Bacteria cellulose producing bacteria and method for preparing bacteria cellulose using above bacterial strain

A technology for bacterial cellulose and bacteria production, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of high energy consumption, complicated process, low yield, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

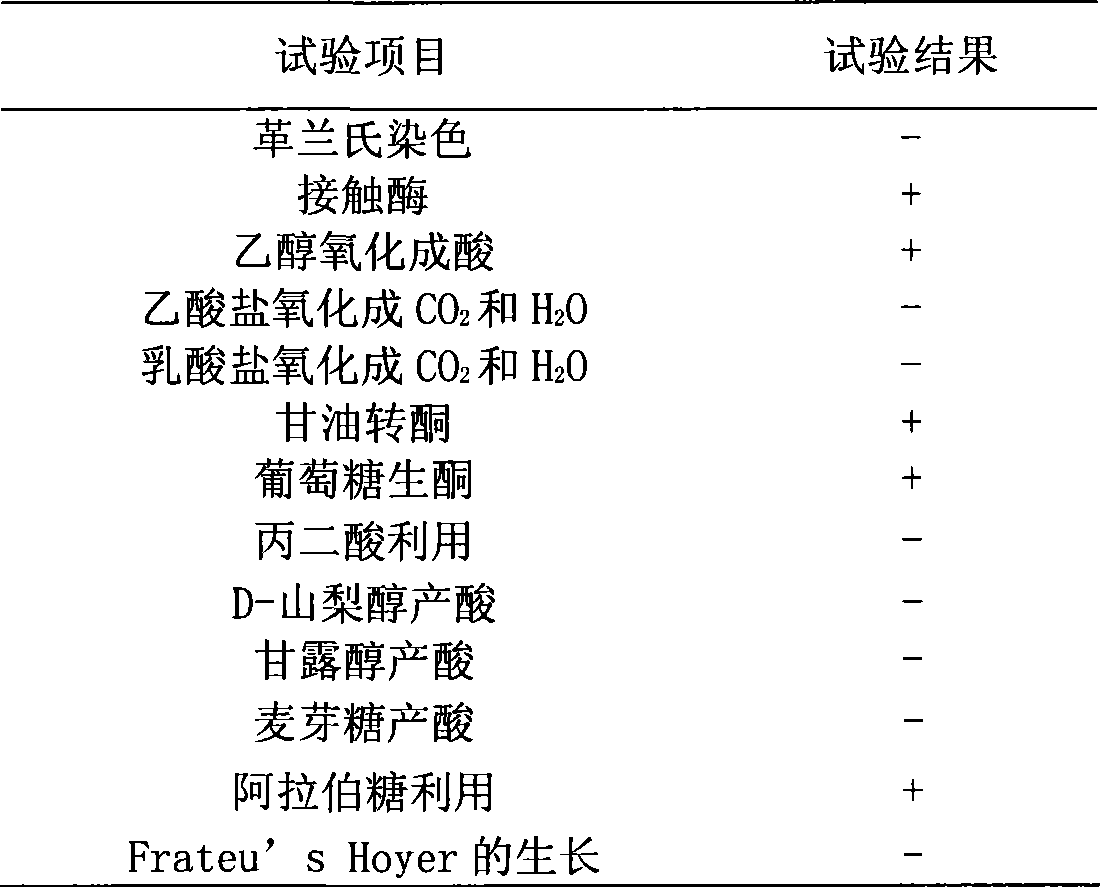

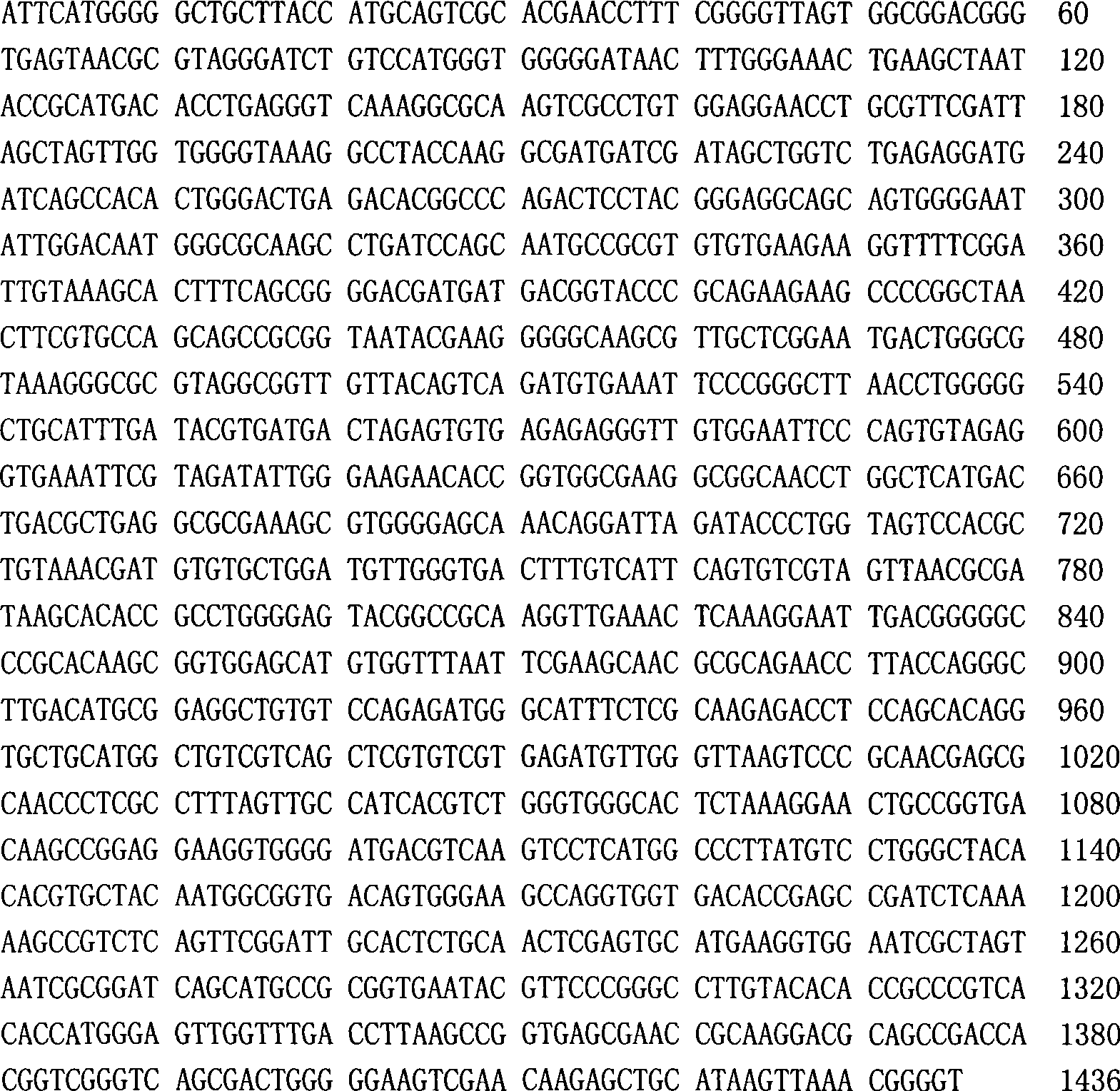

Method used

Image

Examples

Embodiment 1

[0027] Get the slant seed that preserves in 4 ℃ of refrigerators for 5 days [the composition of slant medium (g / L): glucose 80, yeast extract 8, calcium carbonate 15, agar 15, all the other components are water, pH6.5. Cultivate 24 at 28 ℃. hours], use an inoculation needle to inoculate the above slope about 1cm 2 The bacterial classification of area is scraped off, transfers in the liquid activation medium of new configuration [composition (g / L) of liquid activation medium: glucose 80, yeast extract 8, peptone 5, all the other components are water, adjust pH value to 6.0. ], the liquid activation medium was packed in a 250ml Erlenmeyer flask, and the amount of the Erlenmeyer flask was 20ml, and it was shaken and cultivated in a reciprocating shaker at 28°C for 18 hours, the shaker speed was 80r / m, and the stroke was 65mm. Take the above-mentioned cultured liquid activation medium and inoculate it into a new configuration, sterilized at 121°C for 15 minutes and cooled to room...

Embodiment 2

[0029] Get the slant seed that preserves in 4 ℃ of refrigerators for 5 days [the composition of slant medium (g / L): glucose 80, yeast extract 8, calcium carbonate 15, agar 15, all the other components are water, pH6.5. Cultivate 24 at 28 ℃. hours], use an inoculation needle to inoculate the above slope about 1cm 2 The bacterial classification of area is scraped off, transfers in the liquid activation medium of new configuration [composition (g / L) of liquid activation medium: glucose 80, yeast extract 8, peptone 5, all the other components are water, adjust pH value to 6.0. ], the liquid activation medium was packed in a 250ml Erlenmeyer flask, and the amount of the Erlenmeyer flask was 20ml, and it was shaken and cultivated in a reciprocating shaker at 28°C for 18 hours, the shaker speed was 100r / m, and the stroke was 75mm. Take the above-mentioned cultured liquid activation medium and inoculate it into a new configuration, sterilized at 121°C for 15 minutes and cooled to roo...

Embodiment 3

[0031] Get the slant species preserved in the refrigerator for 3 days at 4°C, [the composition of the slant medium (g / L): glucose 100, yeast extract 10, calcium carbonate 25, agar 18, and the remaining components are water, pH7.2. Cultivate at 32°C 36 hours], use an inoculation needle to inoculate about 1cm on the above slope 2 The bacterial classification of area is scraped off, transfers in the liquid activation medium of new configuration [composition (g / L) of liquid activation medium: glucose 100, yeast extract 10, peptone 7.5, all the other components are water, adjust pH value to 7.0. ], the liquid activation medium was packed in a 250ml Erlenmeyer flask, and the amount of the Erlenmeyer flask was 20ml. It was shaken and cultivated in a reciprocating shaker at 32°C for 28 hours. The shaker speed was 90r / m, and the stroke was 75mm. Get the above-mentioned cultivated liquid activation medium and inoculate it into the fermentation medium newly configured, sterilized at 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com