Graphene enhanced photo-thermal evaporation membrane, membrane assembly and sewage concentration treatment device

An evaporation film and graphene technology, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve problems that are not conducive to water vapor escape and restriction, and avoid supply The effects of insufficient liquid, high specific surface area, and high solar absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

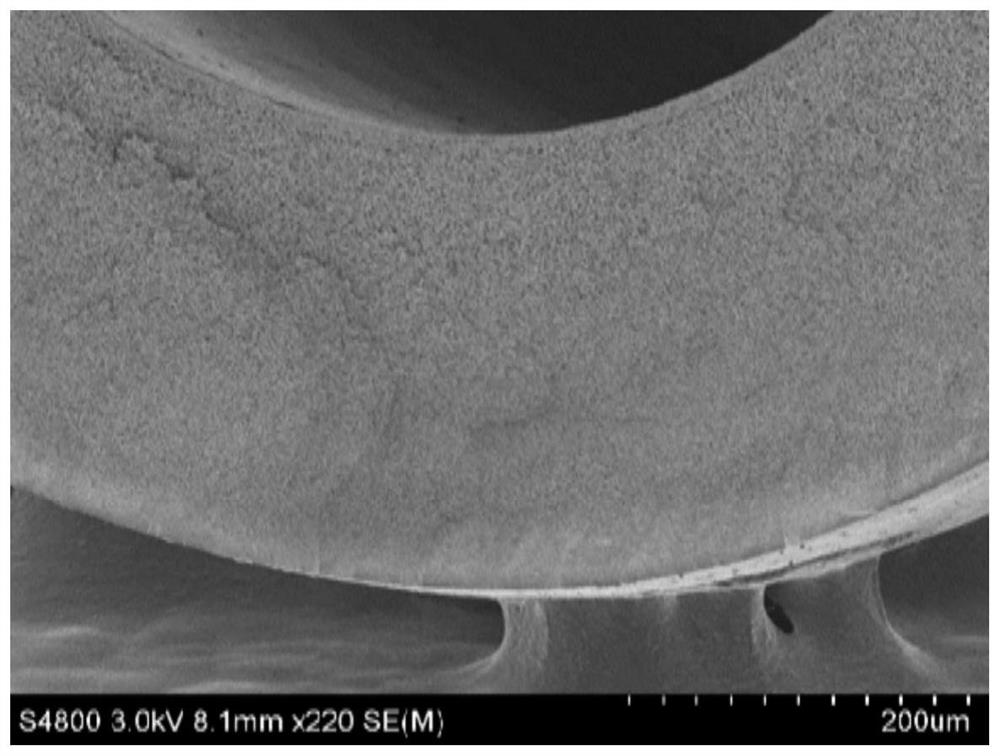

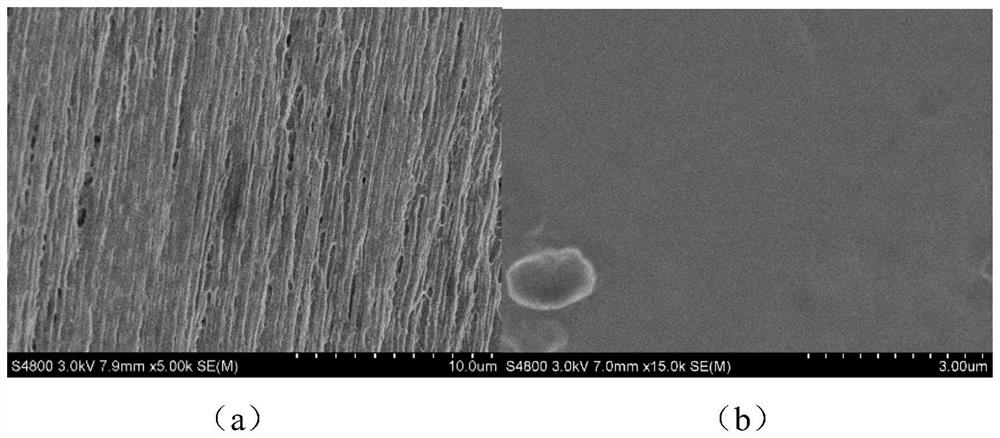

[0045] The specific embodiment of the present invention provides a kind of graphene enhanced photothermal evaporation film, and its preparation method comprises:

[0046] (1) preparing graphene dispersion liquid: adding graphene material in the first organic solvent, ultrasonic dispersion 12~48h obtains graphene dispersion liquid, graphene material accounts for 0.2~20.0wt% of graphene dispersion liquid;

[0047] (2) Preparation of spinning casting solution: polymer powder is vacuum-dried at 40-90°C for 6-24h, dissolved in a second organic solvent to obtain a polymer solution, the polymer powder accounts for 16-24wt% of the polymer solution, and then Add the graphene dispersion liquid into the polymer solution in batches, then add the porogen, and stir at 80° C. for 12 to 72 hours to obtain the spinning casting solution; the porogen accounts for 0.5% of the spinning casting solution. ~10wt%; the volume ratio of the graphene dispersion to the polymer solution is 1:1~1:10.

[00...

Embodiment 1

[0054] Embodiment 1 A kind of graphene enhanced photothermal evaporation film, its preparation method is as follows:

[0055] (1) prepare graphene dispersion liquid: join graphene in the organic solvent N-methylpyrrolidone, ultrasonic dispersion 36h obtains graphene dispersion liquid, graphene accounts for 10wt% of graphene dispersion liquid;

[0056](2) Preparation of spinning casting solution: the polyvinylidene fluoride powder was vacuum-dried at 80° C. for 12 hours, dissolved in the organic solvent N-methylpyrrolidone to obtain a polymer solution, and the polyvinylidene fluoride powder accounted for 22 wt% of the polymer solution. Then the graphene dispersion is added to the polymer solution in batches (the volume ratio of the graphene dispersion to the polymer solution is 1:1), then PEG200 is added, and stirred for 48h at 80°C to obtain a spinning casting solution ; PEG200 accounts for the 5.0wt% of the spinning casting solution, and the spinning casting solution prepared...

Embodiment 2

[0059] Embodiment 2 A kind of graphene enhanced photothermal evaporation film, its preparation method is as follows:

[0060] (1) prepare graphene dispersion liquid: graphene is joined in the organic solvent N,N-dimethylacetamide, ultrasonic dispersion 12h obtains graphene dispersion liquid, graphene accounts for 0.2wt% of graphene dispersion liquid;

[0061] (2) Preparation of spinning casting solution: dry polyvinylidene fluoride powder under vacuum at 40°C for 24 hours, dissolve in organic solvent N,N-dimethylacetamide to obtain a polymer solution, polyvinylidene fluoride powder accounts for solution 16wt%, then the graphene dispersion was added in batches to the polymer solution (the volume ratio of the graphene dispersion to the polymer solution was 1:5), then PEG2000 was added, and stirred for 12h at 80°C to obtain a spinning Silk casting solution; PEG2000 accounts for 0.5wt% of the spinning casting solution;

[0062] (3) Preparation of graphene-enhanced photothermal ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com