An antiferroelectric energy storage ceramic with improved energy storage efficiency and its preparation method and application

A technology of energy storage efficiency and anti-ferroelectricity, applied in circuits, capacitors, electrical components, etc., can solve the problems of low energy storage efficiency, achieve high energy storage efficiency, reduce dielectric constant, and high energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

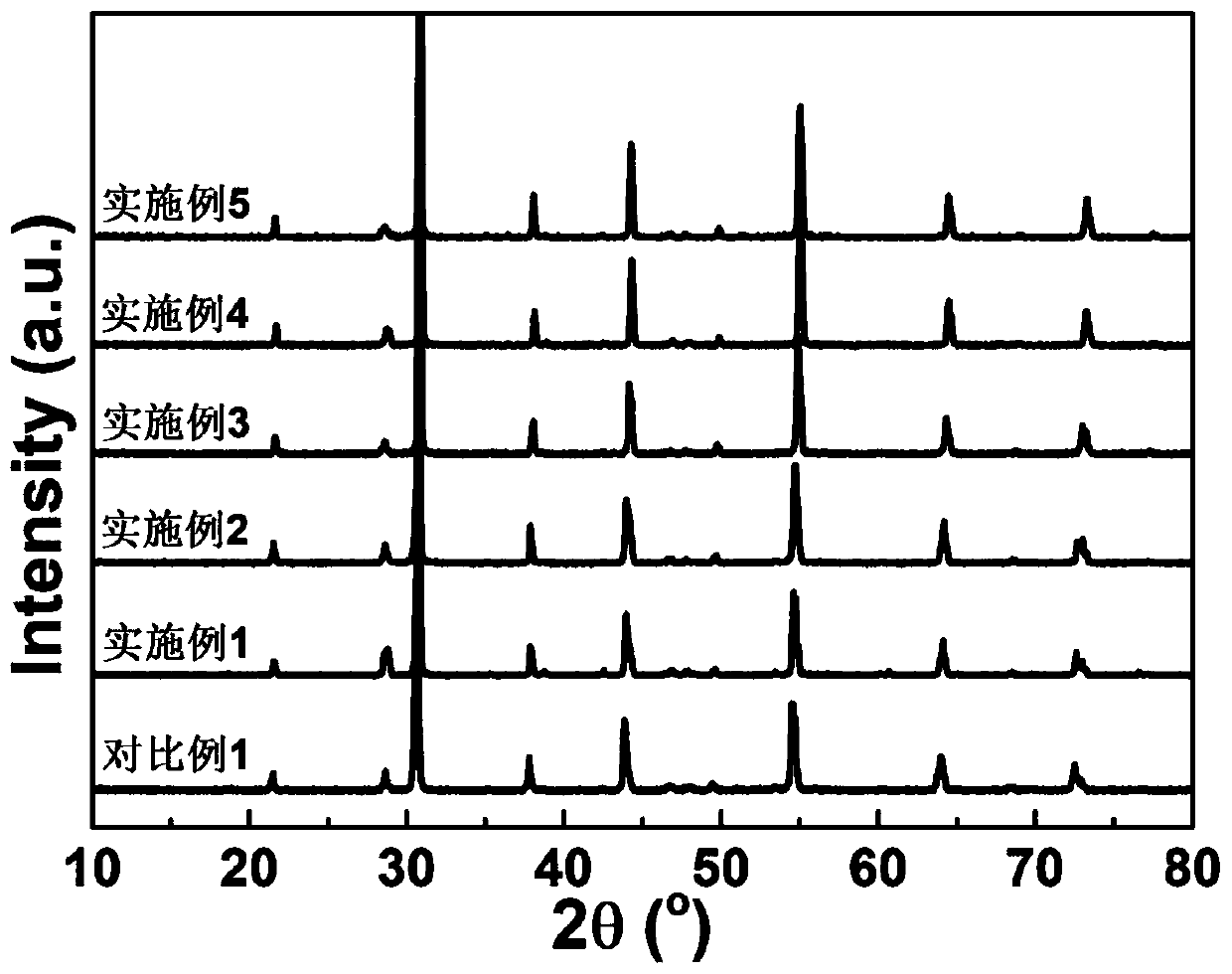

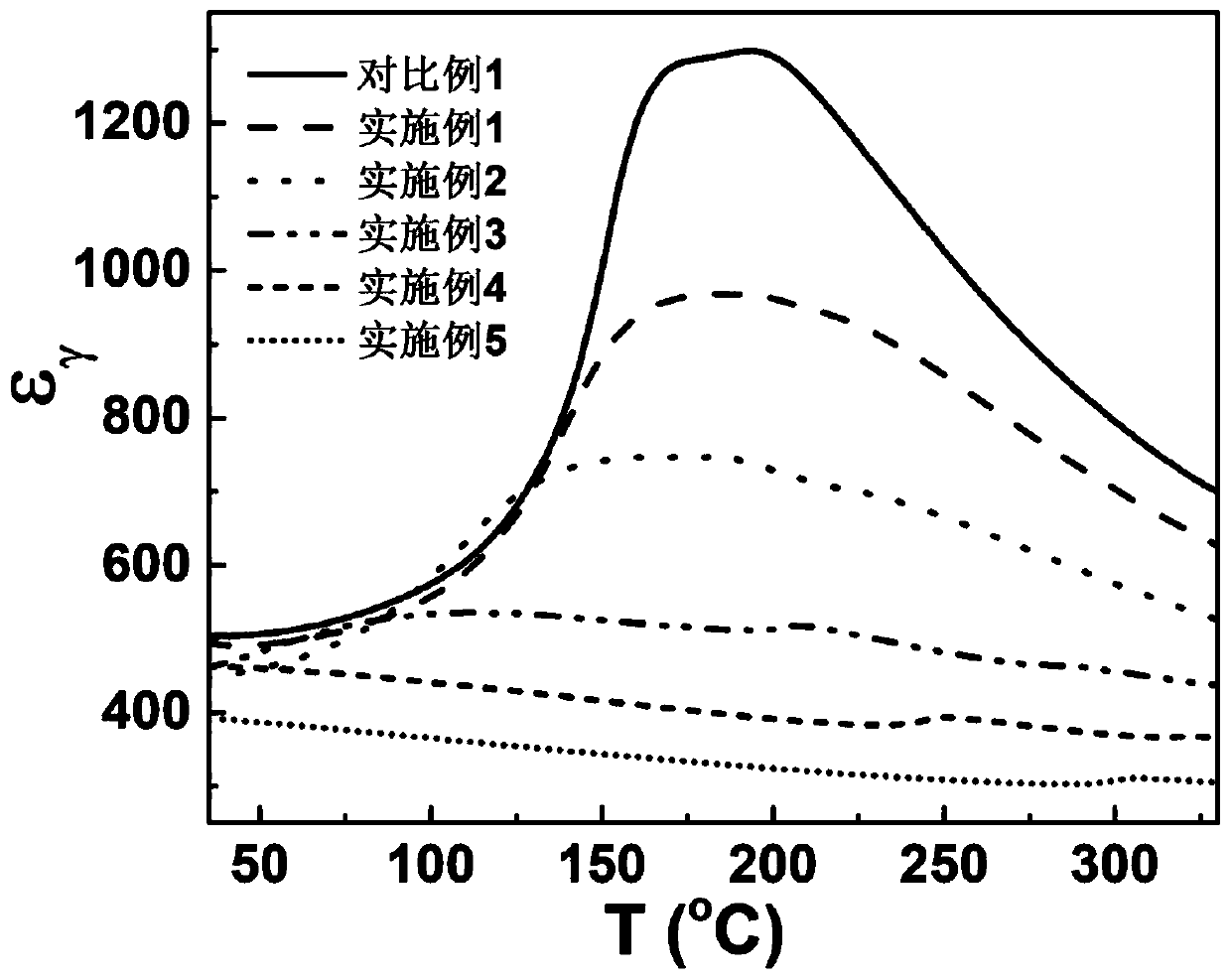

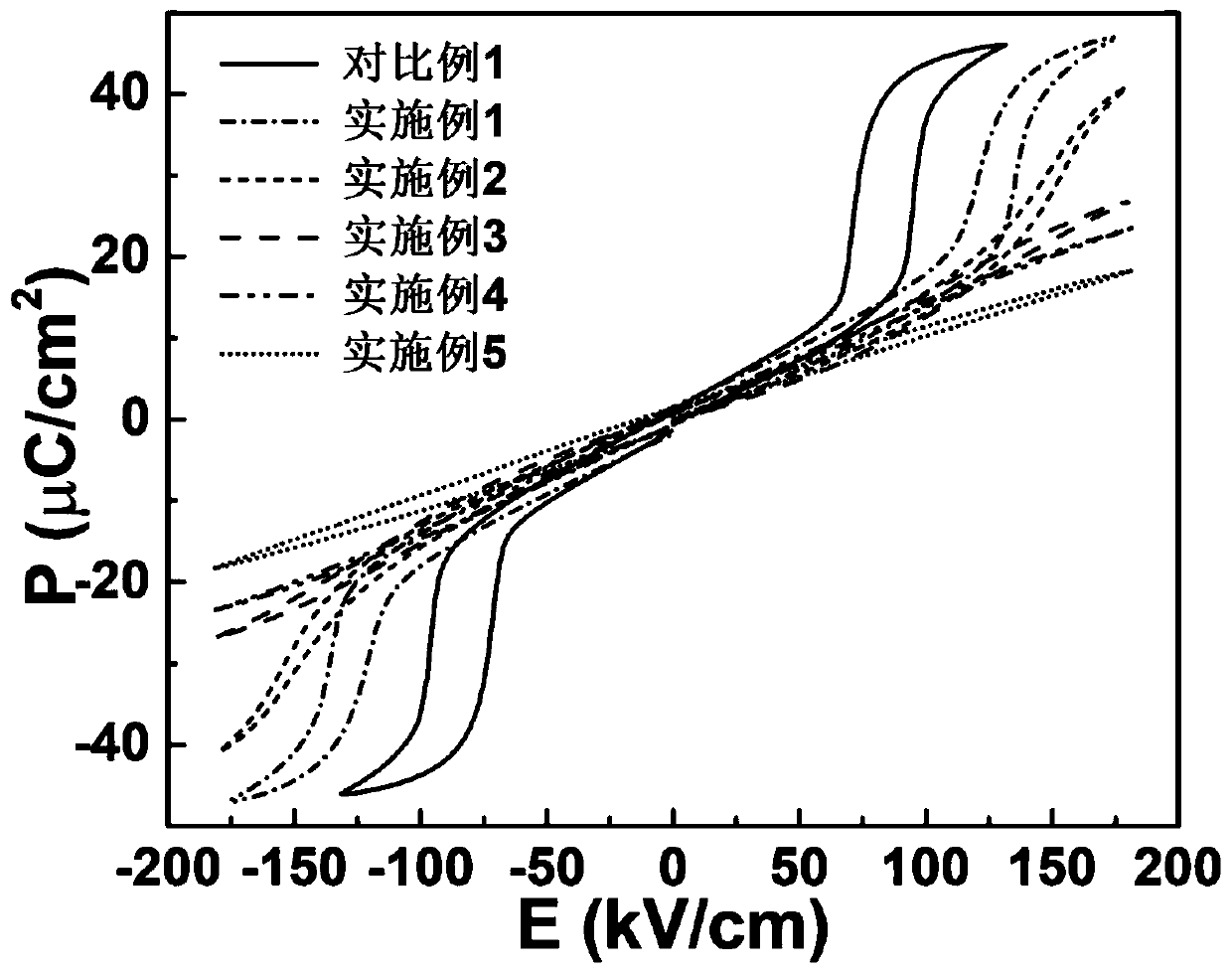

Embodiment 1

[0033] (1) Preparation of antiferroelectric materials with high energy storage density:

[0034] According to the chemical formula (Pb 0.93 Ba 0.04 La 0.02 )(Zr 0.65 sn 0.3 Ti 0.05 )O 3 Carry out batching, prepare 0.2mol (Pb 0.93 Ba 0.04 La 0.02 )(Zr 0.65 sn 0.3 Ti 0.05 )O 3 , PbO (99.9%), La 2 o 3 (99.9%), ZrO 2 (99.5%), SnO 2 (99.6%), TiO 2 (99.6%), BaCO 3 The masses of (99.8%) are 88.901g (6wt% excess lead oxide), 1.304g, 31.950g, 18.158g, 1.604g, 2.392g, respectively. Using wet ball milling method, according to the mass ratio of raw materials: alcohol = 1:0.6, ball milled for 6 hours, after drying, the temperature was raised to 850°C at 5°C per minute, and kept in air for 3 hours. The obtained powder is ball milled, dried, passed through a 60-mesh sieve, pre-pressed at a pressure of 20 MPa, and the pre-pressed powder is subjected to secondary sieving to obtain an antiferroelectric calcined powder with high energy storage density.

[0035] (2) Preparation ...

Embodiment 2

[0040] (1) The same method as (1) in Example 1 was used to prepare the pre-sintered powder of antiferroelectric material with high energy storage density.

[0041] (2) Using the same method as (2) in Example 1 to prepare a linear material powder with high energy storage efficiency.

[0042] (3) Mix the powder obtained in steps (1) and (2) according to the mass ratio of 98:2, ball mill and mix for 4 hours, after drying and pulverizing, add a PVA solution with a concentration of 5%, and the solution accounts for 5% of the powder. The mass percentage is 8%, and after granulation and dry pressing, sintering at 1200°C for 3 hours, and annealing at 1000°C for 1 hour, the energy storage ceramic material is made.

Embodiment 3

[0044] (1) The same method as (1) in Example 1 was used to prepare the pre-sintered powder of antiferroelectric material with high energy storage density.

[0045] (2) Using the same method as (2) in Example 1 to prepare a linear material powder with high energy storage efficiency.

[0046] (3) Mix the powder obtained in steps (1) and (2) according to the mass ratio of 96:4, ball mill and mix for 4 hours, after drying and pulverizing, add a PVA solution with a concentration of 5%, and the solution accounts for 5% of the powder. The mass percentage is 8%, and after granulation and dry pressing, sintering at 1200°C for 3 hours, and annealing at 1000°C for 1 hour, the energy storage ceramic material is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com