Preparation method and application of ZnSnO3/NC composite material

A technology of composite materials and conditions, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems that the conductivity and electrochemical properties of electrode materials need to be further improved, and achieve the improvement of electrical conductivity and electrochemical properties, Improve performance, improve the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

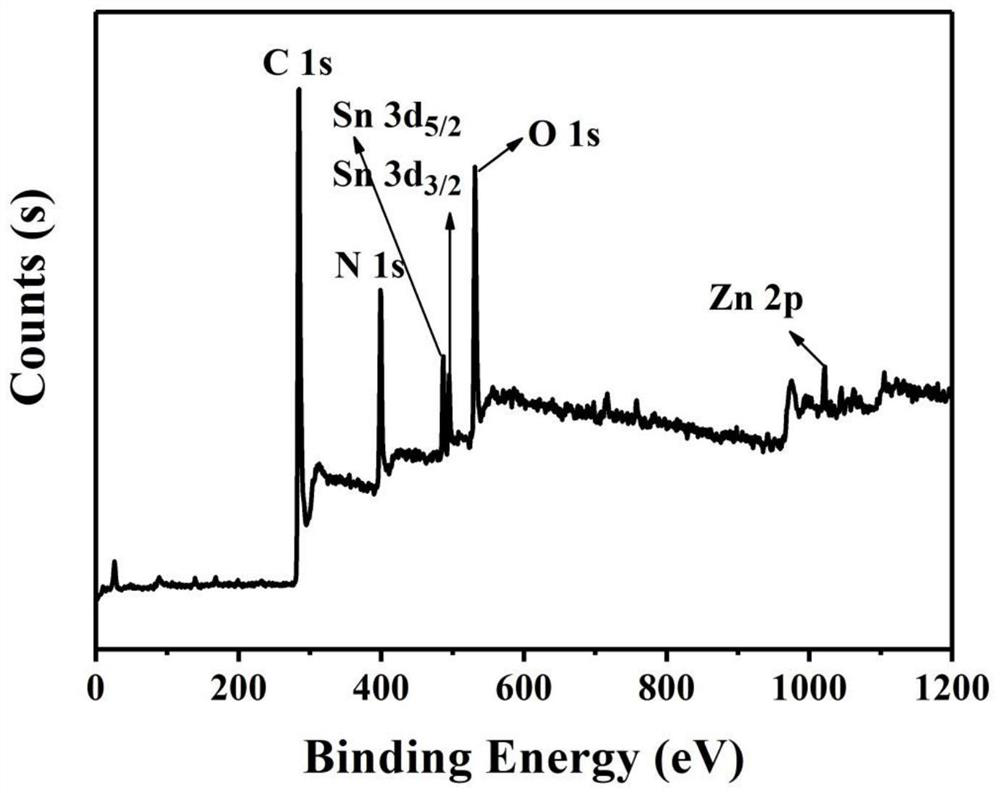

[0031] Embodiment 1: a kind of ZnSnO 3 The preparation method of / NC composite material, comprises the steps:

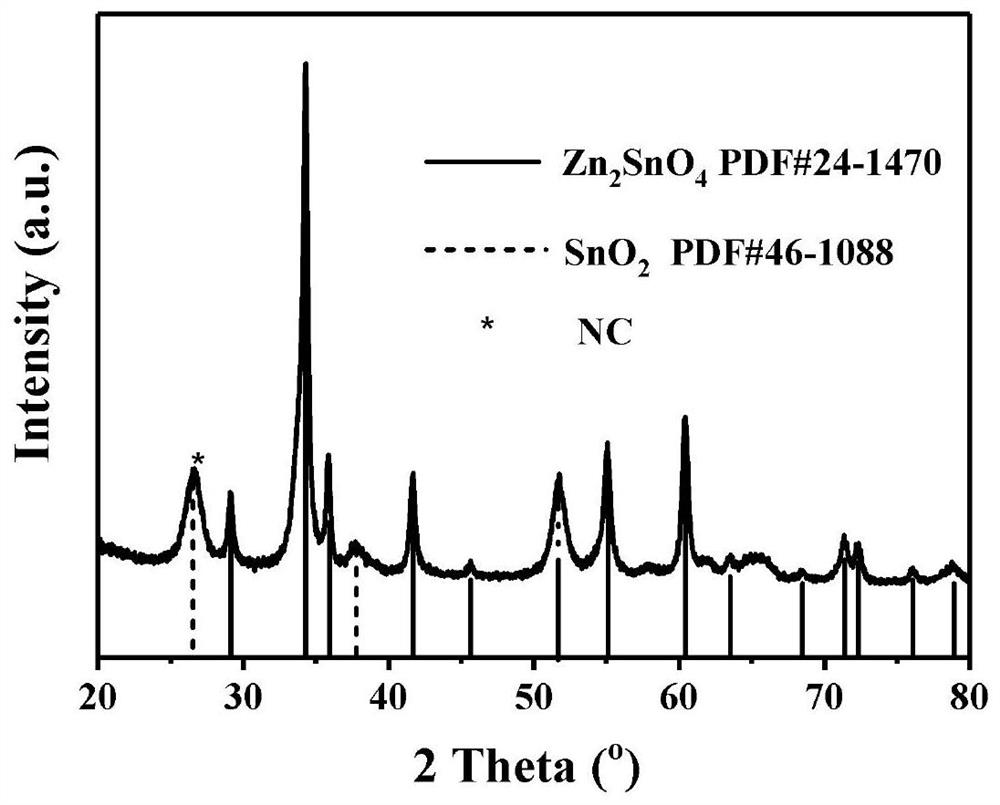

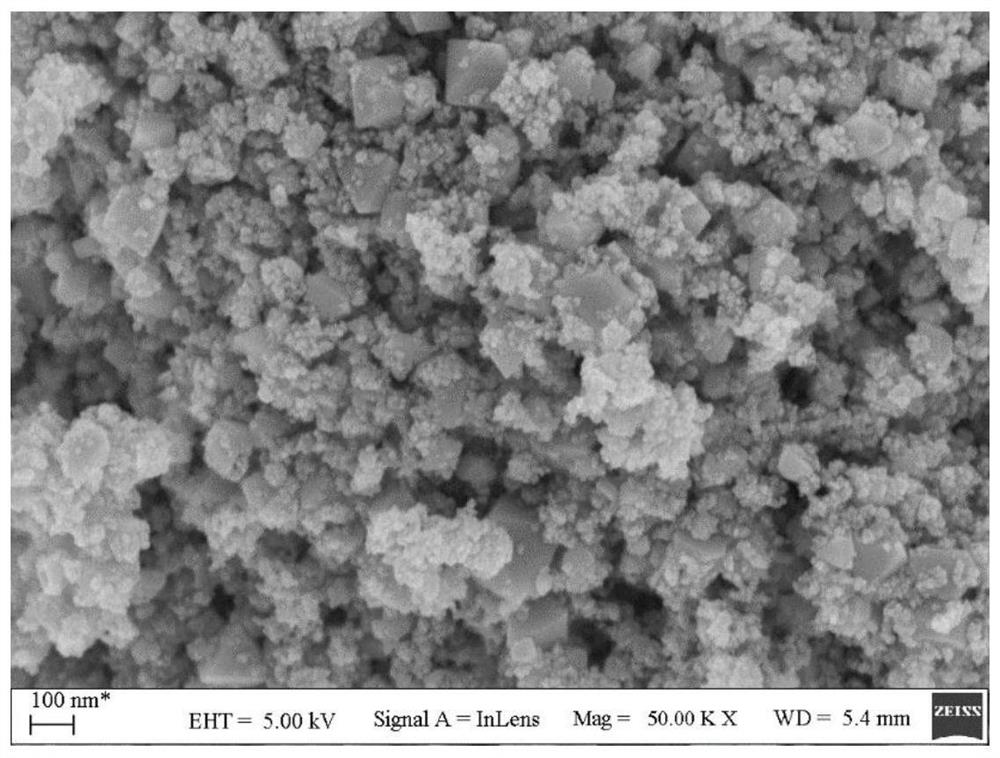

[0032] (1) Preparation of ZnSnO 3 : Under ice bath conditions, 1.2g SnCl 4 ·5H 2 O (0.003mol) and 0.8g ZnSO 4 ·7H 2O (0.003mol) was added to 20mL 0.3mol / L NaOH solution and ultrasonically stirred for 12h to obtain a precipitate, which was washed with absolute ethanol and deionized water three times in turn, and then freeze-dried (temperature -30°C, vacuum degree 1Pa) to obtain a powder ; Move the above powder to a tube furnace, raise the temperature from room temperature to 700°C at a rate of 1°C / min under nitrogen protection, and calcinate for 2 hours to obtain light yellow ZnSnO 3 Powder, particle size is 50-100nm;

[0033] (2) ZnSnO 3 / Preparation of polypyrrole precursor: under ice bath condition, get 0.5g step (1) gained ZnSnO 3 The powder was ultrasonically dispersed into 70 mL of deionized water, 0.5 mL of pyrrole was added, and then 100 mL of 0.05 mo...

Embodiment 2

[0036] Embodiment 2: a kind of ZnSnO 3 The preparation method of electrode material, comprises the steps:

[0037] Under ice bath conditions, 1.2g SnCl 4 ·5H 2 O (0.003mol) and 0.8gZnSO 4 ·7H 2 O (0.003mol) was added into 20mL 0.3mol / L NaOH solution and ultrasonically stirred for 12 hours to obtain a precipitate, which was washed with absolute ethanol and deionized water three times in turn, and then freeze-dried (temperature -30°C, vacuum degree 1Pa) to obtain a powder ; Move the above powder to a tube furnace, raise the temperature from room temperature to 700°C at a rate of 1°C / min under nitrogen protection, and calcinate for 2 hours to obtain light yellow ZnSnO 3 Powder, particle size 50-100nm, purity over 99%.

Embodiment 3

[0038] Embodiment 3: a kind of ZnSnO 3 The preparation method of / NC composite material, comprises the steps:

[0039] (1) Preparation of ZnSnO 3 : Under ice bath conditions, 1.2g SnCl 4 ·5H 2 O(0.003mol) and 0.8gZnSO 4 ·7H 2 O (0.003mol) was added to 20mL 0.3mol / L NaOH solution and ultrasonically stirred for 12h to obtain a precipitate, which was washed with absolute ethanol and deionized water three times in turn, and then freeze-dried (temperature -30°C, vacuum degree 1Pa) to obtain a powder ; Move the above powder to a tube furnace, raise the temperature from room temperature to 700°C at a rate of 1°C / min under nitrogen protection, and calcinate for 2 hours to obtain light yellow ZnSnO 3 Powder, particle size 50-100nm, purity over 99%;

[0040] (2) ZnSnO 3 / The preparation of polypyrrole precursor: under ice-bath condition, get 0.5g step (1) gained ZnSnO 3 Disperse the powder in 70mL deionized water, add 1mL pyrrole, then add 120mL 0.05mol / L ammonium persulfate sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com