Method for preparing bacterial cellulose gel composite material

A technology of bacterial cellulose and composite materials, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., which can solve the problems of material waste and low compounding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

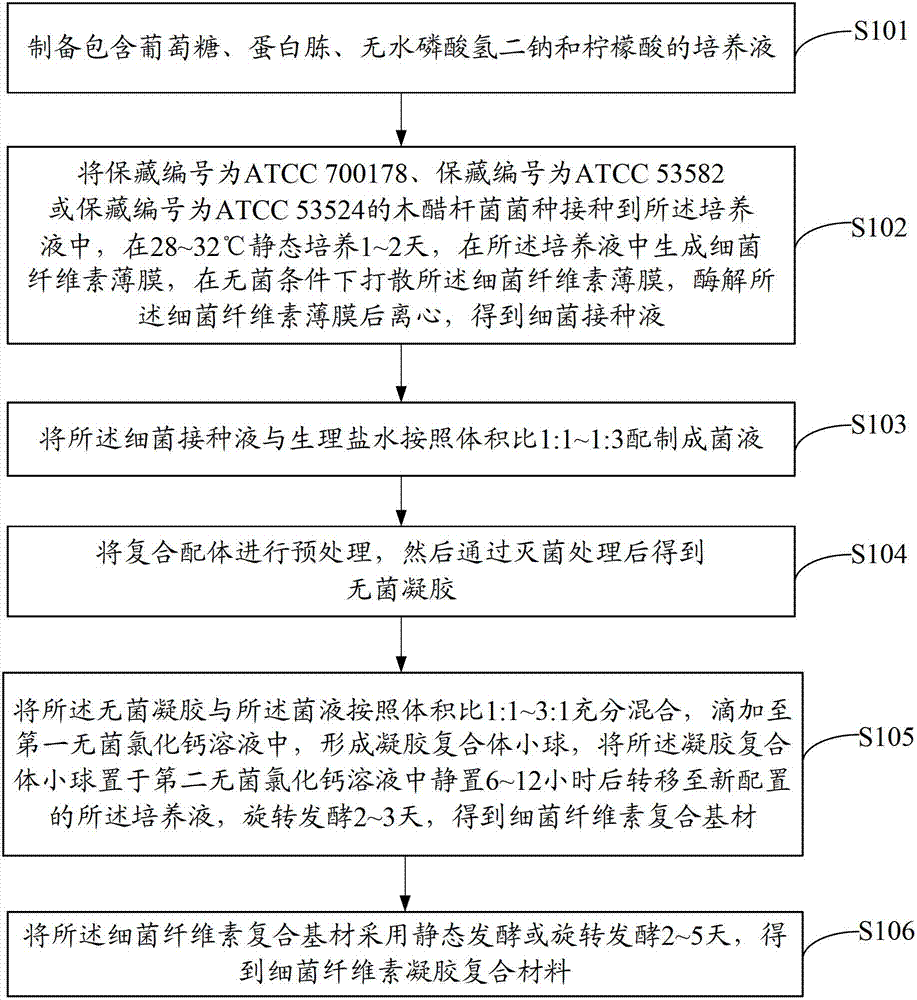

[0026] see figure 1 , the preparation method of the spherical bacterial cellulose gel composite material of one embodiment, comprising:

[0027] S101. Prepare a culture solution containing glucose, peptone, anhydrous disodium hydrogen phosphate and citric acid.

[0028] The culture medium is a nutrient for the growth and maintenance of bacteria, and promotes the formation of products. In this embodiment, the culture solution may include glucose, peptone, anhydrous disodium hydrogen phosphate and citric acid. Dextrose, peptone, anhydrous disodium hydrogen phosphate and citric acid. The specific operation can be as follows: prepare 100mL culture medium. Mix 20 g of glucose, 5 g of peptone, 2.7 g of anhydrous disodium hydrogen phosphate, and 1.15 g of citric acid. Adjust the pH value of the culture solution to 6.0, which is suitable for the growth of bacteria. Then other components can be added to the culture solution according to the needs of different bacterial species for...

Embodiment 1

[0043] Preparation of culture medium: 100 mL of culture liquid was composed of 20 g of glucose, 5 g of peptone, 2.7 g of anhydrous disodium hydrogen phosphate, 1.15 g of citric acid, 1 g of magnesium sulfate, 1 g of ammonium sulfate, and 1 mL of corn syrup extract.

[0044] Preparation of bacterial inoculum: Take 1 mL of JCM 9730 Acetobacter xylinum bacteria liquid and place it in 100 mL of culture liquid. After static culture at 30°C for 2 days, transfer the culture liquid and the resulting bacterial cellulose film to a sterile After breaking up the bacterial cellulose film in a blender, add 2mL of cellulase aqueous solution and enzymolyze it at 30°C for 2 hours. Minutes, take the precipitate as the bacterial inoculum.

[0045] Preparation of bacterial solution: Mix the above-mentioned bacterial inoculum with physiological saline at a ratio of 1:1 by volume and set aside.

[0046] Preparation of sterile gel: Take 25g of chitosan with a molecular weight ranging from 10,000 to...

Embodiment 2

[0050] 1. Preparation of culture medium: 100 mL of culture liquid was composed of 20 g of glucose, 5 g of peptone, 2.7 g of anhydrous disodium hydrogen phosphate, 1.15 g of citric acid, 1 g of magnesium sulfate, 1 g of ammonium sulfate, and 1 mL of corn syrup extract.

[0051] 2. Preparation of bacterial inoculum: Take 1 mL of JCM 9730 Acetobacter xylinum bacteria liquid and place it in 100 mL of culture liquid. After static culture at 30°C for 2 days, transfer the culture liquid and the resulting bacterial cellulose film to In a sterilized mixer, break up the bacterial cellulose film, add 1mL of cellulase aqueous solution for every 100mL of cellulosic bacteria solution, and enzymatically hydrolyze at 33°C for 1 hour. The centrifuge uses a centrifugal force of 3000RCF, centrifuges for 10 minutes, and takes the precipitate as the bacterial inoculum.

[0052] 3. Preparation of bacterial solution: Mix the above-mentioned bacterial inoculum with normal saline according to the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com