Preparation method of TiO2/diatomite composite material

A technology of composite materials and diatomite, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., to achieve the effects of improving catalytic efficiency, stable product quality, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 (mode 1)

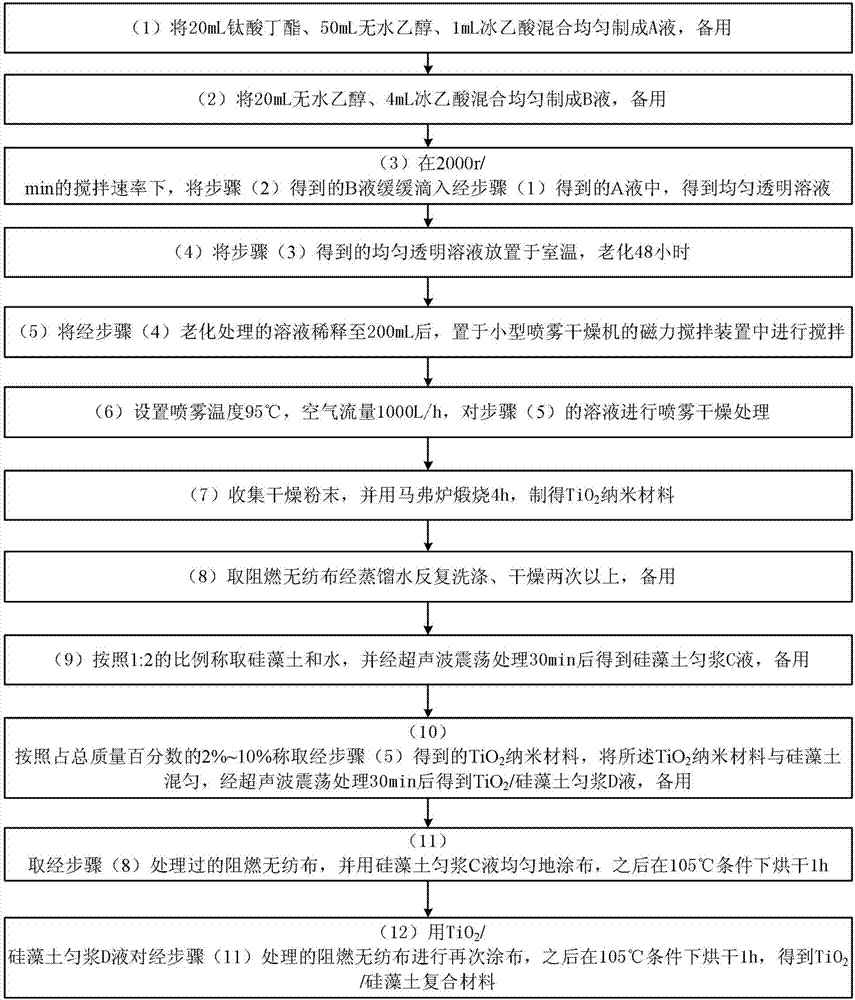

[0038] See attached figure 1 , a kind of TiO provided by the present invention 2 The preparation method of / diatomite composite material specifically comprises the following steps:

[0039] (1) Mix 20mL of butyl titanate, 50mL of absolute ethanol, and 1mL of glacial acetic acid to make liquid A, and set aside;

[0040] (2) Mix 20mL of absolute ethanol and 4mL of glacial acetic acid evenly to make liquid B, set aside;

[0041] (3) At a stirring rate of 2000r / min, slowly drop the liquid B obtained in step (2) into the liquid A obtained in step (1) to obtain a uniform transparent solution;

[0042] (4) Place the homogeneous transparent solution obtained in step (3) at room temperature and age for 48 hours;

[0043] (5) After diluting the aging-treated solution in step (4) to 200mL, place it in the magnetic stirring device of a small spray dryer for stirring;

[0044] (6) Set the spray temperature to 95° C., and the air flow rate to 1000 L / h, and...

Embodiment 2

[0054] Embodiment 2 (mode 2)

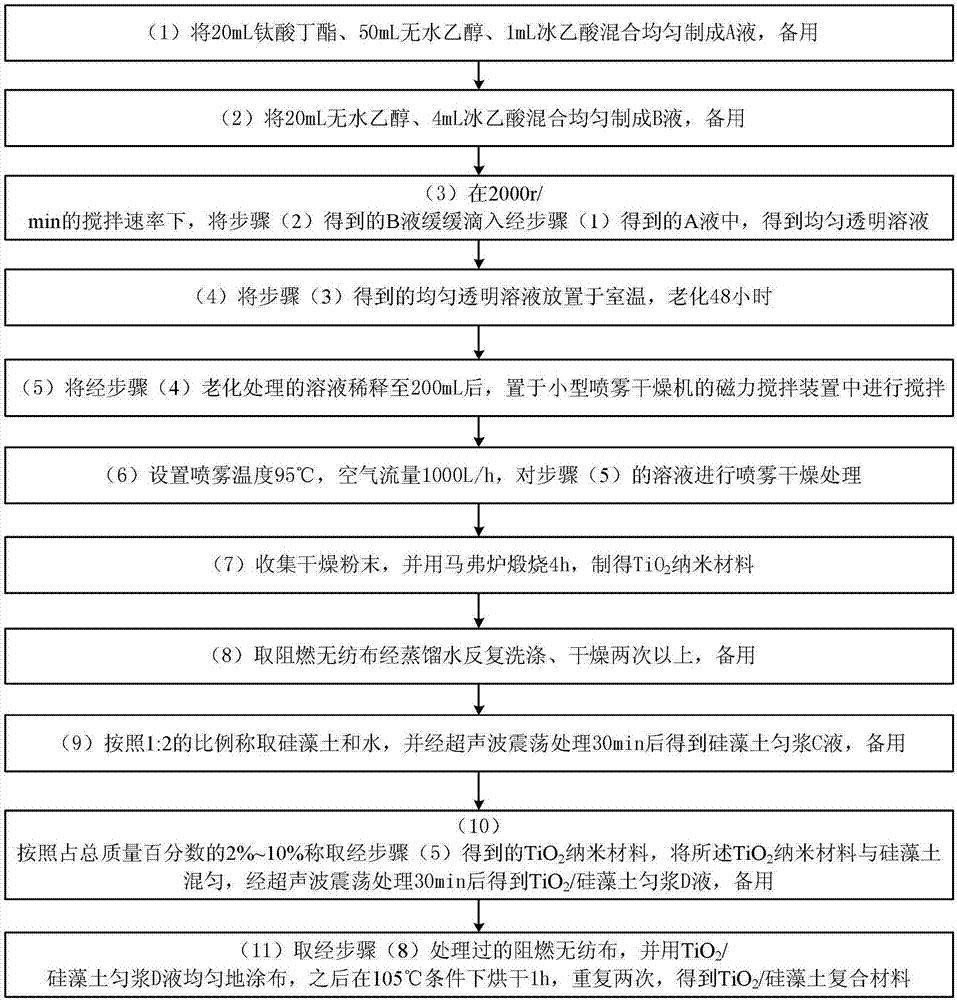

[0055] See attached figure 2 , another TiO provided by the present invention 2 The preparation method of / diatomite composite material specifically comprises the following steps:

[0056] (1) Mix 20mL of butyl titanate, 50mL of absolute ethanol, and 1mL of glacial acetic acid to make liquid A, and set aside;

[0057] (2) Mix 20mL of absolute ethanol and 4mL of glacial acetic acid evenly to make liquid B, set aside;

[0058] (3) At a stirring rate of 2000r / min, slowly drop the liquid B obtained in step (2) into the liquid A obtained in step (1) to obtain a uniform transparent solution;

[0059] (4) Place the homogeneous transparent solution obtained in step (3) at room temperature and age for 48 hours;

[0060] (5) After diluting the aging-treated solution in step (4) to 200mL, place it in the magnetic stirring device of a small spray dryer for stirring;

[0061] (6) Set the spray temperature to 95° C., and the air flow rate to 1000 L / h, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com