Patents

Literature

49results about How to "Improve volume effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hair treatment compositions containing N-hydroxy-alkyl-O-benzyl chitosans and methods of using same

InactiveUS20050226838A1EffectiveMaintain good propertiesCosmetic preparationsHair cosmeticsMedicineAdditive ingredient

The hair treatment composition contains preferably from 0.01 to 20 percent by weight of at least one N-hydroxyalkyl-O-benzyl chitosan and from 0.01 to 20 percent by weight of at least one other hair treatment effective ingredient. The at least one N-hydroxyalkyl-O-benzyl chitosan has at least one hydroxylalkyl group, preferably a hydroxyethyl, hydroxypropyl or hydroxybutyl group, and has from 2 to 20 carbon atoms. Various methods of treating hair with hair treatment compositions containing one or more of the N-hydroxyalkyl-O-benzyl chitosans are described.

Owner:WELLA AG

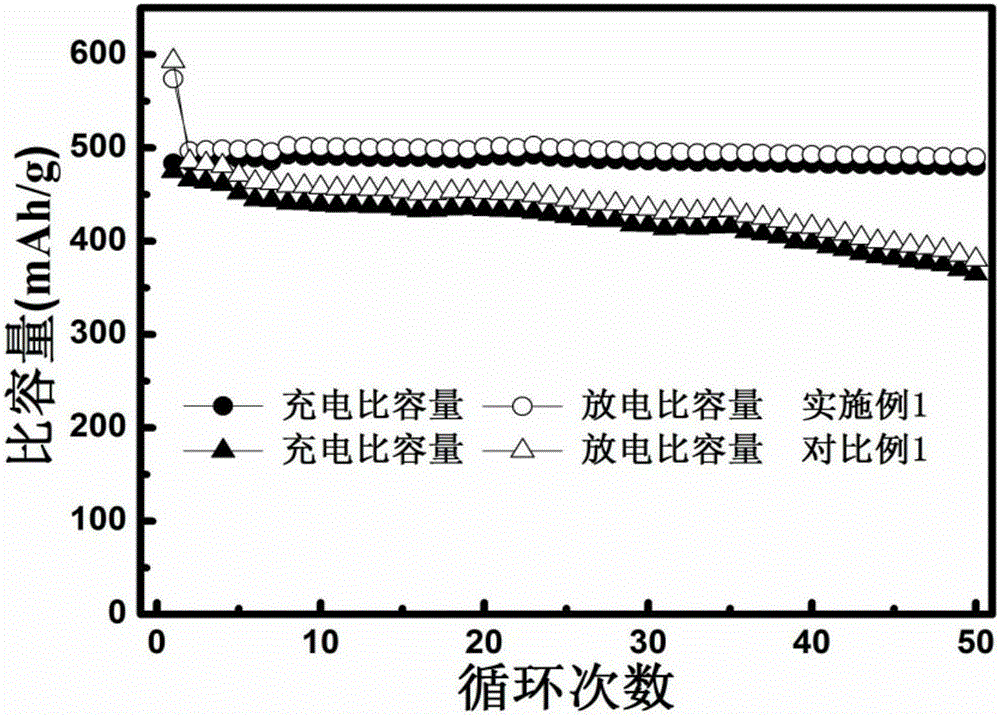

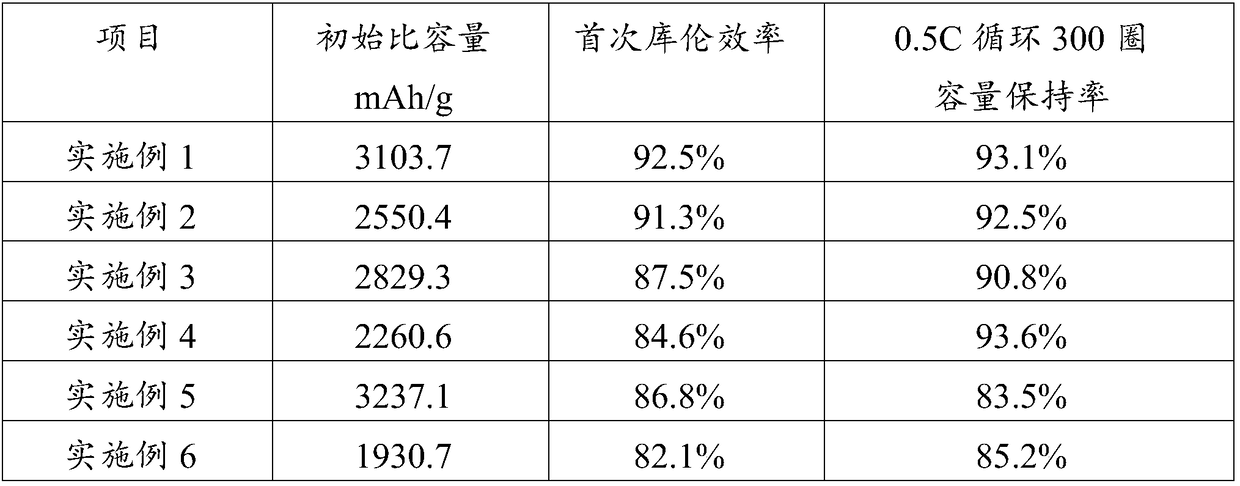

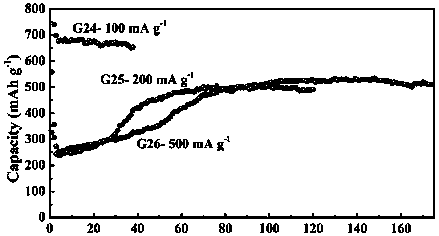

Silicon carbon composite anode material of lithium-ion battery, method for preparing silicon carbon composite anode material, and lithium-ion battery

InactiveCN102403491AHigh specific capacityImprove cycle performanceCell electrodesSecondary cellsCarbon compositesGraphite

The invention provides a silicon carbon composite anode material of a lithium-ion battery, a method for preparing the silicon carbon composite anode material, and the lithium-ion battery. The silicon carbon composite anode material comprises two groups of substances, such as (a) silicon powder, silicon oxide (SiO) powder or a mixture of the silicon powder and the SiO powder, and (b) graphite and expanded graphite. The method for preparing the silicon carbon composite anode material comprises the following steps of: mixing components (a) and components (b); placing a mixture into a ball mill; and ball-milling for 1 to 24 h at the rotation speed of 100 to 600 r / min. By the method, the preparation process is simple and cost is low. The prepared anode material has excellent conducting performance. Correspondingly, the lithium-ion battery is high in specific capacity and good in cycle performance.

Owner:CHERY AUTOMOBILE CO LTD

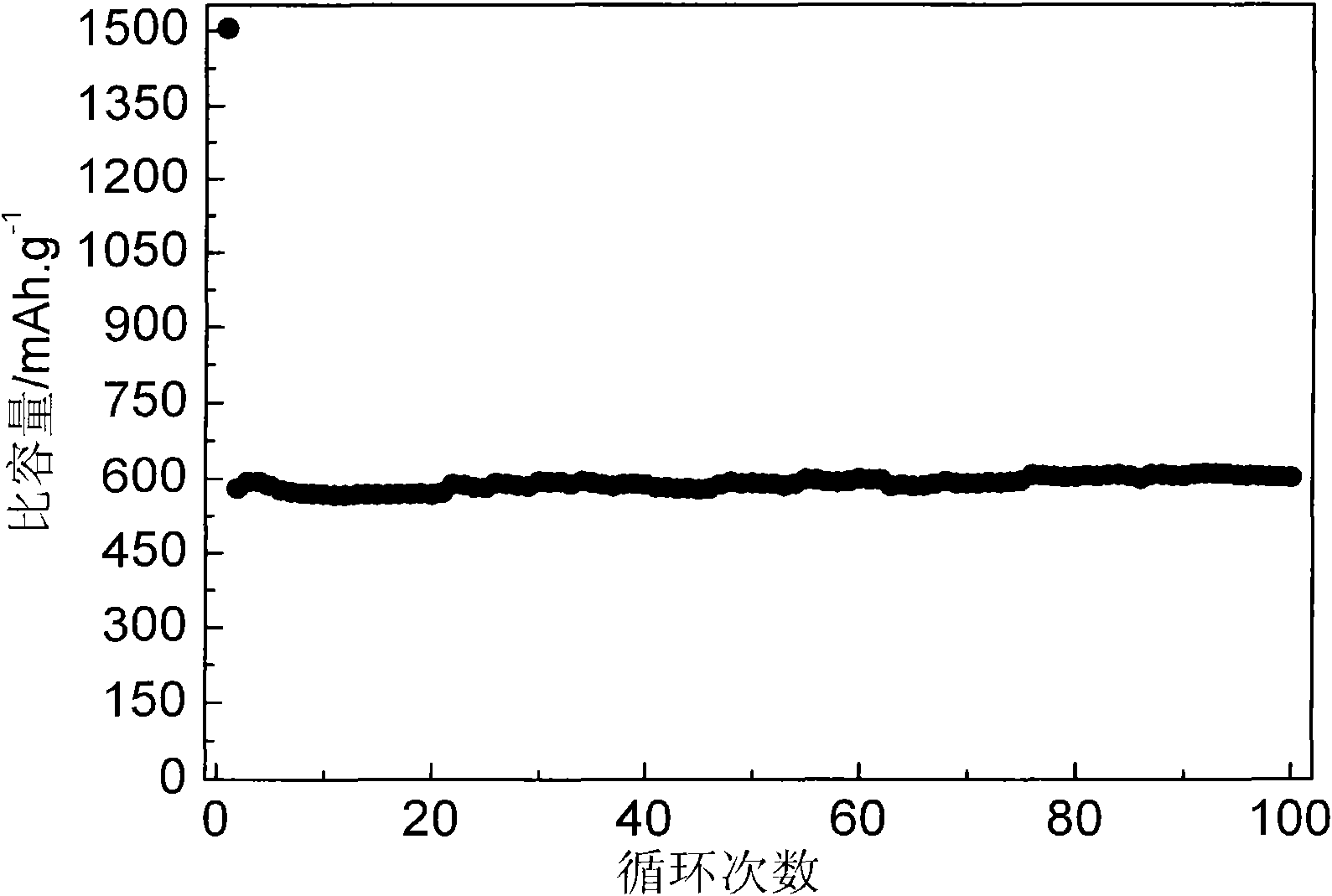

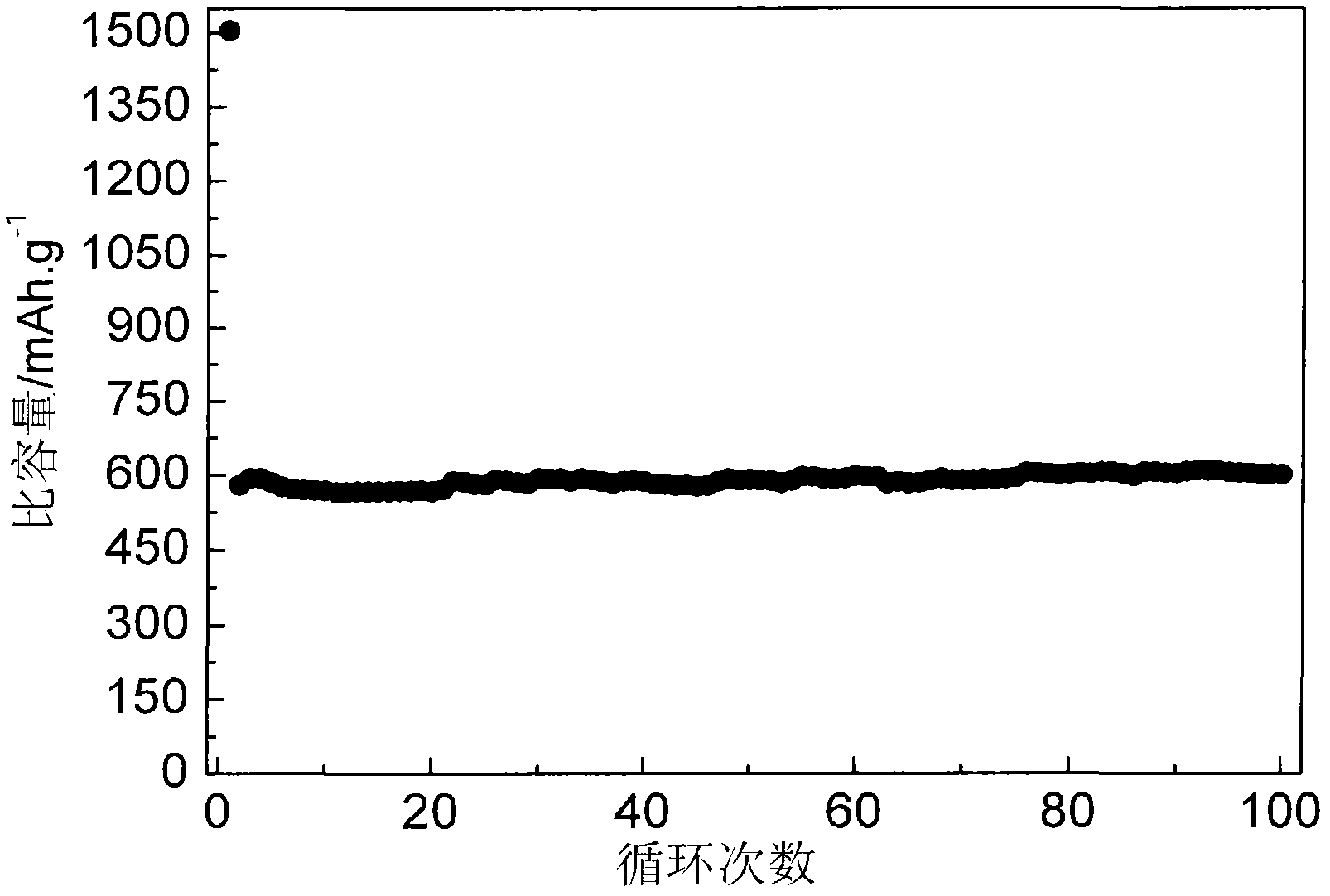

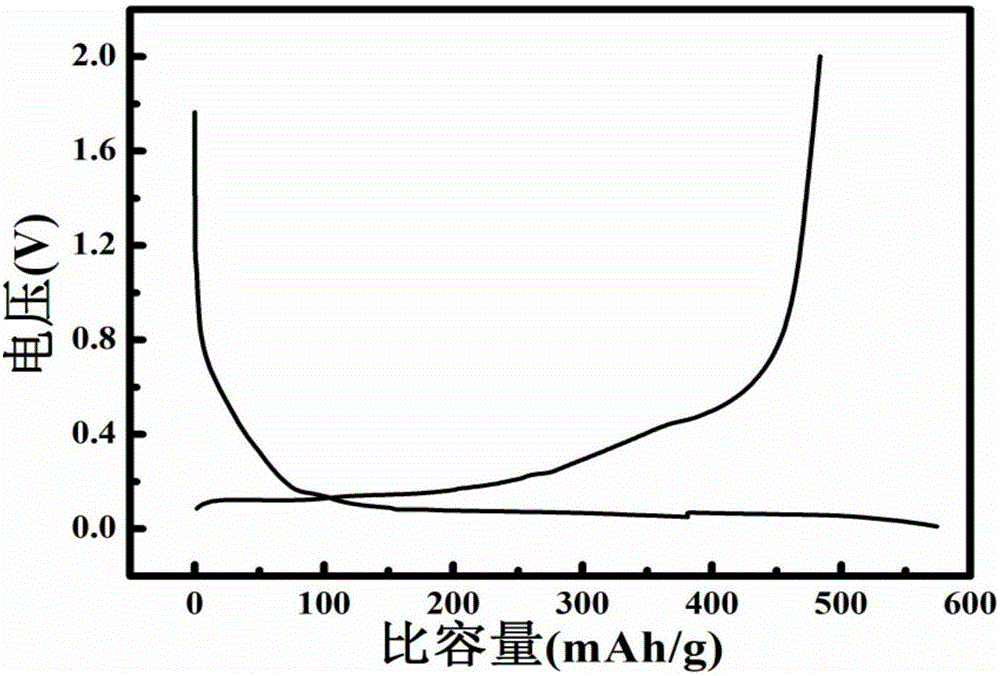

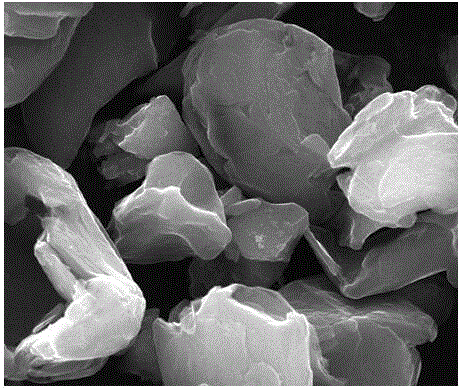

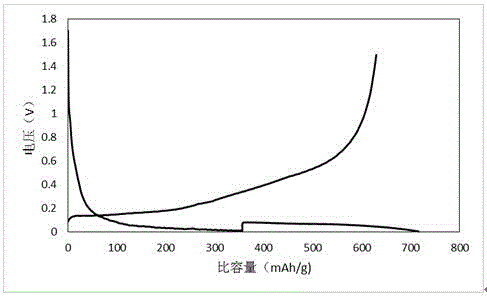

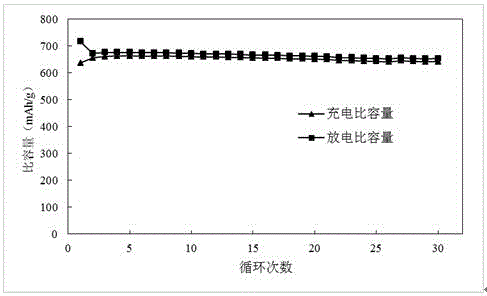

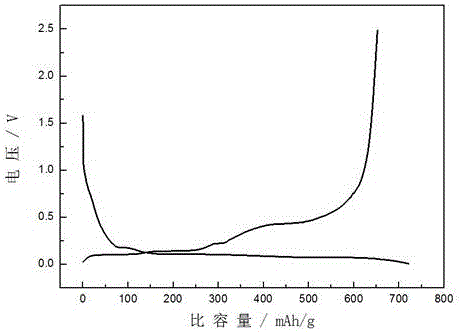

Method for preparing silicon composite cathode material of lithium ion battery

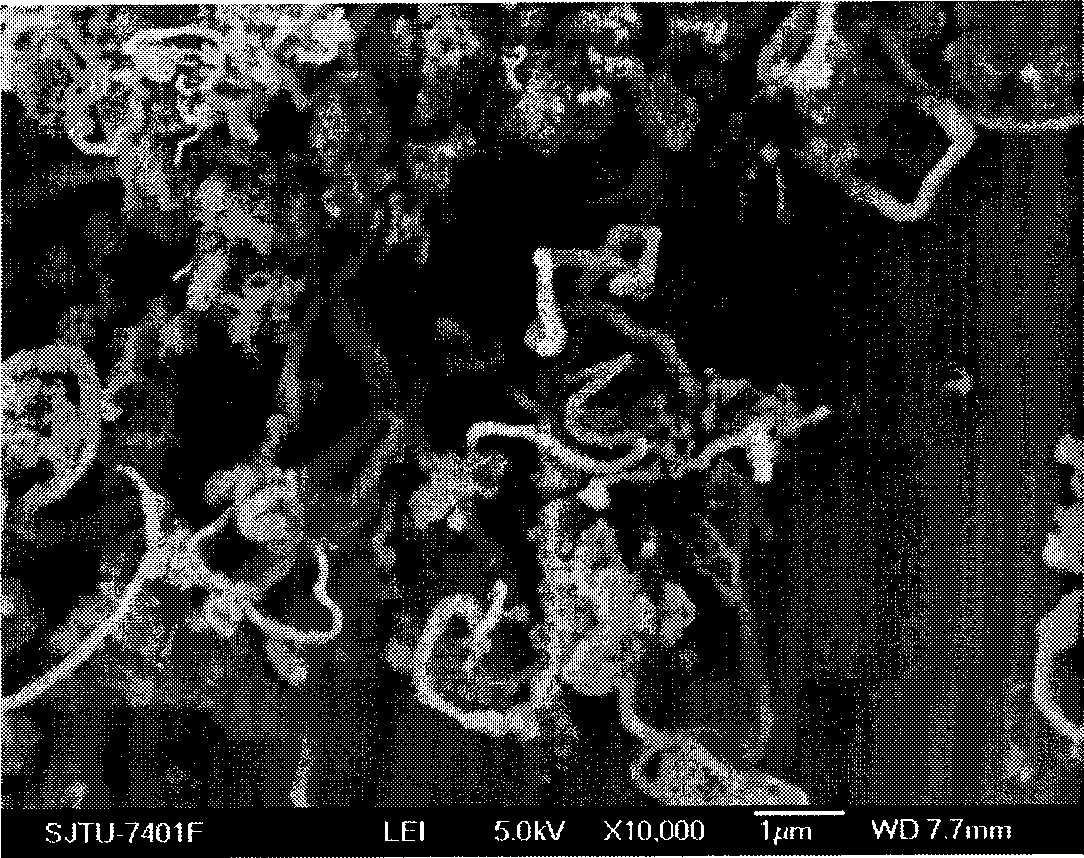

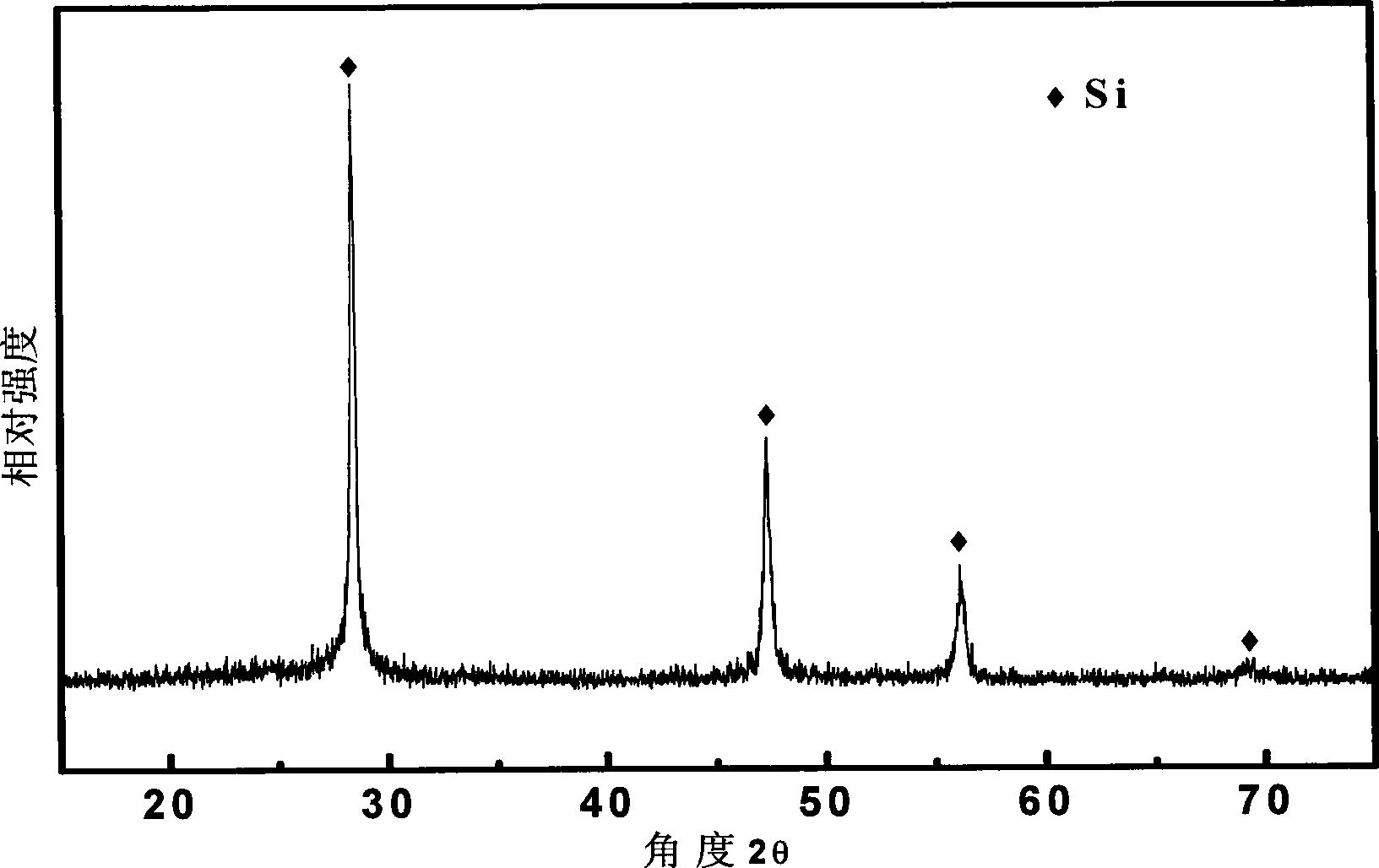

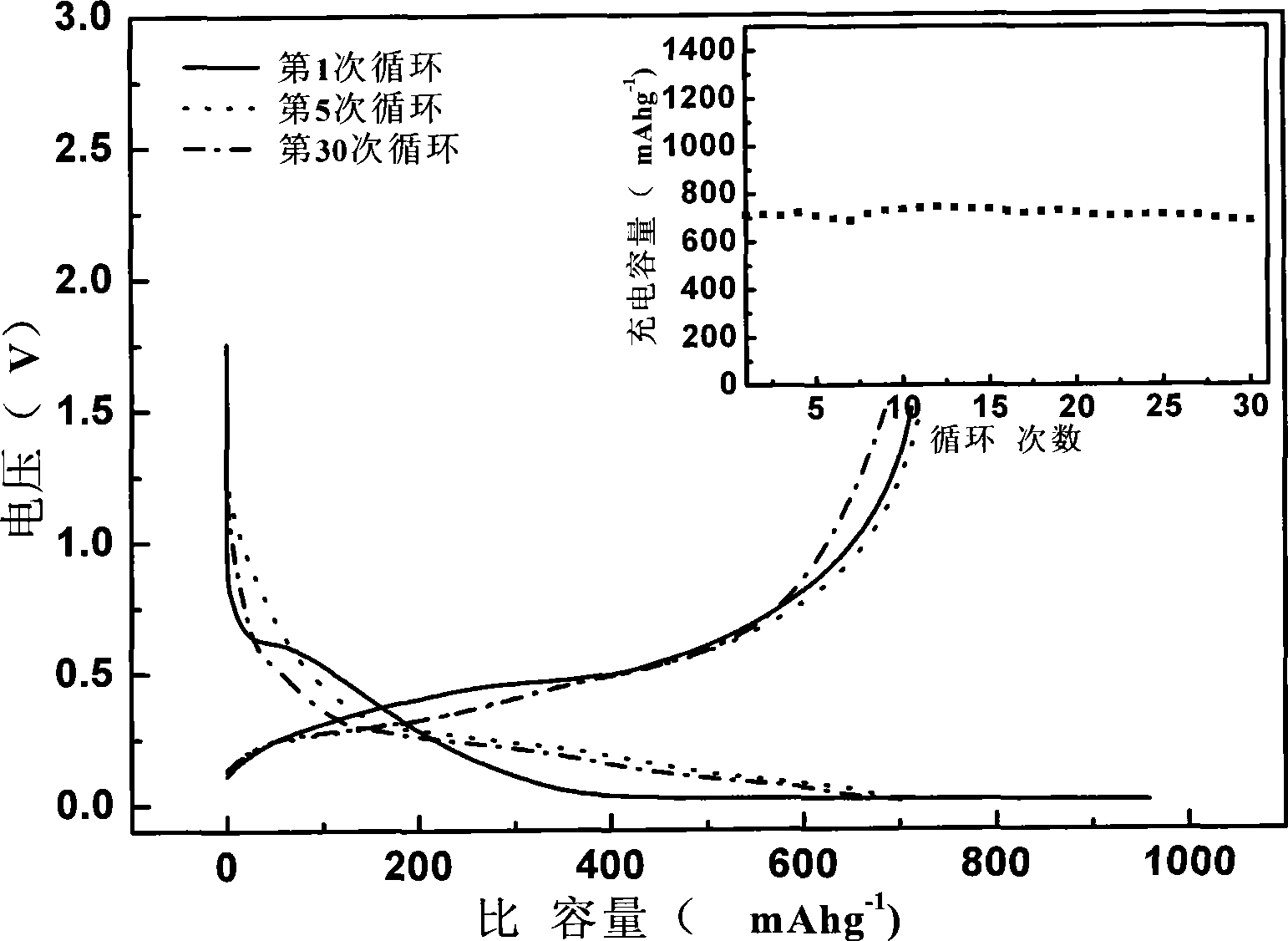

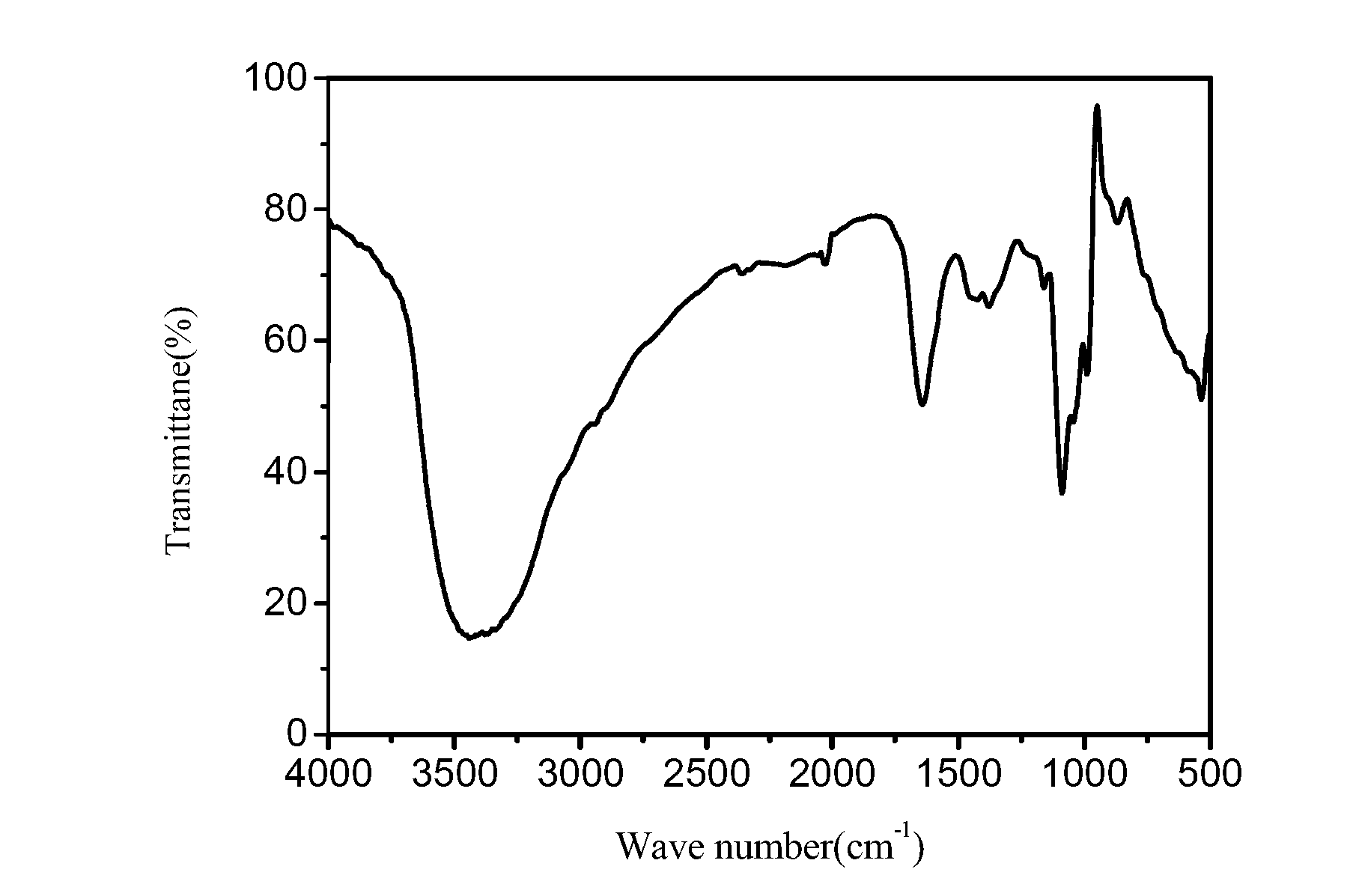

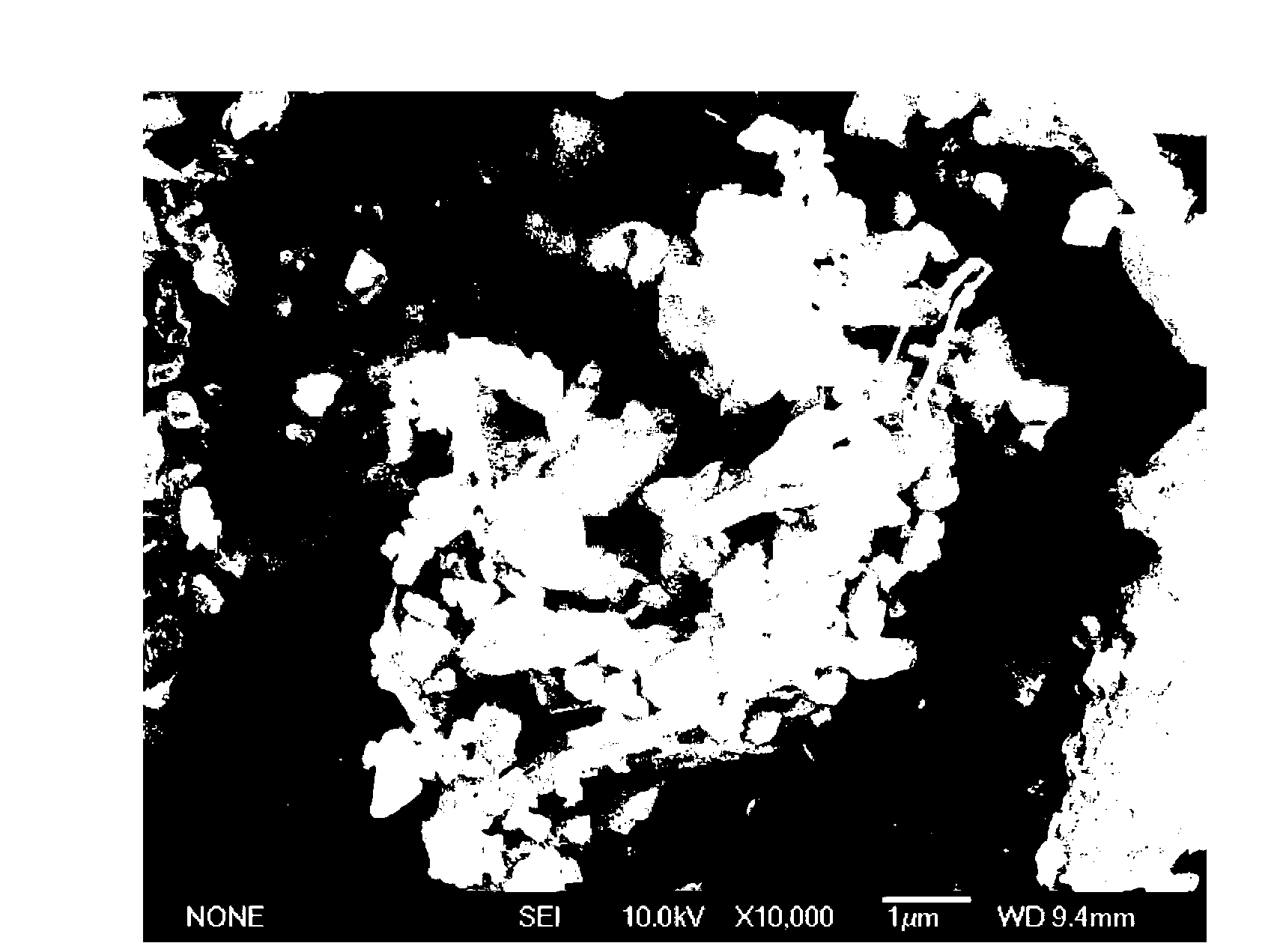

InactiveCN101510602AEvenly dispersedHigh purityElectrode manufacturing processesSiliconSolventCarbon source

The invention discloses a preparation method of a silicon composite anode material for lithium ion batteries and the silicon composite anode material is composed of nc-Si / packing carbon / cracking carbon. Packing carbon powder is adopted as scattered matrix, Li-Si alloy powder is adopted as a reducing agent and a liquid silicon halide or a liquid silane halide is chemically deoxidized by the high-energy ball milling; afterwards, heat treatment and solvent washing are conducted over the deoxidized silicon halide or silane halide under the shielding gas so as to obtain an nc-Si / packing carbon complex, wherein the nc-Si is nanometer porous silicon and nanometer silicon fiber. The nc-Si / packing carbon complex passes through the high-molecular carbon source cladding and heat treatment under the shielding gas to obtain an nc-Si / packing carbon / cracking carbon composite anode material. A charge-discharge test of constant current is conducted at a current density of 0.1 mA / mg to 0.3 mA / mg; the coulombic efficiency of the first circulation of the silicon composite anode material reaches up to 70 percent to 80 percent; and after 30 circulations, the reversible capacity reaches 680 mAh / g and the capacity retention rate reaches more than 95 percent.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing lithium battery silicon carbon anode material

InactiveCN103022448AImprove volume effectAlleviate volume effectCell electrodesCarbon compositesCopper foil

The invention discloses a sodium alginate bonding agent used in a lithium battery silicon carbon anode, particularly discloses a method for preparing a silicon carbon anode material by the bonding agent. The method comprises the steps that: step one, micron-grade silica powder is added into a ball milling tank, and a solvent is added to perform ball milling; step two, natural graphite is added into the industrial silicon powder subjected to the ball milling in the step one to continuously perform the ball milling; step three, substances subjected to the ball milling in the step two are dried, and the dried substances are finely ground; step four, 70-80 parts by weight of the silicon carbon composite material, 5-20 parts by weight of sodium alginate and 5-20 parts by weight of acetylene black are weighed, defined amount of deionized water is added, and the materials are uniformly stirred, then coated on a copper foil and dried to obtain the silicon carbon anode material. The novel bonding agent adopted by the invention can effectively improve the cycling performance of the silicon carbon anode material and prolong the cycling service life of the anode material.

Owner:TIANJIN B&M SCI & TECH

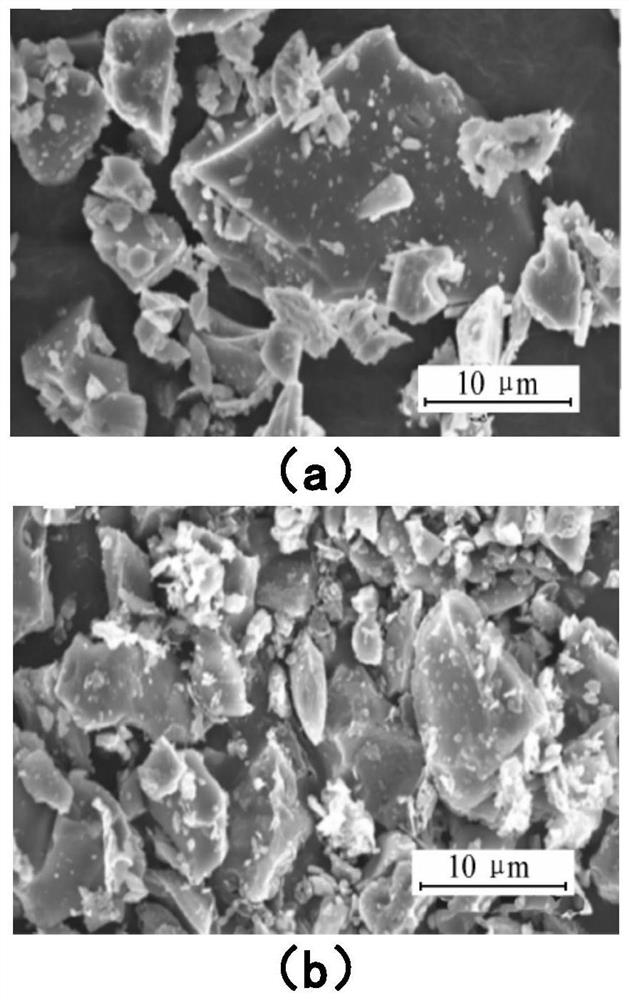

Preparing method for silicon-carbon composite negative electrode material for lithium ion battery

ActiveCN105206801AMaintain stabilityEvenly dispersedMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention discloses a preparing method for a silicon-carbon composite negative electrode material for a lithium ion battery. The preparing method includes the following steps that 1, flake graphite, a polymer solution and nanometer silicon dispersion liquid are evenly mixed, dried and carbonized in a protective atmosphere; 2, pitch and spherical graphite are mixed, ground, placed in an inert protective atmosphere, and subjected to heat treatment to obtain modified spherical graphite; 3, a binder, the modified spherical graphite and the mixed material obtained after carbonization in the step 1 are added into solvent, dispersed evenly and dried to obtain a precursor material; 4, the precursor material is carbonized to obtain the silicon-carbon composite negative electrode material. In the process of the preparing method, it is unnecessary to add special dispersant, nanometer silicon is evenly dispersed in the graphite by means of some ionic groups existing in the polymer solution and high viscosity, the polymer solution has certain stability, and the possibility of nanometer silicon aggregation in the drying process is reduced.

Owner:CENT SOUTH UNIV +1

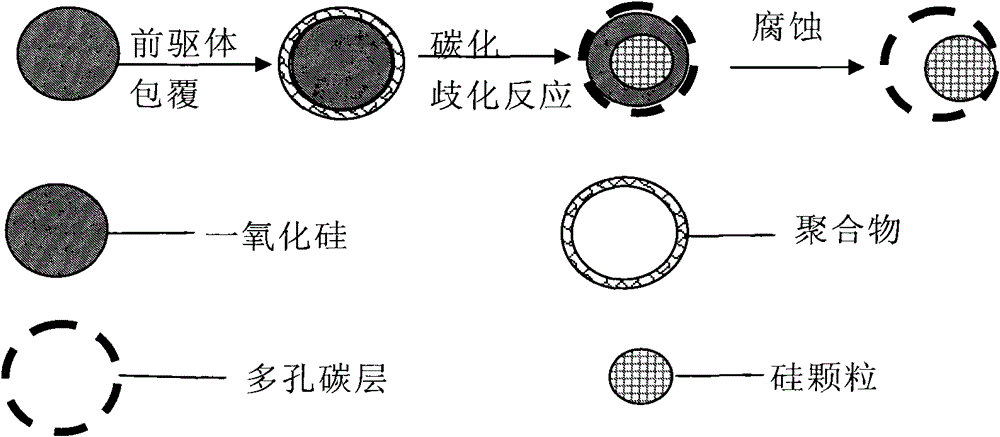

Preparation method of silicon carbon negative pole composite material

InactiveCN106784768AReduce manufacturing costThe process is simple and easy to controlCell electrodesSiliconCarbon source

The invention discloses a preparation method of a silicon carbon negative pole composite material. The method comprises the following steps: dispersing silicon powder and a carbon source in a certain proportion in deionized water, stirring for some time, transferring into a teflon reaction kettle, coating the carbon precursor on the silicon powder surface by a hydrothermal process, and calcining in an inert atmosphere; dispersing the calcined material in a mixed solution a, dispersing at high speed, and drying; and carrying out etching treatment on the dried material by using an etching solution, drying the etched material to obtain the final silicon carbon negative pole composite material. The method effectively increases the lithium ion intercalation positions, improves the bulk effect of silicon, and enhances the electrochemical stability. The material has the advantages of low preparation cost and simple and controllable technique, and is suitable for large-scale industrial production.

Owner:ZHONGTIAN ENERGY STORAGE TECH

Lithium ion battery, negative electrode, negative electrode conductive paste and preparation method of negative electrode conductive paste

InactiveCN108598404AIncrease energy densityImprove cycle stabilityElectrode manufacturing processesSecondary cellsSolventSodium carboxymethylcellulose

The invention discloses lithium ion battery negative electrode conductive paste, and belongs to the field of lithium ion battery material manufacturing. The conductive paste comprises a thickening agent, a binding agent, a conductive agent, a defoaming agent, an active substance and a solvent, on the basis of 100% by mass of the conductive paste, the solid content accounts for 5-30%, and the massratio of the thickening agent, the binding agent, the defoaming agent and the active substance is (0.1-2.0):(0.5-15):(0.5-15):(0.1-5):(70-97.5). The conductive paste is an aqueous binding agent system, carboxymethyl cellulose is used as the thickening agent, and a silicon / silicon carbide / carbon compound is used as the active substance. Moreover, the invention also provides a preparation method ofthe conductive paste, a lithium ion battery negative electrode prepared by employing the conductive paste and a lithium ion battery. The half cell of the lithium ion battery, assembled by employing the negative electrode paste preparation method provided by the invention, has excellent cycle stability and initial coulombic efficiency.

Owner:TSINGHUA UNIV

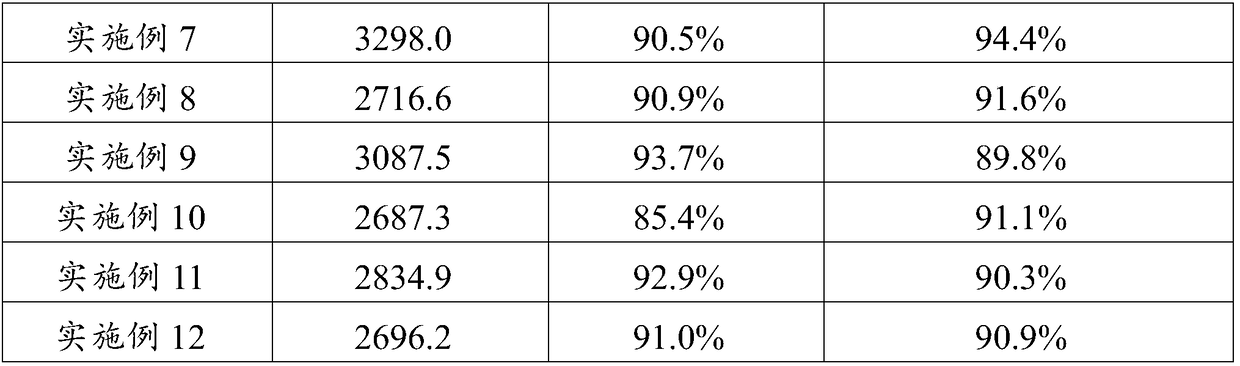

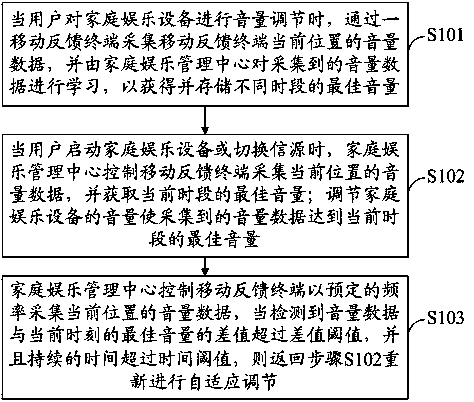

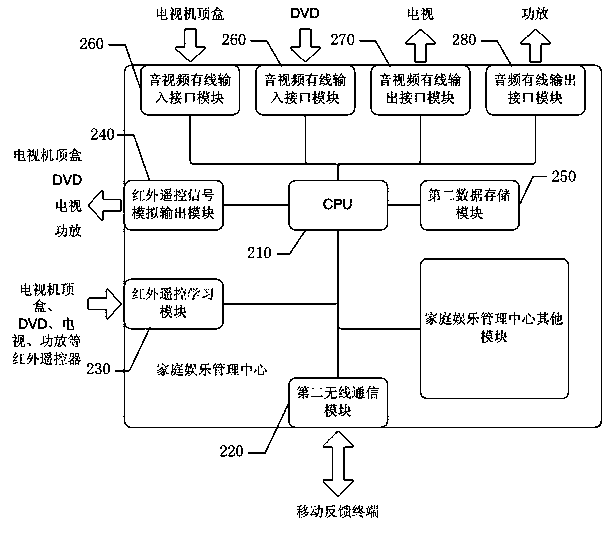

Volume self-adaption control method and volume self-adaption control system

ActiveCN103544971AComfortable volume effectHearing protectionRecord information storageRecording on magnetic disksControl systemComputer module

The invention discloses a volume self-adaption control method and a volume self-adaption control system. The volume self-adaption control method includes that when a user performs volume adjustment on home entertainment equipment, volume data of a mobile feedback terminal in a current location are acquired through the mobile feedback terminal, and a home entertainment management center learns the acquired volume data to acquire the best volume at different periods and stores the best volume in a data storage module; when the user switches on the home entertainment equipment or switches information sources, the home entertainment management center control the mobile feedback terminal to acquire the volume data in the current location and acquire the best volume at the current period from the data storage module; the volume of the home entertainment equipment is adjusted to enable the acquired volume data to reach the best volume at the current period.

Owner:TCL CORPORATION

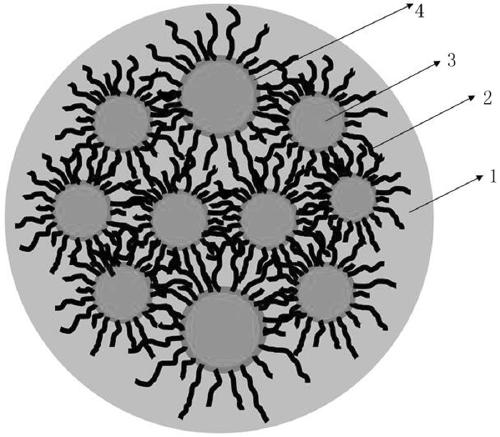

Silicon monoxide composite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN111082006AAlleviate the deficiency of poor electrical conductivityImprove volume effectCell electrodesSecondary cellsCarbon coatingSilicon monoxide

The invention discloses a silicon monoxide composite negative electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of S1, providing silicon monoxide powder, wherein the silicon monoxide powder is silicon monoxide powder without being subjected to disproportionation treatment; S2, carrying out carbon coating on the silicon monoxide powder to obtain a first precursor; S3, growing carbon nanofibers on the surface of the first precursor in situ to obtain a second precursor; and S4, carrying out secondary granulation on the second precursor to obtain the silicon monoxide composite negative electrode material. In the invention, carbon coating is carried out on the silicon monoxide powder to obtain the first precursor, and the carbon nanofibers grow on the surface of the first precursor in situ, so that the silicon monoxide powder can be well connected to form a good conductive network, the defect that silicon monoxide is poorin conductivity is relieved, the initial efficiency is further improved, and the volume effect of the silicon monoxide composite negative electrode material is improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Graphene-silicon composite lithium ion battery negative electrode and preparation method thereof

InactiveCN107910513AIncrease capacityImprove Coulombic efficiencyMaterial nanotechnologyCell electrodesCarbon nanotubeCopper foil

The invention provides a graphene-silicon composite lithium ion battery negative electrode and a preparation method thereof. The graphene-silicon composite lithium ion battery negative electrode is characterized by comprising copper foil and a multi-layer structure arranged on the copper foil, the multi-layer structure comprises graphene layers and silicon-carbon nanotube layers which are arrangedat intervals, and each silicon-carbon nanotube layer comprises silicon nanoparticles and carbon nanotubes, wherein the silicon nanoparticles are coated with the carbon nanotubes. The laminar composite can be applied to a lithium ion battery by serving as a negative electrode material. The negative electrode material has the advantages of being high in specific capacity, stable in cycling performance and the like. By means of the simple step, the silicon nanoparticles are successfully coated with the graphene and the carbon tubes, the volume effect of the silicon material in the charging and discharging process is improved through the laminar special structure, and the conductivity of the electrode is improved by means of the condition of the graphene and the carbon nanotubes, so that theelectrode material is high in specific capacity and coulomb efficiency and good in cycling performance finally.

Owner:上海超碳石墨烯产业技术有限公司 +1

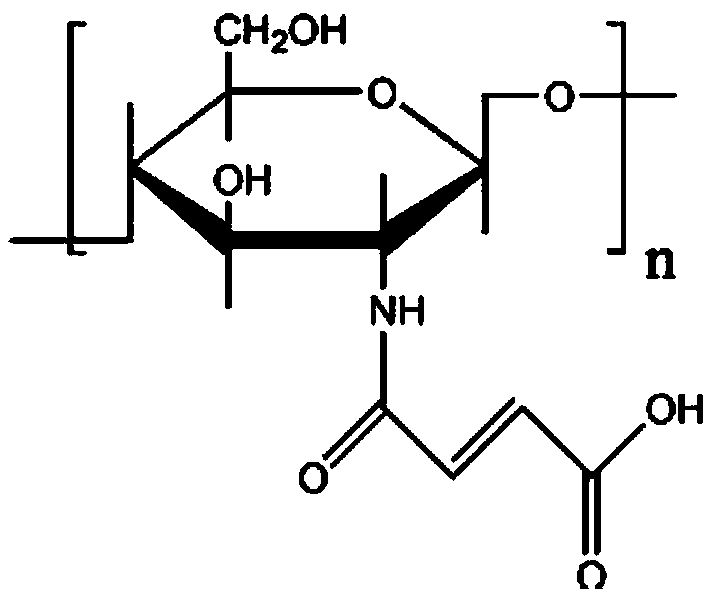

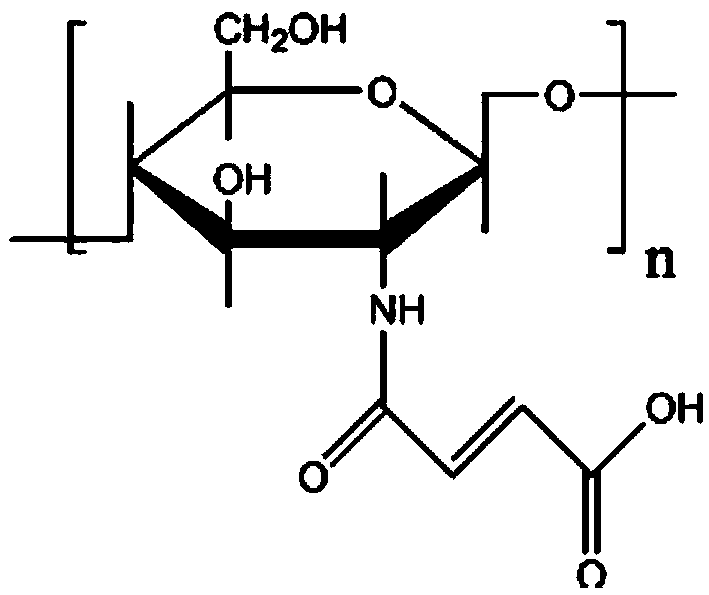

Binder for lithium ion battery silicon-based negative electrode, negative electrode and preparation method thereof

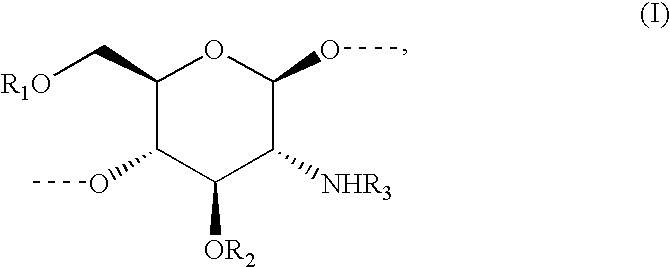

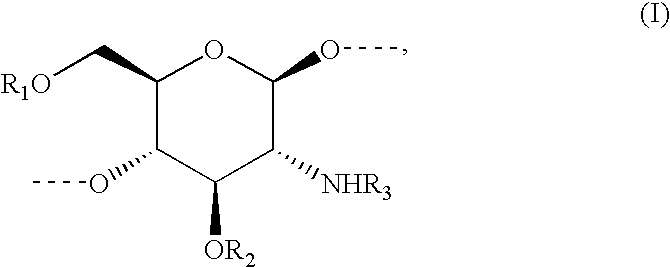

ActiveCN108649228AImprove cycle performanceImprove the first Coulombic efficiencyCell electrodesSecondary cellsLithium-ion batteryMaleic anhydride

The invention discloses a binder for a lithium ion battery silicon-based negative electrode, a negative electrode and a preparation method thereof, related to the technical field of a lithium ion battery. The binder for the lithium ion battery silicon-based negative electrode is maleic anhydride acylated chitosan m-CS obtained by acylating chitosan with maleic anhydride. The binder for the lithiumion battery silicon-based negative electrode disclosed by the invention improves the cycling performance of the silicon-based negative electrode, improves the first coulomb efficiency of the silicon-based negative electrode material to a certain degree, reduces the using amount of the binder in the silicon-based negative electrode system, and benefits improving the overall energy density of the lithium ion battery; and the preparation method is simple, which is suitable for large-scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing spherical ultrafine nickel powder at room temperature

The invention relates to a method for preparing spherical ultrafine nickel powder at a room temperature, which belongs to the technical field of the preparation of function powder materials, and solves the problems of the prior art that the ultrafine nickel powder cannot be prepared at the room temperature. The method comprises the following steps of (1) placing surface active agent into aqueous solution of nickelous salt at the temperature of 20DEG C to 25DEG C to prepare nickel salt active solution; (2) placing aqueous alkali into hydrazine or hydrazine hydrate at the temperature of 20DEG C to 25DEG C, and adjusting the pH value to 12 to 14 to prepare the alkali reducing agent; (3) slowly adding the nickel salt active solution into the alkali reducing agent during the intense agitation process at the temperature of 20DEG C to 25DEG C to be reacted for 30min, and obtaining reaction mixture; and (4) pumping and filtering the reaction mixture at the temperature of 20DEG C to 25DEG C to obtain solids, washing the obtained solids to be neutral through the deionized water, washing the solids for three times through acetone, and then placing the solids into a drying box at the temperature of 60DEG C to be dried, and thus preparing the spherical ultrafine nickel powder. Due to the adoption of the method, the spherical ultrafine nickel powder can be prepared at the room temperature, the cost is low, and convenience in operation can be realized.

Owner:KUNMING SHUYANG TECH

Preparation method of silicon dioxide-coated carbon fiber material, product and application

The invention relates to the field of lithium-ion batteries, in particular to a preparation method of a silicon dioxide-coated carbon fiber material, a product and an application. The preparation method comprises the steps of (1) dispersing natural cellulose into an organic solvent, sequentially adding diisocyanate, a metal catalyst for polyurethane synthesis and a siloxane monomer or a siloxane polymer and carrying out stirring reaction; (2) filtering, drying and then obtaining pretreated natural cellulose; and (3) adopting tetraethylortho silicate as a precursor and the natural cellulose asa template and a carbon source, depositing a silicon dioxide film on the surface of the natural cellulose through a sol-gel method and then burning to obtain the silicon dioxide-coated carbon fiber material. According to the preparation method, a carbon fiber material is adopted as a support and buffer material of silicon dioxide, so that the volume effect generated through lithium ion extractionand insertion when the silicon dioxide is applied to a negative electrode material of the lithium battery is significantly improved, and the cycling stability is improved while the condition that thelithium battery has relatively high specific capacity is ensured.

Owner:汪涛

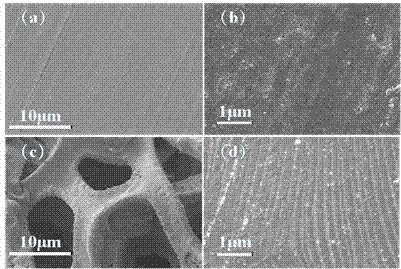

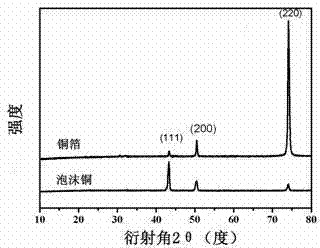

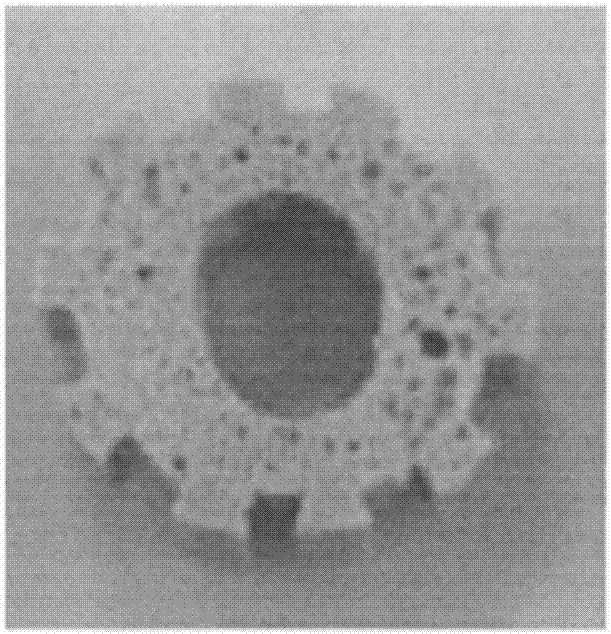

Tin-based composite thin film material for lithium ion battery as well as preparation method and application of thin film material

InactiveCN103904300ASimple processGood repeatabilityCell electrodesSecondary cellsComposite filmHigh energy

The invention provides a tin-based composite thin film material for a lithium ion battery. The tin-based composite thin film material is composed of a copper foil base or a foam copper base and an Sn-M thin film by stacking, wherein the Sn-M thin film is a thin film with a single-layered structure, and is composed of two elements including Sn and M; the Sn is alpha-Sn or beta-Sn; the M is Ti, Al or Zn; the thickness of the Sn-M thin film is 0.01-10 microns. A preparation method comprises the following step of preparing the Sn-M thin film on the copper foil base or the foam copper base by adopting a simultaneous sputtering process of a metal target Sn and the metal M. The thin film is used as an electrode material of a lithium battery. The tin-based composite thin film material for the lithium ion battery has the advantages that compared with a pure Sn film, the metal M is added so that the volume effect problems caused by embedding lithium ions on an electrode and releasing the lithium ions are inhibited, the circulating performance of the Sn is improved and the cycle life of a thin film cathode is prolonged. The method adopts a simple thin film preparation process; the production cost is reduced and the repeatability of preparing a thin-film material is improved; the tin-based composite thin film material for the lithium ion battery is hopeful to be applied to thin film type lithium batteries with high energy and high power.

Owner:NANKAI UNIV

Low density edible animal chews and methods of making same

ActiveCN107105713AIncrease attractiveness/credibilityReduce heatAnimal feeding stuffAccessory food factorsDental ProductEngineering

Edible chews for pets have a low density (e.g. about 1.0 Kg / L or less) and a smooth exterior surface. One method by which the low density and the smooth exterior surface can be achieved uses a modified extrusion die to increase shear and restrict surface bubbles. Another method by which the low density and the smooth exterior surface can be achieved uses an extruder screw with a modified profile that holds a dough longer therein to create a whipping effect resulting in more bubble nucleation sites and hence a more uniform cellular matrix. The puffed (expanded) product was experimentally tested and provided better dental cleaning scores than a current unexpanded similarly formulated commercial dental product.

Owner:SOC DES PROD NESTLE SA

Graphene-metal modified nano heavy anti-corrosion coating as well as preparation method and preparation system thereof

ActiveCN111440508AImprove adhesionImprove water resistanceAnti-corrosive paintsGrain treatmentsEpoxyCarbon monofluoride

The invention provides a graphene-metal modified nano heavy anti-corrosion coating and a preparation method thereof. The coating is prepared from, by mass, 3%-5% of carbon fluoride, 2%-4% of graphene,2%-4% of titanium powder, 2%-4% of zinc powder, 2%-4% of niobium powder, 2%-4% of nickel powder, 2%-4% of iron powder, 1%-1.5% of auxiliaries, 16%-20% of diluents, 6%-8% of dispersing agents and 48%-55% of epoxy resin. The particle sizes of the carbon fluoride, the graphene, the titanium powder, the zinc powder, the niobium powder, the nickel powder and the iron powder in the anticorrosive paintare 700-800nm. The anti-corrosion coating disclosed by the invention has very good ultraviolet-proof performance and anticorrosive performance.

Owner:浙江蓝戎纳米科技开发有限责任公司

Graphite/silicon/graphene composite material and preparation method thereof

ActiveCN106784755AImprove efficiencyImprove cycle performanceCell electrodesSecondary cellsNano siliconCharge discharge

The invention relates to the field of lithium ion battery negative pole materials, and particularly discloses a graphite / silicon / graphene composite material and a preparation method thereof. The invention is characterized in that the graphite / silicon / graphene composite material is in a three-layer sandwich structure which is sequentially composed of graphite, nano silicon and graphene from inside to outside. The three-layer structure is composed of 80-90 wt% of graphite, 1-5 wt% of nano silicon and 5-19 wt% of graphene. The graphite and graphene are compounded with the silicon to prepare the three-layer-sandwich-structure graphite / silicon / graphene composite material. The nano silicon is fixed between the graphite and graphene, and prepared by using the inner graphite as the framework and the outer graphene as the buffer layer. The design of the special structure improves the bulk effect of the silicon material in the charge-discharge process, and enhances the initial efficiency and cycle performance of the material.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Preparation method for silicon-carbon composite material, prepared silicon-carbon composite material, lithium ion battery anode containing silicon-carbon composite material and battery

ActiveCN102437318BIncrease the embedding positionImprove volume effectSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon compositesSilicon monoxide

Owner:CHERY AUTOMOBILE CO LTD

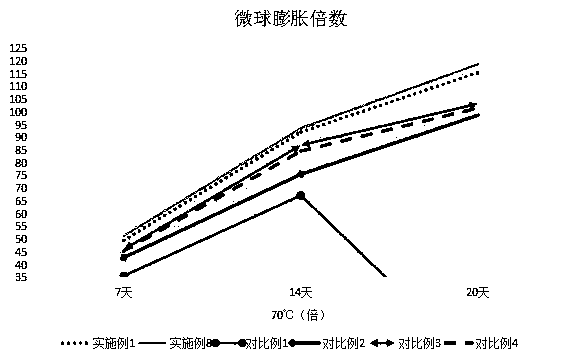

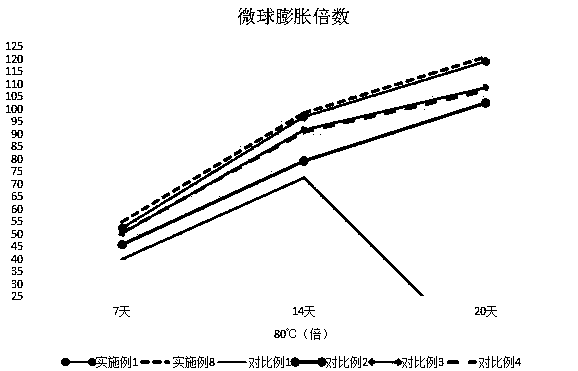

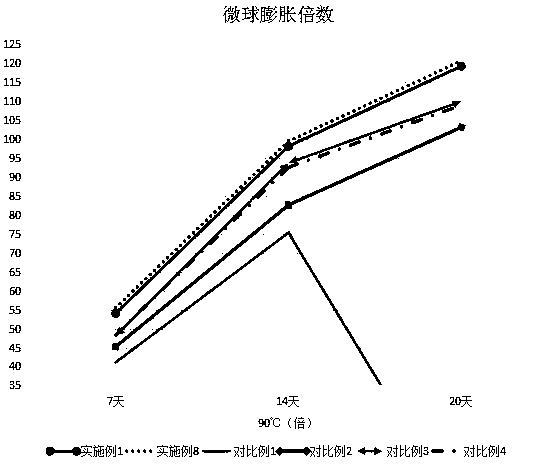

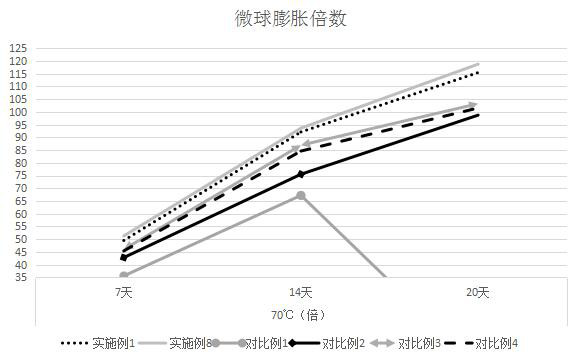

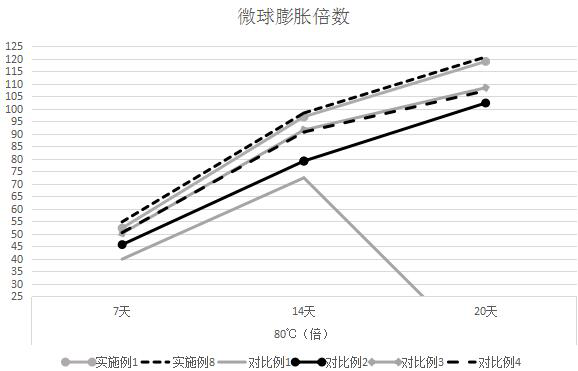

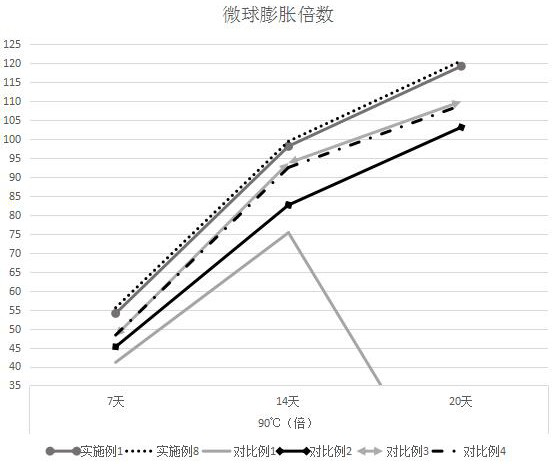

Polymer microsphere water shutoff profile control agent and preparation method thereof

The invention discloses a polymer microsphere water shutoff profile control agent and a preparation method thereof, and belongs to the technical field of oil exploitation. The polymer microsphere water shutoff profile control agent is prepared from the following components: a main agent, a dispersion stabilizer, a cross-linking agent, an initiator, an auxiliary agent and water. The polymer microsphere water shutoff profile control agent has good expansibility, the expansion multiple increases quickly in the first 7 days, the expansion multiple increases slowly after 14 days, and the expansionmultiple of the microsphere is higher and reaches 120 times at most along with temperature rise. In formation water with the temperature of 90 DEG C and the mineralization degree of 20 g / L, the microsphere stabilizing time reaches 6 months or above, and the plugging rate reaches 98.7% or above. The expanded particles have certain elasticity, strength and water retention function, can stay in stratum gaps for a long time to achieve the purposes of profile control and water plugging, can enter the deep part of an oil layer under a certain pressure condition to form effective plugging, and can improve the crude oil recovery rate by 35-42%.

Owner:ZHENGZHOU INST OF TECH

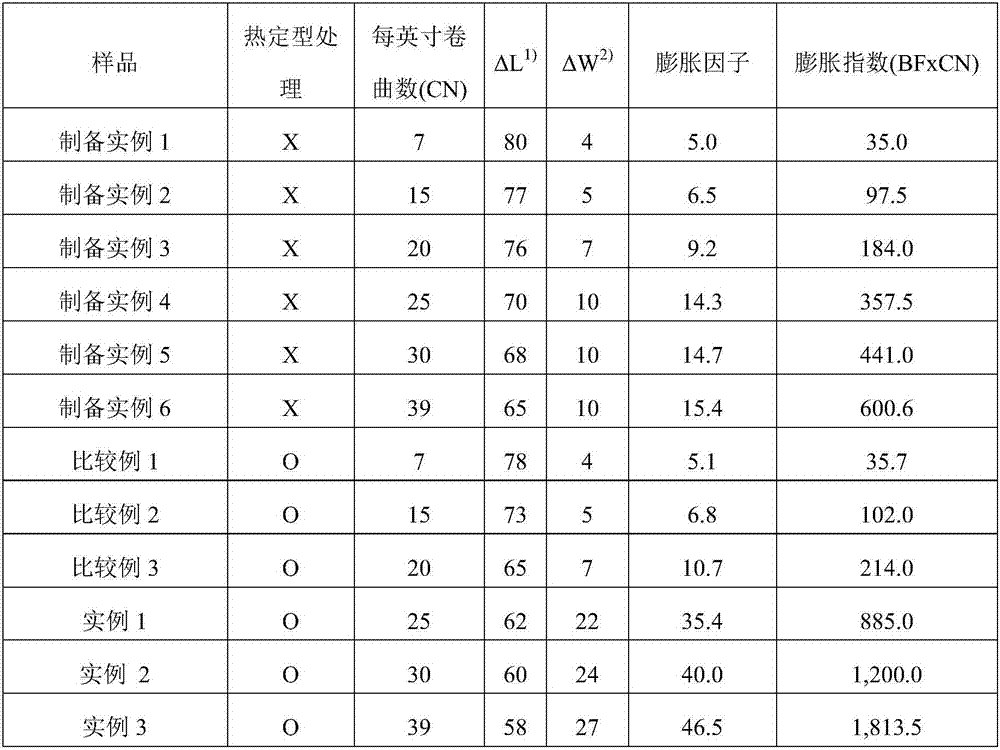

Lyocell crimped fiber

ActiveCN107075739AGood expansion performanceImprove volume effectMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentCellulose pulpLyocell

The present invention relates to a lyocell crimped fiber, which is manufactured by crimping a lyocell multi-filament prepared by spinning a lyocell spinning dope containing a cellulose pulp and an aqueous solution of N-methylmorpholine-N-oxide (NMMO), wherein the lyocell crimped fiber has a blowing index of 800-2,000.

Owner:KOLON IND INC

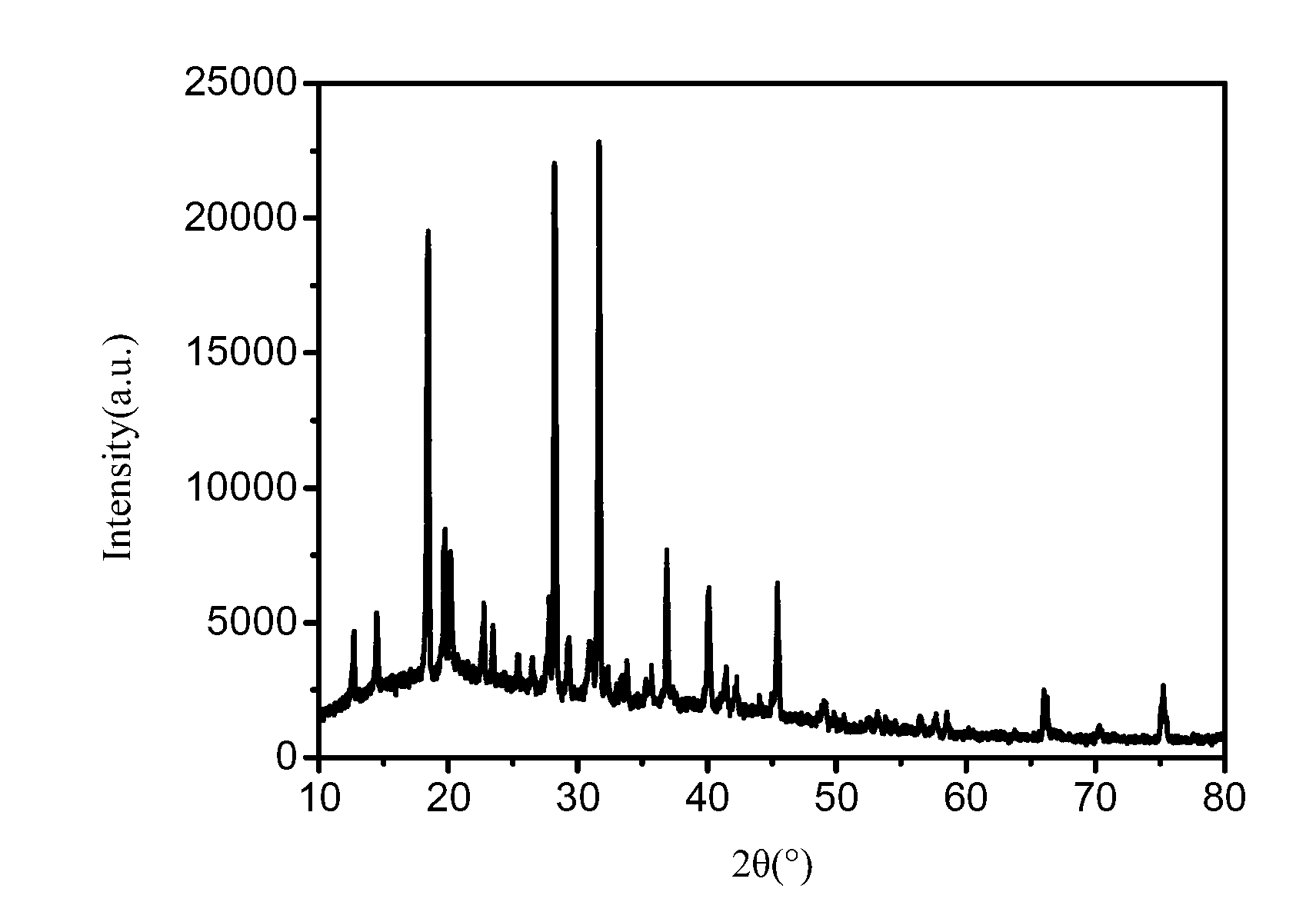

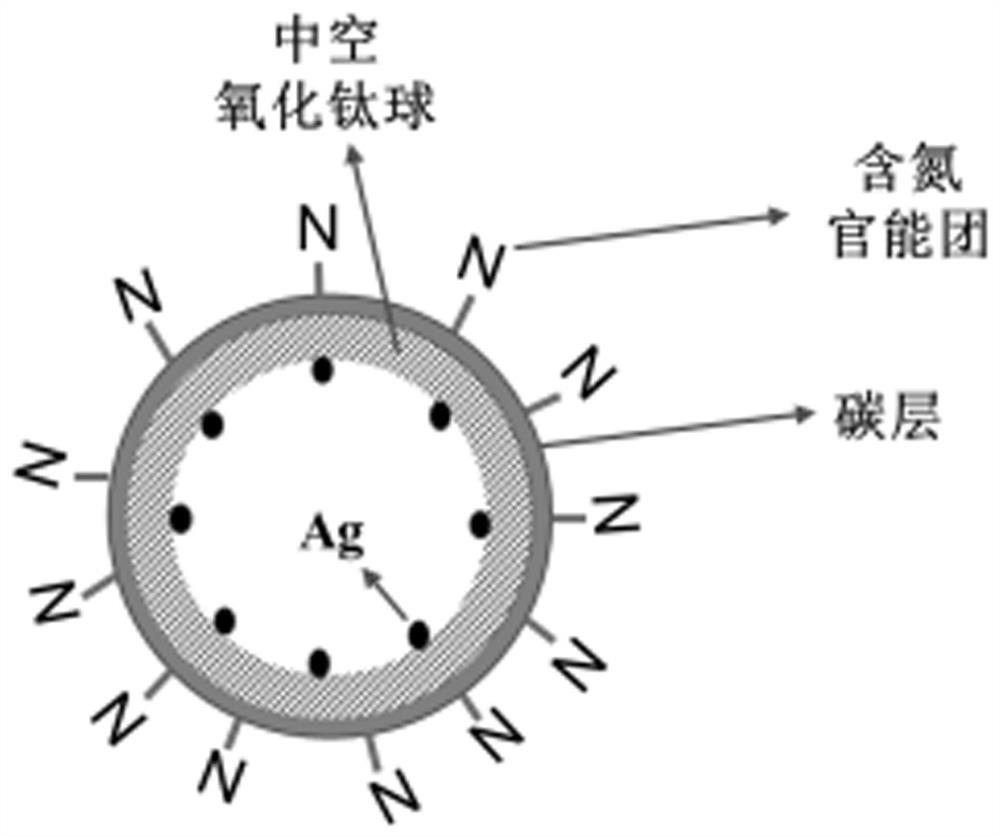

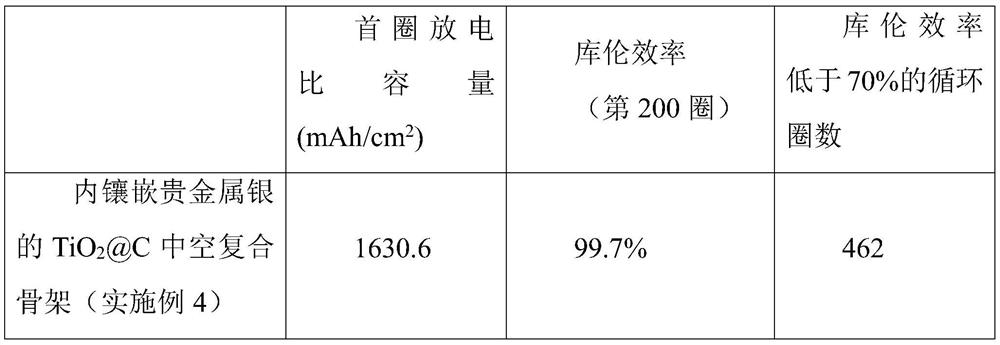

Titanium oxide@C hollow composite framework embedded with precious metal silver, and preparation method and application thereof

ActiveCN113488651AStable structureAchieve deposition/dissolutionNegative electrodesLi-accumulatorsCarbon layerIn situ polymerization

The invention belongs to the field of lithium metal battery negative electrode materials, and particularly discloses a titanium oxide@C hollow composite framework embedded with precious metal silver, and a preparation method and application thereof. The hollow composite framework comprises a titanium oxide hollow ball with an independent closed cavity, precious metal silver nanoparticles embedded in an inner cavity of the titanium oxide hollow ball, a carbon layer compounded on the surface of titanium oxide and a nitrogen-containing functional group. The preparation method comprises the following steps: preparing a SiO2@Ag composite template uniformly loaded with silver nanoparticles by using a silicon dioxide template, adding a titanium source, hydrolyzing, obtaining a titanium oxide precursor on the outer layer of the composite template, then carrying out in-situ polymerization to obtain a nitrogen-doped carbon-coated composite skeleton precursor, roasting at a certain temperature, and etching the silicon dioxide template with a strong alkali to obtain the titanium oxide@C hollow composite framework embedded with noble metal silver. The composite hollow framework material has a closed cavity structure, good conductivity and excellent gradient lithium affinity, the nucleation overpotential of lithium deposition is reduced, lithium metal is selectively induced to be deposited into the cavity structure, the interface side reaction and the volume effect are greatly avoided, the growth of lithium dendrites is inhibited, favorable conditions are created for uniform lithium deposition / dissolution, and the coulombic efficiency and the cycling stability of the lithium metal battery are remarkably improved.

Owner:CENT SOUTH UNIV

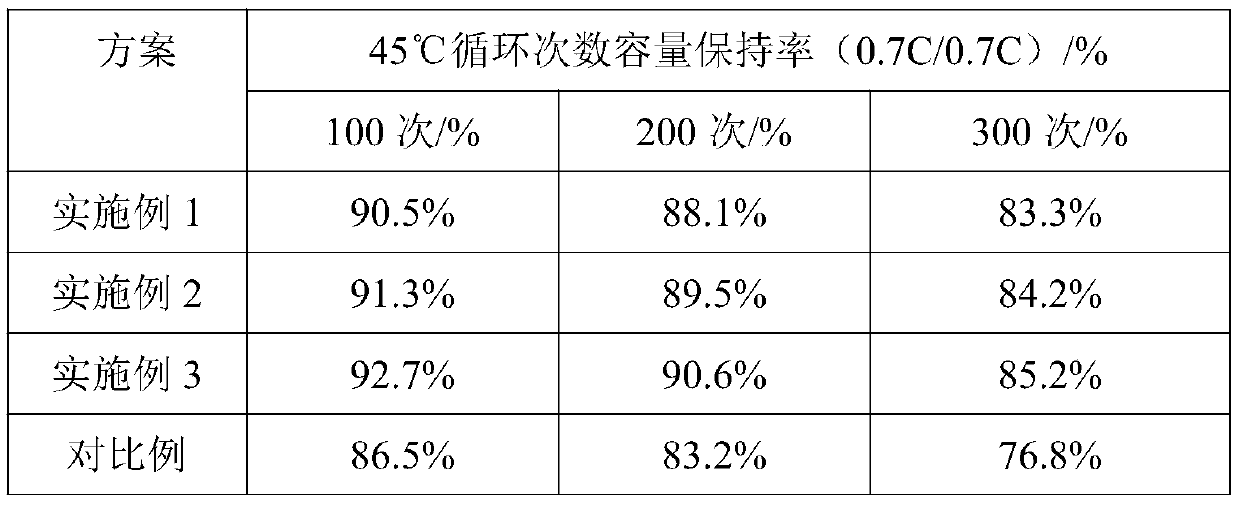

Lithium ion battery negative electrode and preparation method thereof

ActiveCN111463402AImprove cycle performanceLow gram capacitySecondary cellsNegative electrodesLithium-ion batteryBattery cell

The invention discloses a lithium ion battery negative electrode and a preparation method thereof, and belongs to the technical field of lithium-ion batteries. The specific scheme is as follows: the lithium ion battery negative electrode comprises a negative electrode current collector and a negative electrode coating, the negative electrode coating comprises a coating I and a coating II which arerespectively coated on two surfaces of the negative electrode current collector, the coating I comprises a negative electrode active material I, a conductive agent, a thickening agent I, a dispersingagent I and a binding agent I, the coating II comprises a negative electrode active material II, a conductive agent, a thickening agent II, a dispersing agent II and a binding agent II, the viscosityof the thickening agent I is greater than that of the thickening agent II, the viscosity of the dispersing agent I is greater than that of the dispersing agent II, the elastic modulus of the bindingagent I is greater than that of the binding agent II, and the high-viscosity thickening agent I, the high-viscosity dispersing agent I and the high-elastic modulus binding agent I are used in negativeelectrode slurry A, so that the consumption of the thickening I, the dispersing agent I and the binding I can be reduced, the consumption of the conductive agent is increased, and the dynamic performance of a long coating paste layer of the negative electrode is further improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

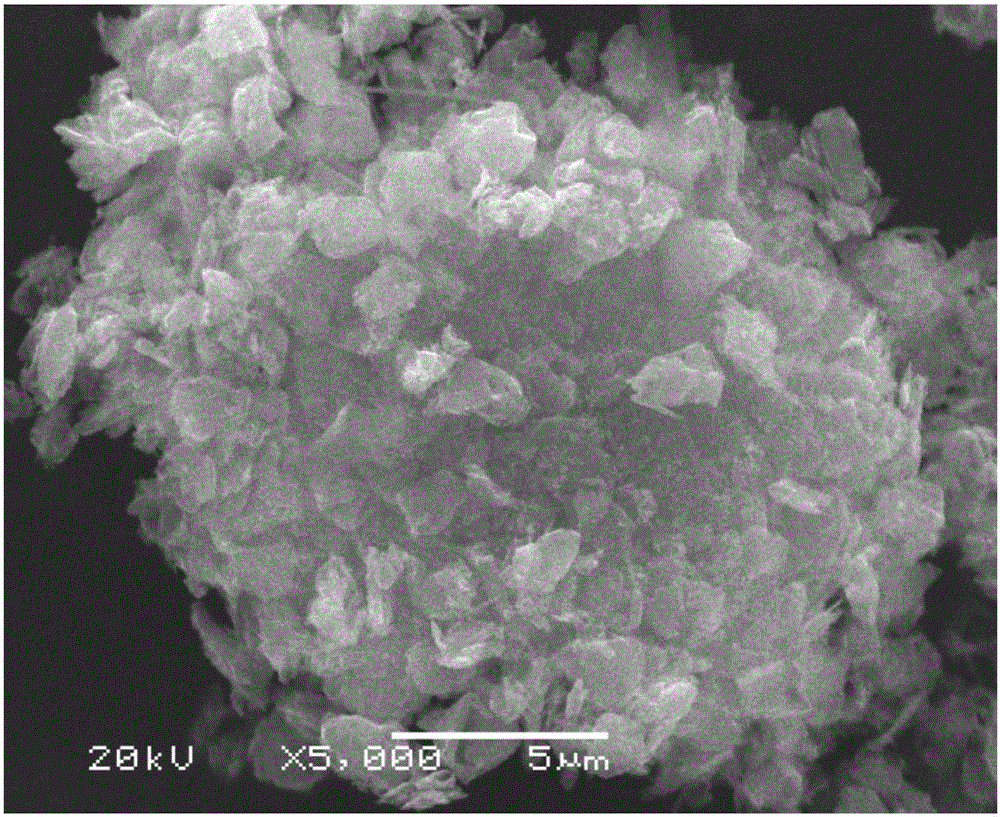

Method for preparing lithium battery silicon carbide negative electrode composite material

ActiveCN109879286AImprove volume effectImprove electrochemical stabilityCarbon compoundsCell electrodesLiquid stateMegasonic cleaning

The invention discloses a method for preparing a lithium battery silicon carbide negative electrode composite material. The method comprises the following steps: ultrasonically cleaning silicon scrapsin a solvent to clean away surface dirt, and drying the cleaned silicon scraps to obtain a silicon material; crushing the obtained silicon material to a submicron level, and stirring and dispersing obtained silicon particles and a carbon source in a solvent to obtain a uniform turbid solution; carbonizing the obtained turbid solution a high temperature in an inert atmosphere to obtain a silicon carbide powder; and grinding the silicon carbide powder to obtain the lithium battery silicon carbide negative electrode composite material. Liquid state doping in the whole process is simple and is easy to implement; the obtained silicon carbide material is a porous spherical or spheroidal structure, and includes a porous Si-SiOx core and an amorphous carbon shell coating the surface of the core,so the volumetric effect of silicon is greatly improved, and the electrochemical stability is significantly improved; and the preparation method has the advantages of low preparation cost, simple andcontrollable process, and suitableness for large-scale industrial production.

Owner:HUNAN JIUHUA CARBON HI TECH

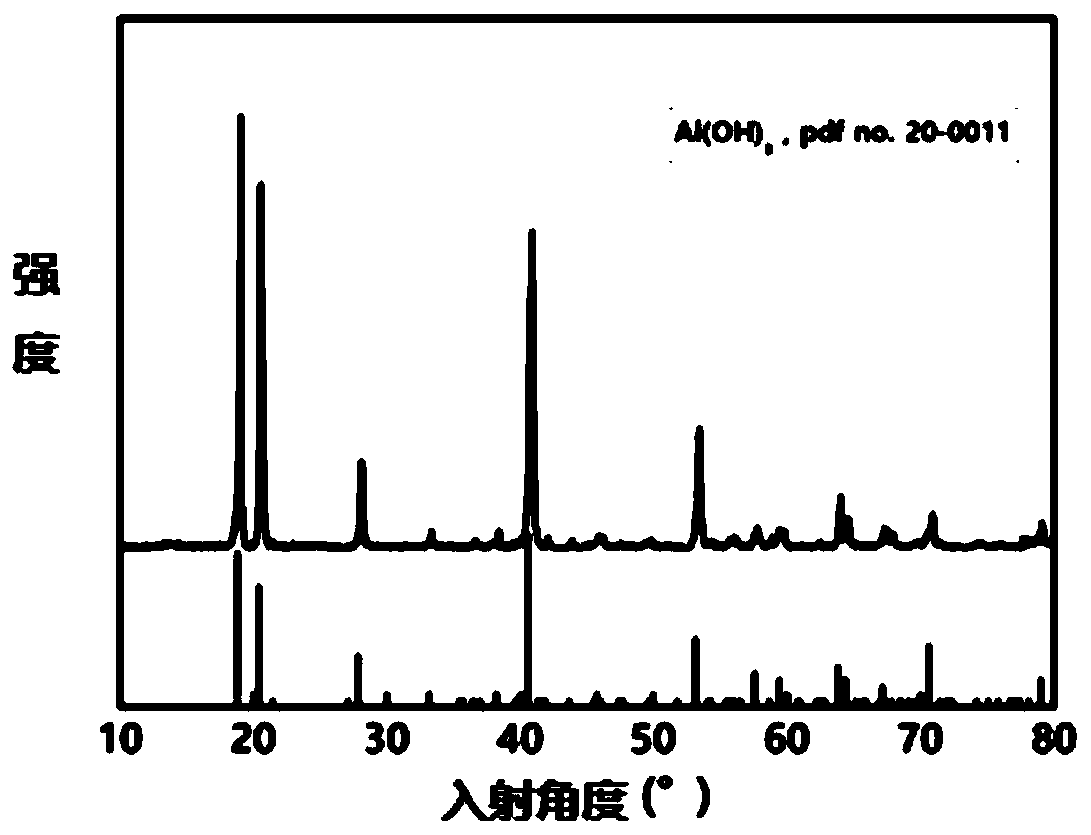

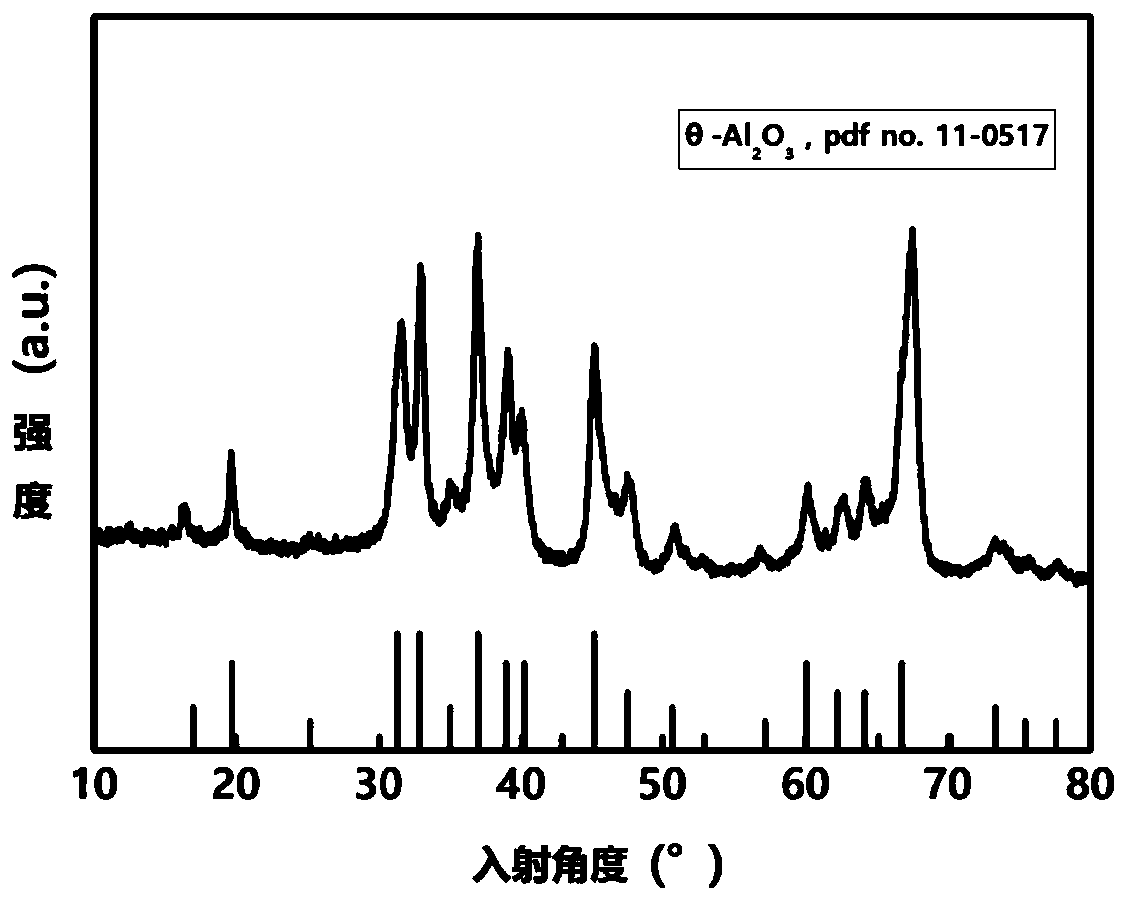

Metal oxide preparation method

InactiveCN110683518ASimple compositionIncrease profitMaterial nanotechnologyOxygen/ozone/oxide/hydroxideOrganic solventPhysical chemistry

The invention belongs to the field of nanometer materials, and particularly relates to a metal oxide preparation method, which comprises: obtaining an organic solvent with a dispersed metal, wherein the metal can react with water to generate a metal hydroxide; mixing the organic solvent and water, and carrying out a reaction to prepare a mixed solution containing the metal hydroxide; carrying outsolid-liquid separation on the mixed solution containing the metal hydroxide, and collecting the solid phase; and calcining the solid phase to obtain the metal oxide, wherein the metal oxide has a micron or nanometer structure. According to the invention, the method is simple, the operation is simple and convenient, and the purity of the obtained product is infinitely close to 100%.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method of antibacterial water-borne wood composite coating

InactiveCN112625487AExcellent resistance to organic solventsSmall particle sizeWax coatingsAntifouling/underwater paintsPolymer scienceA-DNA

The invention relates to a preparation method of an antibacterial waterborne wood composite coating, and belongs to the technical field of wood coatings. The antibacterial waterborne wood composite coating is prepared by taking the waterborne polyurethane emulsion as a matrix emulsion and adding the nano-silver sol and the modified nano-zinc oxide, wherein a coating film formed by the waterborne polyurethane emulsion has good physical and mechanical properties, cold resistance and organic solvent resistance, a silver element and a zinc element have a micro-power effect, and the antibacterial waterborne wood composite coating has good antibacterial property. According to the method, bacteria can lose division and proliferation capacity and die by virtue of reservoir enterprise force, nano-silver can play a role of a catalytic active center, under the action of light, silver and water or air act, and generated active oxygen ion free radicals and hydroxyl free radicals have extremely high chemical activity and can react with the bacteria to destroy a DNA double-helix structure, so that the DNA double-helix structure is damaged, metabolism is disordered, and the effect of inhibiting or killing bacteria is achieved.

Owner:成都萃匀离环保科技有限公司

Two-part cosmetic product with volumizing effect to hair fibers

ActiveUS8999308B2Improve volume effectSufficient amountCosmetic preparationsHair cosmeticsMascaraPolymer chemistry

The present invention relates to a two-part cosmetic product that imparts a filling and / or swelling effect to hair, eyebrows or eyelashes, preferably a mascara. The invention uses an anhydrous base coat composition with a water absorbing ingredient being a salt of acrylic or polyacrylic acid and a CO2 releasing compound which is a carbonate or bicarbonate to expand or swell the film former of the top coat with the in situ generated CO2 when the water containing top coat is applied to the anhydrous base coat.

Owner:COTY GERMANY

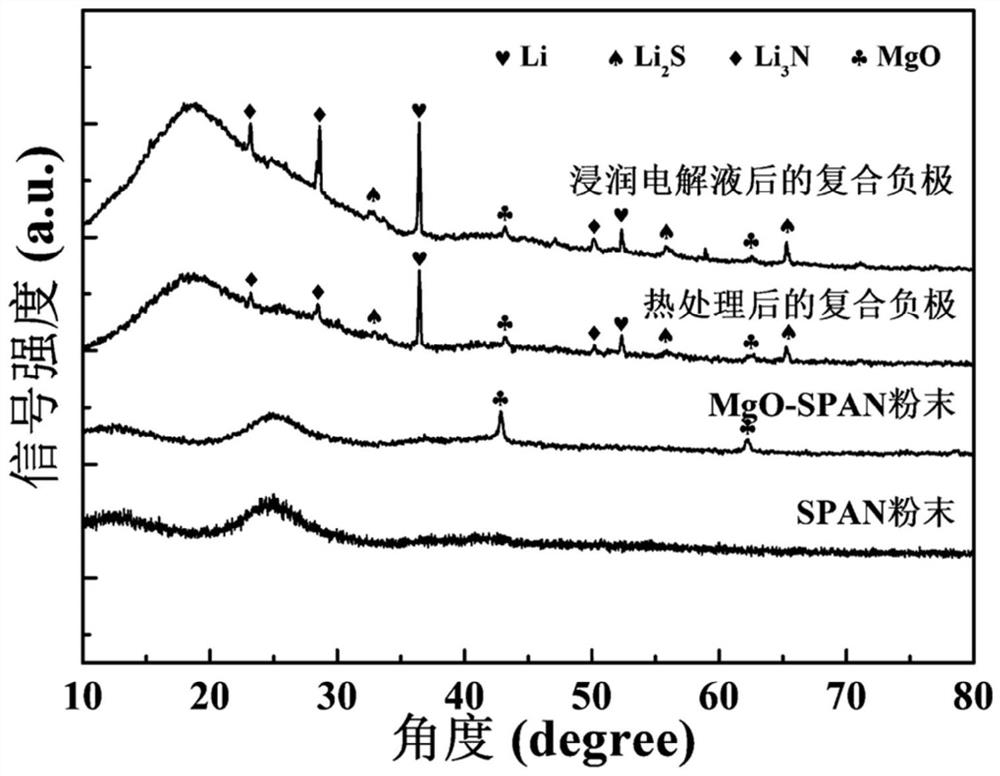

Three-dimensional composite metal lithium negative electrode, metal lithium battery and device

PendingCN112771693AImprove volume effectUniform depositionNegative electrodesLi-accumulatorsMetallic lithiumElectrolytic agent

The invention relates to a three-dimensional composite metal lithium negative electrode, a metal lithium battery and a device. The composite metal lithium negative electrode comprises metal lithium particles and a three-dimensional polymer skeleton, the metal lithium particles are loaded in the three-dimensional polymer skeleton, and the three-dimensional polymer skeleton comprises a lithium-loving fragment, an active site and a polymer-containing part. The volume effect of the metal lithium negative electrode in the charging and discharging process is improved, and the side reaction of the metal lithium and the electrolyte can be inhibited; the specific surface area of the metal lithium negative electrode is increased, and lithium-loving nano-sites are introduced, so that the metal lithium can be guided to be uniformly deposited, and the growth of lithium dendrites can be effectively inhibited; in addition, the three-dimensional framework is coated with active lithium, so that the risk that an SEI film is relatively brittle in a traditional scheme can be effectively inhibited.

Owner:CONTEMPORARY AMPEREX TECH CO

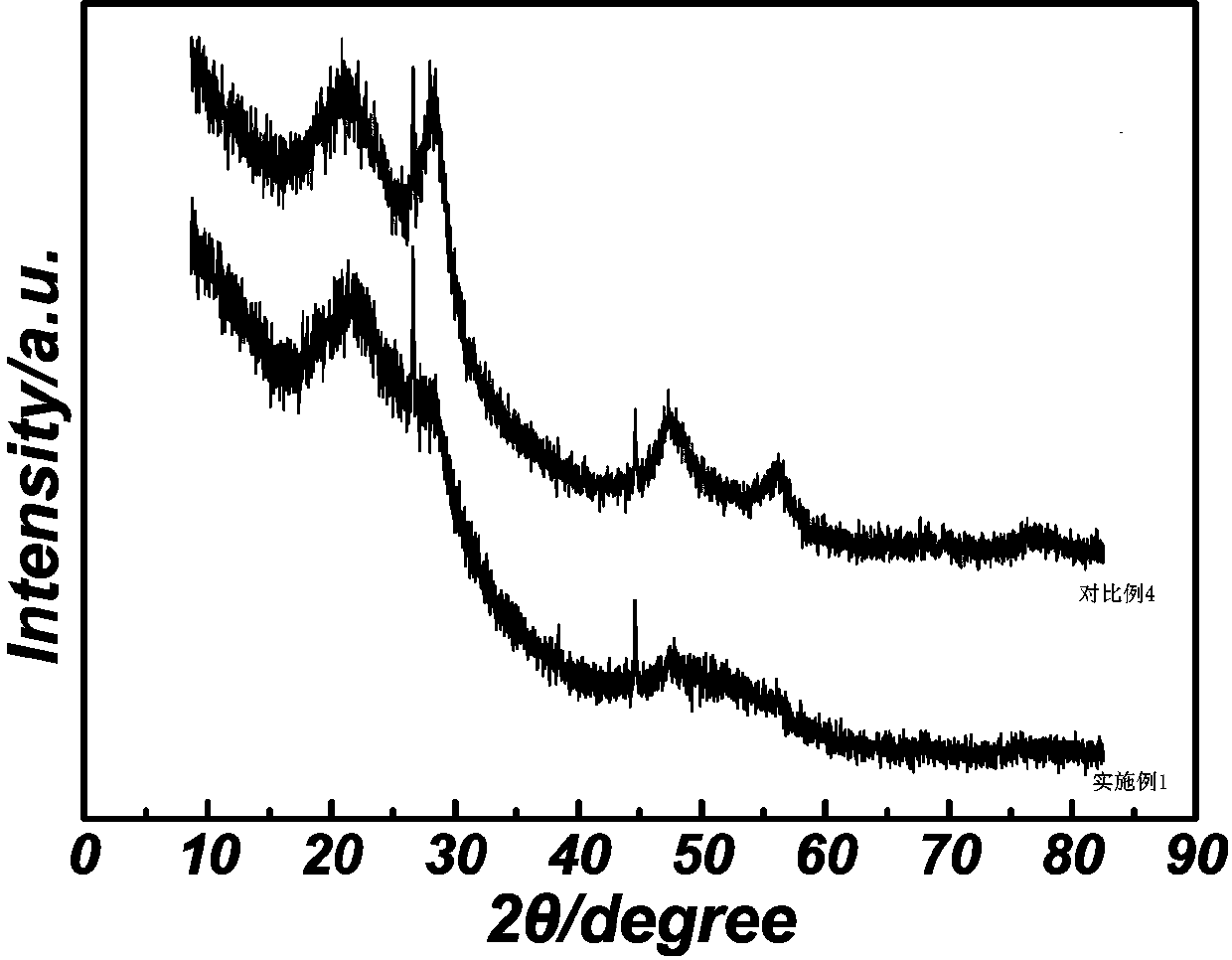

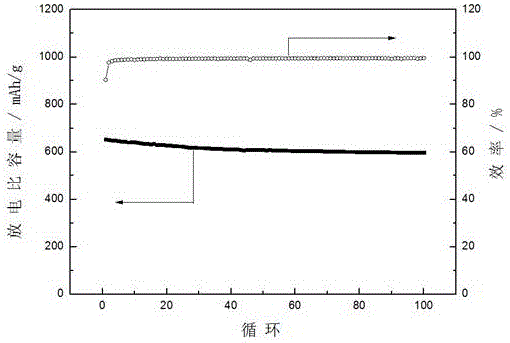

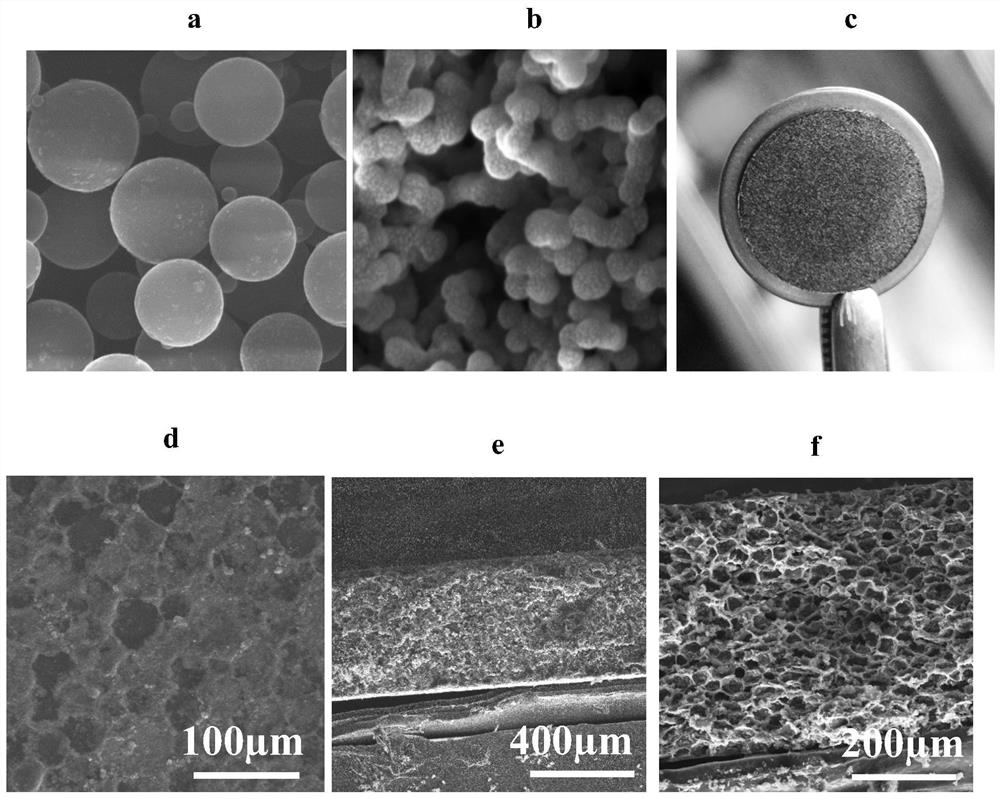

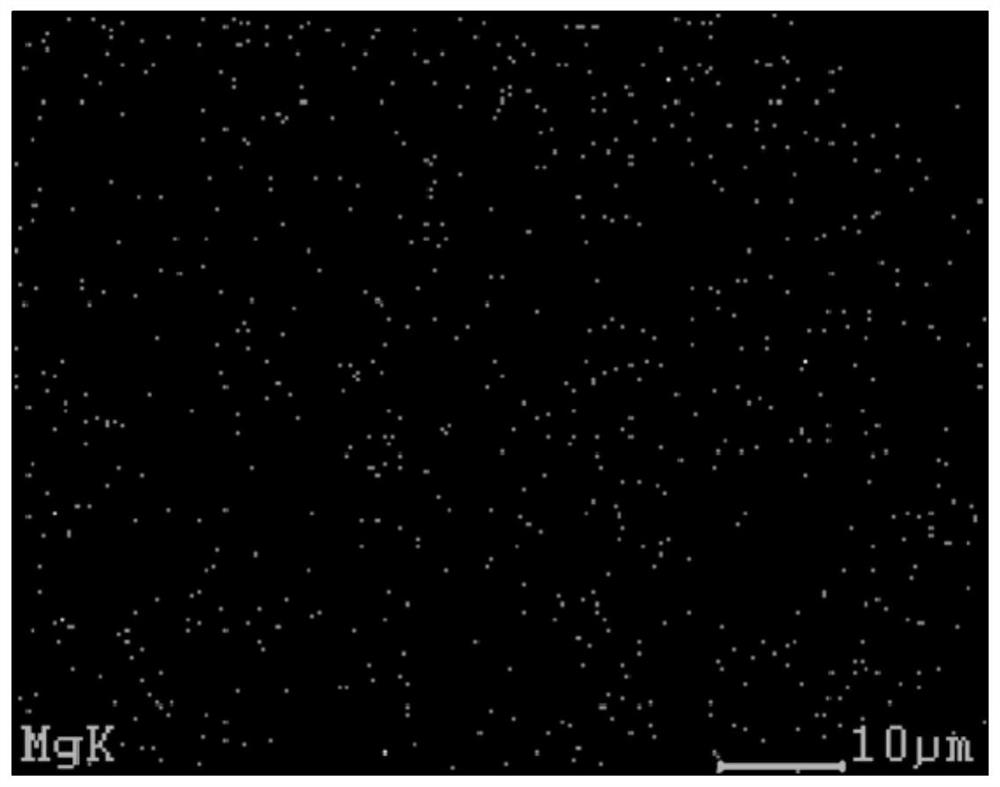

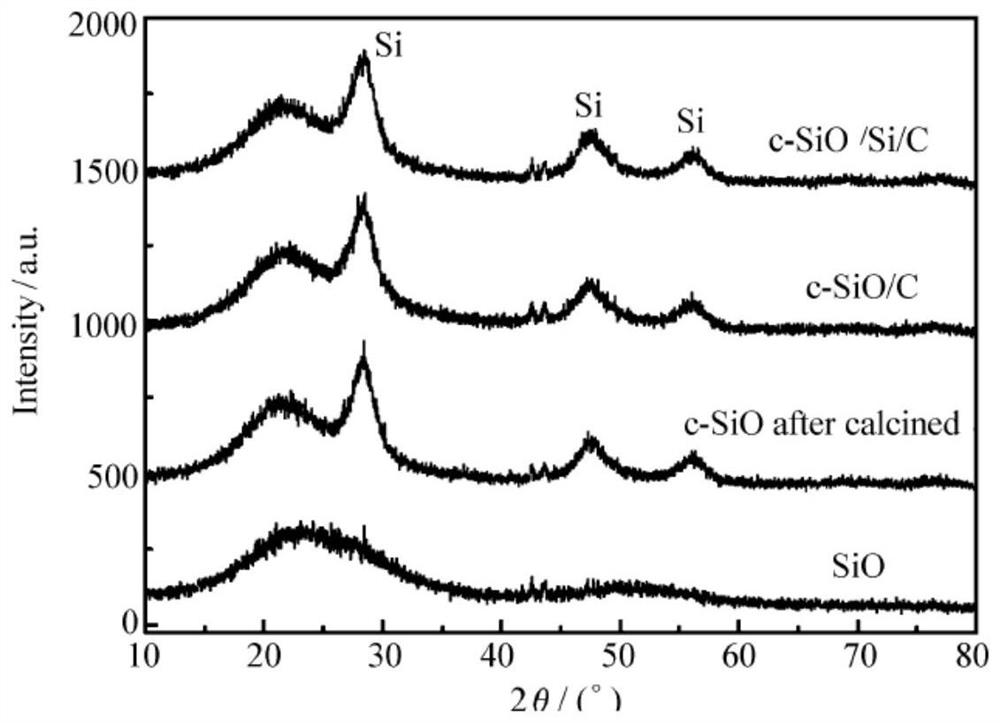

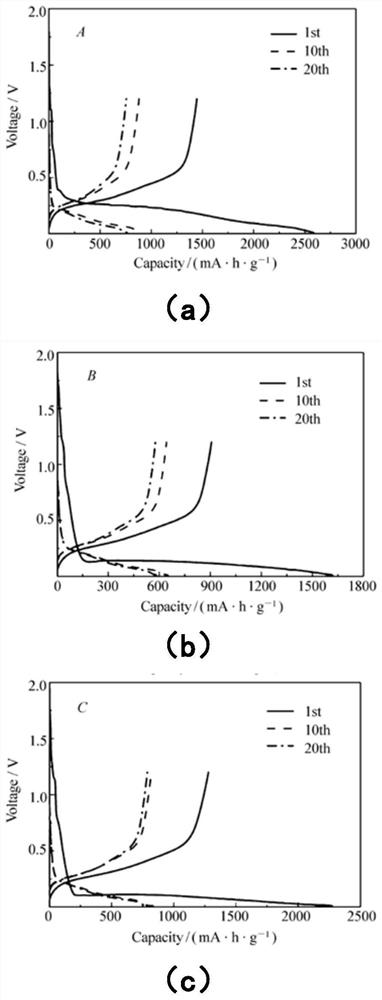

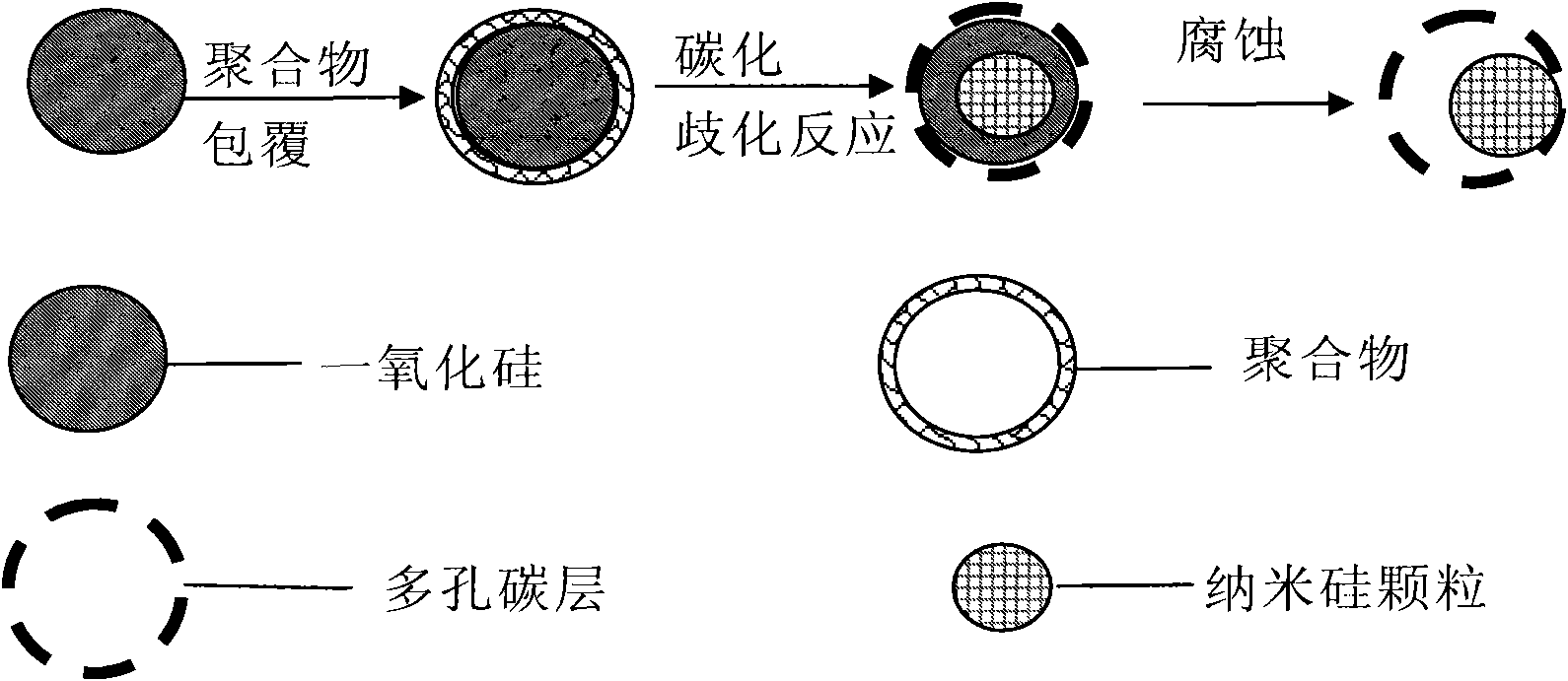

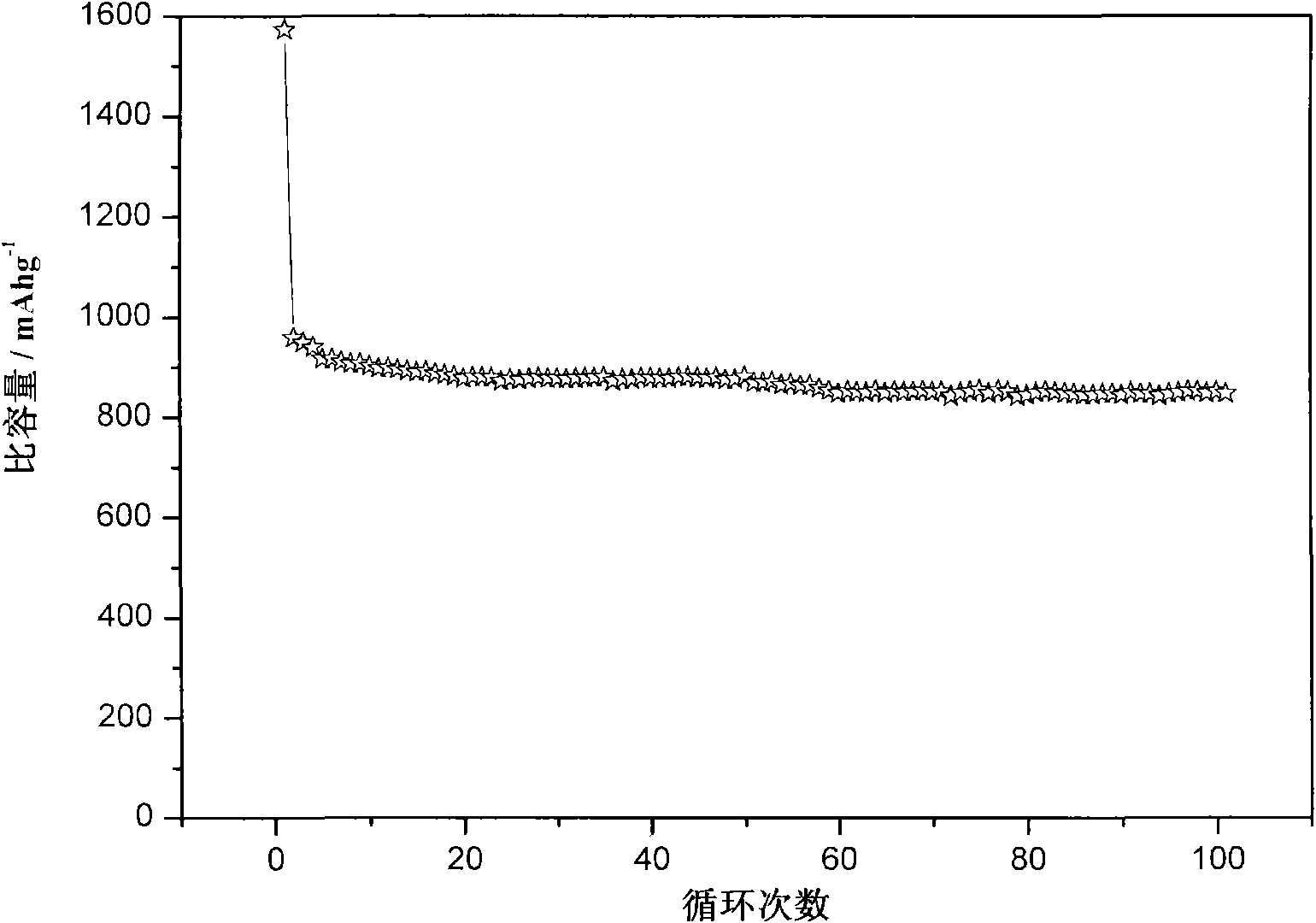

Preparation method of silicon carbon negative electrode material, silicon carbon negative electrode material and lithium ion battery

ActiveCN107565115BWide variety of sourcesLow costCell electrodesSecondary cellsSilicon monoxideSilicon oxide

The invention belongs to the technical field of a lithium ion battery, and relates to a silicon carbon negative electrode material and a preparation method therefor, and the lithium ion battery. The preparation method for the silicon carbon negative electrode material comprises the following steps of (a), by taking silicon monoxide as the substrate material, performing heating treatment on siliconmonoxide to enable silicon monoxide to be subjected to a disproportionation reaction to generate c-SiO; (b), putting c-SiO into a chemical vapor deposition furnace, heating in protective atmosphere until a reaction temperature is reached, and pumping a carbon source to be subjected to a vapor deposition reaction to obtain c-SiO / C, wherein the carbon source is a liquid-state or solid-state compound; and (c), performing corrosion of the c-SiO / C by a corrosive liquid to obtain the silicon carbon negative electrode material c-SiO / Si / C. The preparation method is simple in process and easy to operate; and the prepared silicon carbon negative electrode material has the high lithium storage characteristic as the silicon type material and the high cycling stability as the carbon type material, aswell as high specific capacity, high conductivity and high cycling performance.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

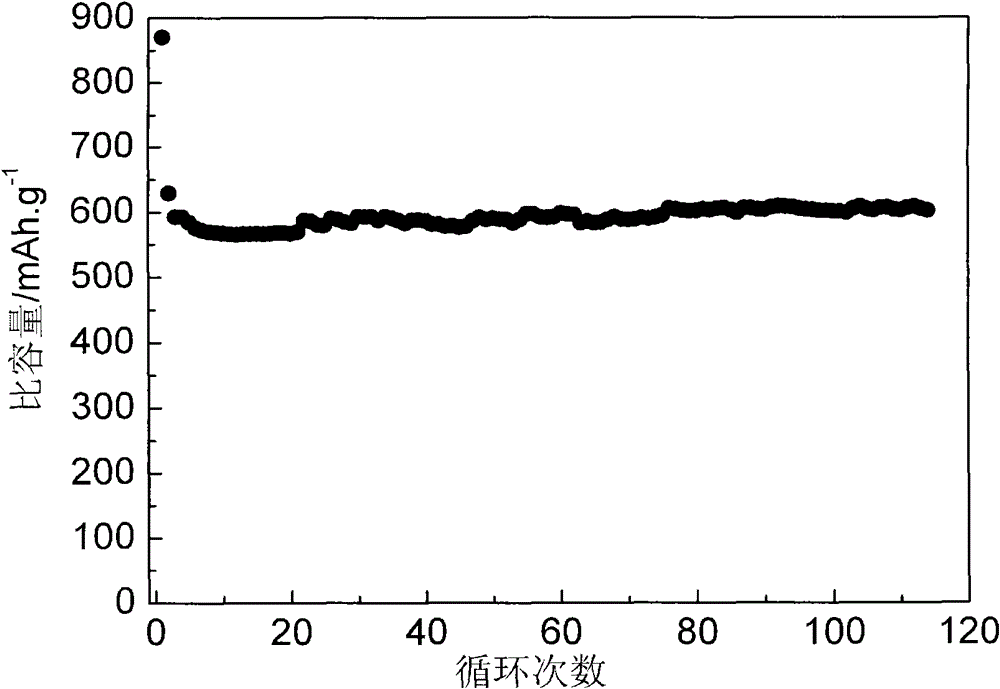

Silicon-carbon composite material, preparation method thereof and cathode material containing same as well as lithium ion battery

ActiveCN102447112BIncrease the embedding positionImprove volume effectCell electrodesSecondary cellsCarbon compositesPorous carbon

The invention provides a silicon-carbon composite material, a preparation method thereof and a battery cathode made of the silicon-carbon composite material as well as a lithium ion battery. The silicon-carbon composite material comprises hollow porous carbon ball-enwrapped nanometer silicon particles; each nanometer silicon particle in the silicon-carbon composite material has a particle size of 5-80 nm, wherein the content of nanometer silicon is 10-90 wt percent. The silicon-carbon composite material has simple manufacturing process and can effectively restrain the expansion of silicon volume, so that the prepared lithium ion cathode material has excellent conductivity, and the corresponding lithium ion battery has large specific capacity and good cycling performance.

Owner:CHERY AUTOMOBILE CO LTD

A polymer microsphere water plugging profile control agent and preparation method thereof

The invention discloses a polymer microsphere water plugging profile control agent and a preparation method thereof, which belong to the technical field of petroleum exploitation and are made of the following components: main agent, dispersion stabilizer, crosslinking agent, initiator, auxiliary agent, water. The invention exhibits good expansibility, and the expansion multiple increases rapidly in the first 7 days, and after 14 days, the expansion multiple increases slowly. As the temperature rises, the expansion multiple of the microspheres is higher, up to 120 times. In formation water at 90°C and salinity of 20g / L, the microspheres are stable for more than 6 months, and the plugging rate reaches more than 98.7%. The expanded particles have certain elasticity, strength and water retention function, and can stay in the formation void for a long time to achieve the purpose of profile control and water plugging. The recovery factor is 35%‑42%.

Owner:ZHENGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com