Method for cultivating nitrosobacteria flora and method for treating wastwater containing ammonia nitrogen

A technology of nitrite bacteria and culture method, which is applied in biological water/sewage treatment, microorganism-based methods, water/sludge/sewage treatment, etc., can solve the problem of long hydraulic retention time, large consumption of dissolved oxygen, and increased dosage of chemicals Costs and other issues, to achieve the effect of simple process and outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Enrichment of nitrous bacteria

[0033] use as Figure 4 The device shown is enriched. The effective volume of the reactor in the device is 3.5L, the residence time is set to 24h, the reaction temperature is room temperature, aeration and stirring, DO>2.0mg / L, and 30-100g / L NaHCO 3 Control 7.5≤pH≤9.5.

[0034] The nitrifying bacteria are derived from the activated sludge of the sewage treatment workshop of the oil refinery. Before enriching the nitrous bacteria group, the method of Example 1 in CN200710010383.0 is used to enrich the nitrifying bacteria to obtain a high concentration of nitrous bacteria and nitric acid bacteria. of activated sludge.

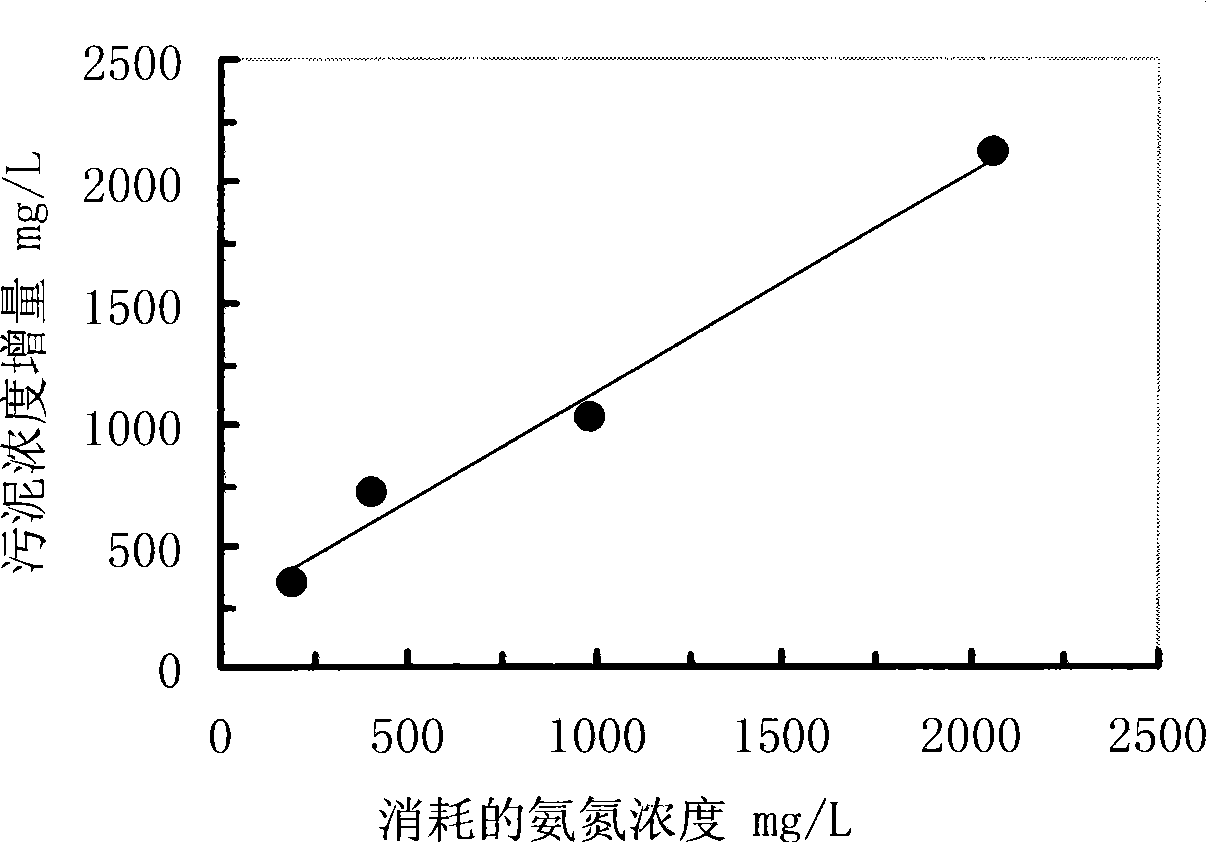

[0035] After the nitrifying bacteria are enriched according to the CN200710010383.0 method, the step of cultivating the nitrosifying bacteria is carried out. The influent is prepared according to the method of CN200710010383.0 (the same below), and the COD value is lower than 150mg / L, see Figure 5 . The in...

Embodiment 2

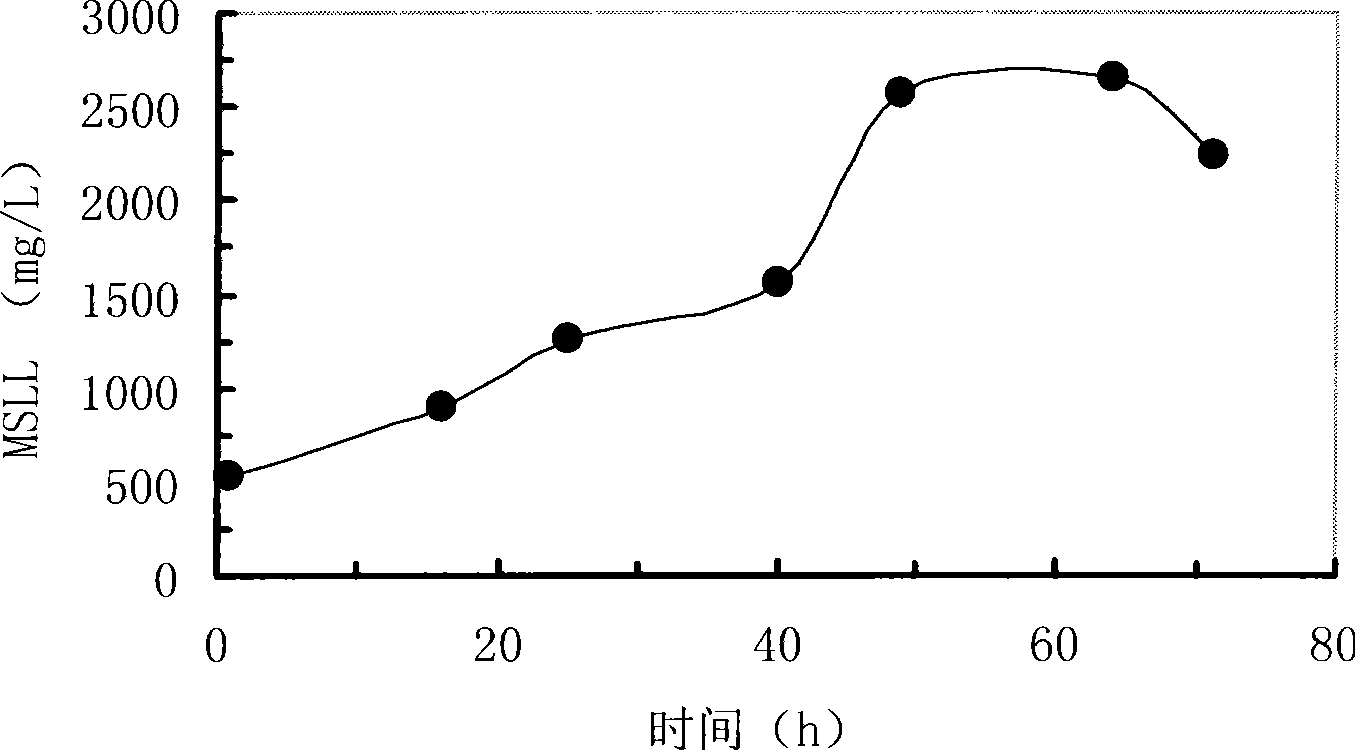

[0036] Embodiment 2 Batch cultivation expands nitrous bacteria group

[0037] A 10L fermenter was directly used for cultivation, and the self-prepared wastewater mentioned in Example 1 was used as the culture solution. In the case of low nitrite concentration, the form of adding ammonium sulfate in batches is used to provide ammonia nitrogen for the growth of nitrifying bacteria. When the nitrite nitrogen rises enough to affect the growth of nitrifying bacteria, that is, the sludge concentration is no longer When it rises, we pump out about 3 / 4 of the culture solution, settle and separate to obtain the cultured nitrifying bacteria and store it for later use. The remaining 1 / 4 is used as seeds. The growth trend of the flora see figure 2 , the final sludge concentration increased to 2650mg / L, more than 4 times higher than the initial sludge concentration of 538mg / L.

Embodiment 3

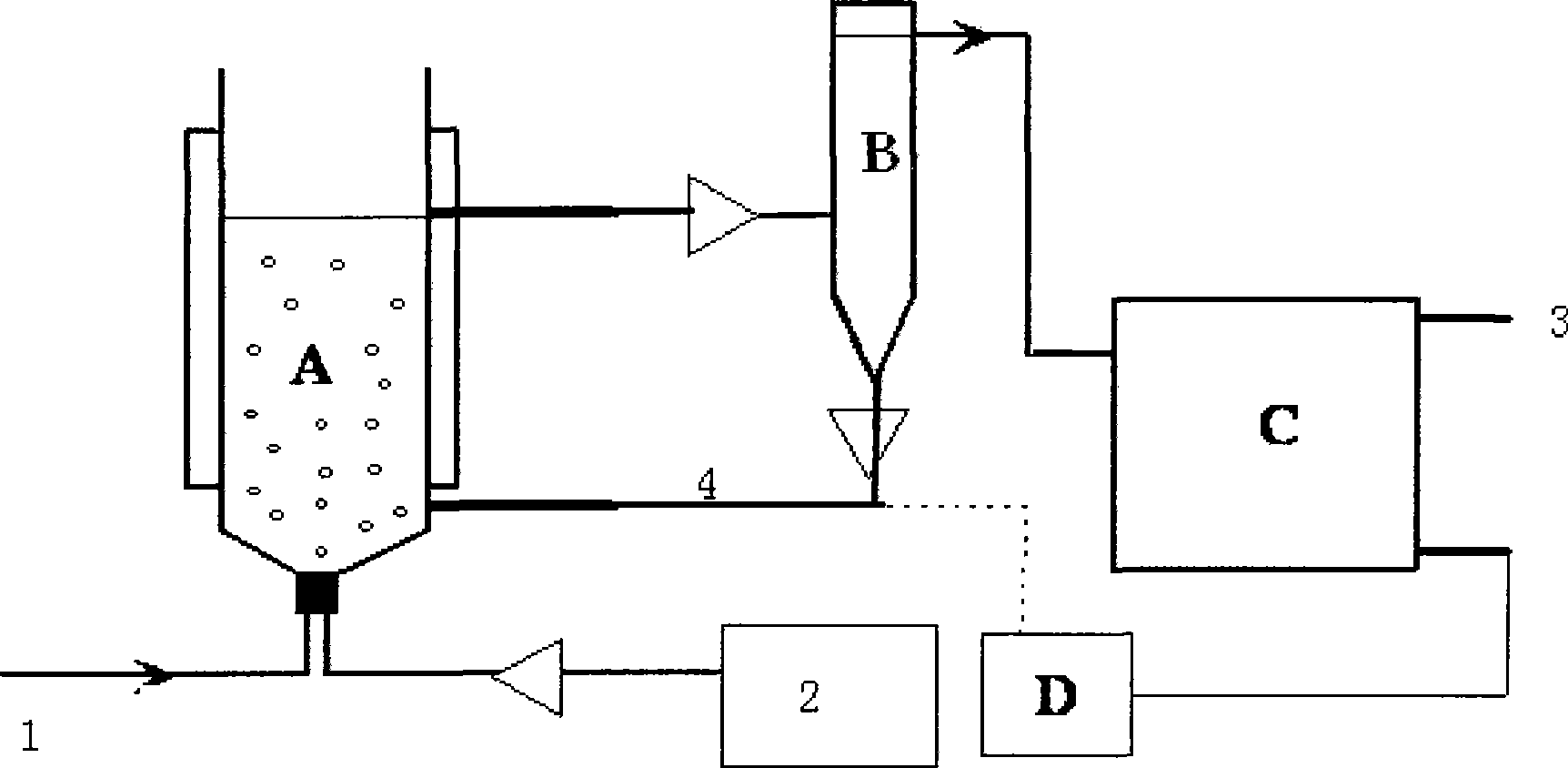

[0038] Example 3 Constant turbidity culture of nitrous bacteria

[0039] For the turbidity culture procedure, see image 3 , A is the nitrifying bacteria cultivation tank, the effective volume is 3.5L, B is the sludge settling tank, C is the effluent collection tank, D is the cultured nitrifying bacteria collection tank. We divide the whole culture process into two phases: proliferation phase and constant turbidity culture phase. The culture medium is self-prepared waste water. In the multiplication stage, the concentration of ammonia nitrogen in the substrate is 3000mg / L, the inoculation amount is 1%, the initial sludge concentration is 592mg / L, aeration and stirring, DO≥2mg / L, and the temperature is kept at room temperature 32°C. After 78 hours of cultivation, the ammonia nitrogen is basically consumed After completion, the sludge concentration in the system increased to 2700mg / L, which was more than 4 times higher than the initial sludge concentration. The constant turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com