Method for preparing cuprous oxide/ bacterial cellulose nano composite material

A nano-composite material and bacterial cellulose technology, applied in copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve problems such as difficult recycling and reuse, and achieve the effect of overcoming recycling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

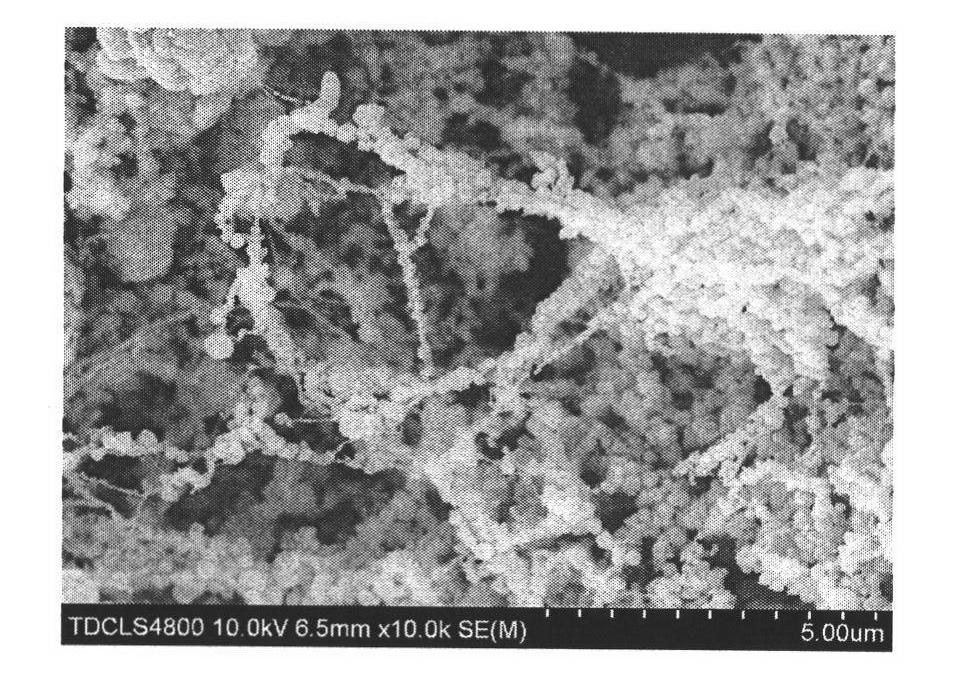

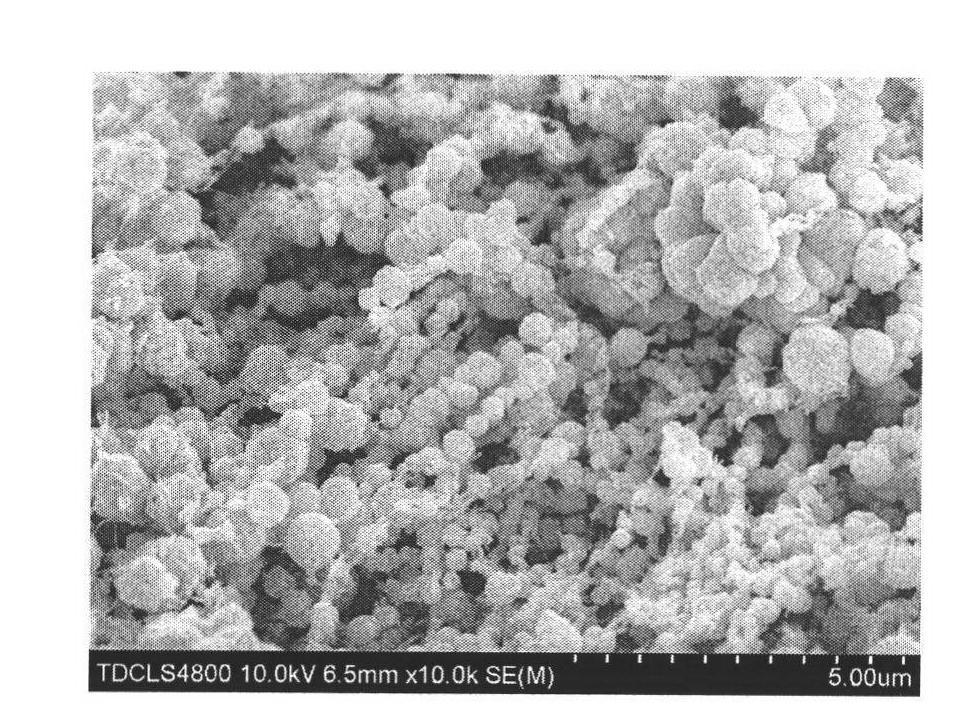

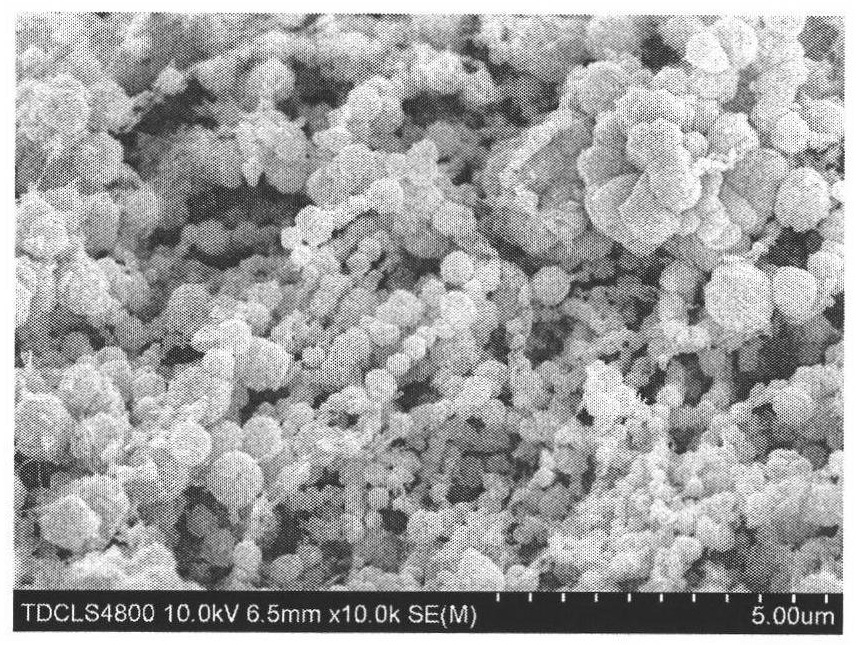

Image

Examples

example 1

[0014] The bacterial cellulose culture method required for the preparation of the composite material is as follows: Glucose (12.5 g), yeast powder (3.75 g), peptone (5.00 g) and disodium hydrogen phosphate (5.00 g) were dissolved in 500 mL of distilled water and placed on ice Acetic acid was used to adjust the pH of the solution to 4.7 to obtain a culture medium solution of Acetobacter xylinum. The culture solution was divided into Erlenmeyer flasks and steam sterilized at 115°C for 30min. After cooling to room temperature, the inoculation method was carried out using the slope inoculation method, followed by stirring at 30°C for 48h (stirring speed r=160r / min). Finally, the culture solution was transferred to a petri dish and cultured in a biochemical incubator (30° C.), and the gel film of BC could be obtained after 5 days. Then BC is cleaned up, and the cleaning process is as follows: boil the bacterial cellulose gel film twice in distilled water, each holding time is 20min...

example 2

[0017] The bacterial cellulose film prepared and cleaned up (preparation method is the same as example 1) is immersed in pH=1, concentration is 49h in the sulfuric acid solution of 0.05mol / L, then it is put into pH=1 (mass fraction is 98% sulfuric acid Solution regulation), the concentration is the NaIO of 0.22mol / L 4 In the solution, react for 2 hours under the condition of avoiding light, temperature at 52°C and constant stirring, then wash the sample with a concentration of 2.0mol / L ethylene glycol solution, and then wash it with deionized water for several times, and then soak it in pH =3.14, the concentration is the NaClO of 0.22mom / L 2 solution for 49h, and then washed the sample with 2.0mol / L ethylene glycol solution and deionized water successively, and then immersed in 0.17mol / L Cu(NO 3 ) 2 After 48 hours in the solution, it was taken out and rinsed with deionized water several times, and then put into a hydroquinone solution with a pH=9 and a concentration of 0.017...

example 3

[0019] The bacterial cellulose film prepared and cleaned up (preparation method is the same as example 1) is immersed in pH=1, and concentration is 50h in the sulfuric acid solution of 0.06mol / L, then it is put into pH=1 (mass fraction is 98% sulfuric acid solution adjustment), the concentration is the NaIO of 0.25mol / L 4 In the solution, react for 3 hours under the condition of avoiding light, temperature at 55°C and constant stirring, then wash the sample with a concentration of 3.0mol / L ethylene glycol solution, wash it with deionized water several times, and then soak it in pH =3.14, the concentration is the NaClO of 0.25mom / L 2 solution for 50 h, then washed the sample with ethylene glycol solution with a concentration of 3.0 mol / L and deionized water in sequence, and then immersed in Cu(NO 3 ) 2 After 50 hours in the solution, take it out and rinse it with deionized water several times, and then put it into a hydroquinone solution with a pH=9 and a concentration of 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com