Tin-based composite thin film material for lithium ion battery as well as preparation method and application of thin film material

A technology of lithium-ion batteries and composite films, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited improvement in cycle performance and long time for preparing films, so as to improve repeatability, stability, and The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

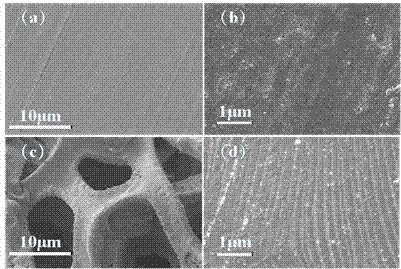

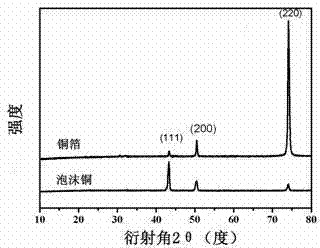

[0028] A tin-based composite film material for lithium-ion batteries, such as figure 1 As shown, it is composed of foamed copper substrate and Sn-Al thin film. The thickness of the foamed copper substrate is 10 μm; The thickness of the Al film is 500nm.

[0029] The preparation method of the above-mentioned tin-based composite thin film material for lithium ion batteries adopts the simultaneous sputtering process of metal target Sn and metal Al to prepare a Sn-Al thin film on a foamed copper substrate, and the steps are as follows:

[0030] 1) Install the cleaned copper foam substrate at the sample position in the magnetron sputtering chamber, and then install the target material Sn. The distance from the substrate is 7cm, and the horizontal angle between the target and the cavity chamber is 20°;

[0031] 2) Vacuum the background of the magnetron sputtering chamber to 0.8×10 -3 Pa, the Ar gas with a purity of 99.999% is introduced into the cavity, the flow rate is 20sccm, t...

Embodiment 2

[0034] A tin-based composite film material for lithium-ion batteries, such as figure 1 As shown, it is composed of copper foil substrate and Sn-Al thin film, the thickness of copper foil substrate is 10 μm; The thickness of the Al film is 700nm.

[0035] The preparation method of the above-mentioned tin-based composite thin film material for lithium ion batteries adopts the simultaneous sputtering process of metal target Sn and metal Al to prepare a Sn-Al thin film on a copper foil substrate, and the steps are as follows:

[0036] 1) Install the cleaned copper foil substrate at the sample position in the magnetron sputtering chamber, and then install the target Sn, the purity of both the copper foil and the target Sn is 99.95%, the target Sn points to the copper foil at the sample position, and the target The distance from the substrate is 7cm, and the horizontal angle between the target and the cavity chamber is 20°;

[0037] 2) Vacuum the background of the magnetron sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com