Homogeneous AuNi alloy catalytic material and preparation method thereof

A technology of catalytic materials and alloys, applied in the field of electrocatalysis, can solve the problems of low efficiency of electrocatalytic reduction of carbon dioxide catalyst, cumbersome preparation process, side reactions of hydrogen evolution, etc., and achieve excellent performance of electrocatalytic reduction of carbon dioxide, excellent specific surface area, reduced preparation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

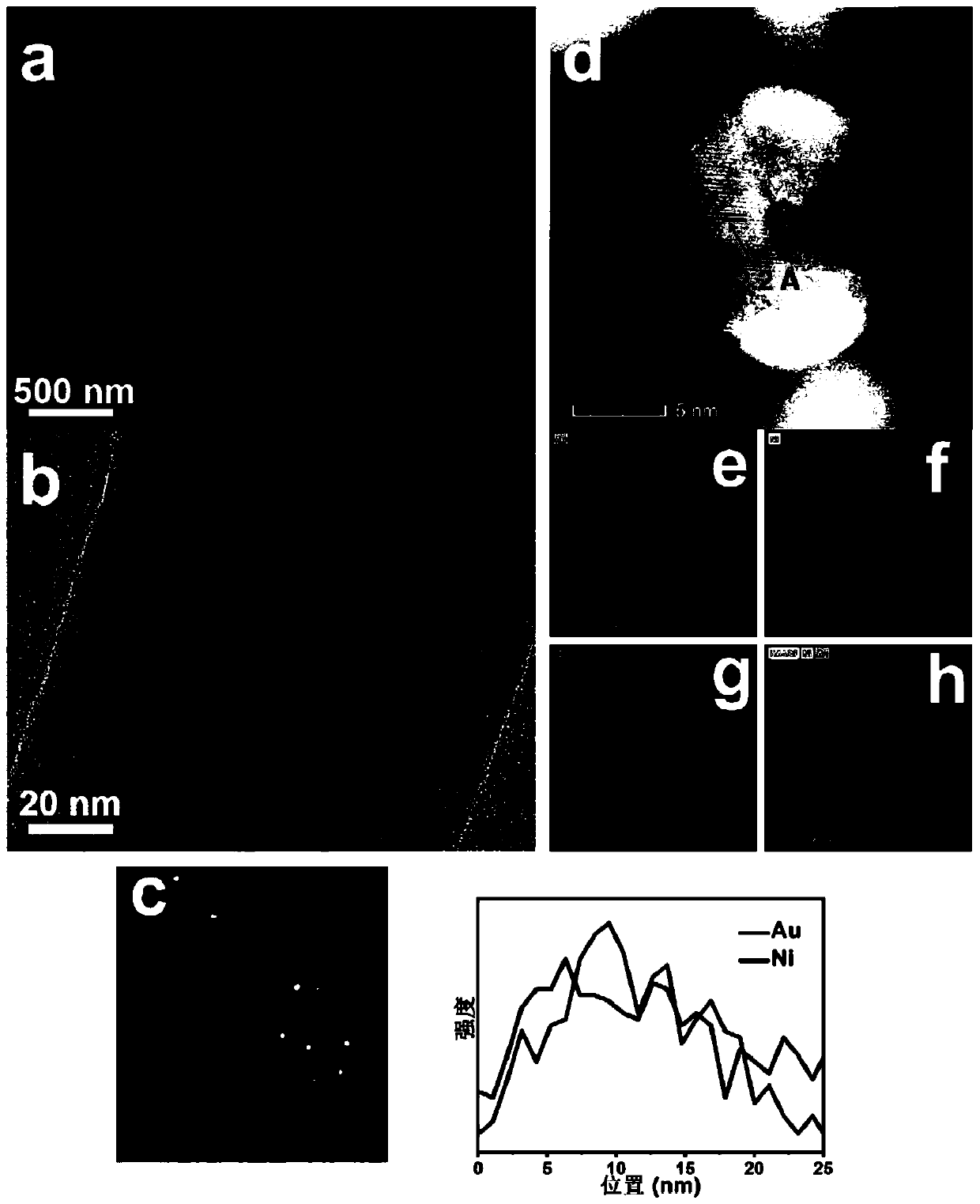

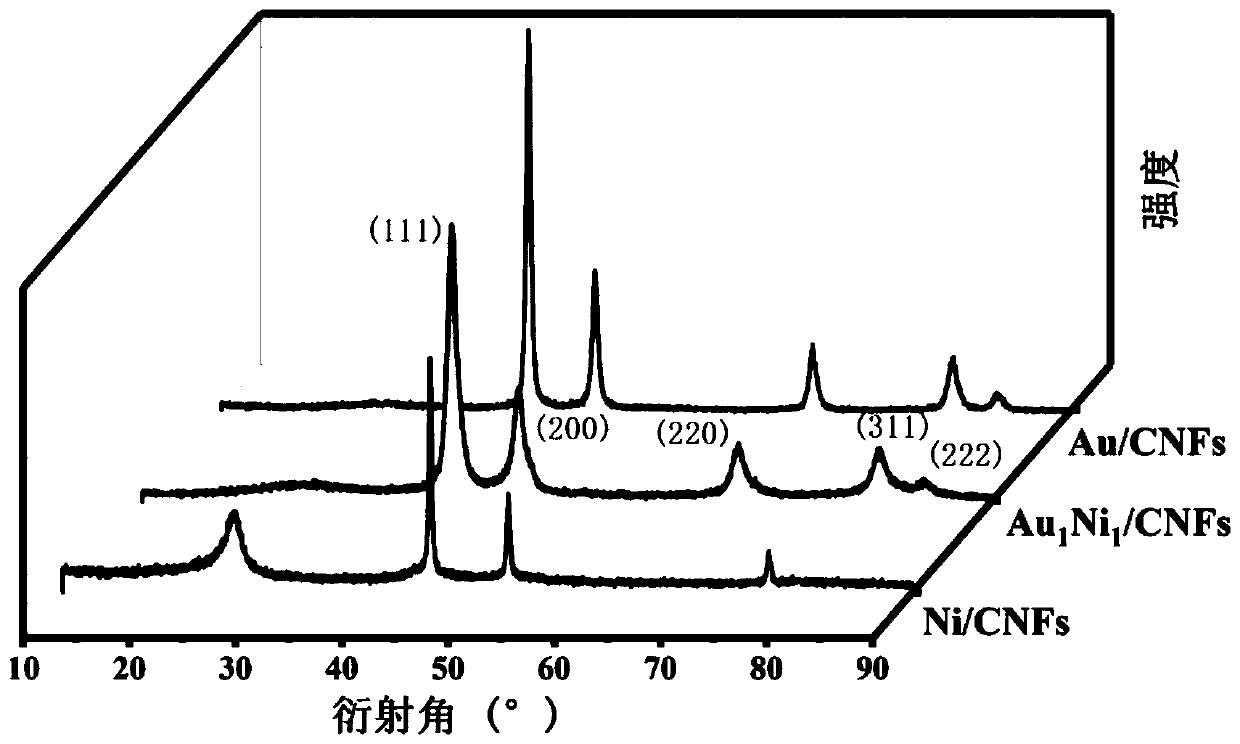

[0045] (1) Preparation of catalytic material Au 1 Ni 1 / CNFs:

[0046] Take by weighing 0.412g of chloroauric acid, 0.291g of nickel nitrate, that is, the gold-nickel molar ratio is 1:1, and adding it to 15g of polyvinyl alcohol / N,N-dimethylformamide solution with a mass fraction of 20%, using Magnetic stirring produces a homogeneous and transparent solution.

[0047] The above solution is spun by electrospinning, the positive voltage of the spinning is controlled to be 15kV, the distance between the positive electrode and the receiver is set to 20cm, and the solution pushing speed is 0.2mL / min, that is, the nanometer containing gold salt and nickel salt is prepared. Fiber membrane.

[0048] Clamp 0.8g of the prepared nanofiber membrane into a graphite sheet, place it in a tube furnace, and carry out a stepwise heating pre-oxidation treatment in an air atmosphere according to the following temperature and holding time: 80°C-4h, 100°C-4h , 120°C-4h, 140°C-4h, 160°C-4h, 180°...

Embodiment 2

[0061] (1) Preparation of catalytic material Au 1 Ni 3 / CNFs:

[0062] Take by weighing 0.412g of chloroauric acid, 0.873g of nickel nitrate, that is, the gold-nickel molar ratio is 1:3, adding it to 15g of polyvinylpyrrolidone / N,N-dimethylformamide solution with a mass fraction of 20%, using Magnetic stirring produces a homogeneous and transparent solution.

[0063] The solution is spun by electrospinning, the positive voltage of the spinning is controlled to be 18kV, the distance between the positive electrode and the receiver is set to 25cm, and the pushing speed of the solution is 0.3mL / min. nanofibrous membrane.

[0064] 0.8g of the prepared nanofiber membrane is sandwiched between graphite sheets, placed in a tube furnace, and subjected to stepwise temperature rise pre-oxidation treatment in an air atmosphere at the following temperatures: 80°C-4h, 100°C-4h, 120°C -4h, 140°C-4h, 160°C-4h, 180°C-4h, so that the fiber membrane can form a stable structure, effectively p...

Embodiment 3

[0069] (1) Preparation of catalytic material Au3 Ni 1 / CNFs:

[0070] Take by weighing 0.247g of chloroauric acid, 0.058g of nickel nitrate, that is, the gold-nickel mol ratio is 3:1, and adding it to 15g of polyacrylonitrile / N,N-dimethylformamide solution with a mass fraction of 20%, using Magnetic stirring produces a homogeneous and transparent solution.

[0071] All the other preparation methods are the same as in Example 1.

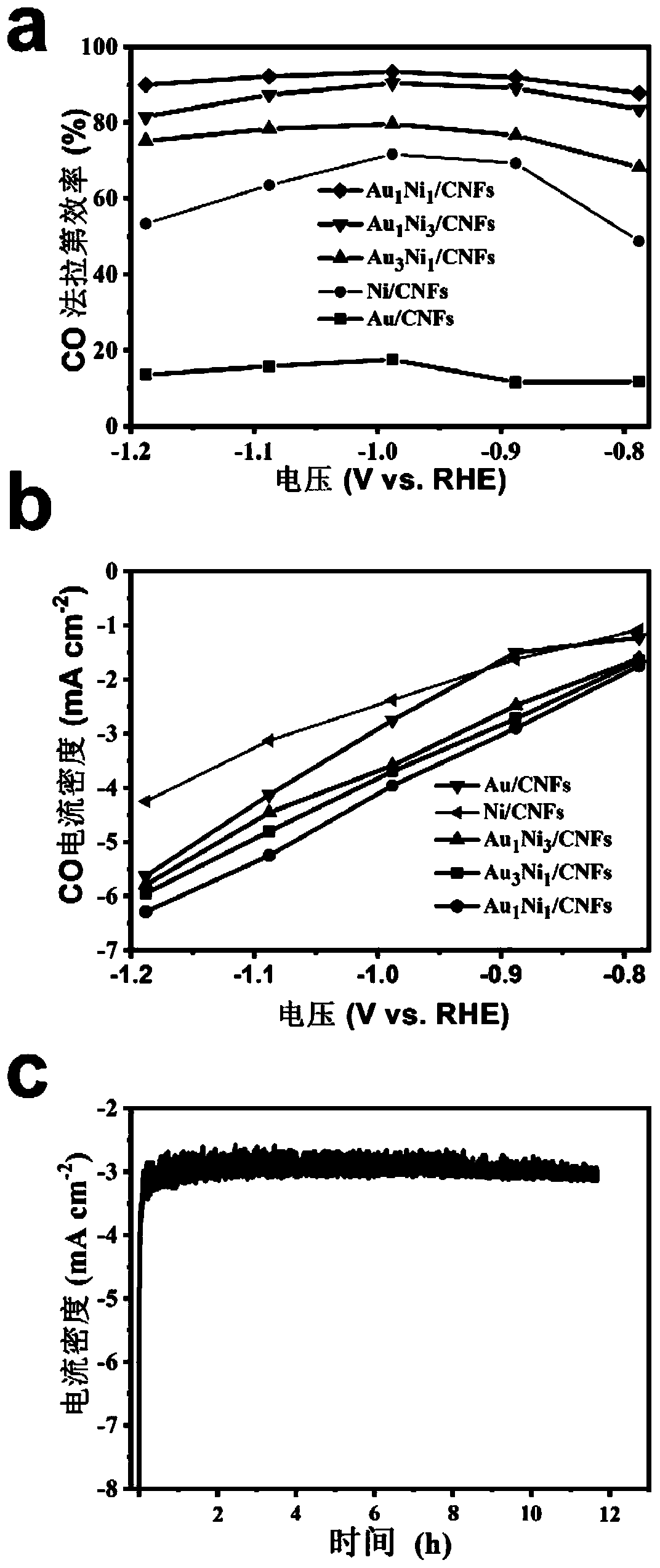

[0072] (2) Performance characterization of catalytic reduction of carbon dioxide:

[0073] The test method is the same as the method in Example 1.

[0074] Catalytic material Au 3 Ni 1 / CNFs catalytic reduction of carbon dioxide performance such as image 3 (a), 3(b), shown by image 3 (a) It can be seen that the catalytic material Au 3 Ni 1 The CO optimal Faradaic efficiency of / CNFs is 80%, given by image 3 (b) It can be concluded that the catalytic material Au 3 Ni 1 / CNFs with a current density of 3.7 mA cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com