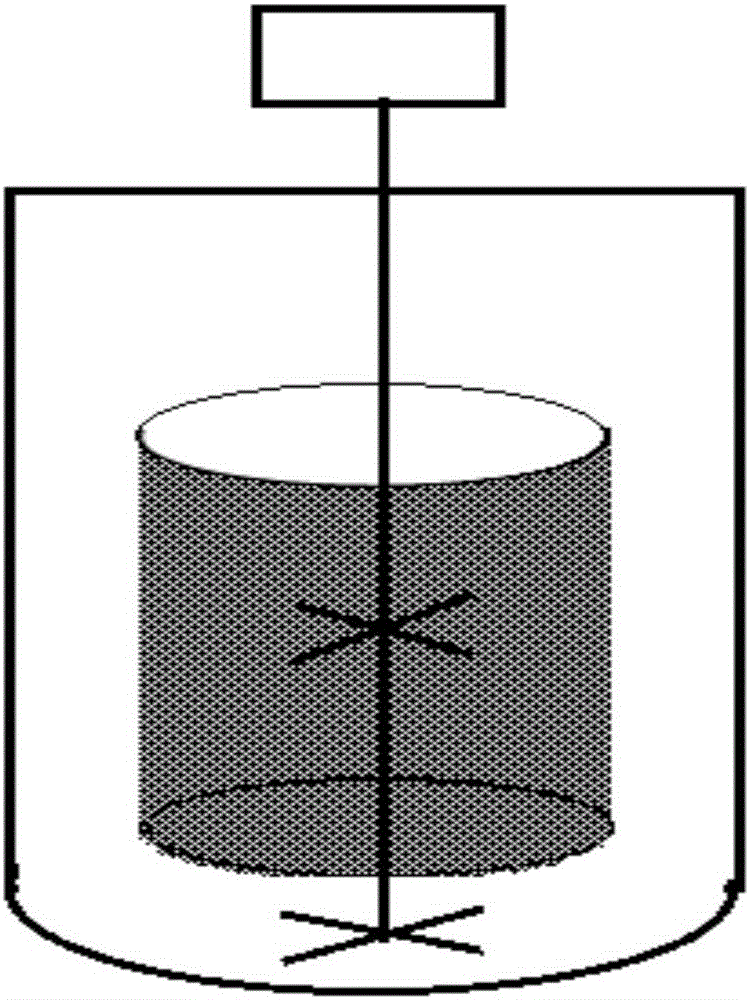

Endoprosthesis process to obtain and methods used

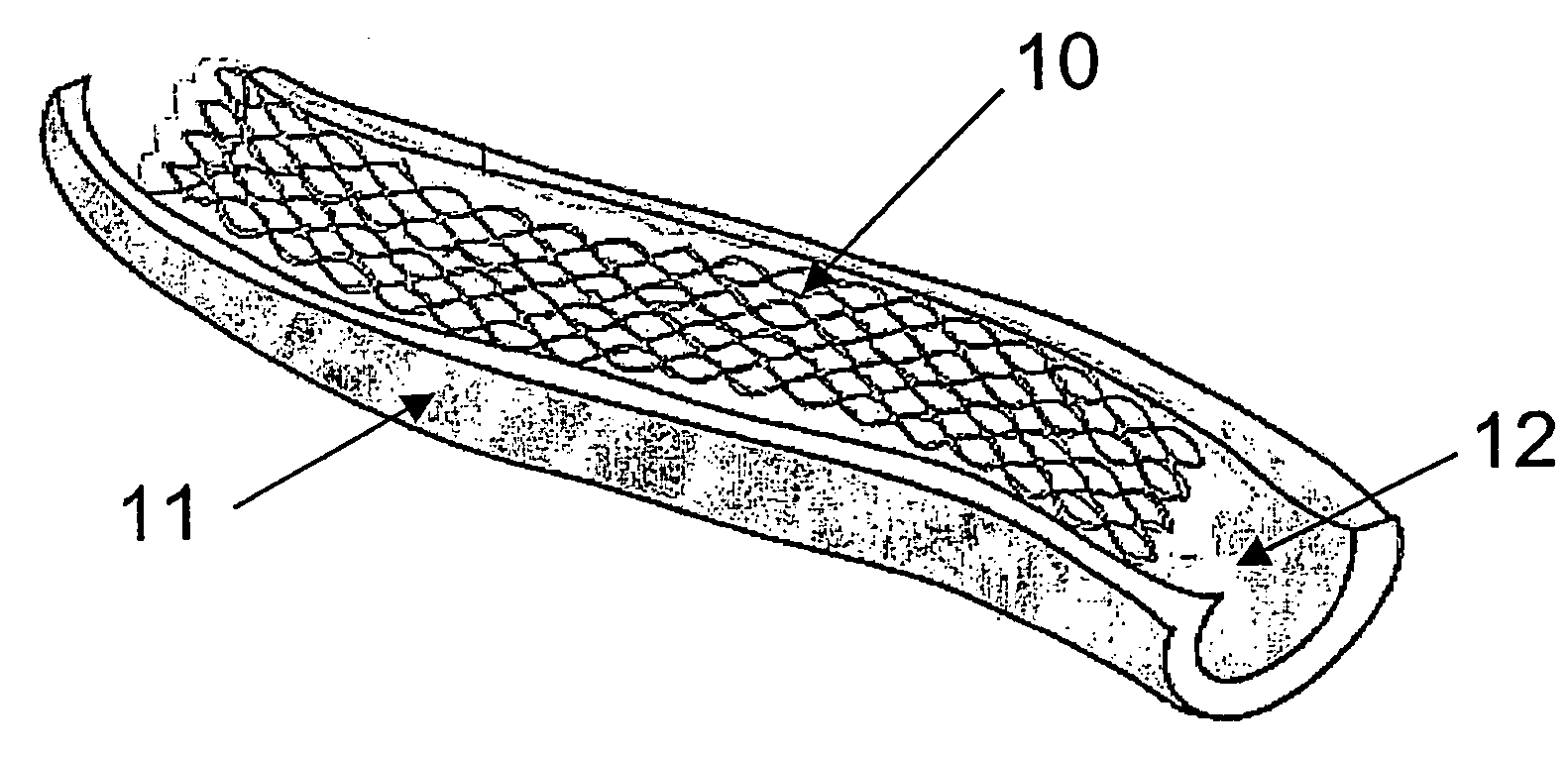

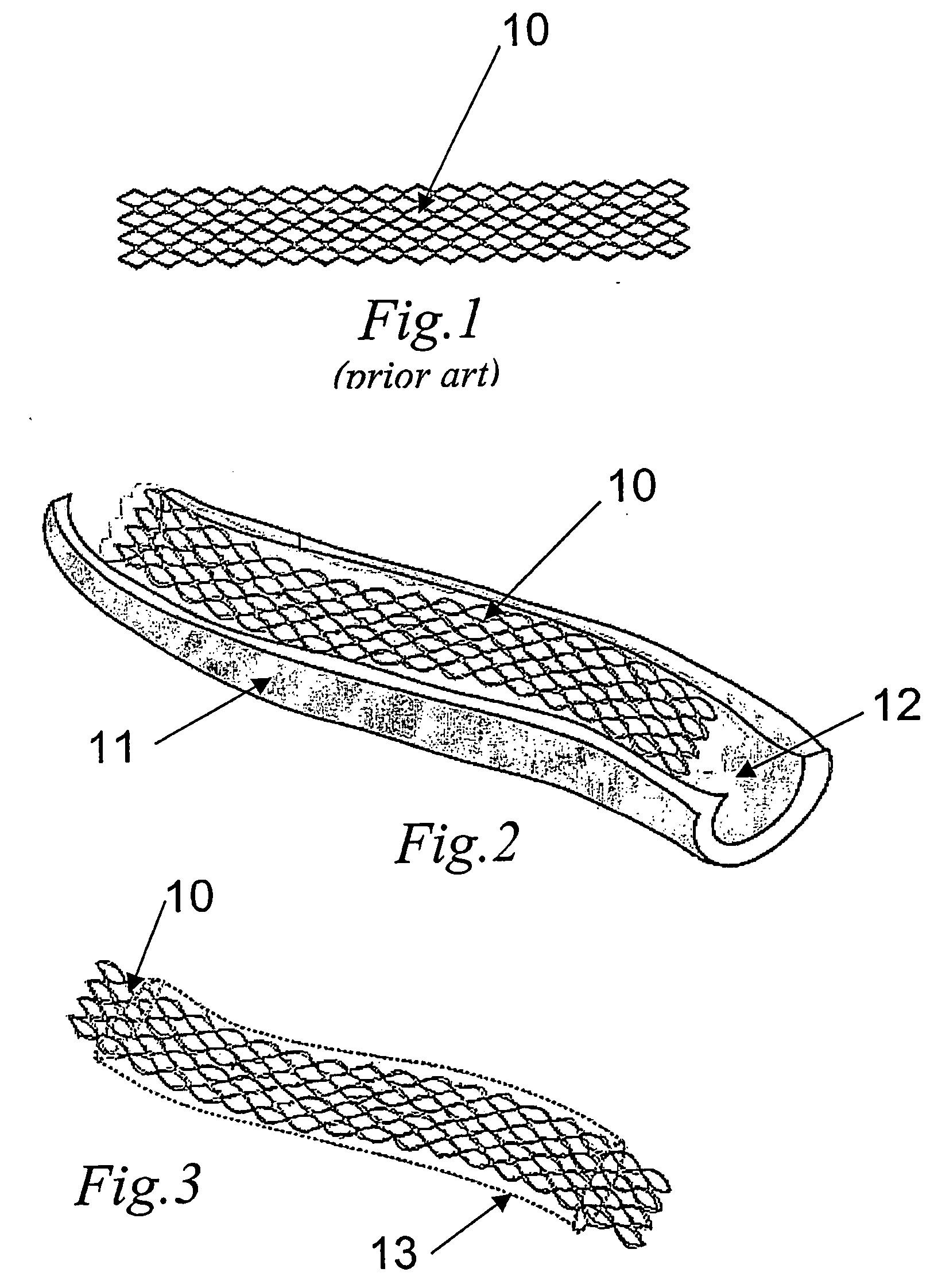

InactiveUS20060147612A1Fully fixedLocal reaction can be reducedStentsSurgeryAcetobacter xylinumBiology

Comprising a wire mesh structure covered with biocompatible material and, more particularly, a substantially cylindrical expandable endoprosthesis (10) covered with biosynthetic cellulosic membrane for the treatment of arterial stenosis, where such structure is introduced in a mold (11), which is made of a material that is impermeable to liquids and permeable to gases, together with a culture medium (12) inoculated with a cellulose-producing microorganism such as the Acetobacter xylinum, resulting in the formation of a cellulosic membrane juxtaposed to the inner wall of said mold. The membrane can be impregnated to the inner wall of said mold (11). The membrane can be impregnated with therapeutic agents to be locally released during a period of days or weeks. Methods used to mount and deploy the endoprosthesis in the body.

Owner:BIOSTENT PROD BIOTECHCOS

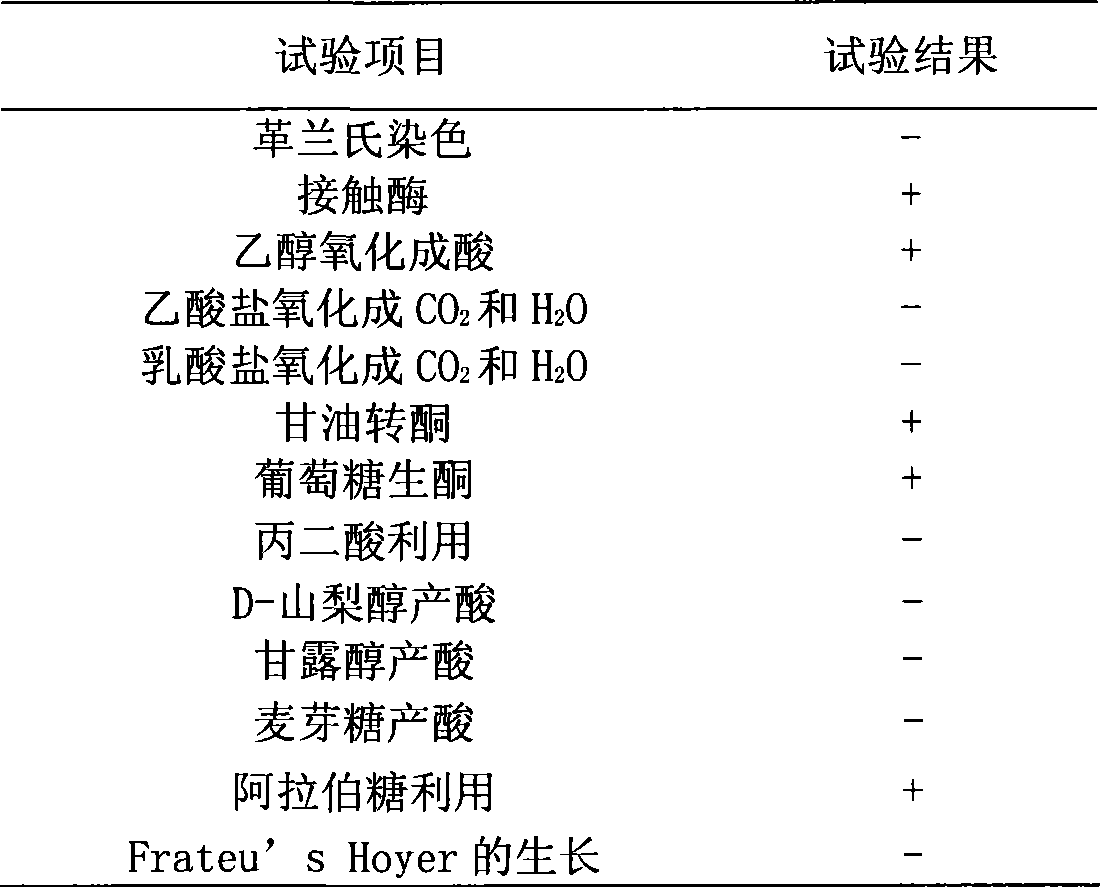

Bacteria cellulose producing bacteria and method for preparing bacteria cellulose using above bacterial strain

The invention provides bacterial cellulose (BC) producing bacteria and a method for preparing the bacterial cellulose by using the bacterial strain. The bacterial strain is a selected gluconic acid acetobacter xylinum GD-BC-1 with an accession number of CCTCC M 208149. The method is to use the bacterial strain as a fermentation bacterial strain and use glucose as a main fermentation material for fermentation so as to obtain the BC. The preparation method comprises the following steps of: activating a slant bacterial strain, liquid-activating the slant bacterial strain, inoculating the liquid-activated slant bacterial strain in a fermentation culture medium to perform dynamic or static fermentation and extracting products of BC from the fermentation solution. The preparation method uses the bacterial strain of gluconic acid acetobacter xylinum GD-BC-1 with the accession number of CCTCC M 208149 for fermentation so as to produce the BC. The BC can be produced through dynamic or static fermentation in a conical flask with glucose as the main fermentation material, and the yield is high and different methods can be used in different production environment to produce BC.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Method for preparing cuprous oxide/ bacterial cellulose nano composite material

InactiveCN102121038AMaintain nanostructureOvercoming the disadvantages of difficult recyclingMaterial nanotechnologyCopper oxides/halidesGas detectorHydroquinone Compound

The invention relates to a method for preparing a cuprous oxide / bacterial cellulose nano composite material. The preparing method comprises the following steps of: obliquely inoculating acetobacter xylinum strains into culture solution, and culturing the strains to obtain a bacterial cellulose gel film; performing surface activation treatment on the bacterial cellulose gel film in sulfuric acid solution and sodium hypochlorite solution respectively; and sequentially soaking the surface activated bacterial cellulose gel film into Cu(NO3)2 solution and hydroquinone solution to perform reduction reaction to obtain the cuprous oxide / bacterial cellulose nano composite material. The method has the advantages that: the preparation process is simple; and the prepared composite material keeps the nano structure of cuprous oxide particles, simultaneously has good strength performance, and has wide application prospect on the aspects of electrode devices, catalysts, gas sensitive sensors and the like.

Owner:TIANJIN UNIV

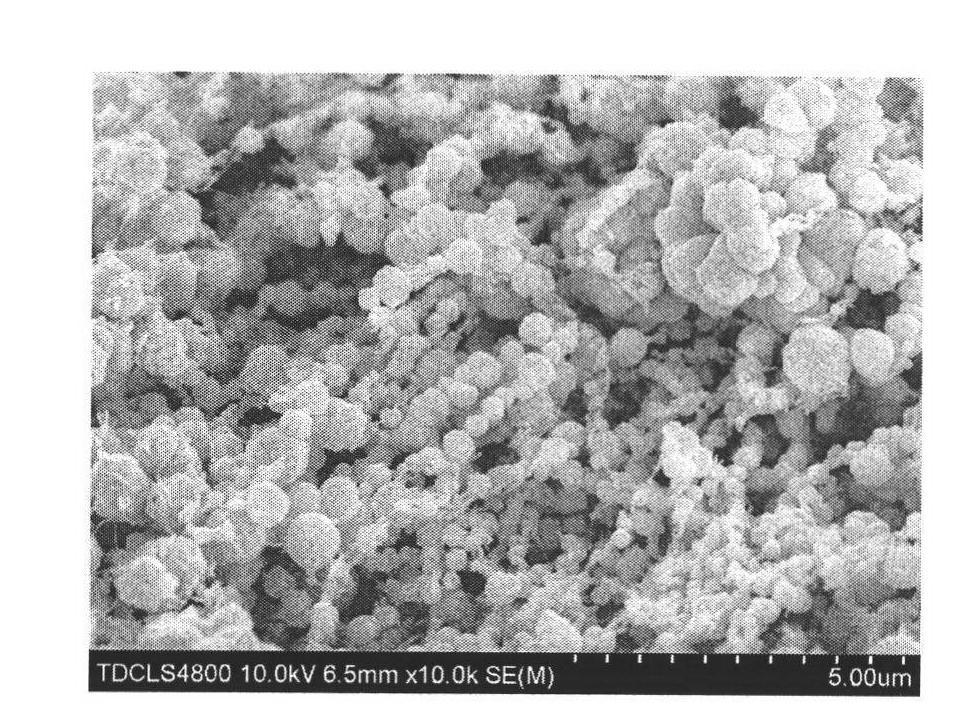

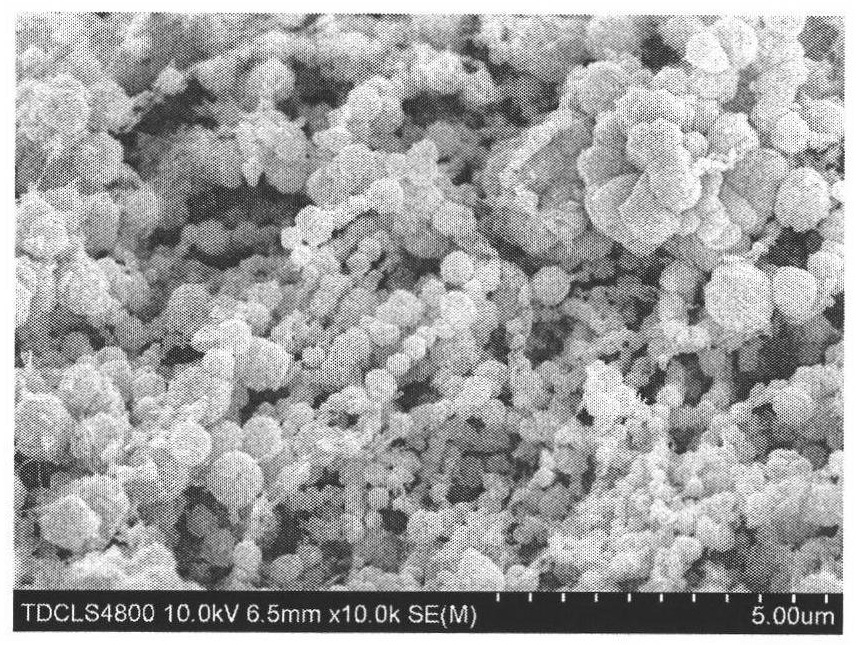

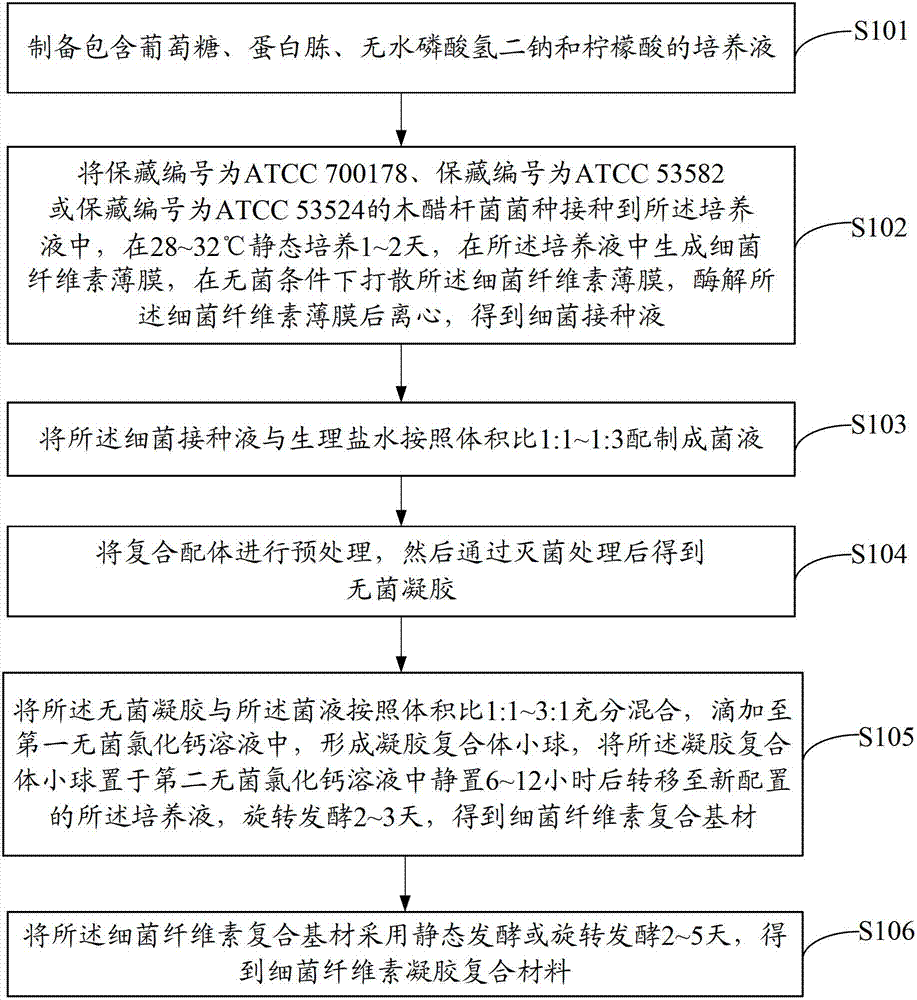

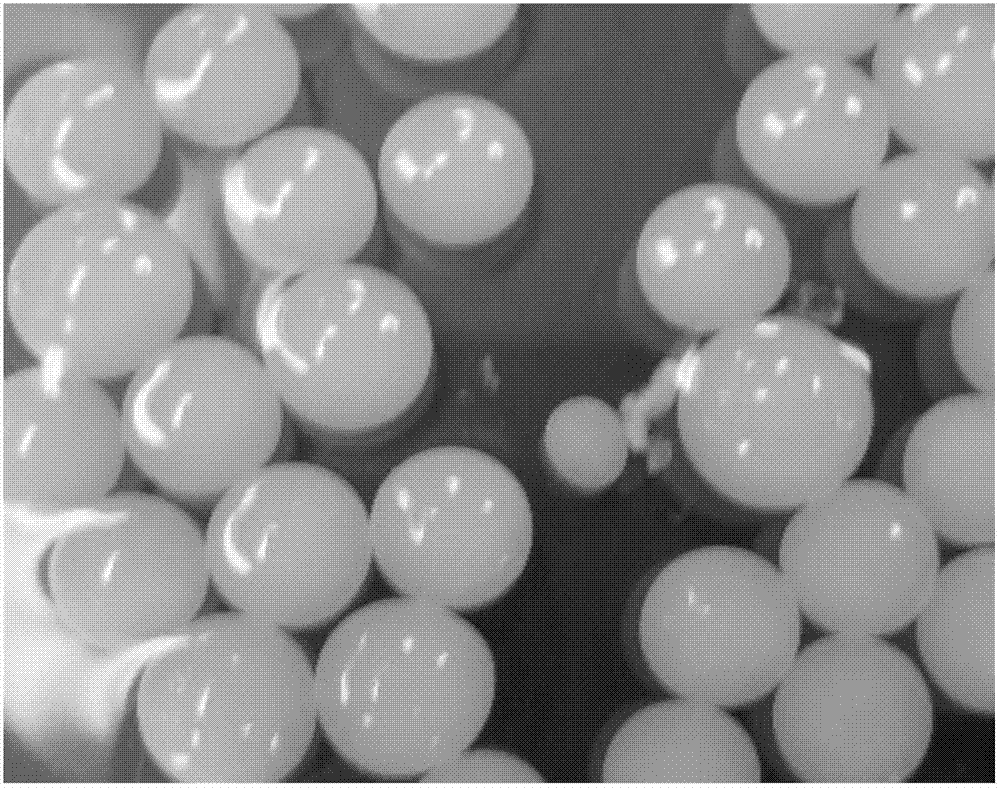

Method for preparing bacterial cellulose gel composite material

The invention relates to a method for preparing a bacterial cellulose gel composite material, which comprises the following steps: preparing culture solution; inoculating a strain of acetobacter xylinum into the culture solution, carrying out static culture for 2 days at a temperature of 30 DEG C to generate a bacterial cellulose thin film, dispersing the bacterial cellulose thin film under the aseptic condition, and centrifuging after carrying out enzymolysis on the bacterial cellulose thin film so as to obtain bacterial inoculated solution; preparing bacteria solution from the bacterial inoculated solution and normal saline according to a volume ratio of 1:1 to 1:3; after preprocessing a composite ligand, sterilizing the composite ligand to obtain aseptic gel; sufficiently mixing the aseptic gel and the bacteria solution according to a volume ratio of 1:1 to 3:1, dropwise adding the mixture into first aseptic calcium chloride solution to form gel complex globule, then transferring the gel complex globule into second aseptic calcium chloride solution to carry out standing for 6 to 12 hours, placing the obtained product into newly prepared culture solution and carrying out rotating fermentation for 2 to 3 days so as to obtain a bacterial cellulose gel composite base material; and carrying out rotating fermentation or static fermentation on the bacterial cellulose gel composite base material for 2 to 5 days so as to obtain the ball-like or film-shaped bacterial cellulose gel composite material. The method is high in composite rate and in material utilization rate.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of biology cellulose composite membrane face-mask material

PendingCN101332158AIncrease moisture contentGood moisturizing effectCosmetic preparationsToilet preparationsCarboxymethyl celluloseCellulose

The present invention discloses a preparation method for a biological cellulose composite membrane mask material. In the preparation method, water soluble macromolecular carboxymethyl cellulose is added into a culture medium, and then acetobacter xylinum is switched in for static culturing to obtain a biological cellulose composite membrane. The biological cellulose composite membrane generated after the carboxymethyl cellulose is added has good water retention property and good ventilation property, and the output and the water content of the biological cellulose composite membrane are improved to a certain extent. The biological cellulose composite membrane mask material can be obtained after the generated biological cellulose composite membrane is processed.

Owner:吴永辉

Vascular stent material of tissue engineering and manufacturing method thereof

ActiveCN101584882AGood biocompatibilityDoes not cause immune rejectionCoatingsBlood vesselsPorositySide effect

The invention discloses a vascular stent material of tissue engineering and manufacturing method thereof, which comprises selecting acetobacter xylinum as a model strain; using oxygen permeable materials to prepare hollow tubular dies which are arranged in the fermentation liquid and introduced with oxygen for fermentation until the bacterial celluloses completely cover the outer surface of the dies and the required porosity, thickness, uniformity and structural characteristic are reached to obtain a vascular stent raw material of tissue engineering; removing impurities to reduce the impurity rate to below 0.05%, sterilizing and packaging to prepare the vascular stent material of tissue engineering. The invention is simple in process and safe and has no toxic and side effect, and the material has more uniform spatial structure, more suitable porosity, uniform texture of each material in batches by controlling the fermentation process to effectively improve the quality and favourably achieve the scaled production.

Owner:HAINAN YEGUO FOODS

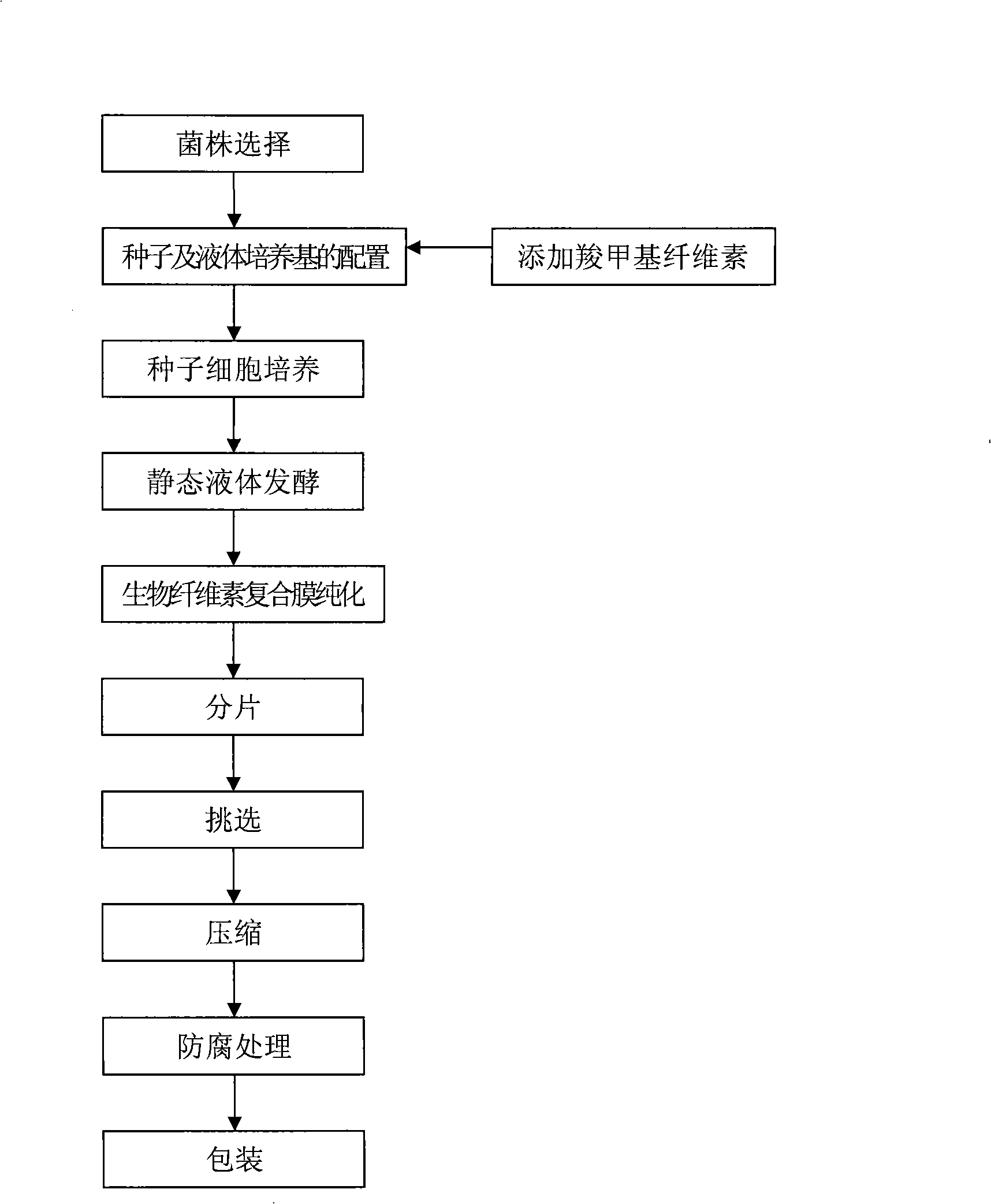

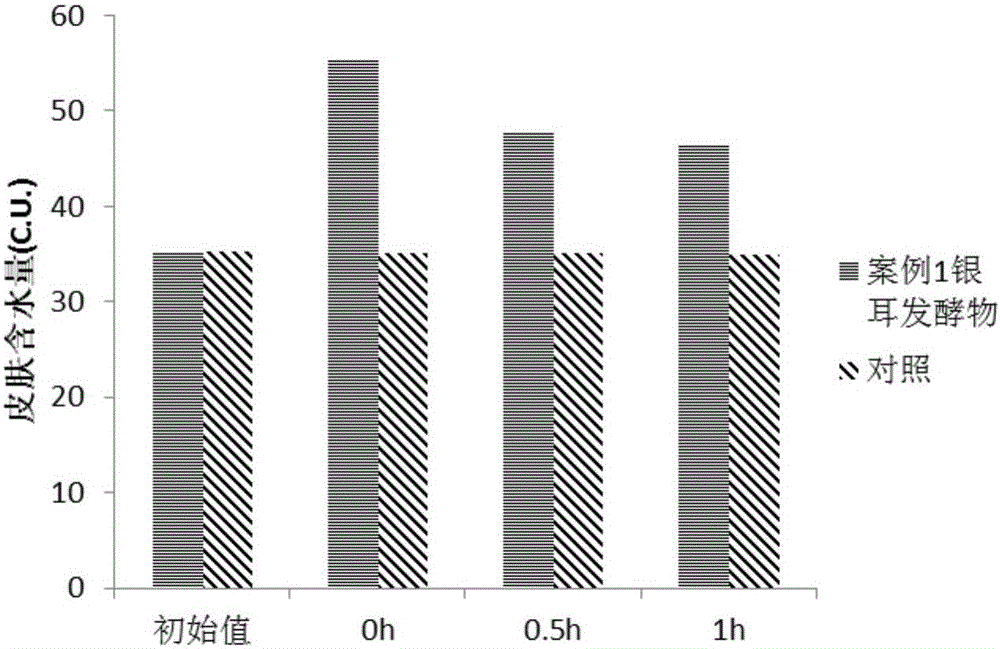

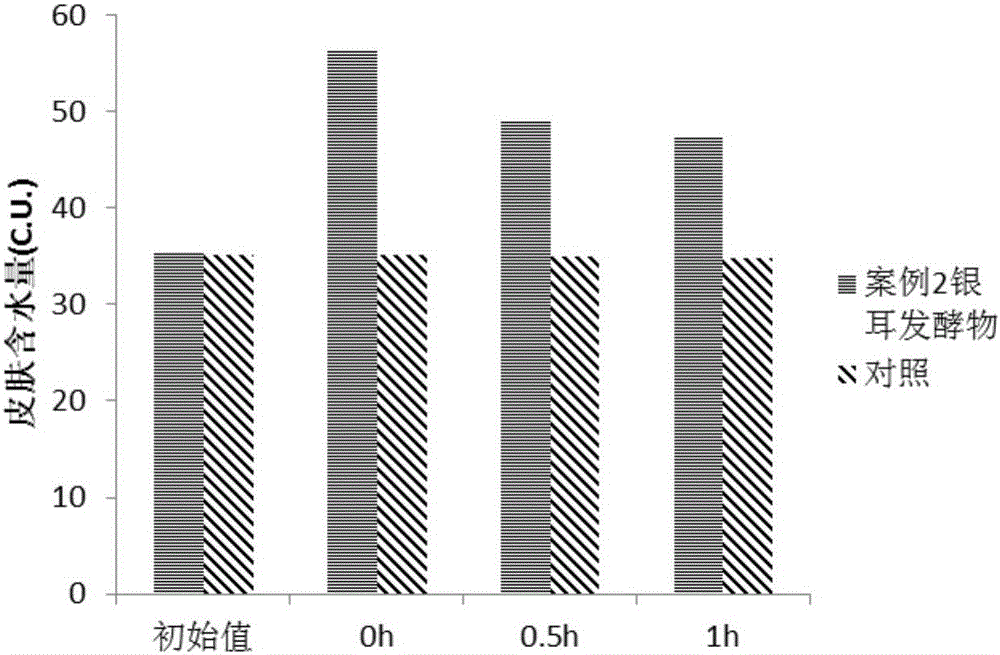

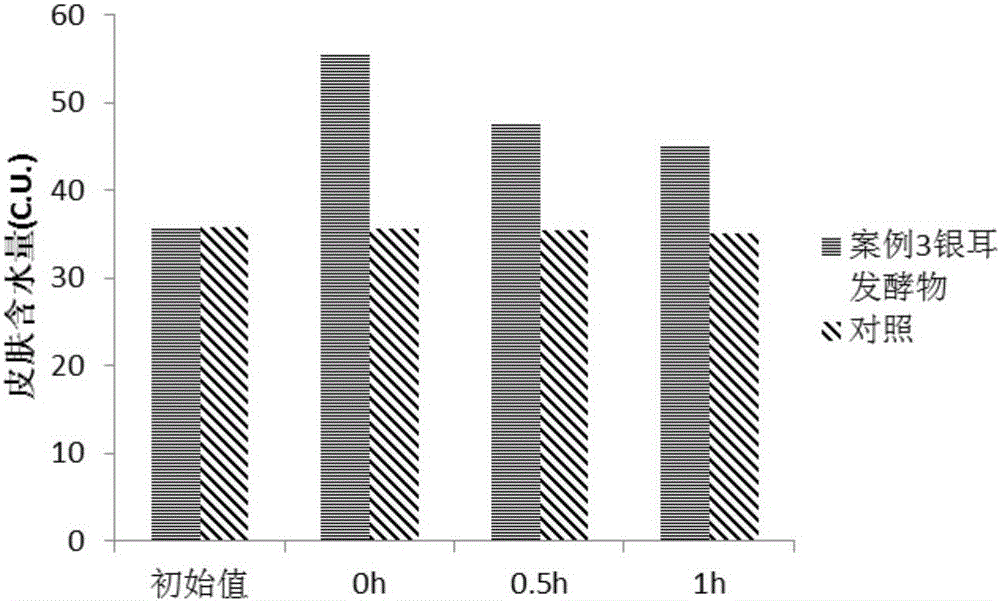

Preparation method and application of tremella fermentation extract

ActiveCN105002254AFully absorbedCause negative effectsCosmetic preparationsToilet preparationsTremellaZygosaccharomyces

The invention discloses a preparation method of a tremella fermentation extract and its application. The preparation method of the tremella fermentation extract comprises the following step: tremella undergoes fermentation cultivation by the use of a strain or its culture solution or its suspension so as to obtain a fermentation product, namely the tremella fermentation extract. The strain is at least one of the following strains: zygosaccharomyces rouxii, pasteur yeast, brewer's yeast, wine yeast, acetobacter xylinum, Lactobacillus delbrueckii subsp. Bulgaricus, Streptococcus thermophilus, Bifidobacterium bifidum, lactococcus lactis and enterococcus faecalis. Through experiments, it proves that the tremella fermentation extract prepared by the method contains no chemical components, can be directly used as a finished product of facial mask or essence or toner, is more natural than other existing products in the market and will not have any negative effect on the skin. In addition, smaller components can be obtained by the preparation method in comparison with a common extraction method and the extract is easier to fully absorb by the skin.

Owner:SHANGHAI BIOTRULY BIOTECH CO LTD

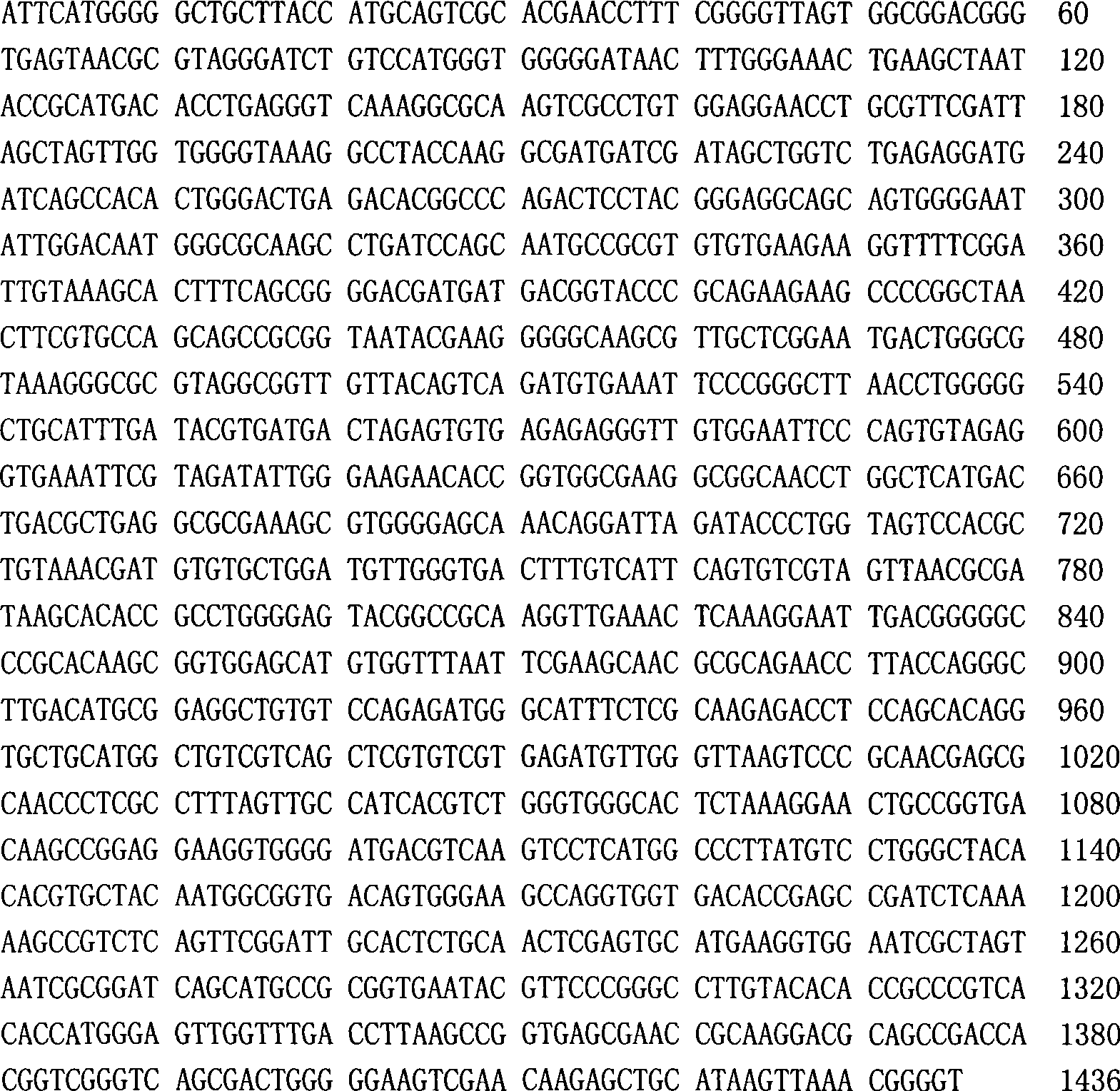

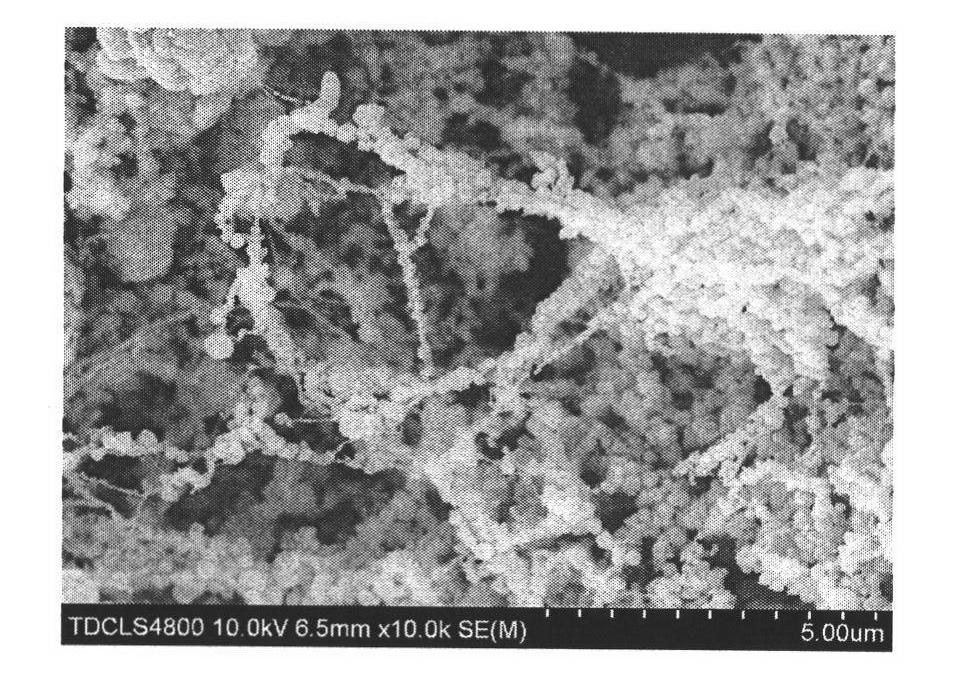

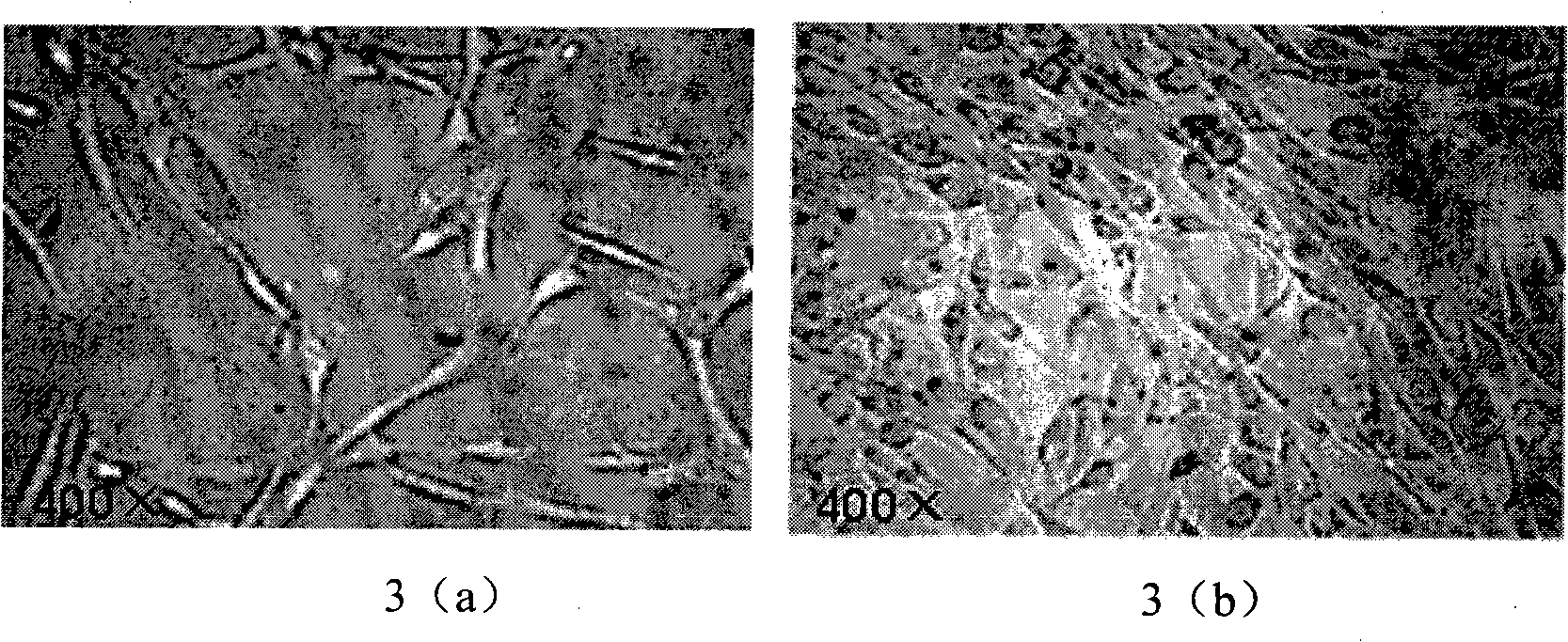

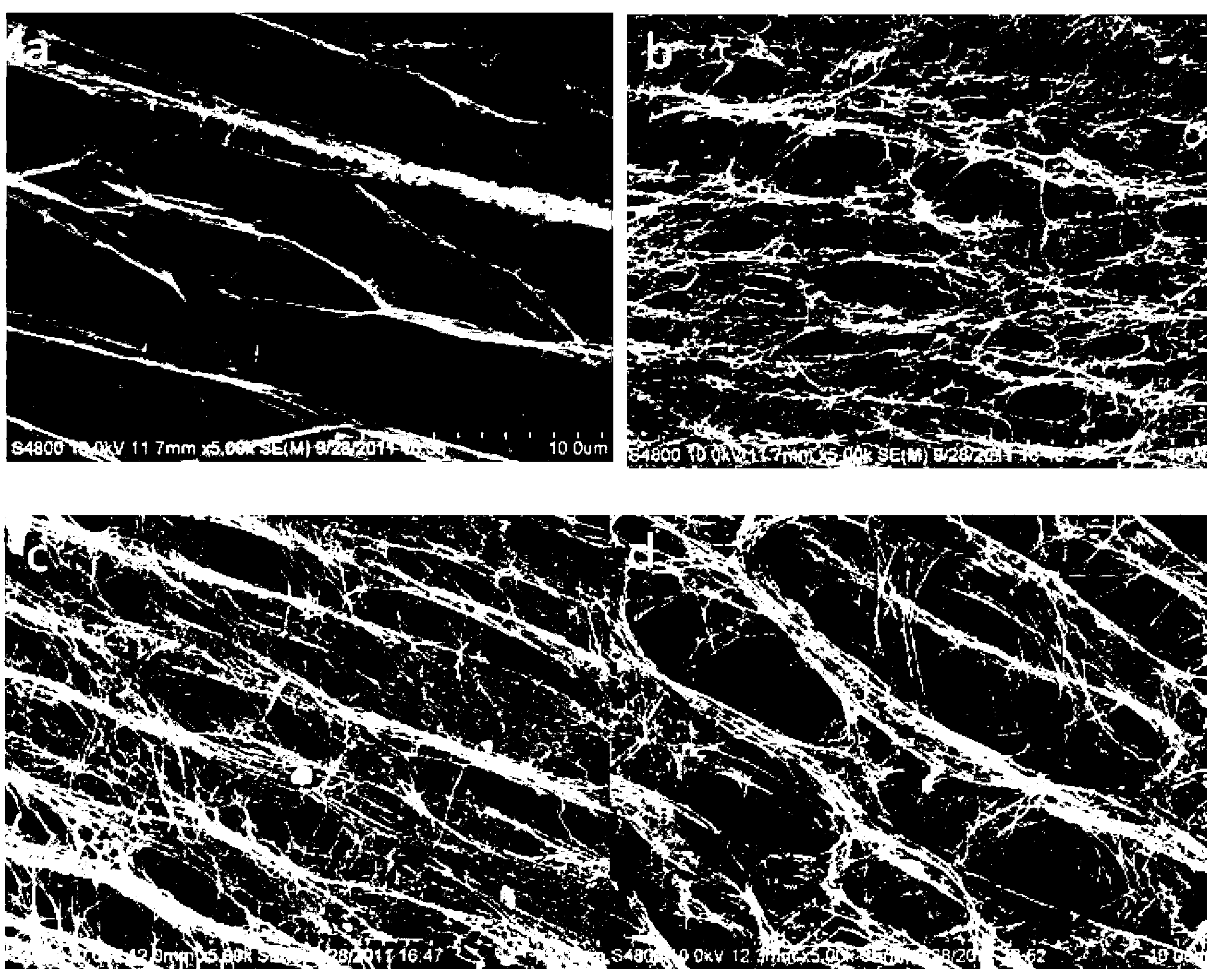

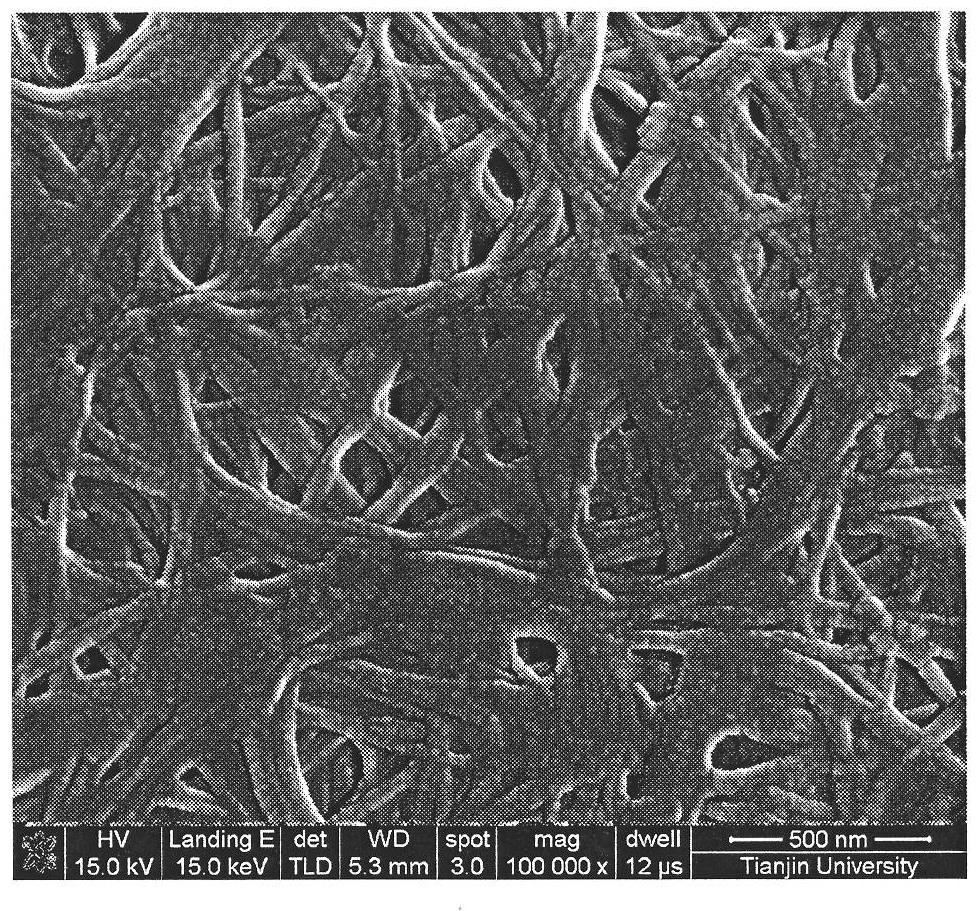

Acetobacter xylinum and method for preparing nano-cellulose skin tissue repair material by using the same

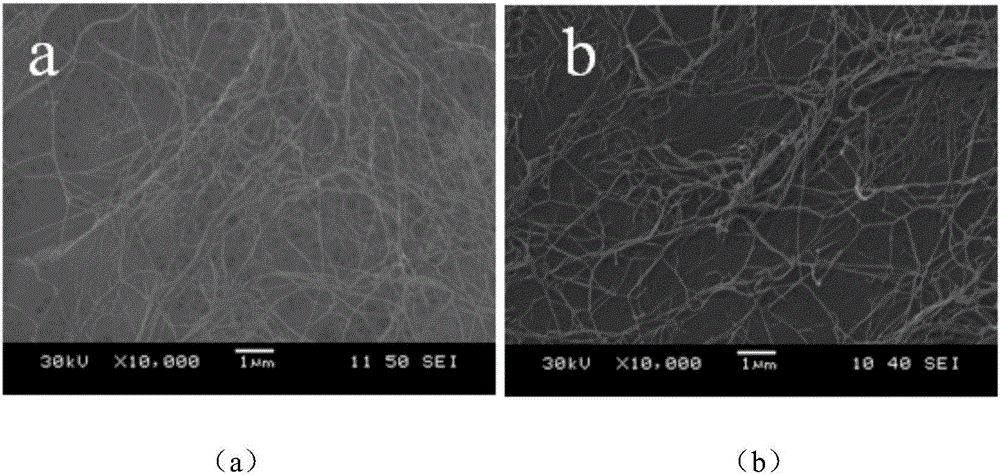

InactiveCN101302486AGood biocompatibilityImprove plasticityBacteriaMicroorganism based processesBiocompatibility TestingMoisture

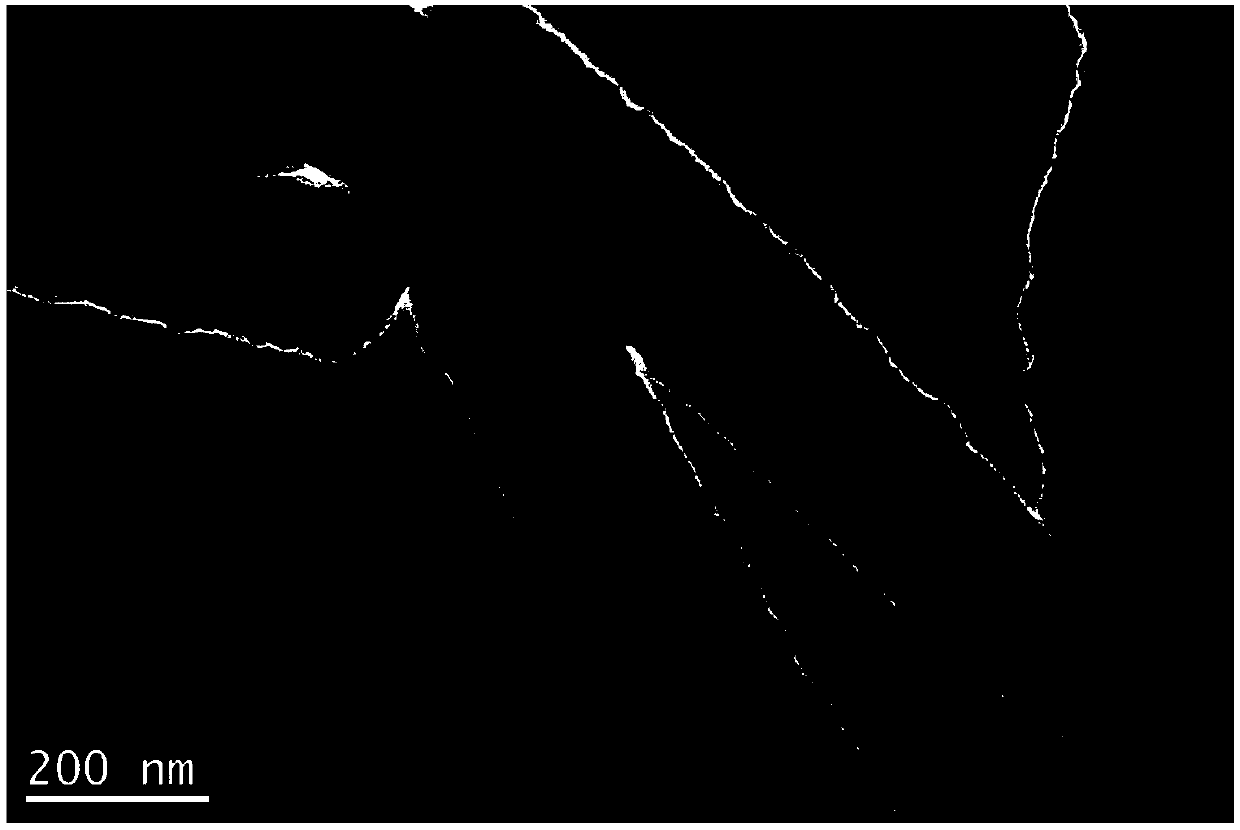

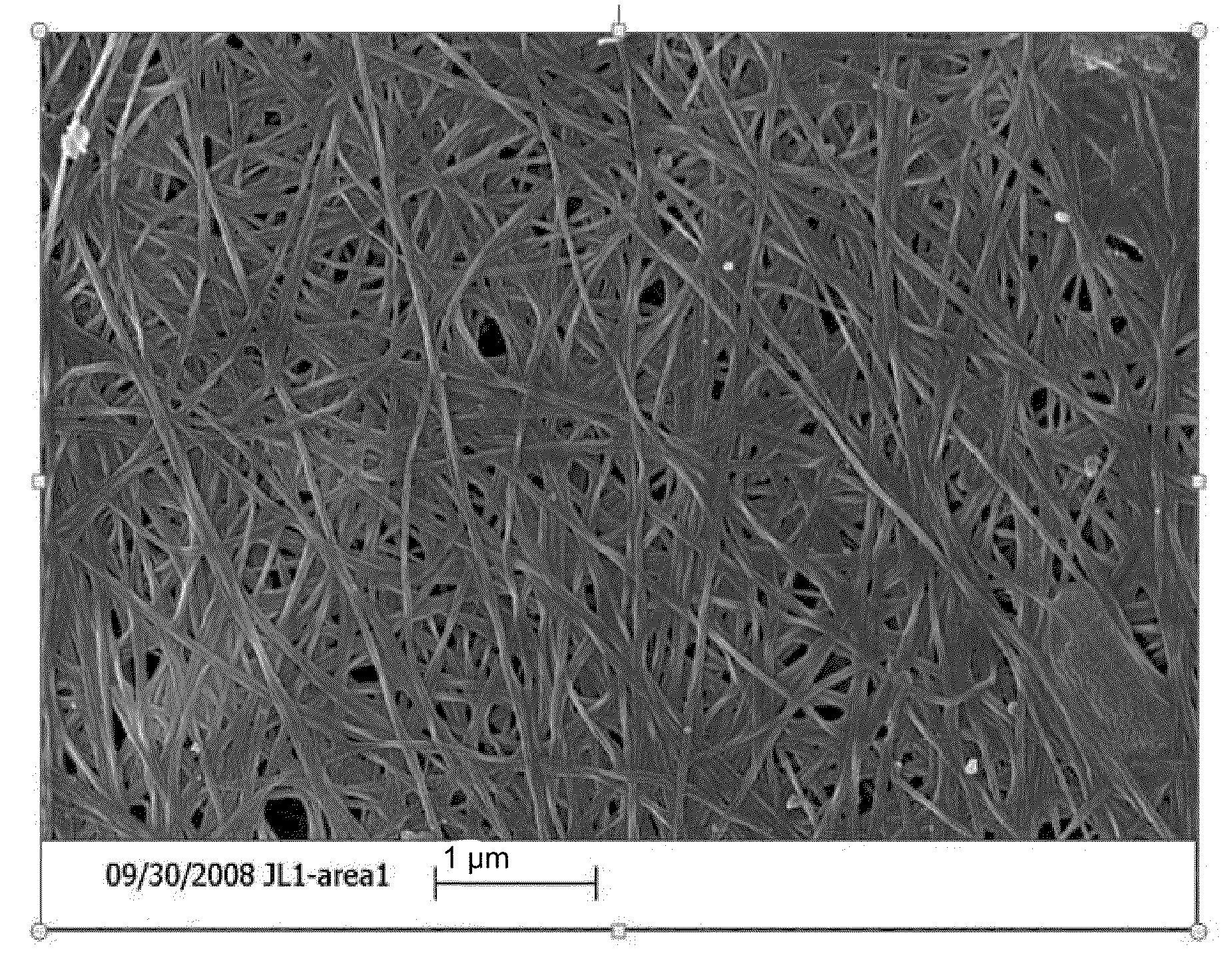

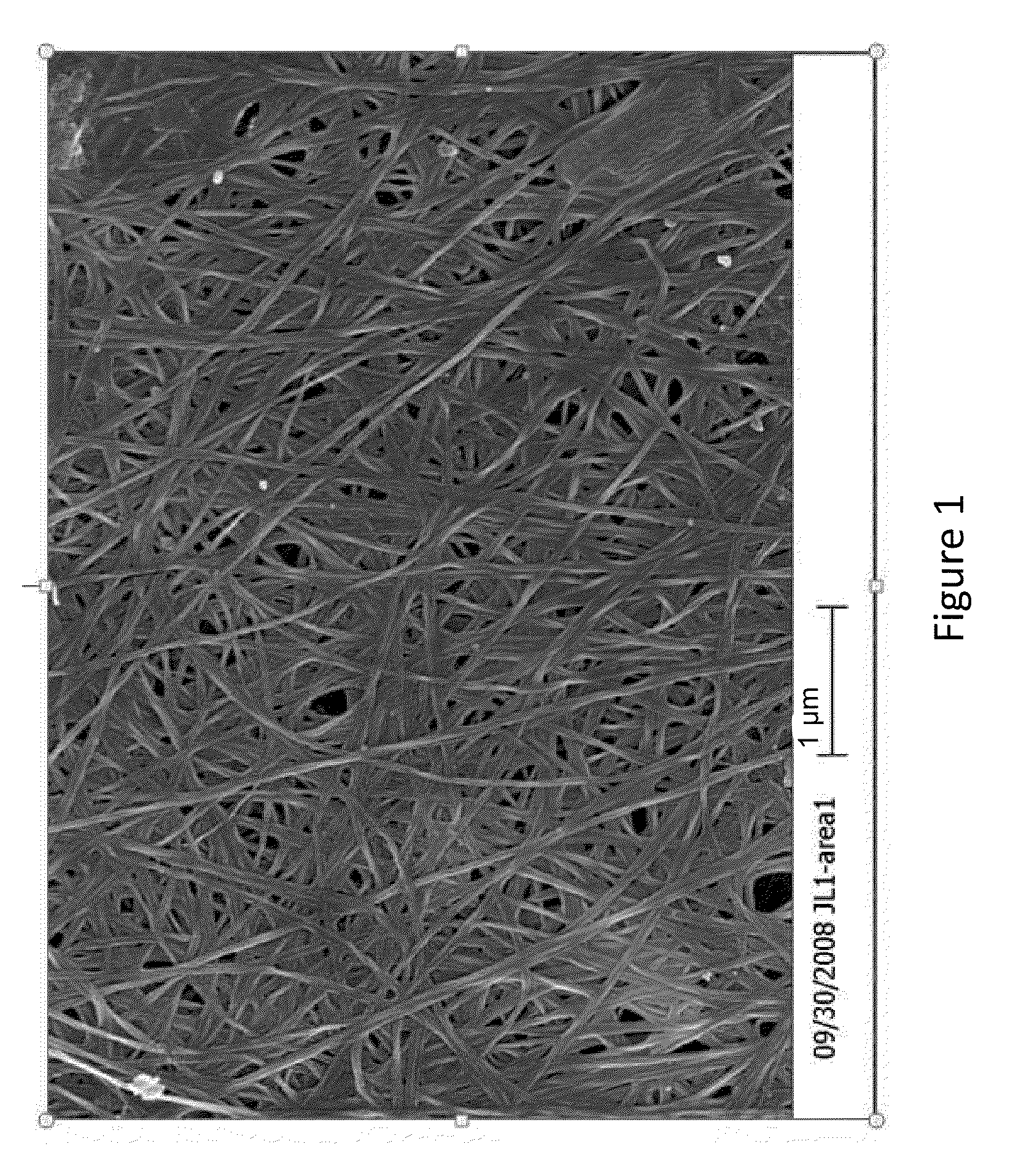

The invention provides an Acetobacter xylinum Y05 strain and a method for preparing nanometer cellulose skin tissue repairing material with the same. The preparation method comprises the following steps that: Acetobacter xylinum Y05 (CCTCC M 207163) preserved on an inclined plane is made into a shake-flask seed and cultivated statically to obtain a nanometer cellulose membrane; and the well-cultivated membrane is separated, purified and then compounded with natural polysaccharide (chitosan, etc.) and protein (collagen, silk fibroin, etc.), so as to prepare the repairing material. The nanometer repairing material has good biocompatibility, flexibility and strength which are similar to human skin, as well as good plasticity and elasticity, can be suitable for various irregular wound surfaces, can keep moisture for a long time, and can be used as a skin substitute and medical dressings for burns, chronic skin ulcers and other skin injuries or defects in clinical practice.

Owner:HUAZHONG UNIV OF SCI & TECH

New method for producing bacterial cellulose

ActiveCN102337320AIncrease productionIncrease productivityMicroorganism based processesFermentationHuskMicrobiology

The invention discloses a new method for producing bacterial cellulose. The method comprises the following steps of: accommodating culture medium fermentation liquor in which three strains, namely acetobacter xylinum, acetic acid bacteria and angel yeast are inoculated at the bottom of a pouring fermentation tower which is used for producing vinegar and serves as production equipment by a pouringfermentation method, wherein a culture medium is a mixed solution of stocked rice saccharification liquor and alcoholic fermentation mash; filling corncob and husks in a packing layer on the middle part of the tower, and horizontally laying the husks at the bottom and on the upper part of the corncob, wherein the corncob and the husks are used as thallus attached vectors; lifting the three kinds of strain culture medium fermentation liquor at the bottom of the tower to the top of the tower by using a pump, spraying to the packing layer, returning to the bottom of the tower through the packinglayer, and performing cyclic pouring in the mode at the fermentation temperature of between 28 and 32 DEG C at the frequency of 1 time per 4 hours, wherein the pouring time each time is 1 minute, 12 hours are used as one control cycle, and the total fermentation time is 144 hours; and stopping the pouring fermentation, tearing a bacterial cellulose membrane on the corncob off, washing, and dryingto obtain the bacterial cellulose.

Owner:贵州国芯生物科技有限公司

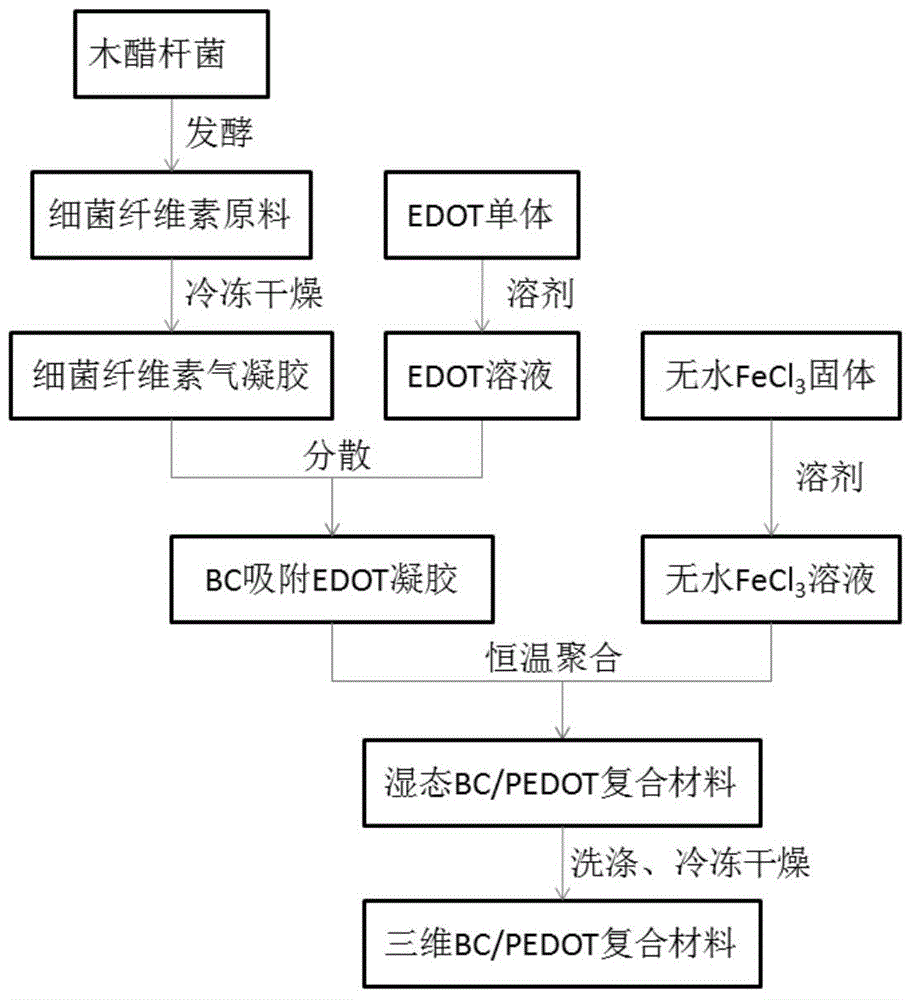

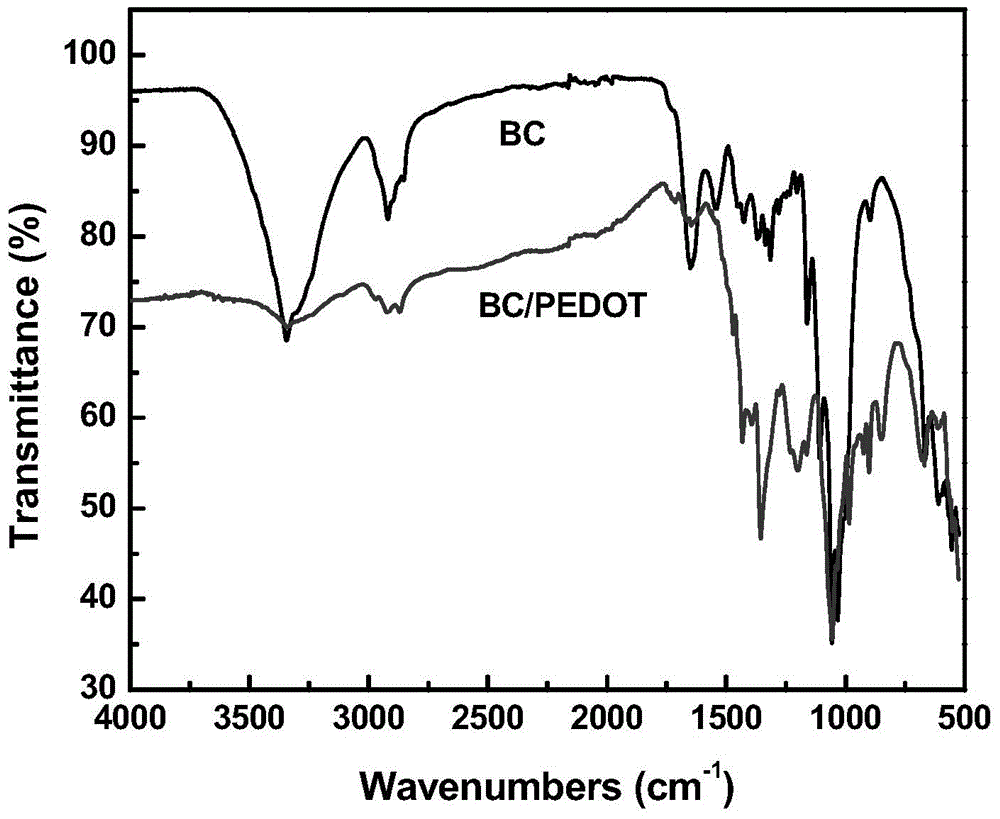

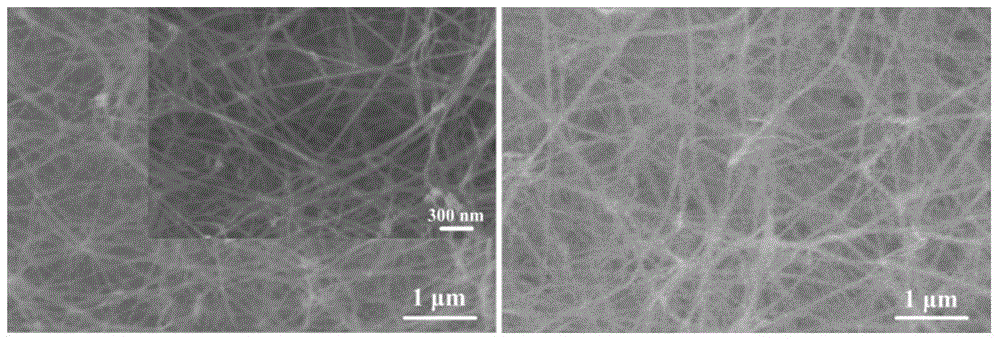

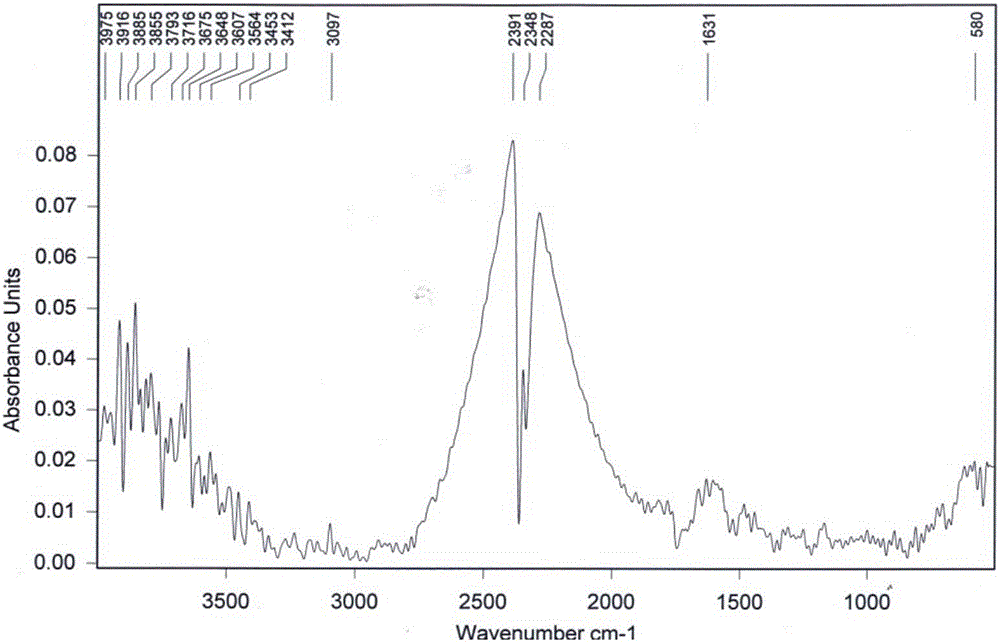

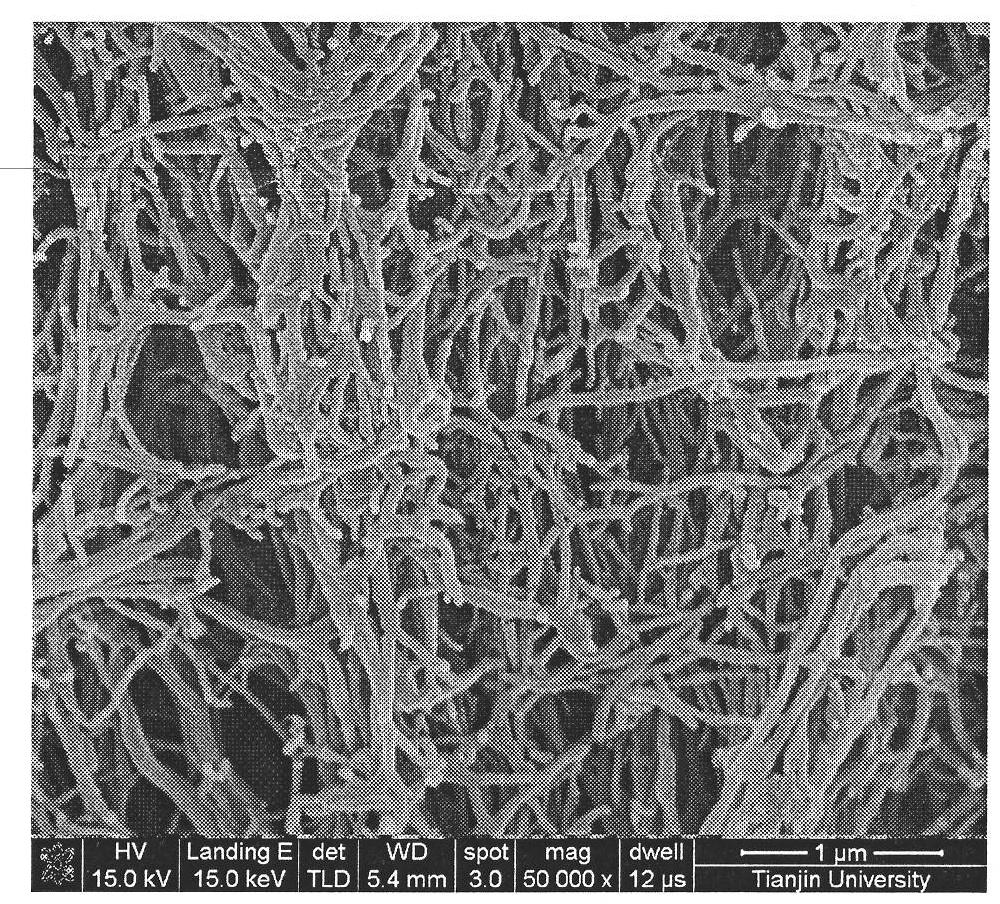

A bacterial cellulose/poly(3,4-ethylenedioxythiophene) nanometer conductive composite material and a preparing method thereof

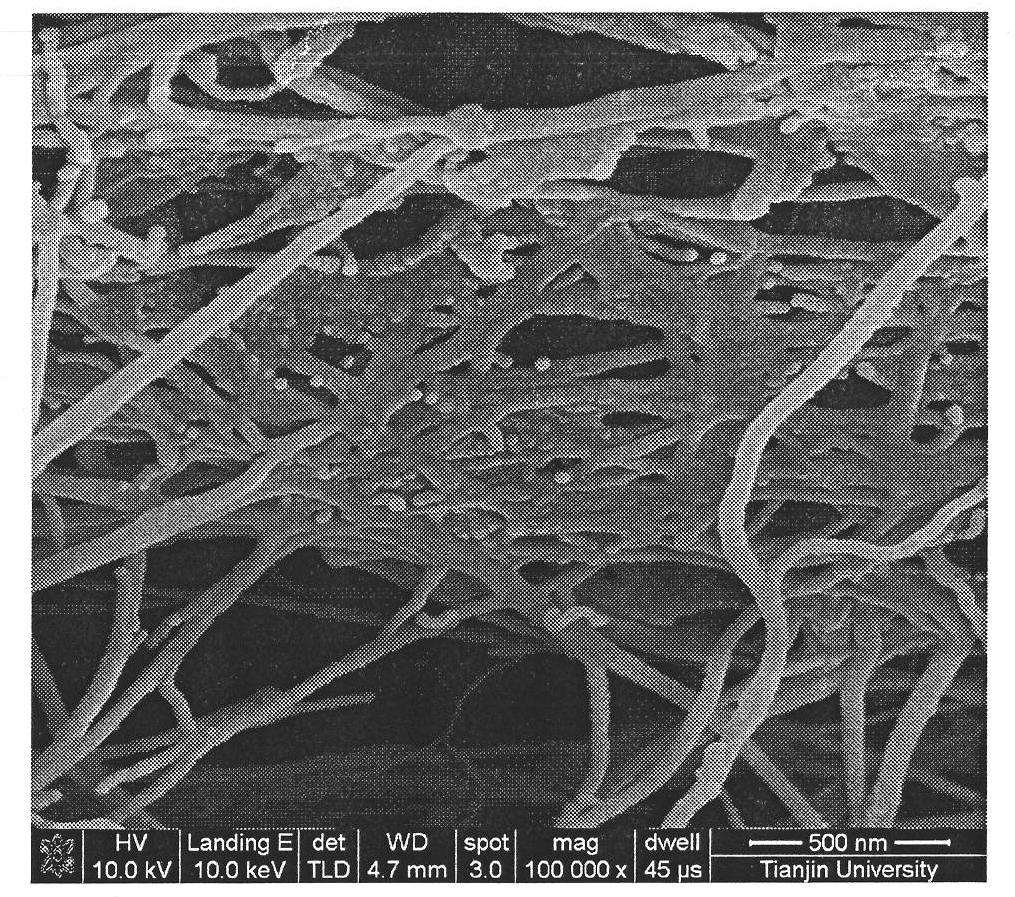

InactiveCN103980670AUniform chemical structureImprove controllabilityFreeze-dryingBiocompatibility Testing

The invention discloses a bacterial cellulose / poly(3,4-ethylenedioxythiophene) nanometer conductive composite material and a preparing method thereof. The method includes: a step of removing impurities of bacterial cellulose fermented by acetobacter xylinum, pretreating to obtain a clean bacterial cellulose raw material, and performing freeze-drying to obtain bacterial cellulose aerogel; a step of adding the bacterial cellulose aerogel into a 3,4-ethylenedioxythiophene solution, dispersing uniformly, and performing ultrasonic processing so as to allow the ethylenedioxythiophene monomer to be fully adsorbed by the bacterial cellulose; a step of adding a solution of ferric chloride anhydrous with the same volume, performing in-situ oxidation polymerization under ultrasonic constant-temperature conditions, and a step of subjecting the obtained crude product to ultrasonic washing with methanol (or ethanol) and deionized water repeatedly, fully dipping the crude product with deionized water, and performing freeze-drying to obtain the nanometer conductive composite material. The nanometer conductive composite material has advantages of low cost, mild reaction, high speed, good biocompatibility and a three-dimensional net structure.

Owner:NANJING UNIV OF SCI & TECH

Red date and black tea fungus beverage and its brewing method

InactiveCN1593252AJujube aroma is mellowHigh technology contentTea extractionUnknown materialsAdditive ingredientFiltration

Disclosed is a femented beverage with black tea bacterium as the bacterial and its brewing process, which employs by-product of red date or jujube fabrication as the raw material, and utilizes saccharomycete, Acetobacter xylinum and plant lactic acid bacillus as the bacterial through the procedures of first stage culturing, second stage culturing, fermentation, centrifugation and germ-free filtration.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Air filter type bacterial cellulose mask and production method thereof

ActiveCN101589854AEfficient killingAvoid infectionFire rescueLavatory sanitoryEcological environmentResource consumption

The invention discloses an air filter type bacterial cellulose mask and a production method thereof. The mask is made of dried bacterial cellulose which is used as a mask frame material. The preparation method comprises the following steps: selecting acetobacter xylinum as a type strain, and culturing the acetobacter xylinum to obtain a bacterial cellulose membrane; and after soaking the membrane in acid liquor and alkali liquor, washing the soaked membrane till the rate of impurities is less than 0.5 percent, soaking the membrane in nano-silver solution, then drying the membrane by adopting a freeze drying mode, and obtaining the air filter type bacterial cellulose mask through compound preparation. The preparation process is simple, the filter performance of the mask can be effectively improved by using the bacterial cellulose as a material, and the bactericidal and antitoxic capacities of the mask are enhanced by soaking in the nano-silver solution; and the mask has the characteristics of low production cost, strong adsorption capacity, high bactericidal activity, long durative bactericidal time and the like, and can effectively reduce resource consumption and protect ecological environment.

Owner:HAINAN YEGUO FOODS

Bacteria cellulose pervaporation membrane and uses thereof

InactiveCN101234299ASolve the problem that the thickness uniformity is difficult to controlAddressing Chemical StabilityDistillationCulture fluidMicrobiology

The invention provides a bacterial cellulose pervaporation membrane, which is characterized in that the preparation method is as follows: Acetobacter xylinum DT4.2 strain of the active wood fermentation is put into the seed culture fluid and shaking cultured at constant temperature of 25 to 32 DEG C for 8 to 24 hours; the seed solution is put into the fermentation culture solution to be evenly shaken; and then the fermentation culture solution is moved to the container for culturing for 7 to 15 days at the constant temperature of 25 to 32 DEG C; pellicle membrane formed on the surface of the fermentation solution is taken out and then is processed by the alkali liquor with the quality concentration of 1 to 20 percent; the residual alkali liquor in the membrane is washed to neutrality by the deionized water to prepare into the membrane after drying. The invention also discloses the application of the membrane. The preparation method of the membrane has the advantages of simple preparation, good mechanical and chemical property, excellent heat stability, strong hydrophilicity, high separation choice to the water in the organic water solution at lower temperature, long service life; moreover, the membrane material itself can be biodegradation which is a environmental friendly material.

Owner:许春元

Bacterial cellulose culture method based on potato waste residue

ActiveCN102337311ASolve the reuse problemLow costMicroorganism based processesFermentationBiotechnologyEngineering

The invention relates to a bacterial cellulose culture method which concretely comprises the steps of: inoculating acetobacter xylinum strain in a culture medium for recovery; after recovery, inoculating 2-20% of acetobacter xylinum strain in the culture medium; culturing the inoculated acetobacter xylinum strain by a shaking bed for 2-3 days under the condition of 100-180 rpm; and transferring the obtained fermentation liquor into a shallow tray and culturing for 2-5 days in a static state to obtain bacterial cellulose, wherein the culture temperature is 26-31 DEG C, the culture ventilation amount is 0.3-0.6vvm, and the culture medium is potato culture solution. The culture method has the characteristics that: potato waste residue obtained after starch production is firstly taken as the raw material of the culture medium, is treated by a simplest method and then is used as the culture medium for culturing the bacterial cellulose; the culture medium is low in cost and high in yield; meanwhile, the problem of recycling the potato waste residue can be solved, and the culture time is short; and in addition, the invention provides an important condition for stably culturing the bacterial cellulose in a large scale.

Owner:BEIJING GUANLAN TECH

Loudspeaker diaphragm of bacteria cellulose

InactiveCN101365264AAddress process complexitySolve process uniformityElectrical transducersMicroorganism based processesHigh rateCulture fluid

The invention is a bacterial cellulose acoustic vibration film. The vibration film is characterized in that the manufacturing method of the vibration film comprises the following steps of inoculating Acetobacter xylinum strains into a culture fluid; inoculating the strain liquid to a ferment culture fluid and shaking up after homothermal shake cultivation is conducted for the strains; moving the ferment liquid to a container; and conducting homothermal and static cultivation for a plurality of days until a surface film is formed on the surface of the ferment liquid; or moving the ferment liquid to a shaker; conducting homothermal and static cultivation; processing the bacterial cellulose by using lye with the mass concentration in the range of 1% to 8% after the bacterial cellulose is taken out; washing out the remained lye in the film with deionized water to achieve neutrality; and drying with an oven or heat-pressing, processing and shaping to get the film. The invention has the advantages of simple manufacturing method, good mechanical properties, and high thermal stability. The invention has the basic properties of an excellent acoustic vibration film as well as high rate modulus of elasticity and relatively large dissipation factors. In addition, the invention is durable and environmental friendly as the film can realize self-biodegradation.

Owner:许春元 +1

Probiotics active health-care fluid for preventing and treating senile dementia and preparation method thereof

ActiveCN102973614APlay a role in dementiaPlay a role in the prevention and treatment of Alzheimer's diseaseFungiNervous disorderSide effectActive enzyme

The invention discloses a probiotics active health-care fluid for preventing and treating senile dementia and a preparation method of the probiotics active health-care fluid. The probiotics active health-care fluid for preventing and treating senile dementia comprises the following raw materials: photosynthetic bacteria, saccharomyces cerevisiae, lactobacillus, acetobacter xylinum, bifidobacterium, brown sugar, defatted soybean powder, honey, sodium chloride, oligosaccharide and deionized water. By adopting the probiotics active health-care fluid, large amounts of probiotics are compensated, so that the intestinal flora is improved, the intestinal leak syndrome is prevented, and the chemical substances (including heavy metal and other harmful substances) without being digested are prevented from entering the intestinal lining and playing roles in blood circulation; and as a result, the senile dementia caused by heavy metal poisoning can be prevented and treated. The probiotics can generate large amounts of active enzymes by which the peptide produced in the human body can be quickly degraded, and the blood cells generated in the human body can be decreased, so that the senile dementia and the degeneration can be delayed. Compared with the prior art, the probiotics active health-care fluid has the advantages of being high in efficiency and stability, and free from side effects.

Owner:远邦控股集团制药股份有限公司

Use method of bacteria cellulose in ancient protection of wrought silk cultural relics

InactiveCN101492882AHigh strengthGood flexibilityMicroorganism based processesFermentationFreeze-dryingDissolution

The invention relates to an application method of bacteria cellulose for the protection of ancient silk relics, comprising the specific steps as follows: treating the surface of the ancient silk relic to prepare two bacteria cellulose repair agents: wherein, acetobacter xylinum is activated with a slant culture medium to experience fermentation culture to obtain pure cultures which are admixed with a liquid culture medium to obtain the repair agent a, or acetobacter xylinum freeze-dried powders are dissolved with aseptic sugar-containing stroma to admix the dissolution liquid with liquid culture stroma to obtain the repair agent b; spraying an atomizing agent a or b onto the surface of the silk relic for culture to form a layer of cellulose membrane on the surface of the silk relic, and then obtain the well-processed relic after post-treatments. By making use of the characteristics of high strength and high flexibility of the bacteria cellulose generated by the acetobacter xylinum, the invention mixes and atomizes strains and the culture stroma to be dispersed on the surface of the silk relic, and a thin layer of nano-cellulose membrane is formed on the surface of the silk relic after the culture, thus improving the flexibility and mechanical strength of the ancient silk relics.

Owner:荆州文物保护中心 +1

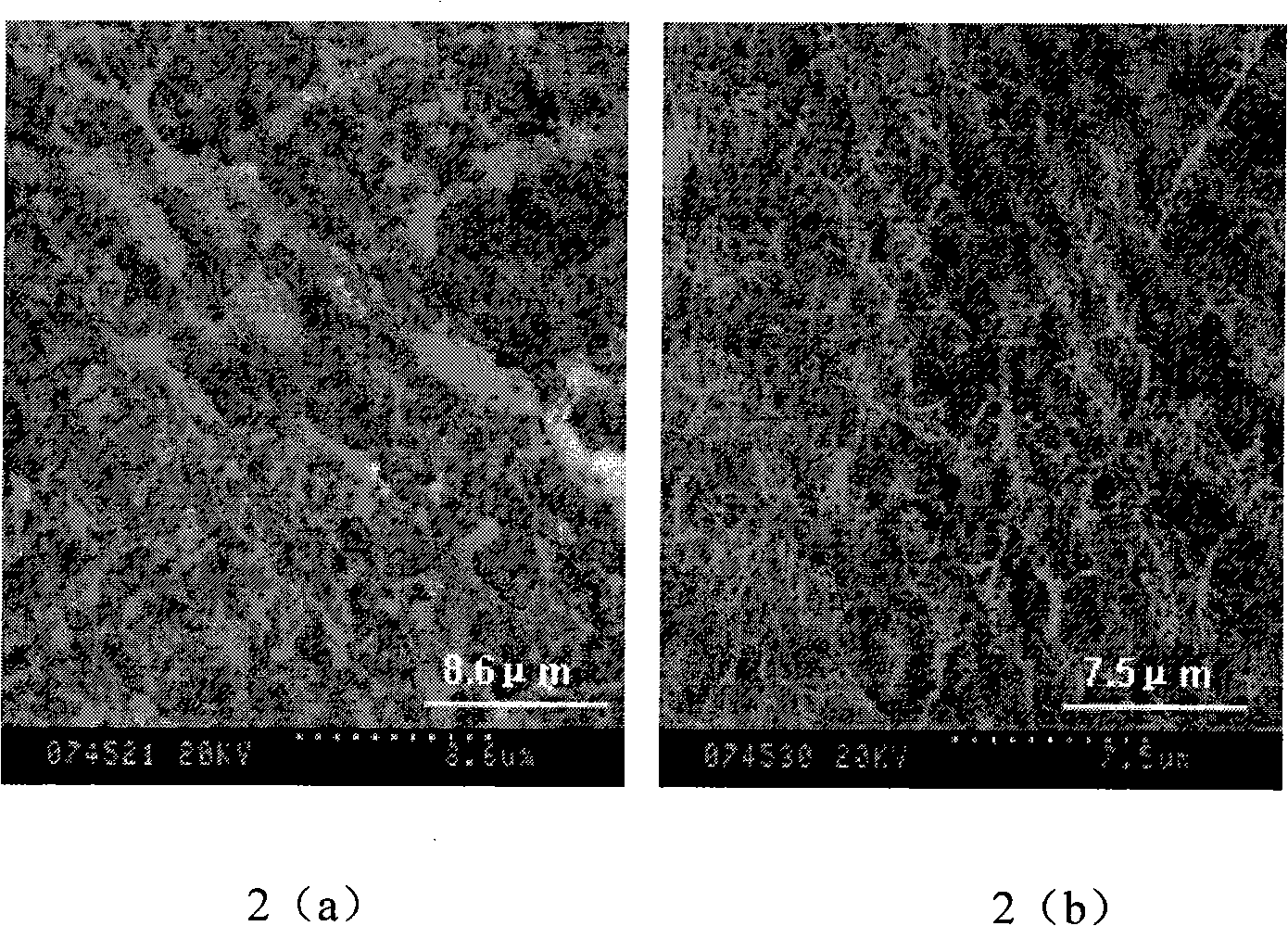

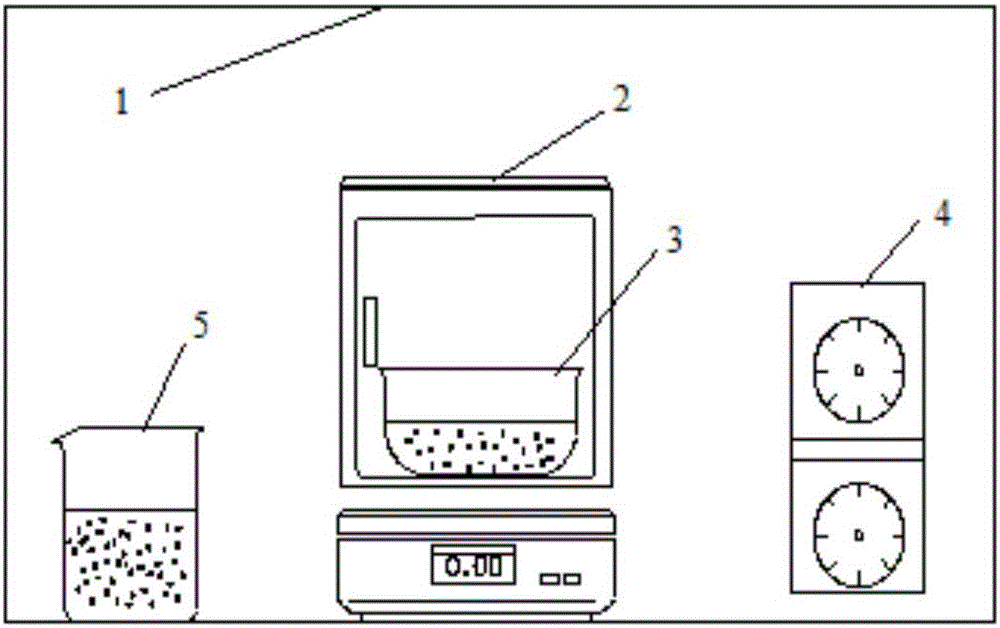

Preparation method of aloe polysaccharide/bacterial cellulose composite membrane for medical dressing

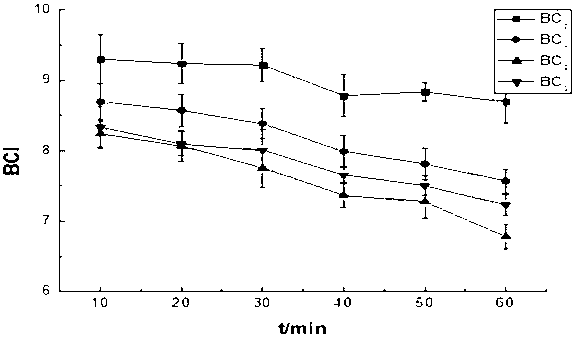

InactiveCN106693032AImprove featuresMaintain normal physiological functionAbsorbent padsBandagesPhysical performance testPhysical performance testing

The invention discloses a preparation method of an aloe polysaccharide / bacterial cellulose composite membrane for a medical dressing. The preparation method comprises the following steps: activating a strain Acetobacter xylinum NUST4.2; preparing a seed solution of the strain Acetobacter xylinum NUST4.2; adding aloe polysaccharide with different concentrations into a fermentation culture medium of the strain Acetobacter xylinum NUST4.2 to carry out dynamic-static combined fermentation production, so as to obtain an aloe polysaccharide / bacterial cellulose composite membrane; purifying the aloe polysaccharide / bacterial cellulose composite membrane; respectively carrying out infrared characterization and scanning electron microscope observation on the structure and morphology of the aloe polysaccharide / bacterial cellulose composite membrane; and carrying out physical performance test on the aloe polysaccharide / bacterial cellulose composite membrane as a medical dressing, so as to show that the requirements of the medical dressing are met. By virtue of the preparation method, more choices are provided for the medical dressing for healing skin wounds, and meanwhile, a positive role for the development of the medical dressing is achieved.

Owner:南京荣之盛生物科技有限公司

Heavy metal ion adsorption film and preparation method thereof

InactiveCN107442091AEfficient removalImprove plasticityOther chemical processesWater contaminantsWastewaterSewage

The invention discloses a heavy metal ion adsorption film and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method comprises the following steps: 1, fermenting to produce bacterial cellulose by using acetobacter xylinum; 2, obtaining a bacterial cellulose film and performing purification treatment on the bacterial cellulose film, then performing cationization on the cellulose film by taking 3-chloro-2-hydroxypropyl trimethyl ammonium chloride as an etherifying agent; 3, performing crosslink blending reaction on the cationized bacterial cellulose film and chitosan, so as to obtain a chitosan-bacterial cellulose composite material. The composite material prepared by the invention has a better adsorption effect on heavy metal ions, can effectively remove the heavy metal ions in domestic sewage and industrial wastewater, and can be recycled and reused. The composite material has good application prospect in the field of sewage treatment.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing chitosan oligosaccharide/bacterial cellulose sponge

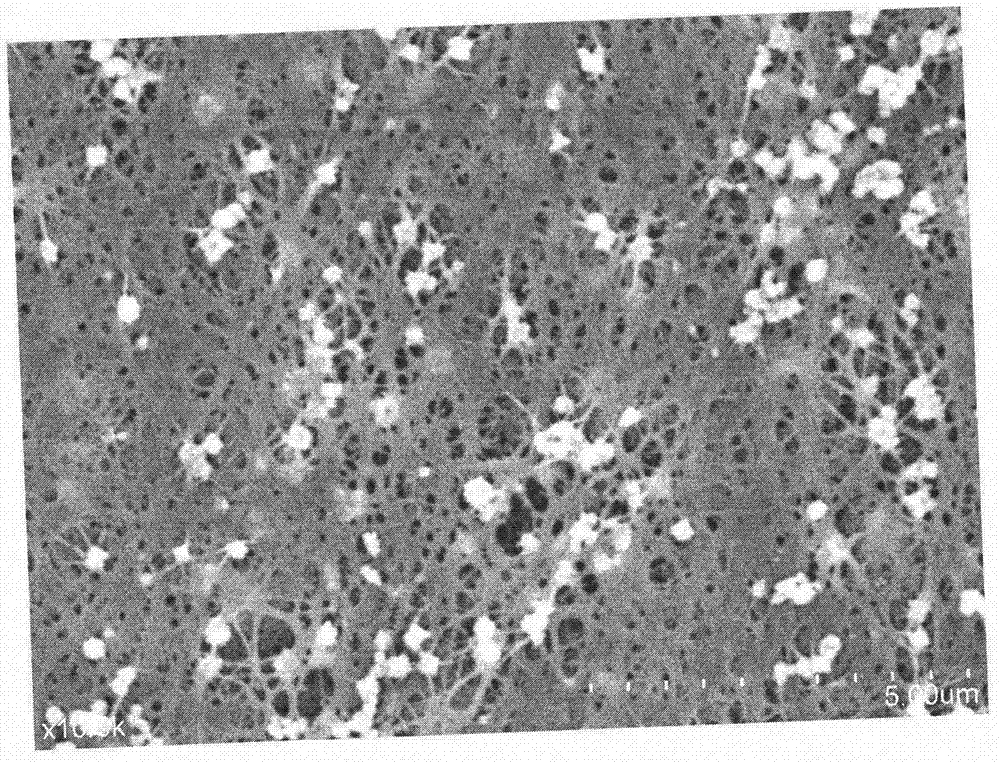

InactiveCN103007335AHigh porosityDense and uniform poresAbsorbent padsBandagesAcetobacter xylinumBiocompatibility Testing

The invention discloses a method for preparing chitosan oligosaccharide / bacterial cellulose sponge. The method comprises the steps of: screening out acetobacter xylinum at the stage with highest activity by means of MTT (Methyl Thiazolyl Tetrazolium Colourimetry); adding the chitosan oligosaccharide into a culture system to prepare a chitosan oligosaccharide / bacterial cellulose compound; rinsing the chitosan oligosaccharide / bacterial cellulose compound using distilled water; adding 1% sodium hydroxide solution into the rinsed compound to boil for 4 hours; soaking the compound at room temperature for 0.5 hour by adding 0.5% acetic acid; flushing the compound 5 times using distilled water; and freezing and drying the above processed compound to prepare the chitosan oligosaccharide / bacterial cellulose sponge. The chitosan oligosaccharide / bacterial cellulose sponge prepared by the invention is in a three-dimensional network structure, high in porosity, and dense and uniform in interspace. Experiments prove that the chitosan oligosaccharide / bacterial cellulose sponge is better in hydroscopicity, moisture permeability and blood coagulation effect in comparison with a traditional wound dressing; cytotoxicity by biocompatibility test is 0-grade; the raw materials are easily available; and the preparation process is simple. The chitosan oligosaccharide / bacterial cellulose sponge prepared by the invention is easy to achieve industrialized production and is good in biocompatibility, and thus can be widely used in the field of biomedical materials.

Owner:HAINAN UNIVERSITY

Preparation method of bacterial cellulose

ActiveCN106399422AReduce fermentation costsLow costMicroorganism based processesFermentationNano crystallineBiology

The invention discloses a preparation method of bacterial cellulose. The preparation method comprises the following steps that (1) preparation of shake flask bacteria: acetobacter xylinum ATCC 700178 is inoculated to a seed culture medium and cultured at the temperature of 28 DEG C to 33 DEG C for 12-24 h, and a first-stage seed solution is obtained; (2) enlarge cultivation of the seed: the first-stage seed solution is inoculated to the seed culture medium and subjected to enlarge cultivation, and a second-stage solution is obtained; (3) fermentation: the second-stage seed solution is inoculated to a fermentation tank filled with a molasses culture medium, the fermentation tank is filled with immobilized media, and fermentation is performed for 6-8 days; (4) extraction: the biological nano-crystalline cellulose is extracted from the fermentation liquor. According to the preparation method of the bacterial cellulose, the yield of the biological nano-crystalline cellulose can be improved greatly, the obtained biological nano-crystalline cellulose product is cotton-shaped or flake-shaped, the fibrous structure is looser, and the degree of polymerization is smaller.

Owner:南京生命原健康科技有限公司

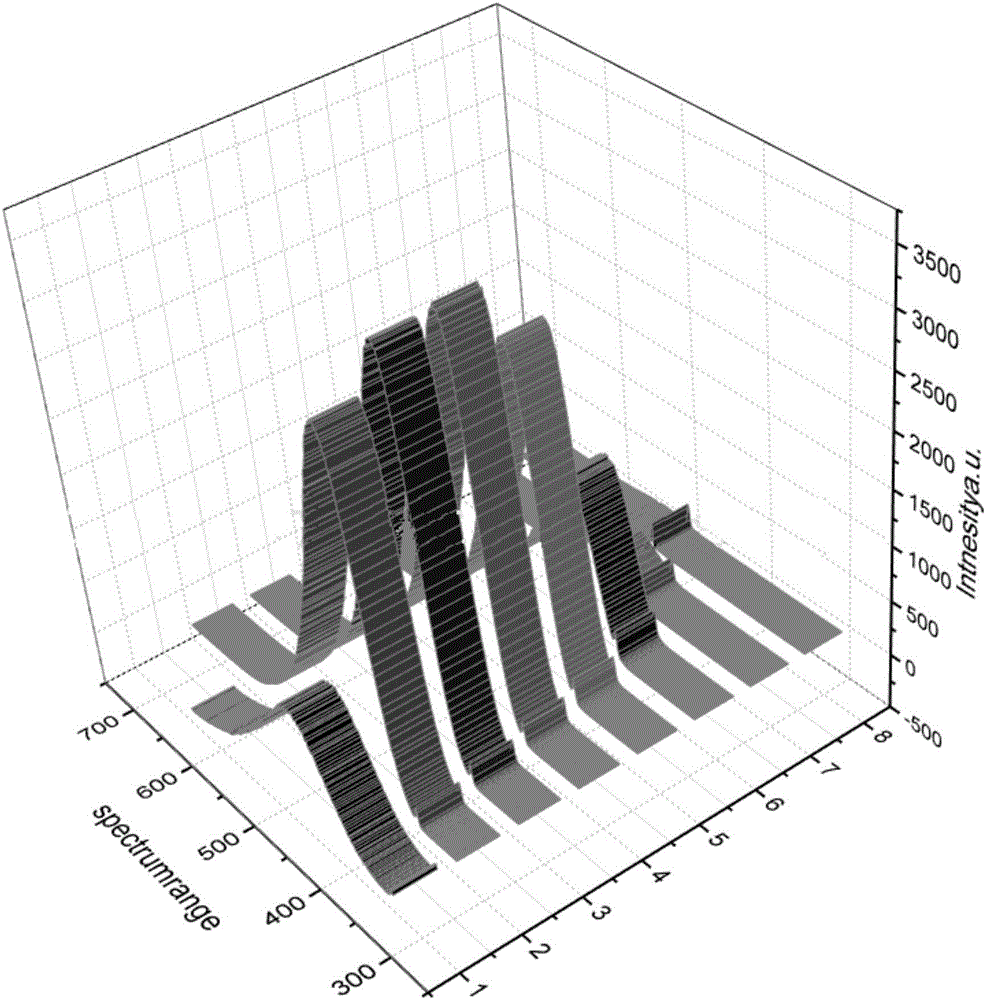

Preparation method of water-soluble carbon dot and application of water-soluble carbon dot in microbial fermentation

InactiveCN106676139ASimple preparation processEfficient preparation processMaterial nanotechnologyMicroorganism based processesQuantum yieldNew energy

The invention discloses a preparation method of a water-soluble carbon dot and application of the water-soluble carbon dot in microbial fermentation, belonging to the technical field of new energy and new materials. According to the preparation method, river crab shell waste is as the raw material, and the acquired carbon dot fluorescence quantum yield can achieve 35% through a simple thermal cracking process. The prepared water-soluble fluorescence carbon dot has biocompatibility, and has an obvious acceleration effect on the fermentation of pneumonia klebsiella pneumonia, the yield of 1,3-propylene glycol can be improved by 30%. Furthermore, the water-soluble fluorescence carbon dot is applied to the standing fermentation of the acetobacter xylinum, the product bacteria cellulose yield can be improved by 75%. The water-soluble fluorescence carbon dot is applied to the microbial fermentation for the first time, and an obvious promotion effect is achieved, and a new growth factor is provided for the microbial fermentation.

Owner:DALIAN UNIV OF TECH

Preparation method for bacterial cellulose in-situ doped composite material

InactiveCN105646949AHigh crystallinityHigh degree of polymerizationMicroorganism based processesFermentationFuel cellsHigh energy

The invention discloses a preparation method for a bacterial cellulose in-situ doped composite material, comprising the steps of preparing a fluid medium, then introducing strain acetobacter xylinum, performing rotary shake culture for 12 to 24 hours at the temperature of 15 to 25 DEG C, performing pinhole filter and adding amino acid chelating ferrous, performing rotary shake culture for 3 to 5 days at the temperature of 15 to 25 DEG C, filtering, washing with deionized water, then cooling and drying, performing high-temperature calcination on a formed composite material by an atmosphere furnace, and taking out after natural cooling to obtain the bacterial cellulose in-situ doped composite material. The material prepared by the invention has the advantages of high-energy density, high electrocatalytic activity, and the like, can be applied to the fields of oxygen reduction reactions, fuel cells, supercapacitors and the like, and the preparation technology is simple and the operation is convenient.

Owner:SOUTHWEAT UNIV OF SCI & TECH

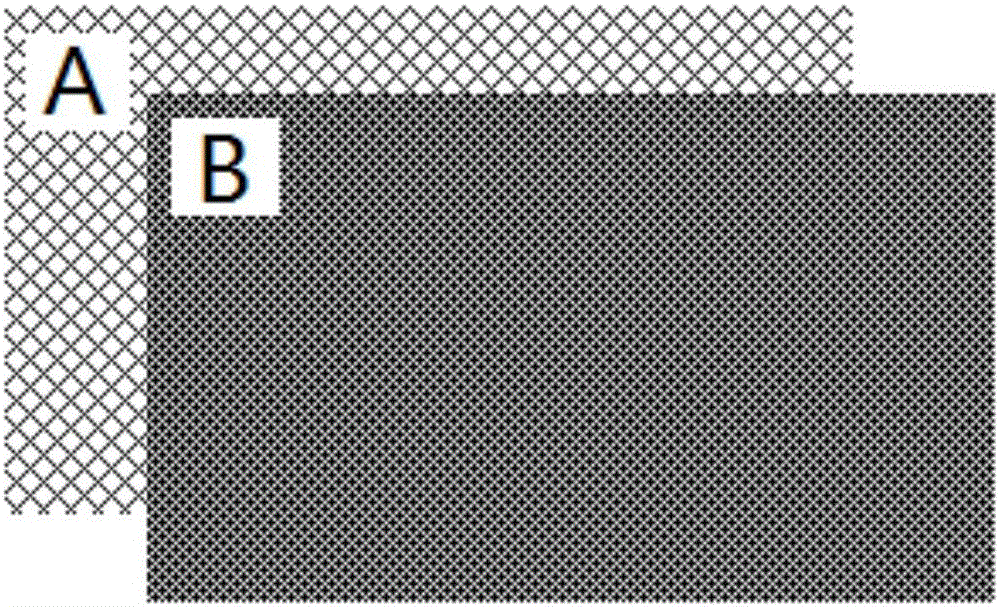

Bacterial cellulose/fabric laminated composite material and preparation method thereof

ActiveCN103938447AEasy to operateEasy to usePhysical treatmentFibre typesOxygen plasmaUltraviolet lights

The invention discloses a bacterial cellulose / fabric laminated composite material and a preparation method thereof. The preparation method comprises the following steps: (1) inoculating acetobacter xylinum into a fluid medium for enlarged cultivation; (2) appropriately cutting a fabric and treating with low-temperature oxygen plasmas or aqueous alkali, or through ultraviolet light surface grafting; and sterilizing and then drying the fabric; (3) arranging the medium containing floccules into a culture dish, spreading the treated fabric on bacterium solution, adding the medium containing floccules into the fabric, and arranging in a biochemical incubator until the laminated composite material is formed; and (4) soaking the composite material with deionized water at normal temperature, soaking the composite material with sodium hydroxide solution for two days, and soaking the composite material with deionized water until the composite material is neutral. The composite material is formed at a time, the appetency of the single fabric and the texture is improved, and the water retainability and the transdermal absorption ratio of the fabric are improved; meanwhile, the operation is convenient and simple and the using efficacy is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

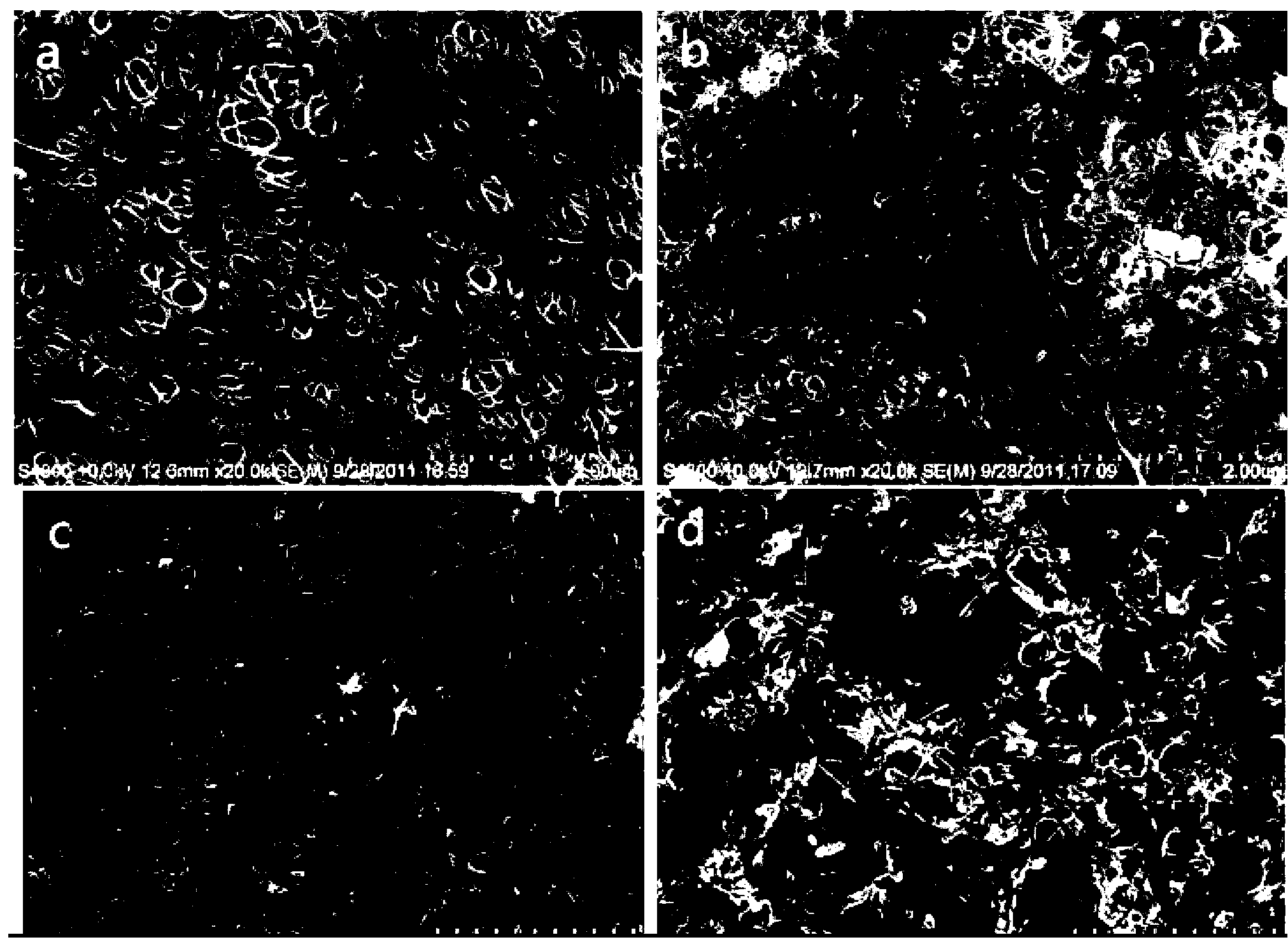

Bacterial cellulose-inorganic nanoparticle hybrid membrane and preparation method thereof

ActiveCN102008902AThe synthesis process is simpleSynthetic conditions are mildSemi-permeable membranesSilicic acidHigh energy

The invention relates to a biosynthesis method for preparing a bacterial cellulose-inorganic nanoparticle hybrid membrane by using microbes. The first preparation method comprises the following steps of: culturing acetobacter xylinum in a liquid nutrient medium added with titanate dihydroxybis[2-hydroxypropanoato-O1,O2]diammonium, and purifying to prepare a bacterial cellulose-TiO2 nano hybrid membrane; the second preparation method comprises the following steps of: hydrothermally decomposing titanate dihydroxybis[2-hydroxypropanoato-O1,O2]diammonium to synthesize TiO2 colloidal particles, and adding the colloidal particles into a nutrient medium, culturing acetobacter xylinum in the nutrient medium, and purifying to prepare the bacterial cellulose-TiO2 nano hybrid membrane; and the thirdpreparation method comprises the following steps of: culturing acetobacter xylinum in a liquid nutrient medium added with sodium silicate or silicic acid, and purifying to prepare the bacterial cellulose-TiO2 nano hybrid membrane. The method has the advantages that: the preparation method is simple, clean, non-toxic and environmentally-friendly, and can solve the problems of high energy consumption, environmental pollution, cytotoxicity and the like in physical and chemical preparation methods.

Owner:南通诚恩机械有限公司

Cellulose/silicon oxide composite aerogel elastomer, preparation method thereof and application of elastomer in field of oil-water separation

ActiveCN108031447AImprove oil absorption capacityGood chemical stabilityOther chemical processesLiquid separationElastomerSupercritical drying

The invention discloses a cellulose / silicon oxide composite aerogel elastomer, a preparation method thereof and an application of the elastomer in the field of oil-water separation, and belongs to thefield of oil-water separation materials. Bacterial cellulose has wide macropores, and is obtained by in-situ co-culture of acetobacter xylinum and polystyrene small spheres with different sizes, andthe pore size of the cellulose can be adjusted in the range of 500-1700[mu]m. The silicon oxide is compounded with the bacterial cellulose to topologize the three-dimensional network structure of thecellulose, and therefore the cellulose / silicon oxide composite aerogel with a high porosity and elasticity is obtained. The cellulose / silicon oxide composite aerogel elastomer provided by the invention can be directly dried at normal temperature and pressure, the steps such as supercritical drying or freeze drying necessary for the preparation of a traditional aerogel are avoided, and the production costs are reduced; after the aerogel elastomer is reused for 20 times, the oil absorption capacity can still reach 94% of initial capacity; and the preparation method provided by the invention is simple, and the material is friendly to the environment, is biodegradable, does not cause secondary pollution to the environment, and has good application prospects in the field of oil-water separation.

Owner:JILIN UNIV

Osseointegrative meniscus and cartilage implants based on beta-glucan nanocomposites

InactiveUS20100297239A1Good biocompatibilityUse of procedurePowder deliverySkeletal disorderExtracellular fiberBeta-glucan

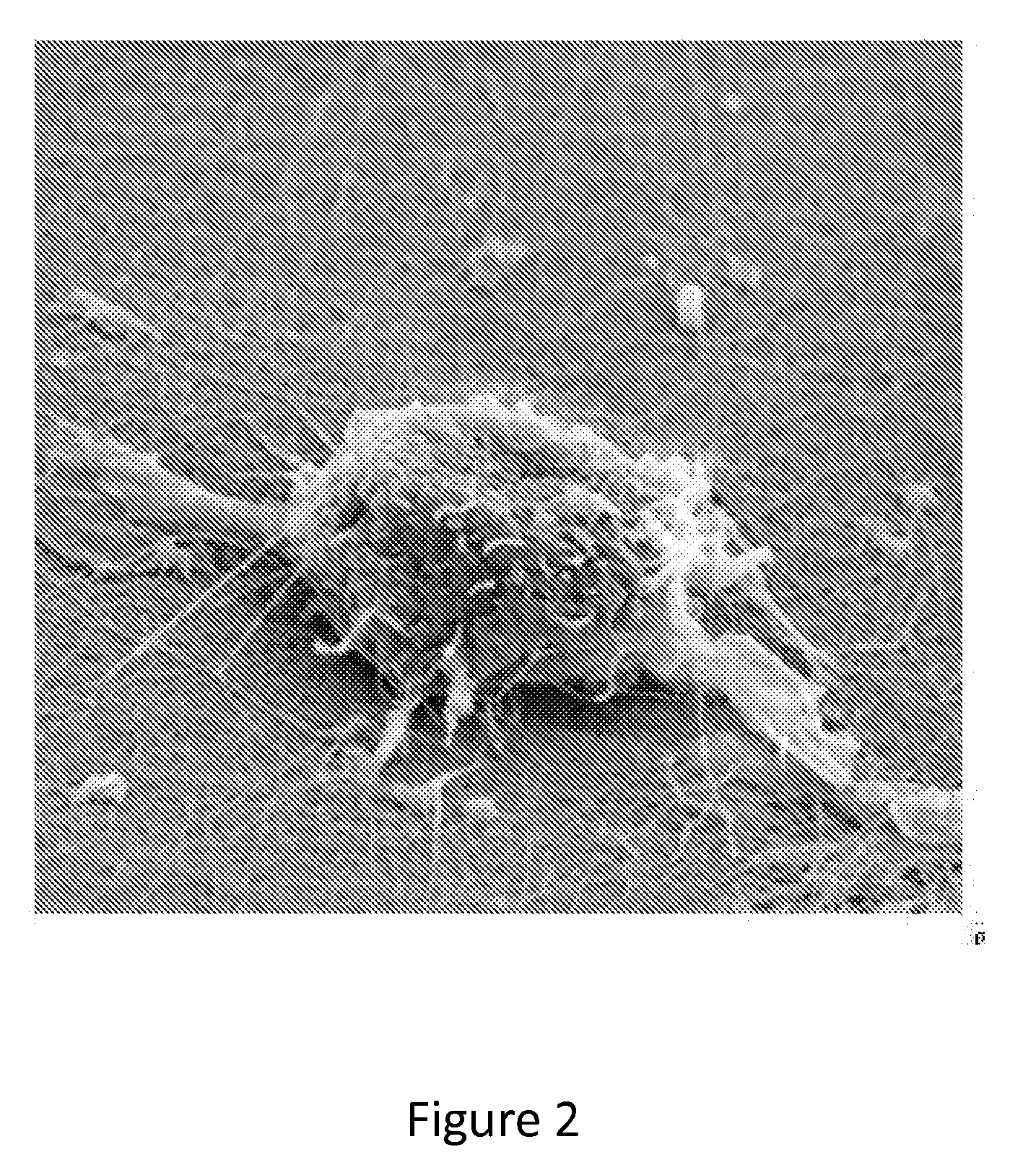

The present invention provides engineered composite materials for use in medical treatment of injured or degenerated menisci, cartilage, and bone. The composite materials include a cellulosic layer substantially or completely consisting of β-1→4-glucan units, and a hydrogel layer substantially or completely consisting of copolymers of β-1→2-glucan, β-1→3-glucan, and / or β-1→4-glucan, or mixtures of two or all three of these units. Production of the composite materials is achieved in a single culture milieu, using regulation of oxygen availability to control production of the various units and deposition of the layers by Acetobacter xylinum or other microorganisms that produce extracellular cellulosic material.

Owner:BC GENESIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com