Patents

Literature

95 results about "Tin thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of forming films including germanium tin and structures and devices including the films

ActiveUS20150048485A1Polycrystalline material growthSemiconductor/solid-state device manufacturingMaterials scienceChemical vapor deposition

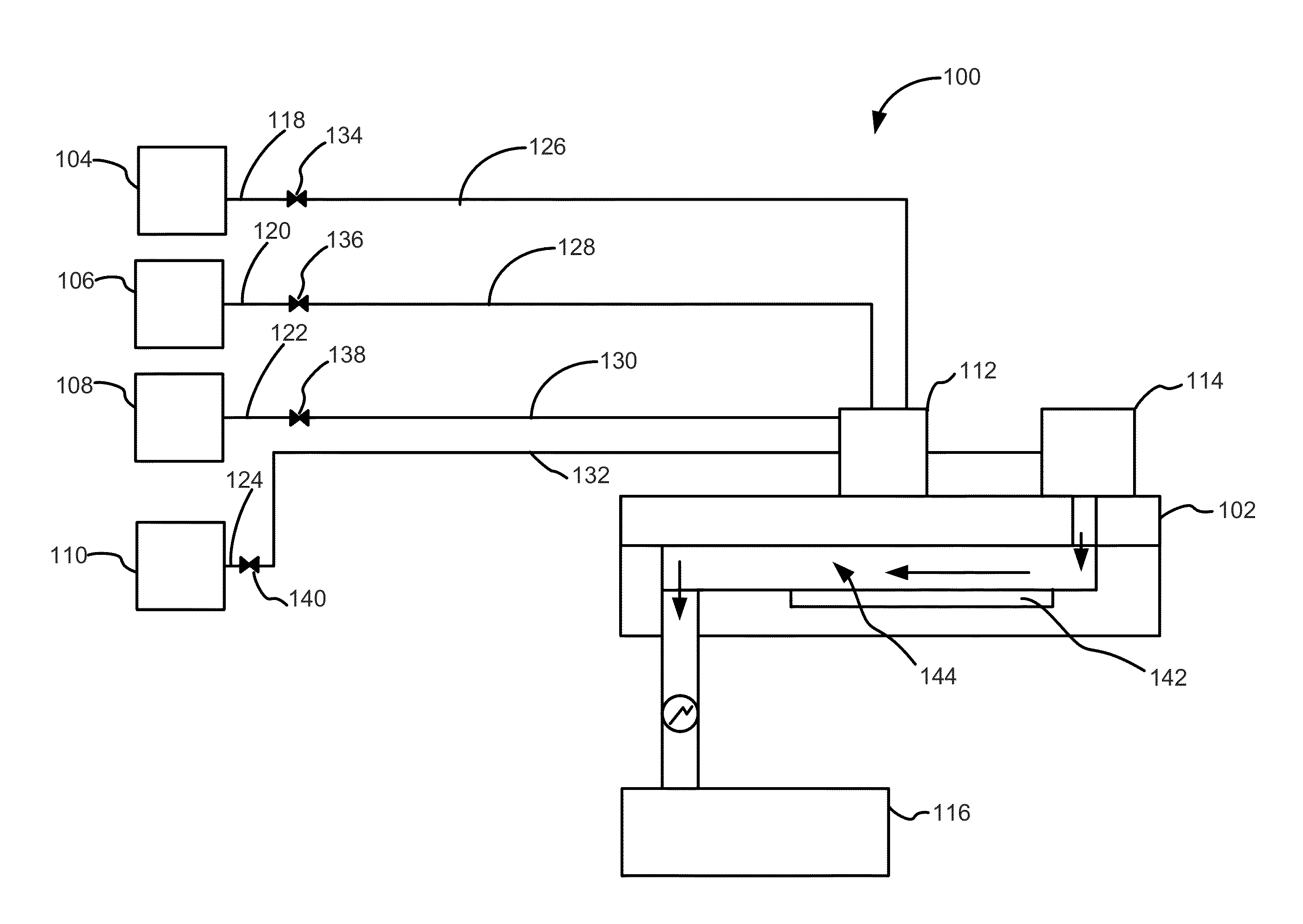

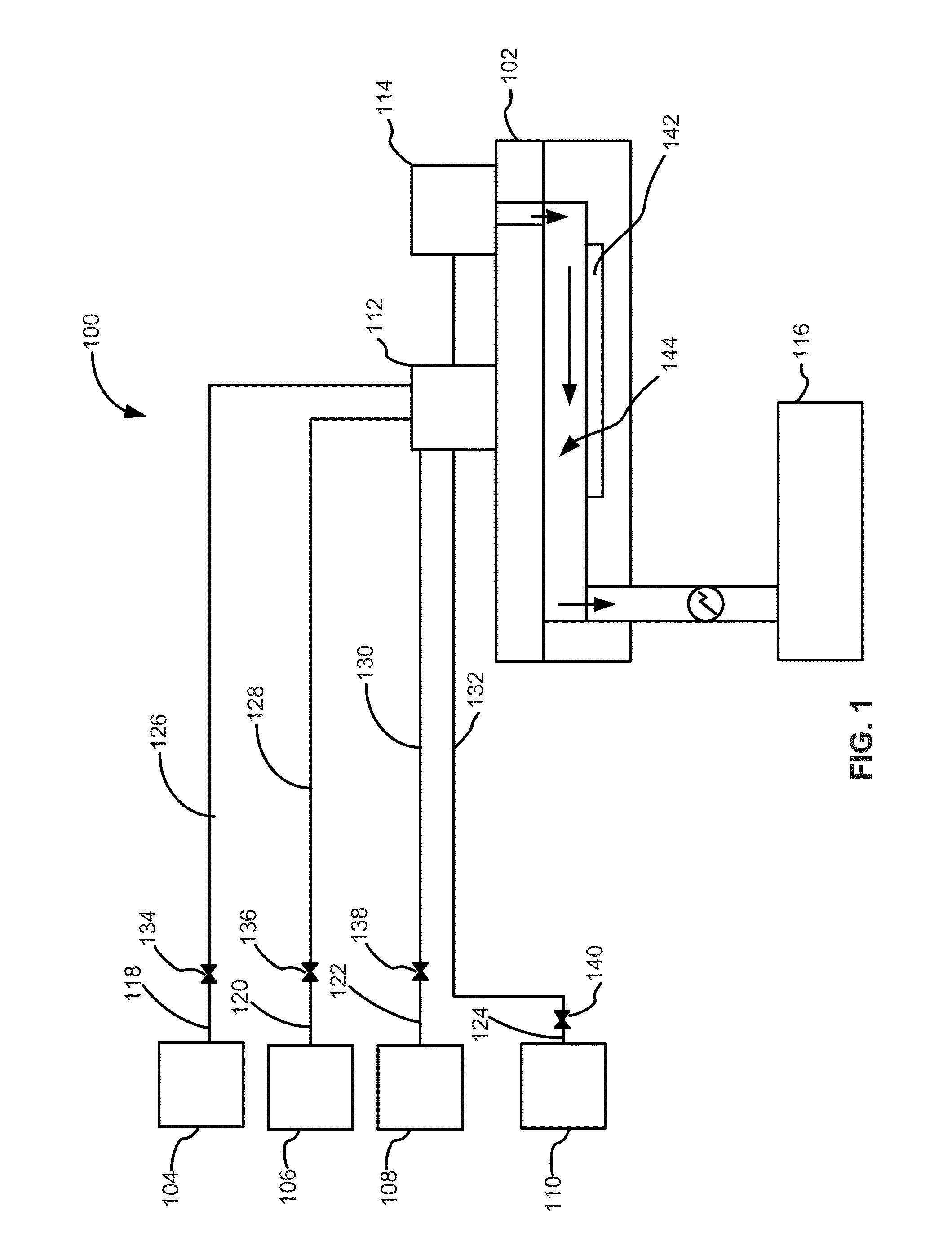

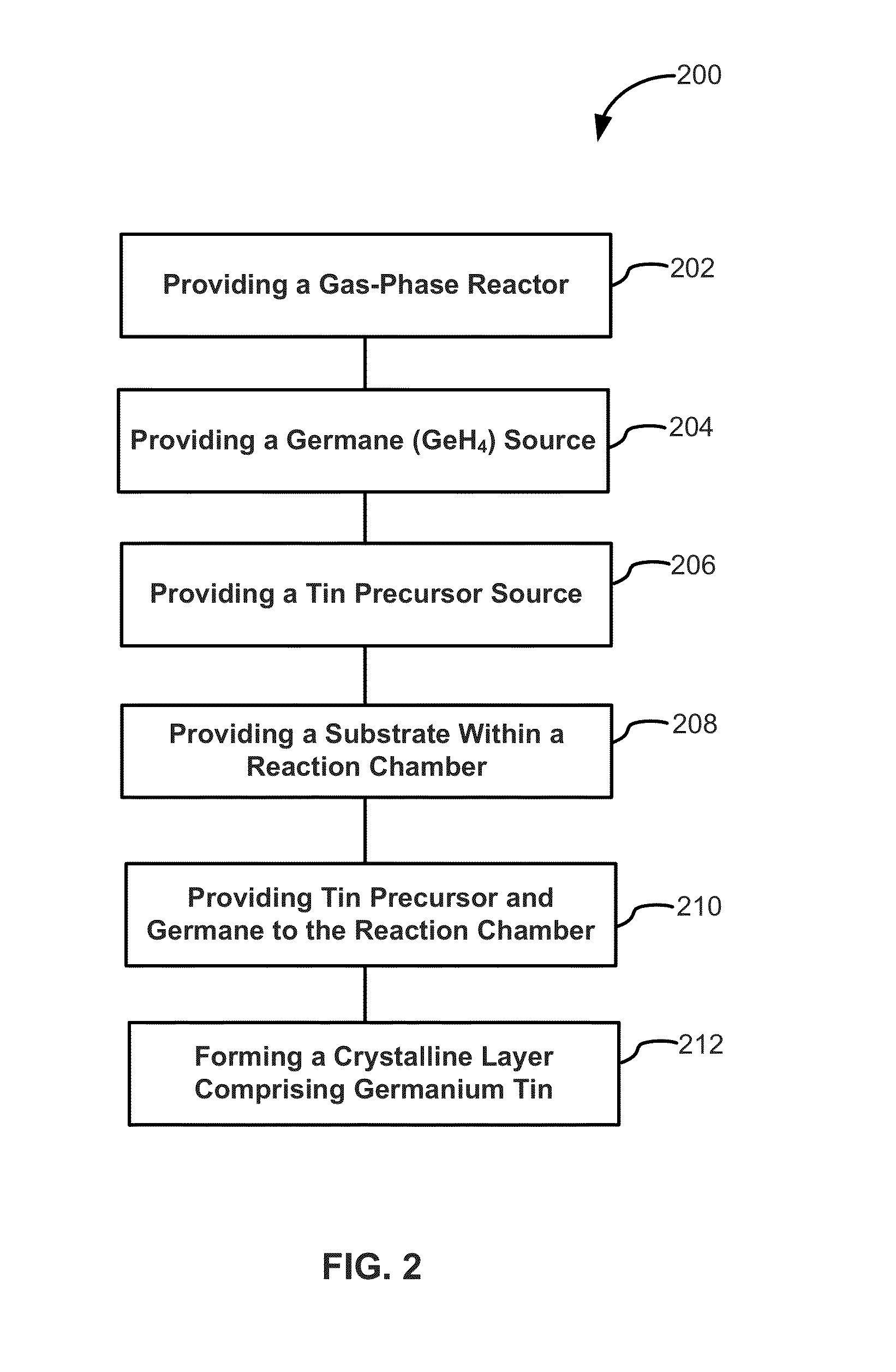

Methods of forming germanium-tin films using germane as a precursor are disclosed. Exemplary methods include growing films including germanium and tin in an epitaxial chemical vapor deposition reactor, wherein a ratio of a tin precursor to germane is less than 0.1. Also disclosed are structures and devices including germanium-tin films formed using the methods described herein.

Owner:ASM IP HLDG BV

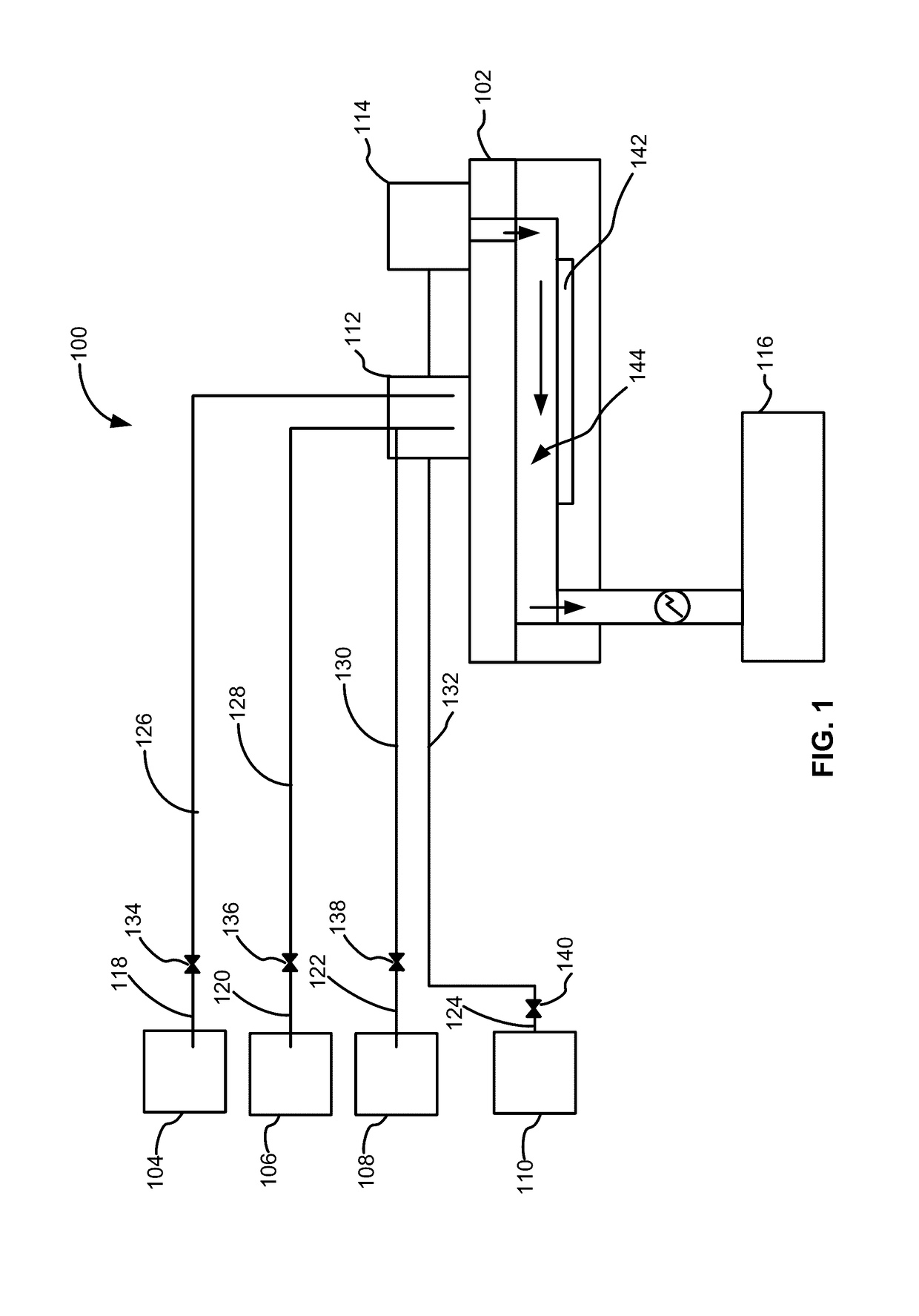

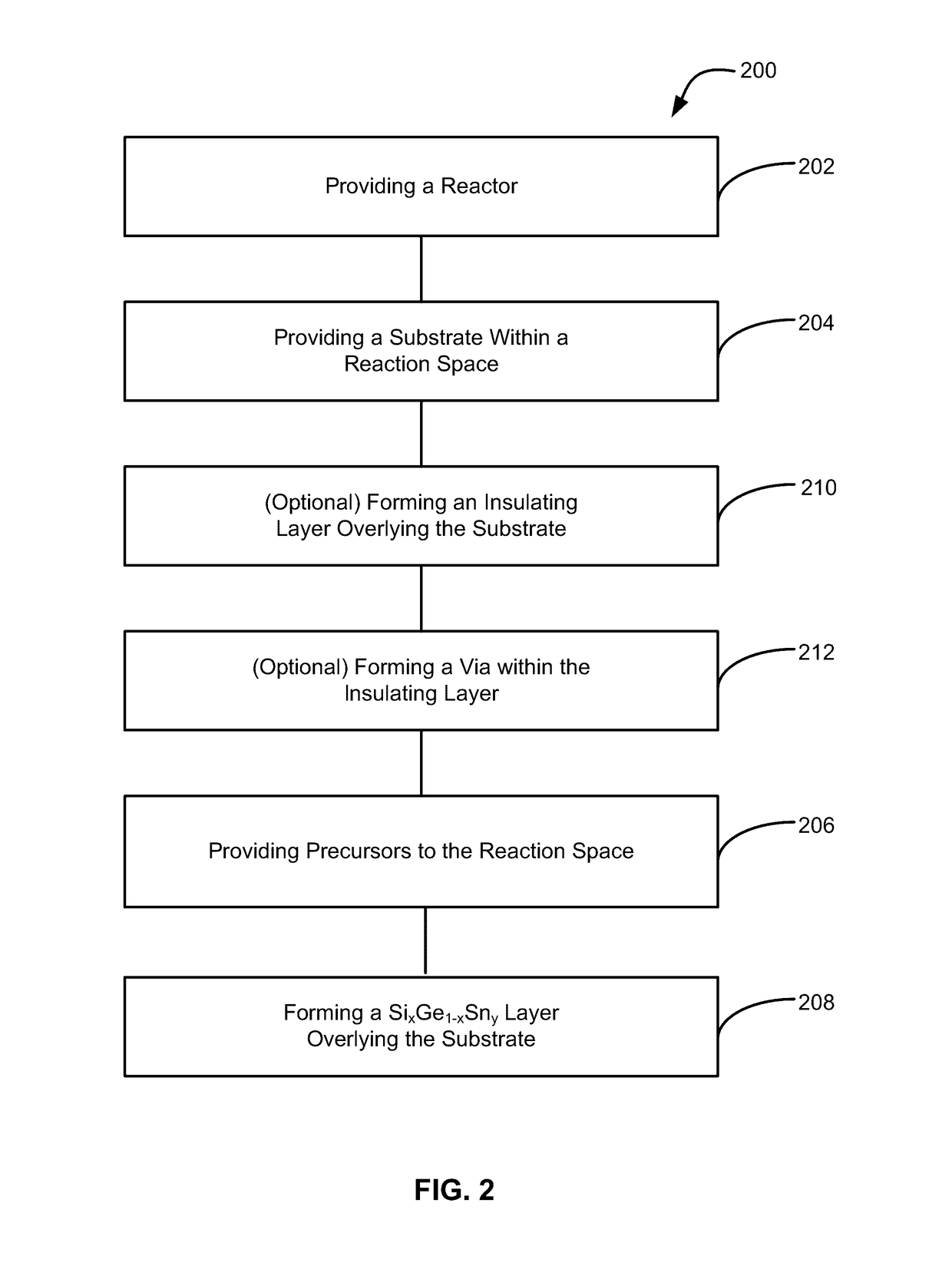

Methods of forming silicon germanium tin films and structures and devices including the films

ActiveUS20170154770A1Low throughput timeSemiconductor/solid-state device manufacturingSemiconductor devicesHigh volume manufacturingChemical vapor deposition

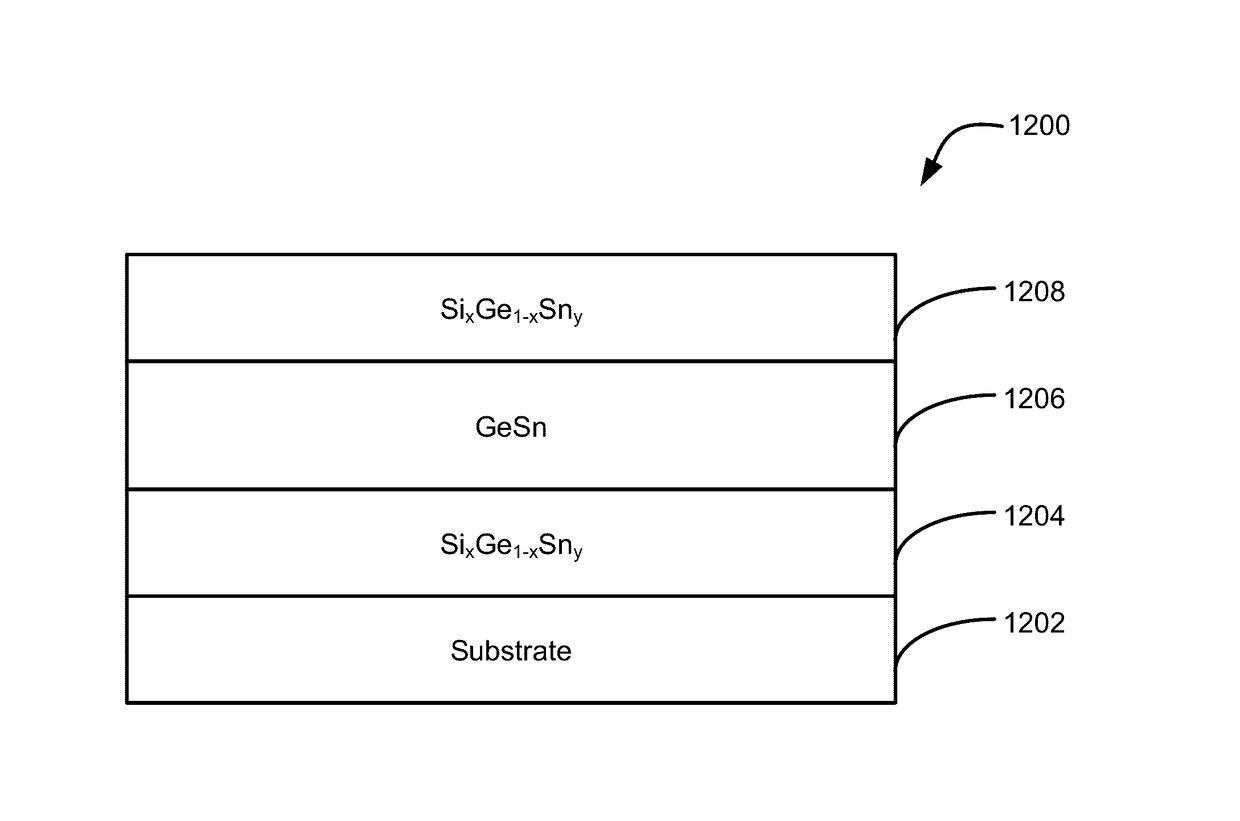

Methods of forming silicon germanium tin (SiGexGe1−xSny) films are disclosed. Exemplary methods include growing films including silicon, germanium and tin in an epitaxial chemical vapor deposition reactor. Exemplary methods are suitable for high volume manufacturing. Also disclosed are structures and devices including silicon germanium tin films.

Owner:ASM IP HLDG BV

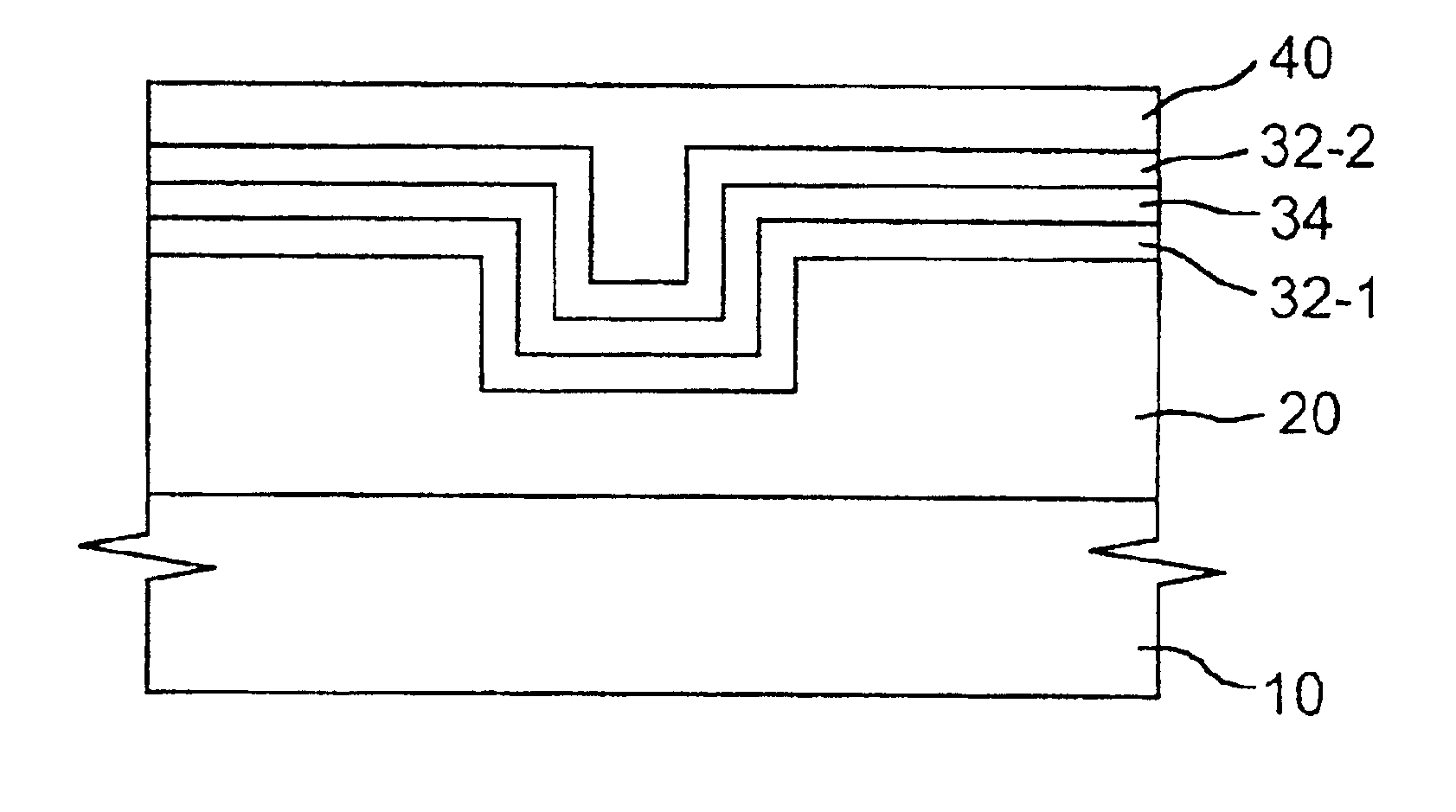

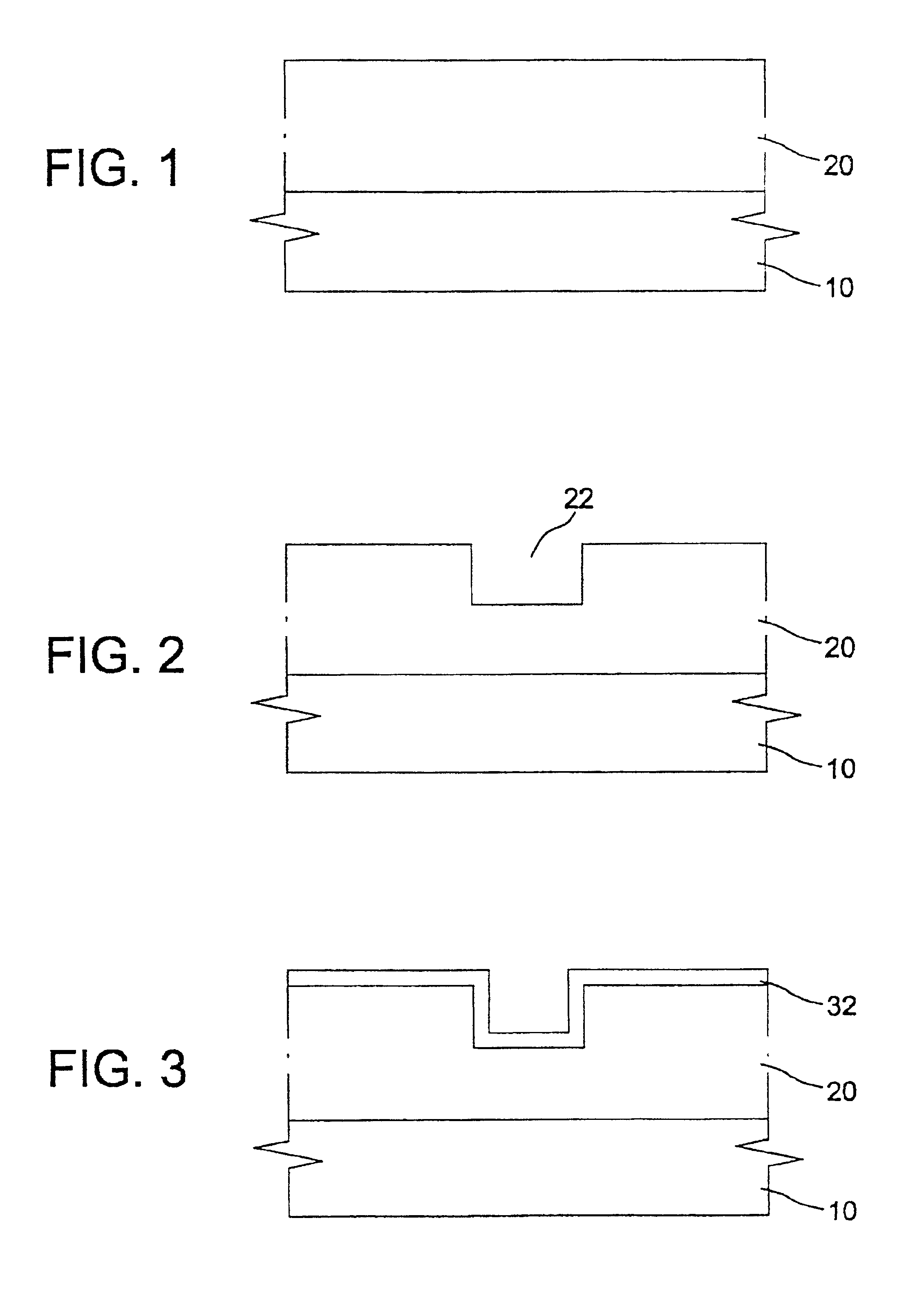

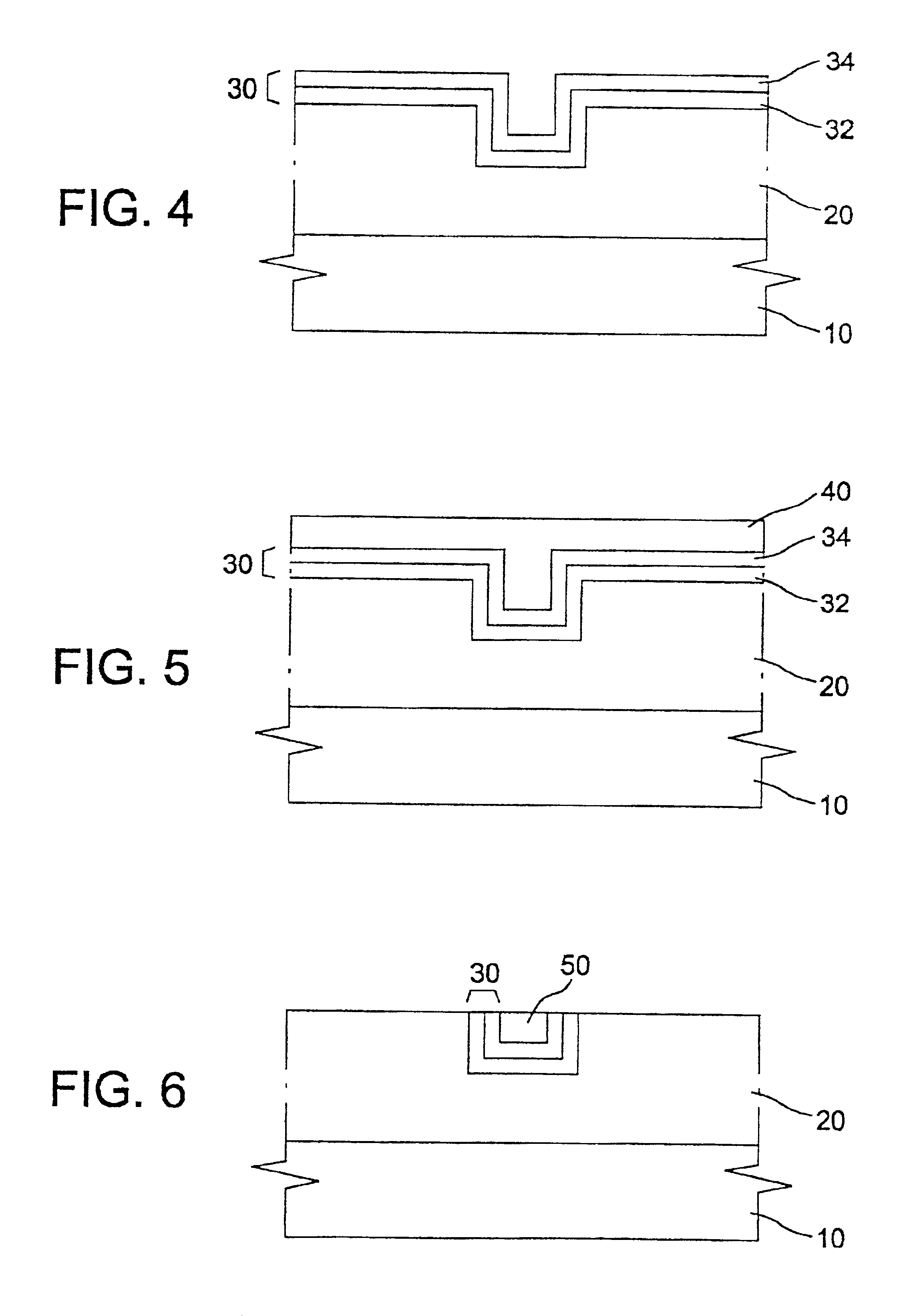

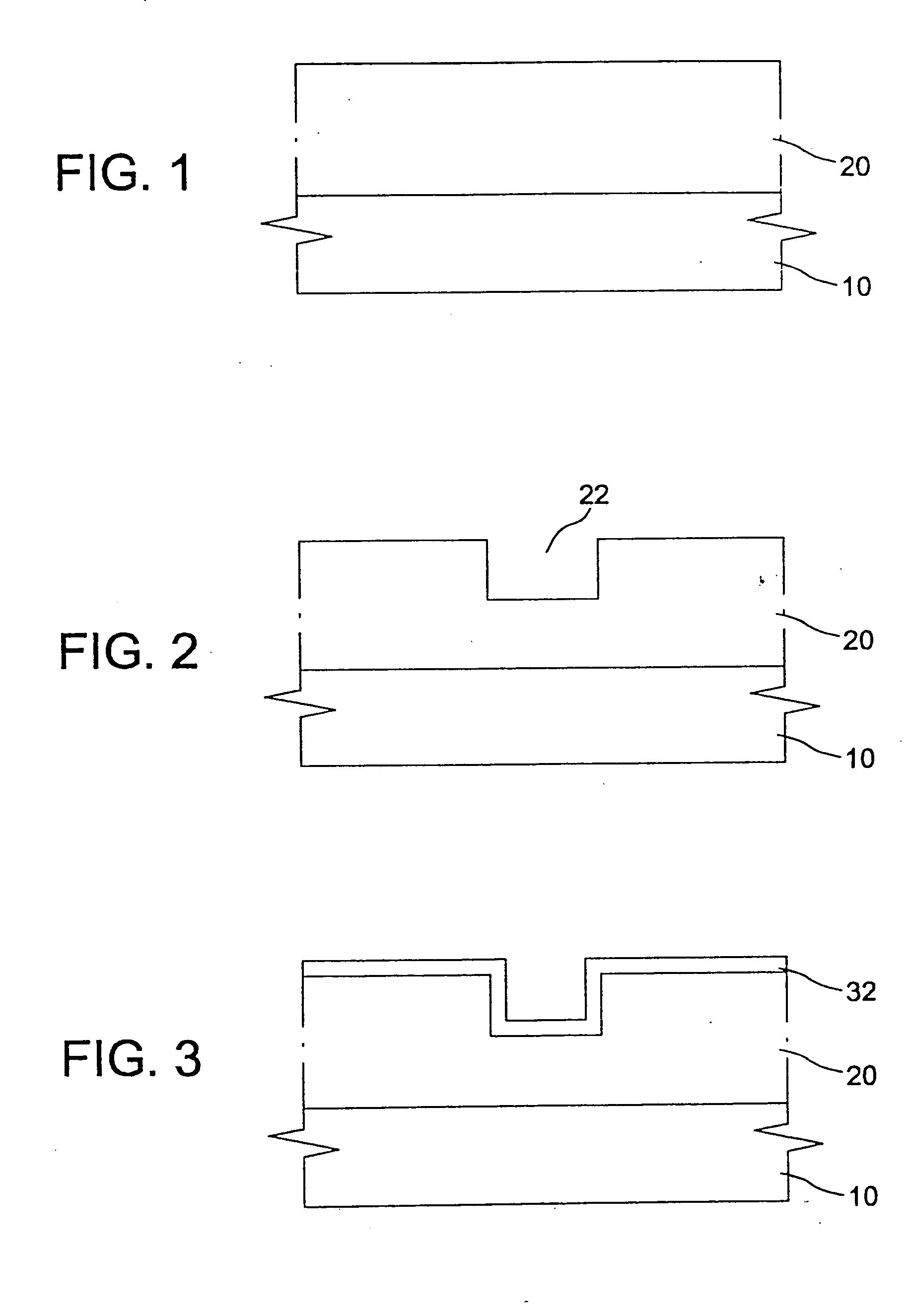

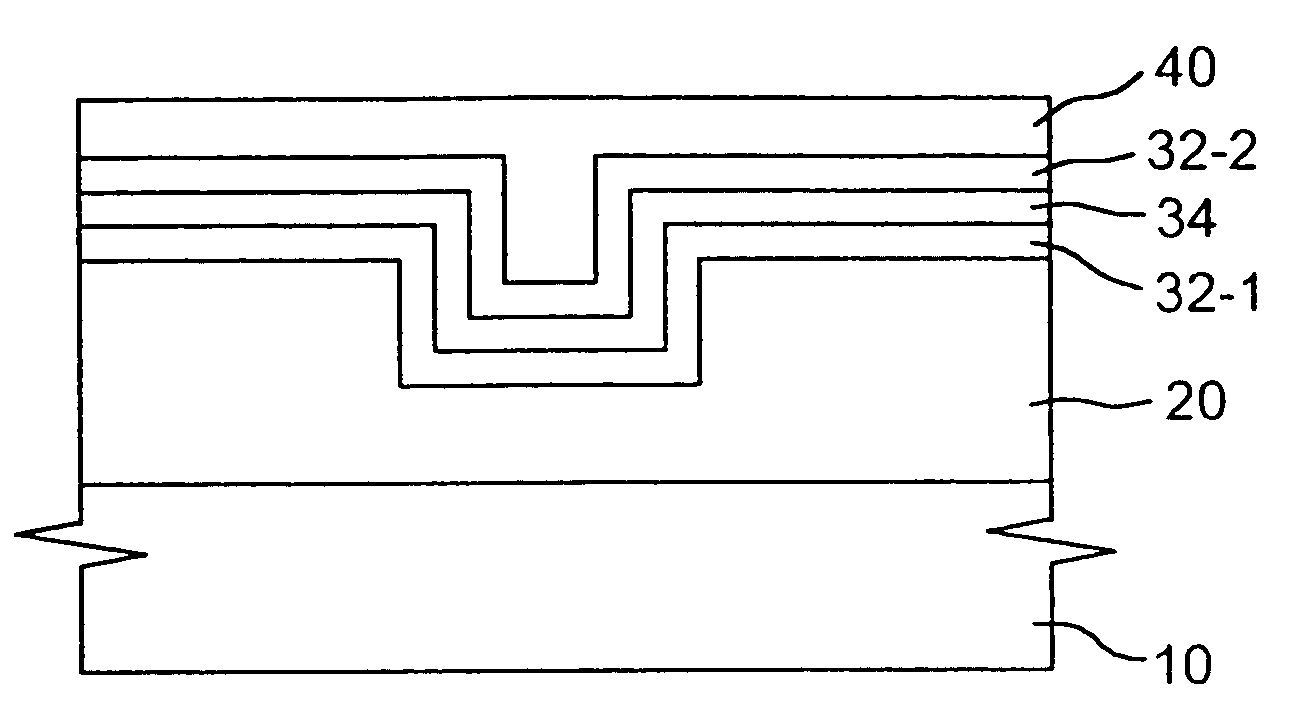

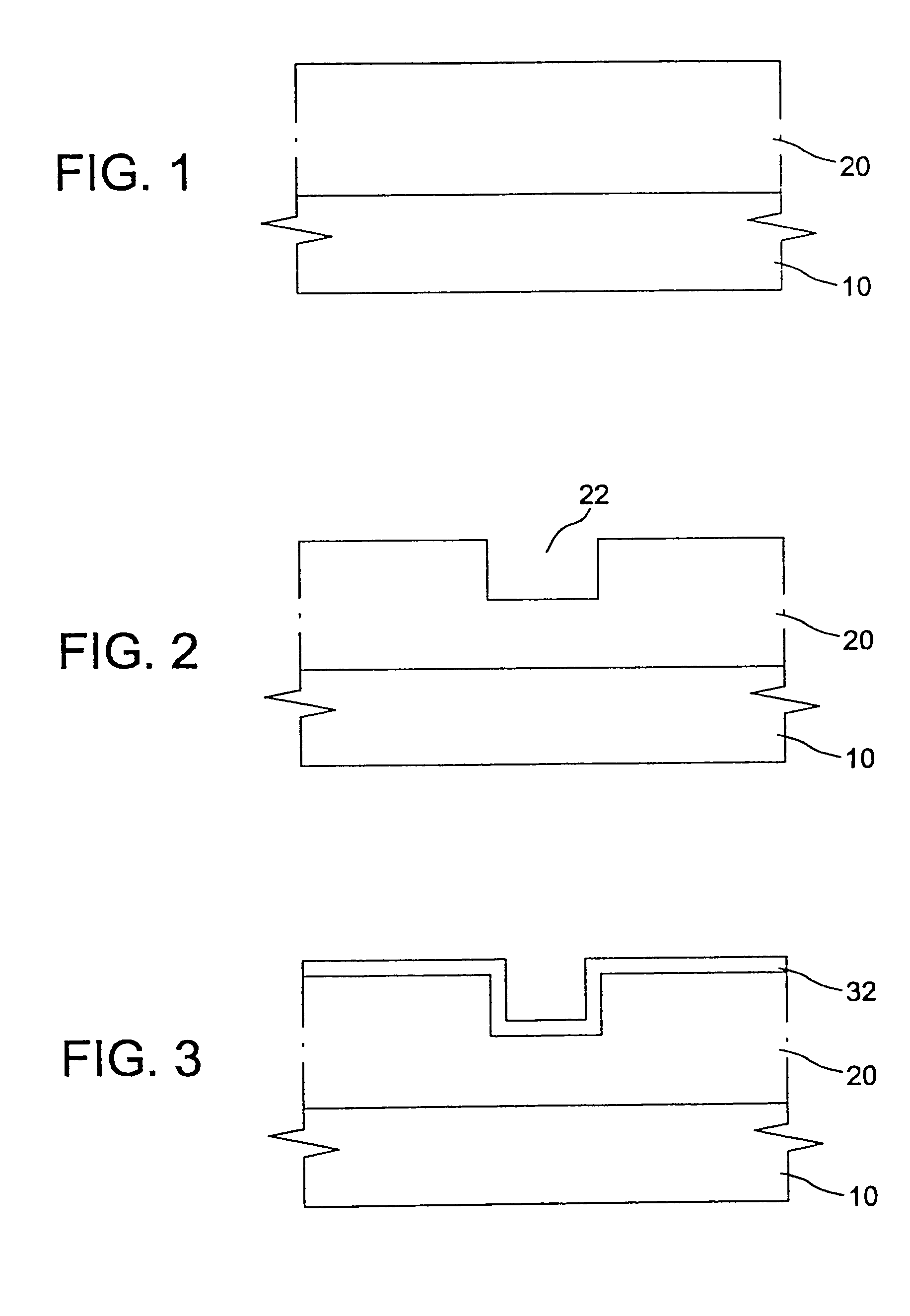

Copper interconnect structure having stuffed diffusion barrier

InactiveUS6936535B2Semiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper interconnect

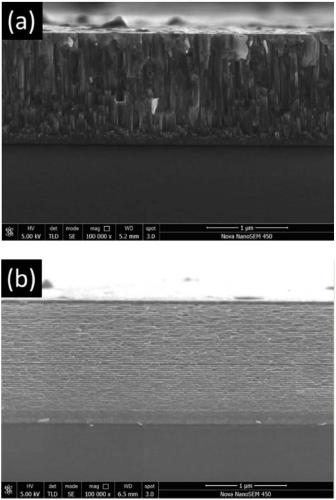

The present invention provides a method of fabricating a semiconductor device, which could advance the commercialization of semiconductor devices with a copper interconnect. In a process of metal interconnect line fabrication, a TiN thin film combined with an Al intermediate layer is used as a diffusion barrier on trench or via walls. For the formation, Al is deposited on the TiN thin film followed by copper filling the trench. Al diffuses to TiN layer and reacts with oxygen or nitrogen, which will stuff grain boundaries efficiently, thereby blocking the diffusion of copper successfully.

Owner:ASM INTERNATIONAL

Copper interconnect structure having stuffed diffusion barrier

InactiveUS20050101132A1Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectMetal interconnect

The present invention provides a method of fabricating a semiconductor device, which could advance the commercialization of semiconductor devices with a copper interconnect. In a process of metal interconnect line fabrication, a TiN thin film combined with an Al intermediate layer is used as a diffusion barrier on trench or via walls. For the formation, Al is deposited on the TiN thin film followed by copper filling the trench. Al diffuses to TiN layer and reacts with oxygen or nitrogen, which will stuff grain boundaries efficiently, thereby blocking the diffusion of copper successfully.

Owner:ASM INTERNATIONAL

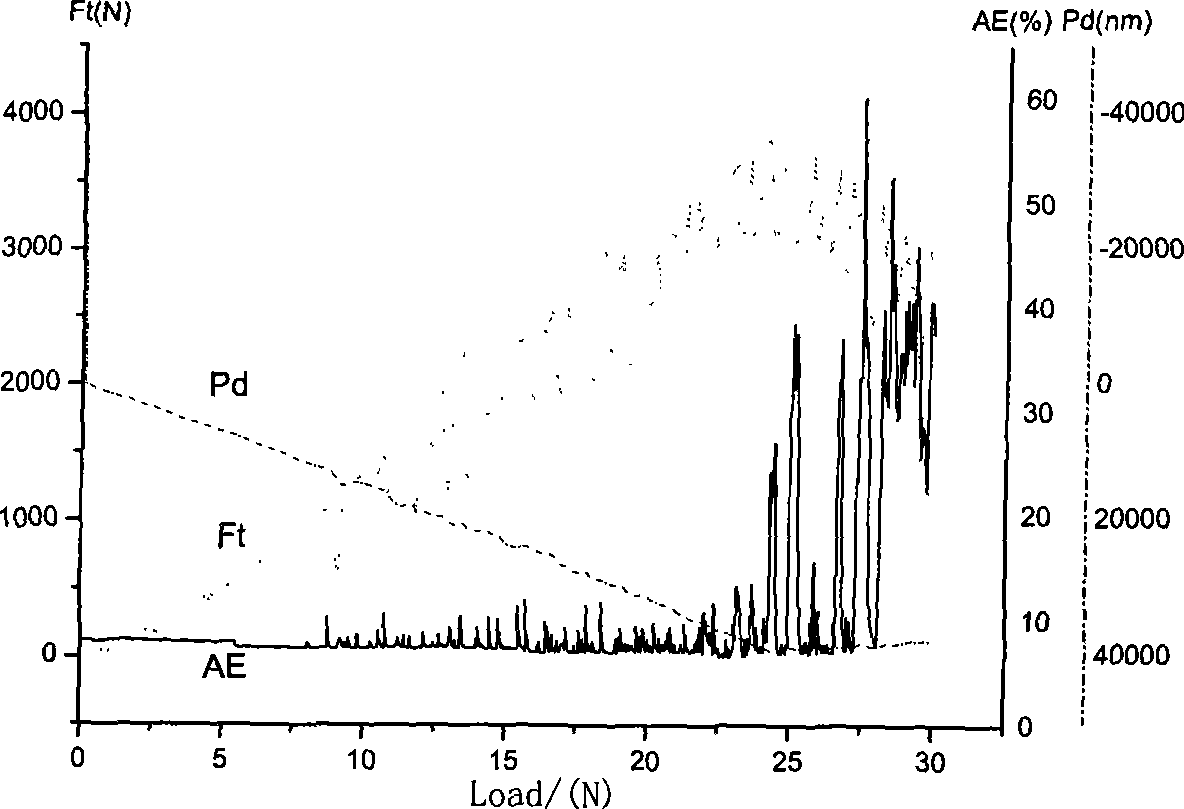

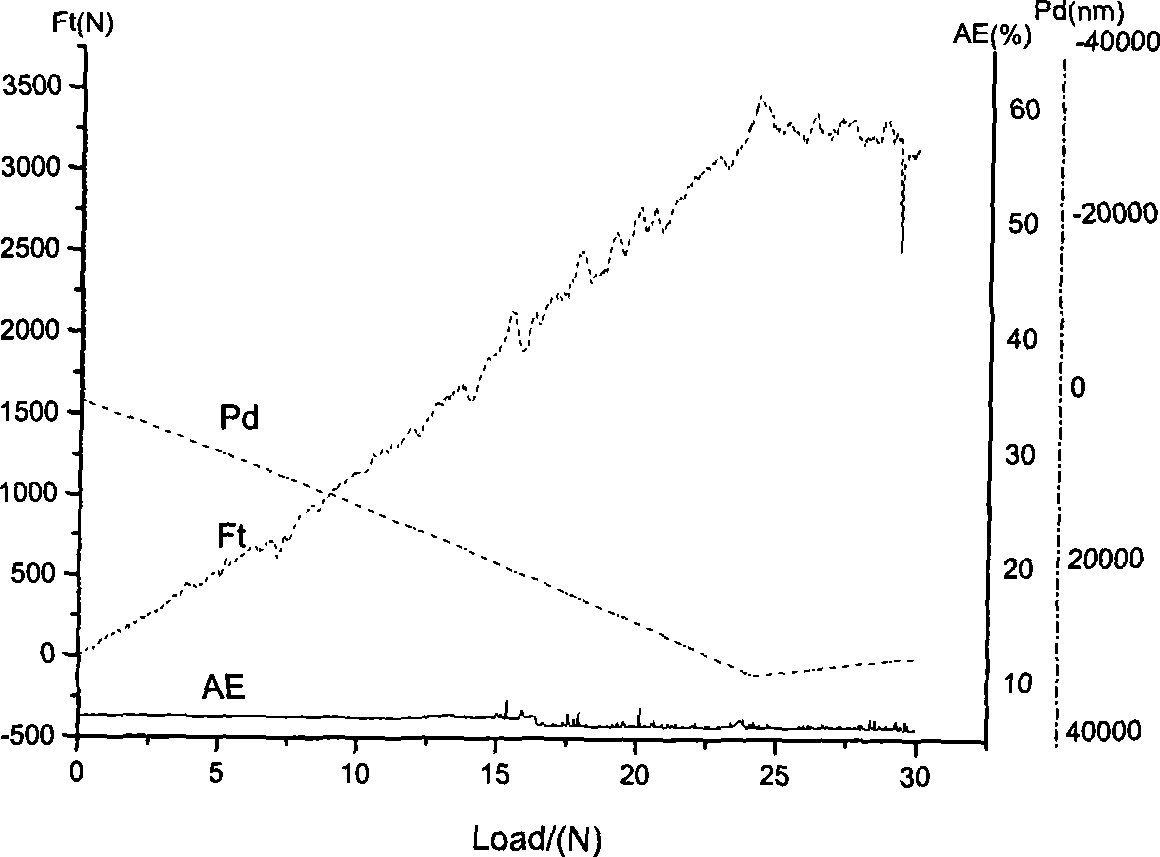

TiAlN/TiN for tool and mould material surface and preparation thereof

InactiveCN101435070AExtended service lifeImprove wear resistanceLayered productsVacuum evaporation coatingAutomatic controlWear resistance

The invention discloses a magnetic filtration TiAlN / TiN thin film on the surface of tool and die material and a preparation method thereof. A layer of magnetic filtration TiN thin film is firstly plated on the surface of the tool and die material by adopting a magnetic filter, then a layer of magnetic filtration TiAlN thin film is plated, and the total thickness of double layers of thin films is 1 to 4 Mu m. The magnetic filtration TiAlN / TiN thin film has short preparation time, low cost and good wear resistance, is beneficial to prolonging the service life of the tool and die; and the processing quality of the plated film is high, the preparation technique is simple, the operation is easy and the plating process adopts electrical and mechanical automatic control.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Copper interconnect structure having stuffed diffusion barrier

InactiveUS7732331B2Semiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper interconnect

The present invention provides a method of fabricating a semiconductor device, which could advance the commercialization of semiconductor devices with a copper interconnect. In a process of metal interconnect line fabrication, a TiN thin film combined with an Al intermediate layer is used as a diffusion barrier on trench or via walls. For the formation, Al is deposited on the TiN thin film followed by copper filling the trench. Al diffuses to TiN layer and reacts with oxygen or nitrogen, which will stuff grain boundaries efficiently, thereby blocking the diffusion of copper successfully.

Owner:ASM INTERNATIONAL

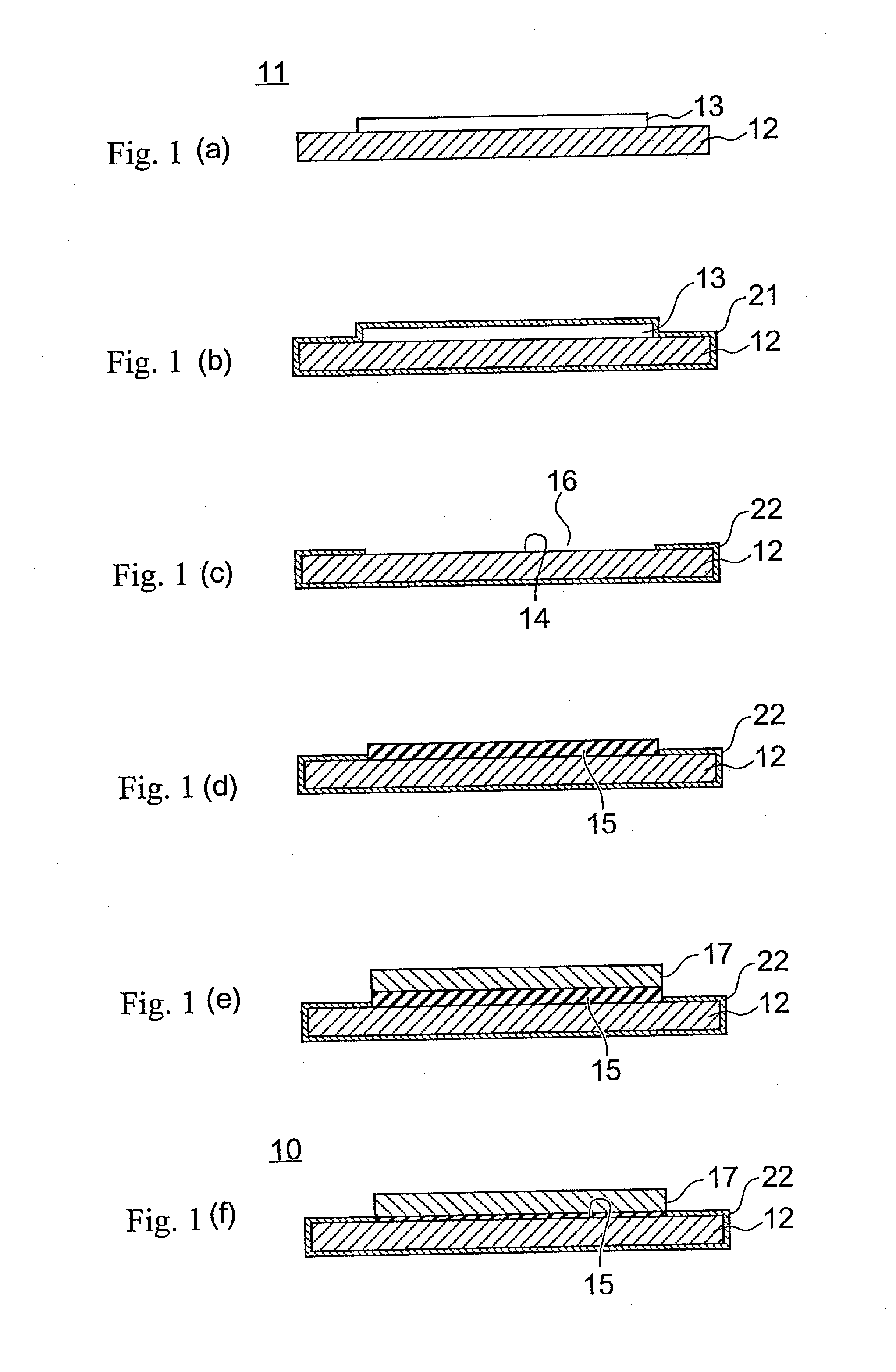

Nitride-based semiconductor substrate and method of making the same

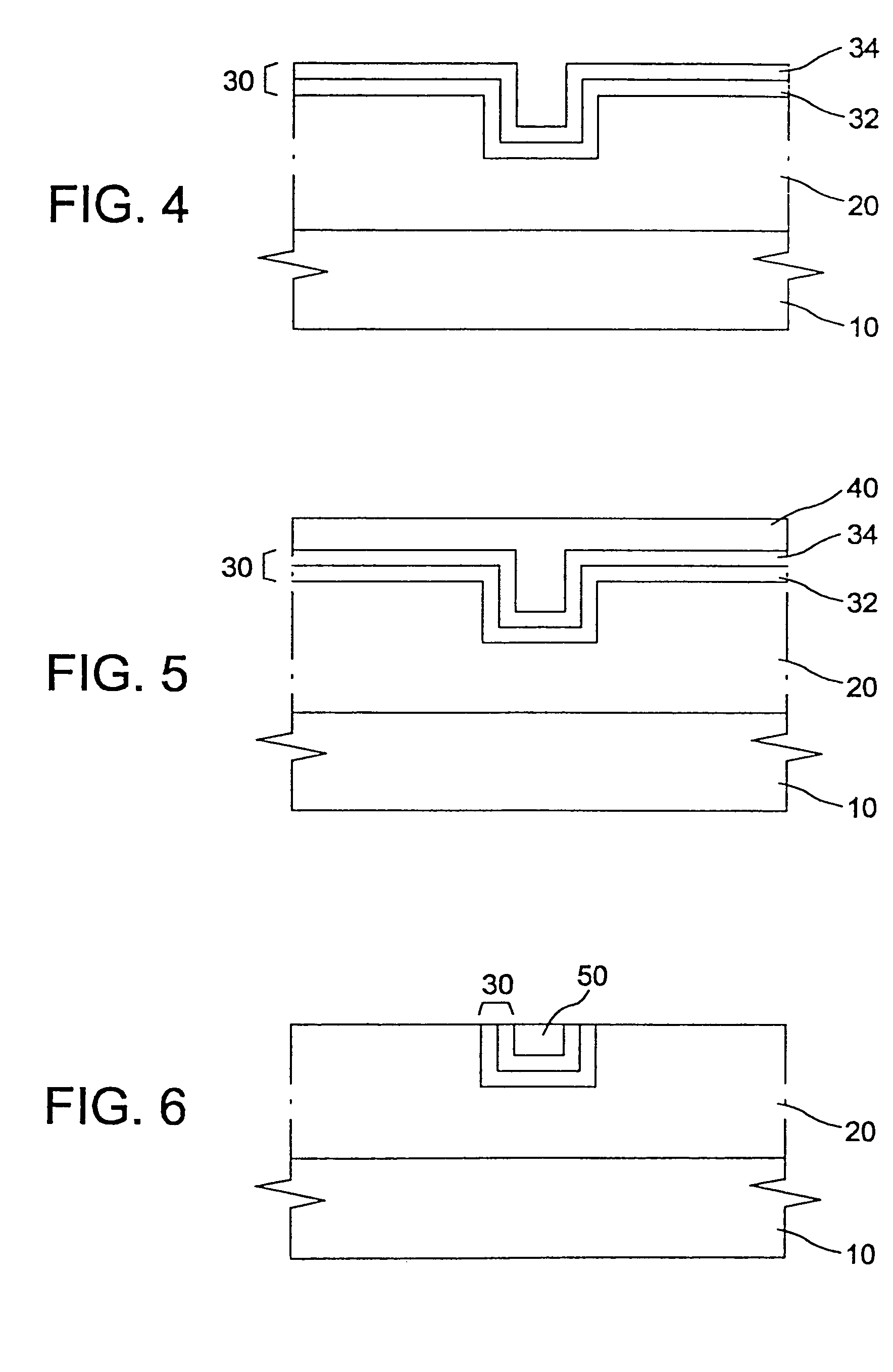

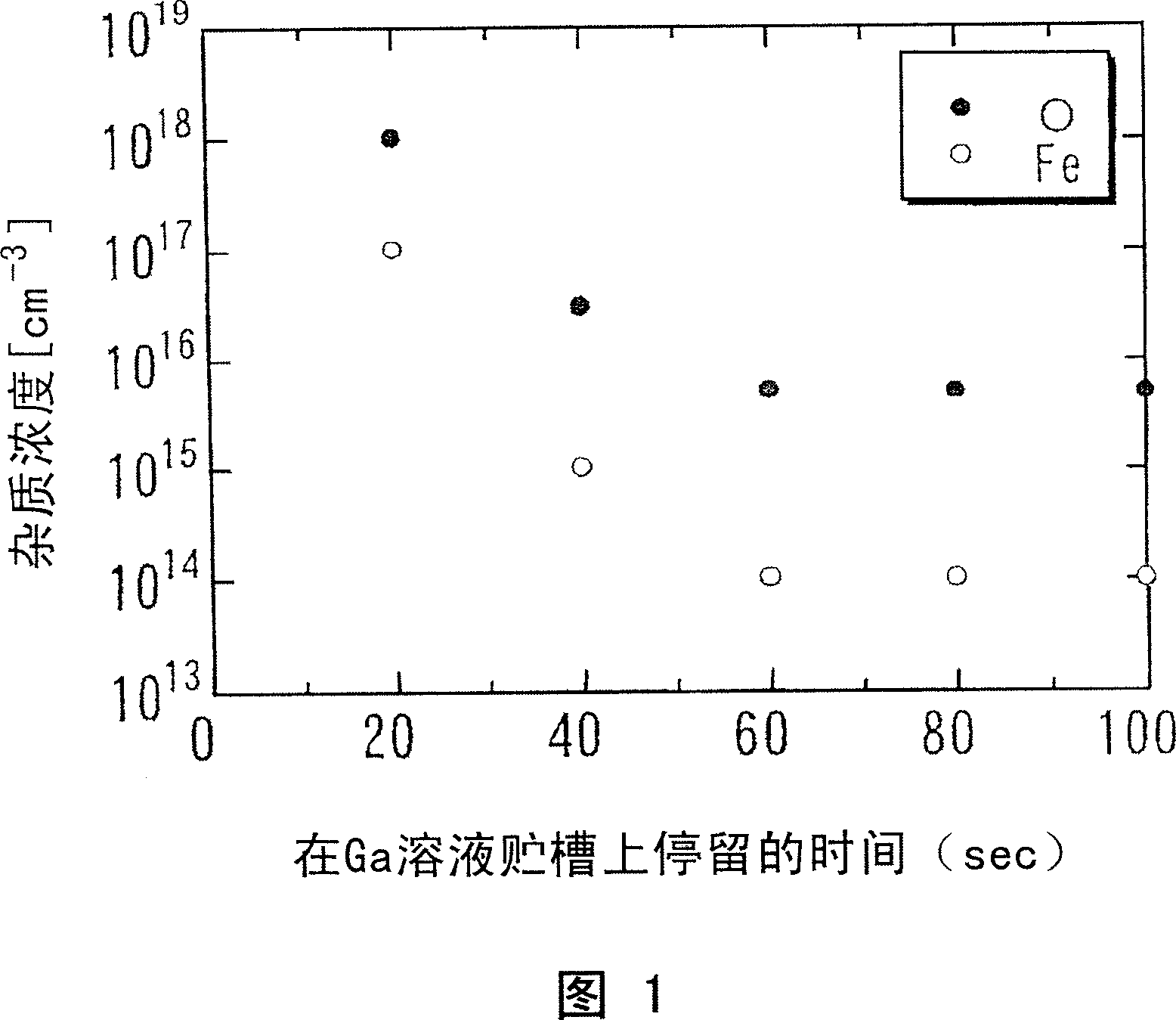

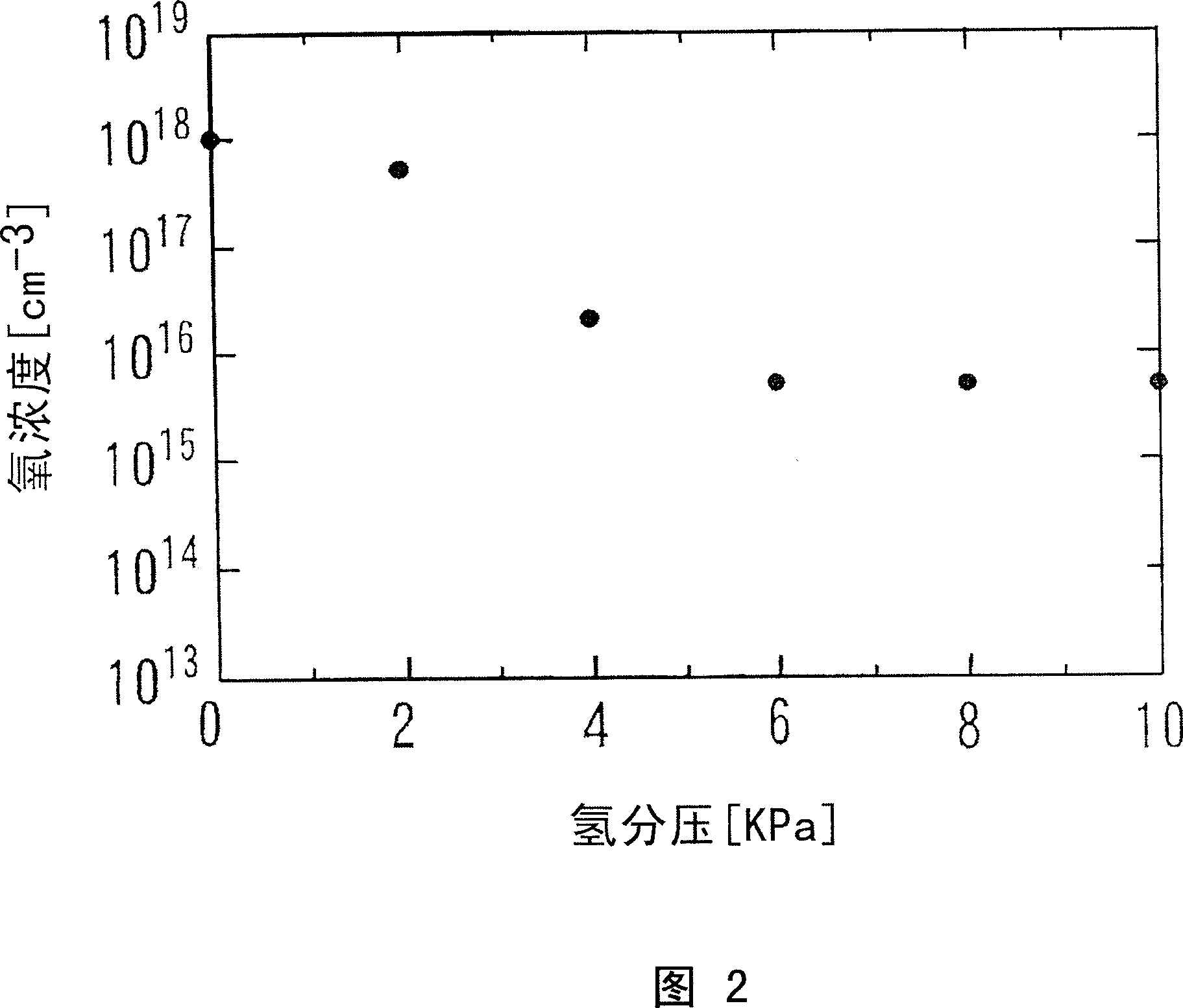

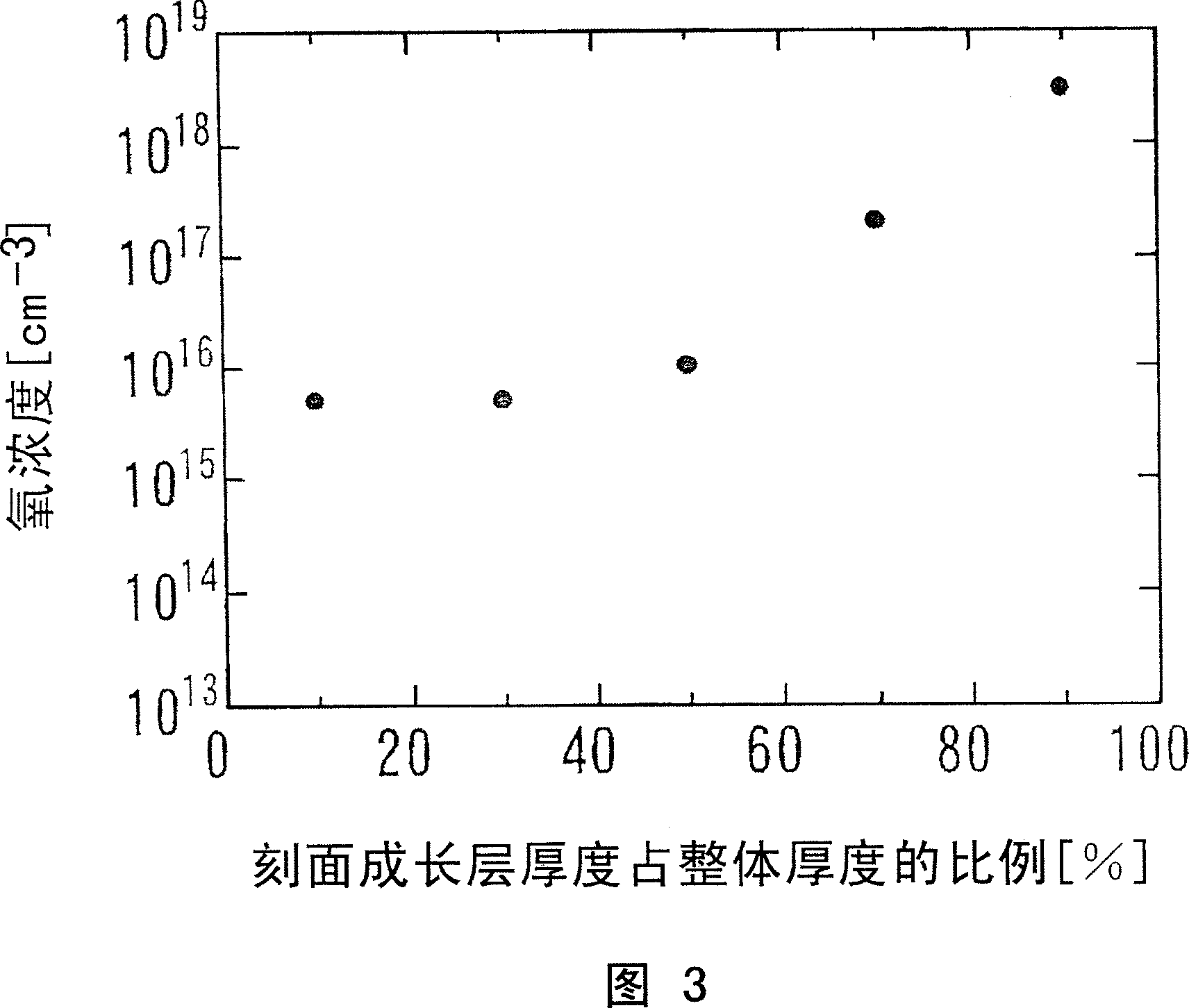

ActiveCN1960014AHigh transparencyImprove reliabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogenTotal thickness

The present invention provides a nitride-based semiconductor substrate having a small light absorption coefficient and high transparency, and capable of securing sufficient electroconductivity, and its manufacture method. After forming a GaN film 12 and a Ti film 13 on a sapphire substrate 11, the substrate is heated in a mixed atmosphere of a hydrogen gas and an ammonia gas to convert the Ti film into a porous TiN thin film 14, then a facet-grown GaN 15 is formed on the porous TiN thin film 14, the GaN crystal is grown so that the thickness of GaN layer in the initial growth stage growing while forming facet faces other than c face becomes less than 30% of total thickness of the finally grown GaN layer to obtain a GaN thick film 17, and peeling the GaN thich film from the sapphire substrate 11 through voids 16.

Owner:SUMITOMO CHEM CO LTD

Spaying method for large-area double-sided and fluorine-doped tin oxide transparent conductive film

InactiveCN102372442AOvercome serious pollution problemsCost-effectiveTin thin filmsMaterials science

The invention discloses a spraying method for a large-area double-sided and fluorine-doped tin oxide transparent conductive film. In the spraying method, a large amount of fog drops containing a fluorine-doped tin oxide precursor spraying liquid are sprayed into a coating chamber by adopting a spraying pyrolysis preparation technology; the fog drops are driven by an exhaust fan to regularly and directionally move; under the action of high temperature, the fog drops are subjected to solvent volatilization, a thermal decompose reaction of solute and the like and then uniformly form nucleuses and grow on the front side and the back side of a vertically-arranged glass matrix to form the fluorine-doped tin oxide film; residual waste gas is exhausted from an exhaust system; and finally, the prepared double-sided and fluorine-doped tin oxide film is cooled under strong wind to finish the preparation process of the film. The double-sided and fluorine-doped tin oxide film prepared by the method has the advantages of low cost, small pollution to a film surface, high transmissivity of visible light and infrared reflectivity and favorable conduction performance; meanwhile, since the spraying pyrolysis preparation technology is adopted, the process is simple and feasible, the preparation efficiency of the film is high and the film can be prepared in double sides and a large area.

Owner:XIAN UNIV OF TECH

Technique for magnetron sputtering TiN film on magnesium alloy surface

InactiveCN101386976AUniform thicknessHigh purityVacuum evaporation coatingSputtering coatingWear resistanceProcess conditions

The invention discloses a process for magnetron sputtering of a TiN thin-film on the surface of a magnesium alloy. The process comprises the steps of treating before sputtering, arranging a substrate and sputtering to form a film. Compared with the prior art, the process realizes the purpose of preparing the TiN thin-film on the surface of the magnesium alloy through magnetron sputtering process, and the TiN thin-film with the thickness between 0.2 and 6 mu m can be prepared under the groped processing condition, and the obtained thin-film is high in purity, good in compactness and good combining force with the substrate; the film thickness can be controlled and the thin-film with uniform thickness can be achieved in a large area of the substrate; and neutral salt spray corrosion to the treated magnesium alloy is not less than 24 hours, so that the wearing resistance is good.

Owner:SHANGHAI UNIV OF ENG SCI

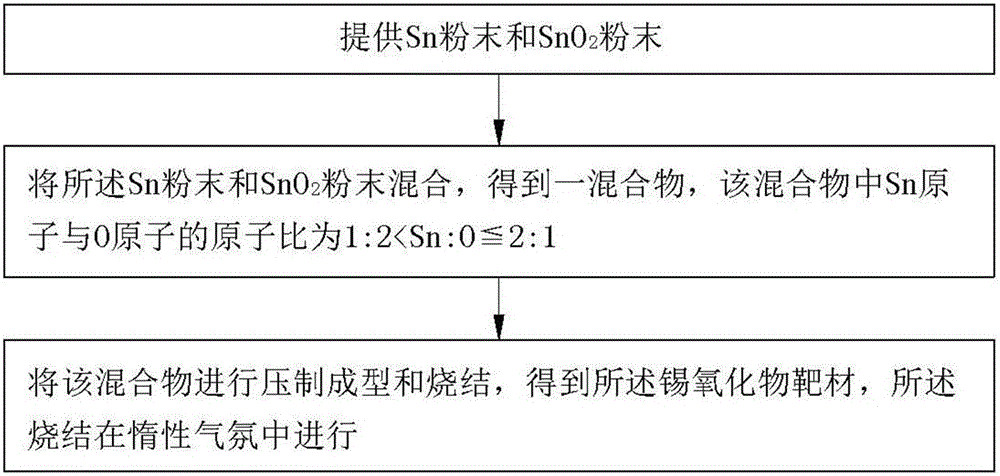

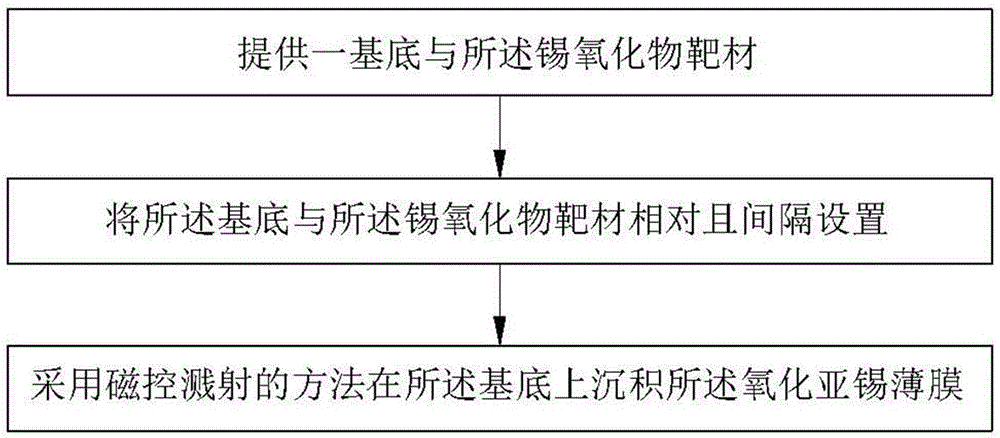

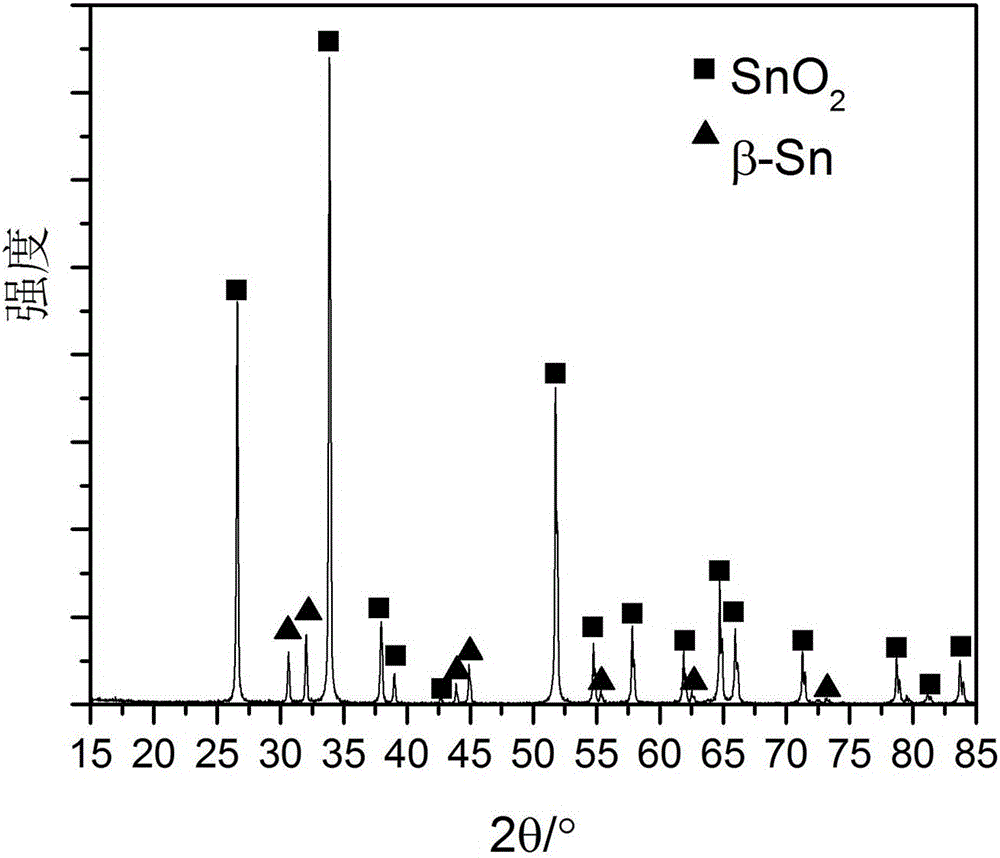

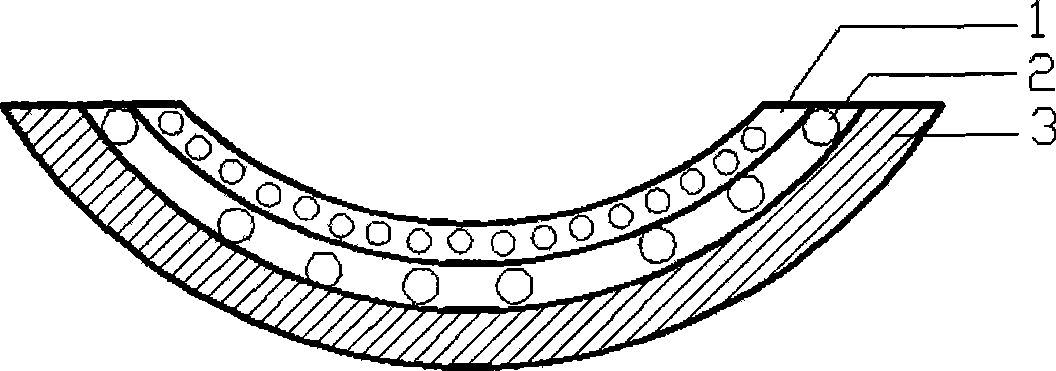

Preparation method for stannous oxide thin film

InactiveCN106206245APrecise control of ingredientsIngredient ControlElectric discharge tubesVacuum evaporation coatingSTANNOUS OXIDEMaterials science

Disclosed is a preparation method for a stannous oxide thin film. The preparation method comprises the steps of providing a substrate and a tin oxide target, wherein the tin oxide target comprises elementary substances of Sn and SnO<2> which are uniformly mixed, and atomic ratio of Sn atoms to O atoms in the tin oxide target is greater than 1 to 2 and less than or equal to 2 to 1; enabling the substrate and the tin oxide target to be arranged oppositely at intervals; and depositing the stannous oxide thin film on the substrate by adopting a magnetron sputtering method.

Owner:TSINGHUA UNIV +1

Membrane stress control method

InactiveCN101457347AQuality is not affectedAdaptableVacuum evaporation coatingSputtering coatingMembrane stressPolymer thin films

The invention relates to a method for controlling stress of films, belonging to the thermal control field of spacecrafts. The method employs a magnetic-control sputtering film deposition technique to deposit a tin film and an aluminium film on a polymer film, subsequently pumps vacuum and heats so that Sn-Al alloy is formed between the tin film and the aluminium film and expansion distortion of the crystal lattice is generated to introduce reverse stress to counterbalance the existing intrinsic compressive stress, thus presenting a smooth film in microscopic view. The method can be applied to the stress control technique of micro-mechanical shutter films and flexible thermal-control films used for satellite thermal-control, has strong adaptability and wide applicability, does not affect quality of films, and has unique advantages on the stress control and wide application prospect.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Copper-zinc-tin-sulfur quaternary compound, thin film solar cell formed by same, and preparation method thereof

InactiveCN101794826ARich sourcesThe stoichiometric ratio is easy to control and adjustableFinal product manufactureSemiconductor devicesHigh pressureTin(II) sulfide

The invention discloses a copper-zinc-tin-sulfur quaternary compound, a thin film solar cell formed by the same, and a preparation method thereof. The thin film solar cell comprises a conductive glass / metal gate electrode and a metal backing electrode, and is characterized in that: a p-copper-zinc-tin-sulfur quaternary compound thin film and an n-stannic sulfide thin film which form a p-n structure are arranged between the conductive glass / metal gate electrode and the metal backing electrode. The preparation method for the copper-zinc-tin-sulfur quaternary compound comprises the following steps: mixing copper sulfide, zinc sulfide and stannous sulfide in a mole ratio of 1:0.2-0.8:0.2-0.8; adding the mixture into an appropriate amount of water and performing ball grinding for more than 1 hour; transferring the obtained mixed liquid to a high-pressure autoclave; and performing hydro-thermal treatment for more than 2 hours at the temperature of between 120 and 280 DEG C to obtain copper-zinc-tin-sulfur quaternary compound powder. The thin film solar cell prepared by the invention has the advantages of strong adhesive force, low resistance and rich raw material sources; and the preparation method has the advantages of simple preparation process, low cost and environmental friendliness.

Owner:HEFEI UNIV OF TECH

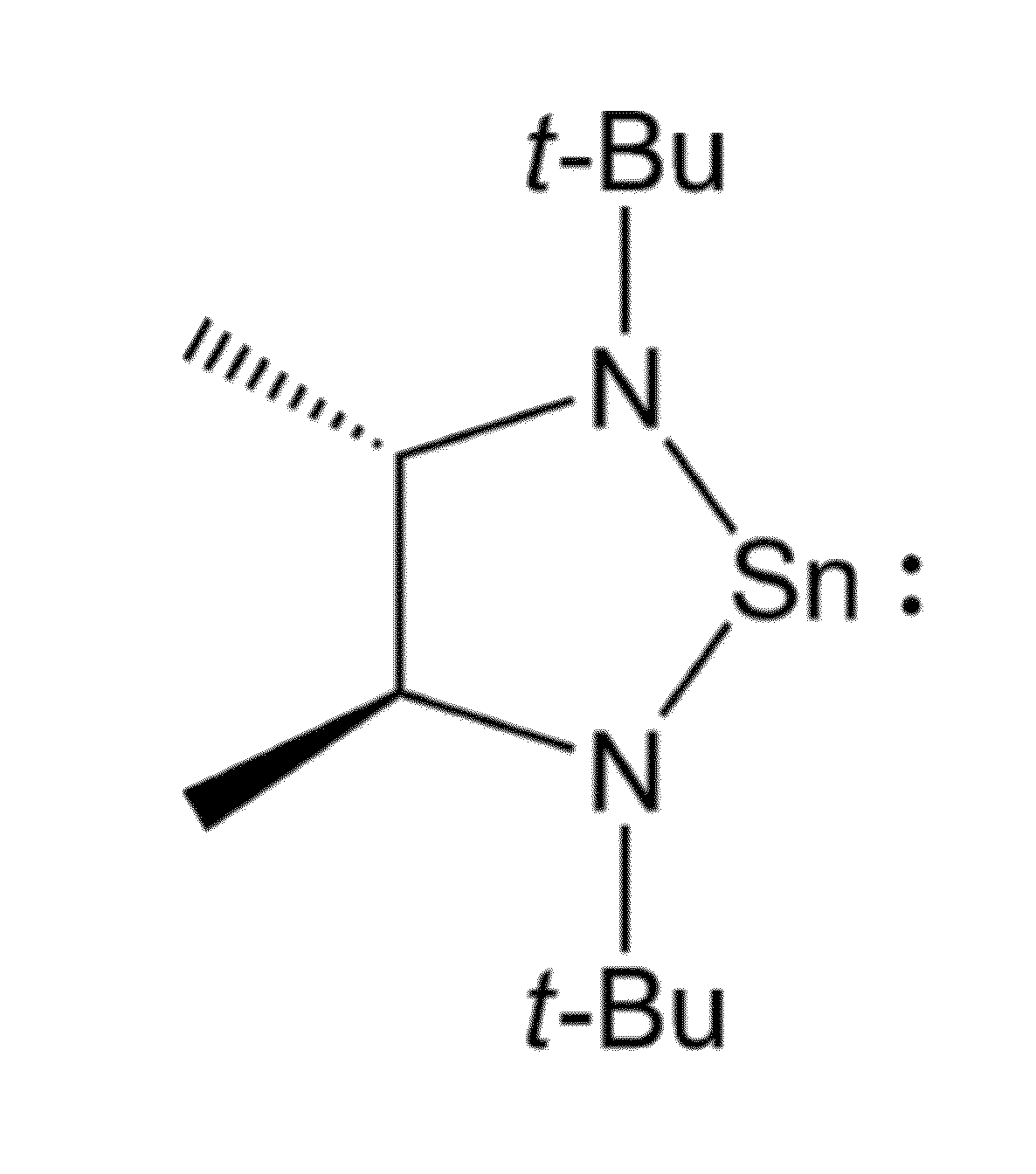

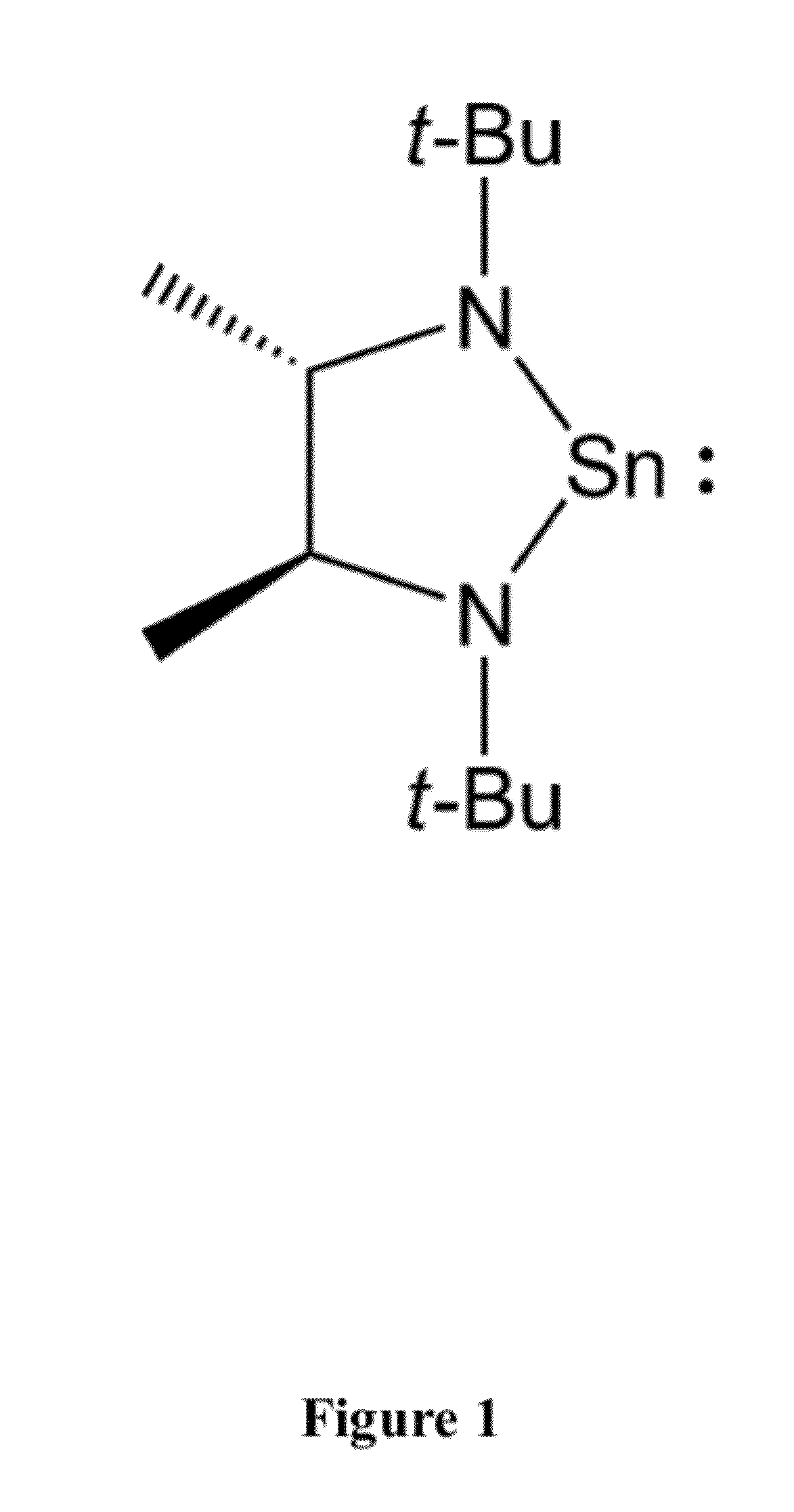

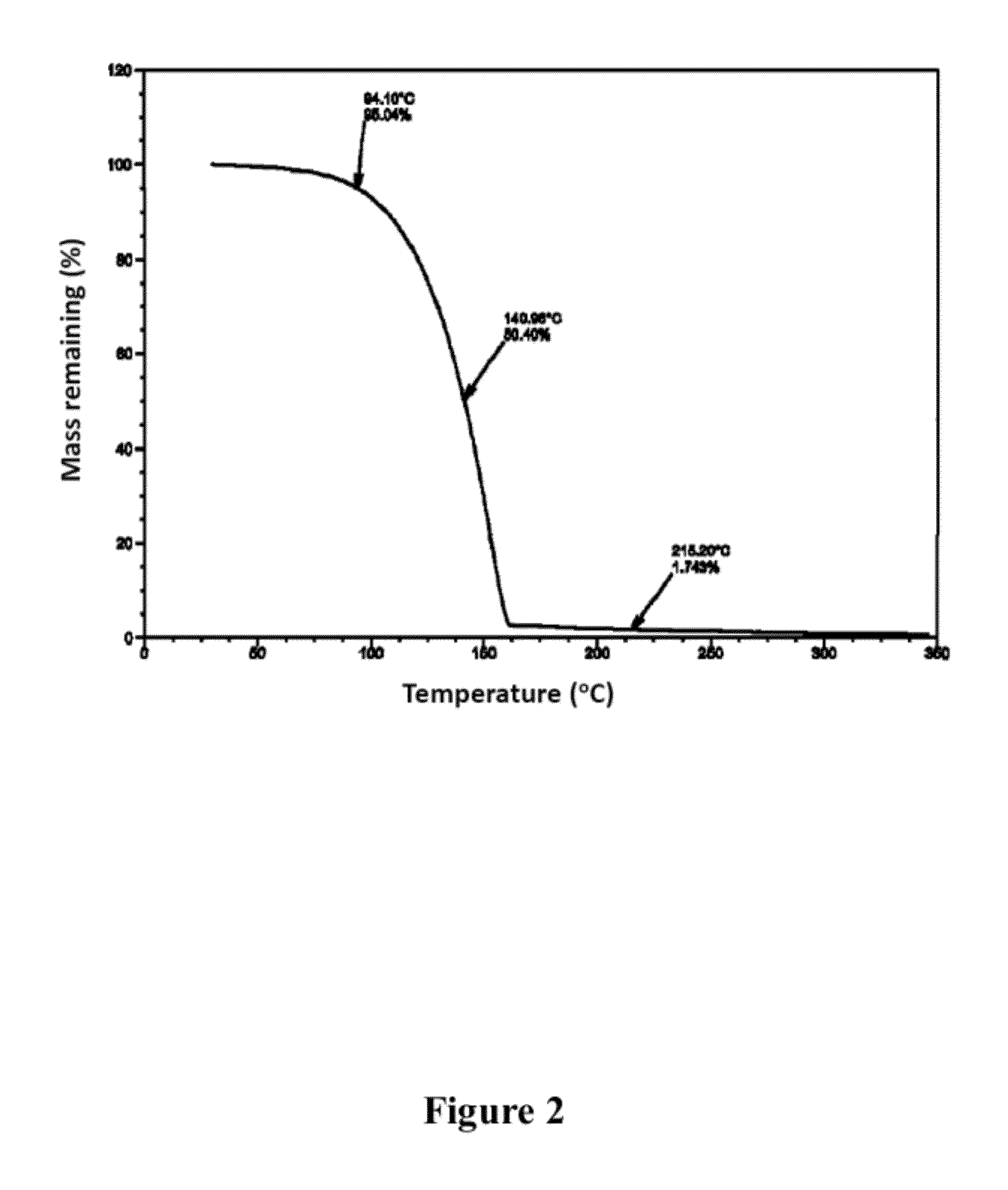

Cyclic metal amides and vapor deposition using them

ActiveUS8796483B2Flat surfaceImprove conductivityTin organic compoundsGroup 4/14 organic compounds without C-metal linkagesBorideGas phase

Novel cyclic amides containing tin or lead are disclosed. These cyclic amides can be used for atomic layer deposition or chemical vapor deposition of tin or lead as well as their oxides, sulfides, selenides, nitrides, phosphides, carbides, silicides or borides or other compounds. Tin(IV) oxide, SnO2, films were deposited by reaction of a cyclic tin amide vapor and H2O2 or NO2 as oxygen sources. The films have high purity, smoothness, transparency, electrical conductivity, density, and uniform thickness even inside very narrow holes or trenches. Deposition temperatures are low enough for thermally sensitive substrates such as plastics. Suitable applications of these films include displays, light-emitting diodes, solar cells and gas sensors. Doping SnO2 with aluminum was used to reduce its conductivity, making material suitable as the active semiconductor layer in electron multipliers or transparent transistors. Deposition using the same tin precursor and H2S deposited tin monosulfide, SnS, a material suitable for solar cells.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

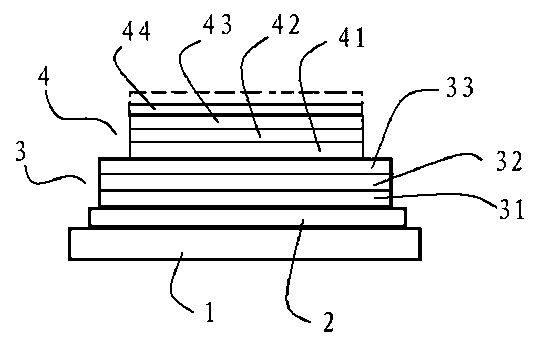

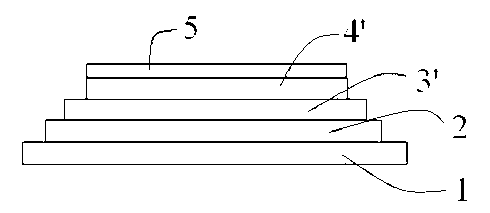

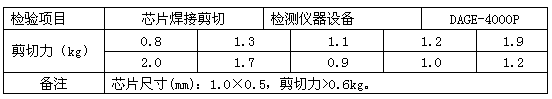

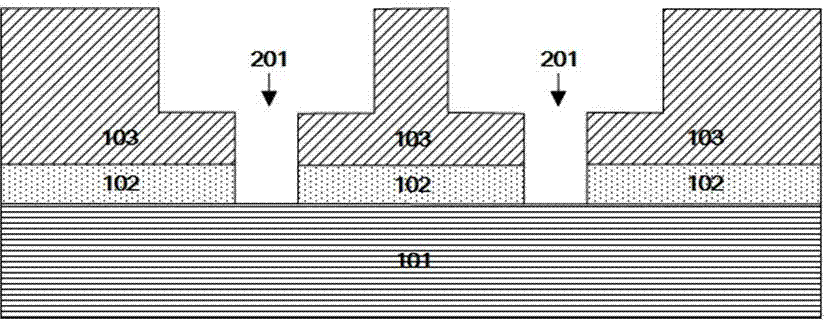

Welding substrate for electronic product and manufacturing method of welding substrate

ActiveCN103227161AGraphical lines with high precisionHigh precisionSemiconductor/solid-state device detailsSolid-state devicesAlloyGold layer

The invention discloses a welding substrate for an electronic product. The welding substrate comprises a base plate, wherein the base plate is provided with a metallized graph layer, the metallized graph layer is provided with a gold-tin film layer, a barrier layer is arranged between the gold-tin film layer and the metallized graph layer and is a single metal film layer or a composite metal film layer, and the gold-tin film layer is a gold-tin alloy layer or is of a multi-layer structure formed by alternately compounding gold layers and tin layers. With the adoption of the film substrate, the graph line accuracy is high, the surface smoothness of the film layer is good, a chip can be directly welded and located without needing to precasting solders, the installation and locating accuracy of the chip can be ensured, and the film substrate is suitable for photoelectric products of high-power LED (light-Emitting Diode) optical communication and the like. Meanwhile, according to the film substrate disclosed by the invention, the proper component proportion of gold and tin in the film substrate can be adopted according to different chips needed to be welded on the underlay film substrate, so that the welding performance of the chips is better.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

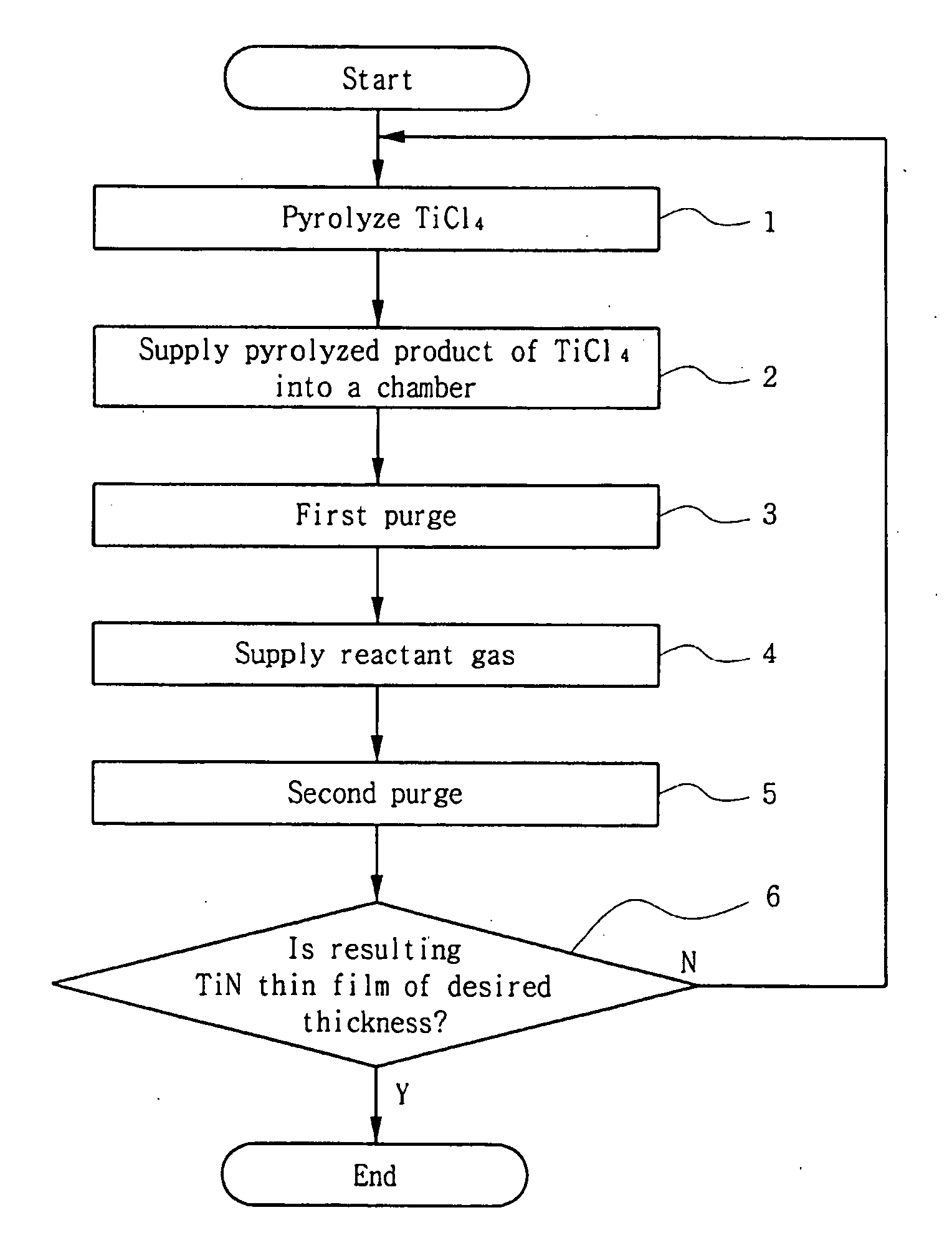

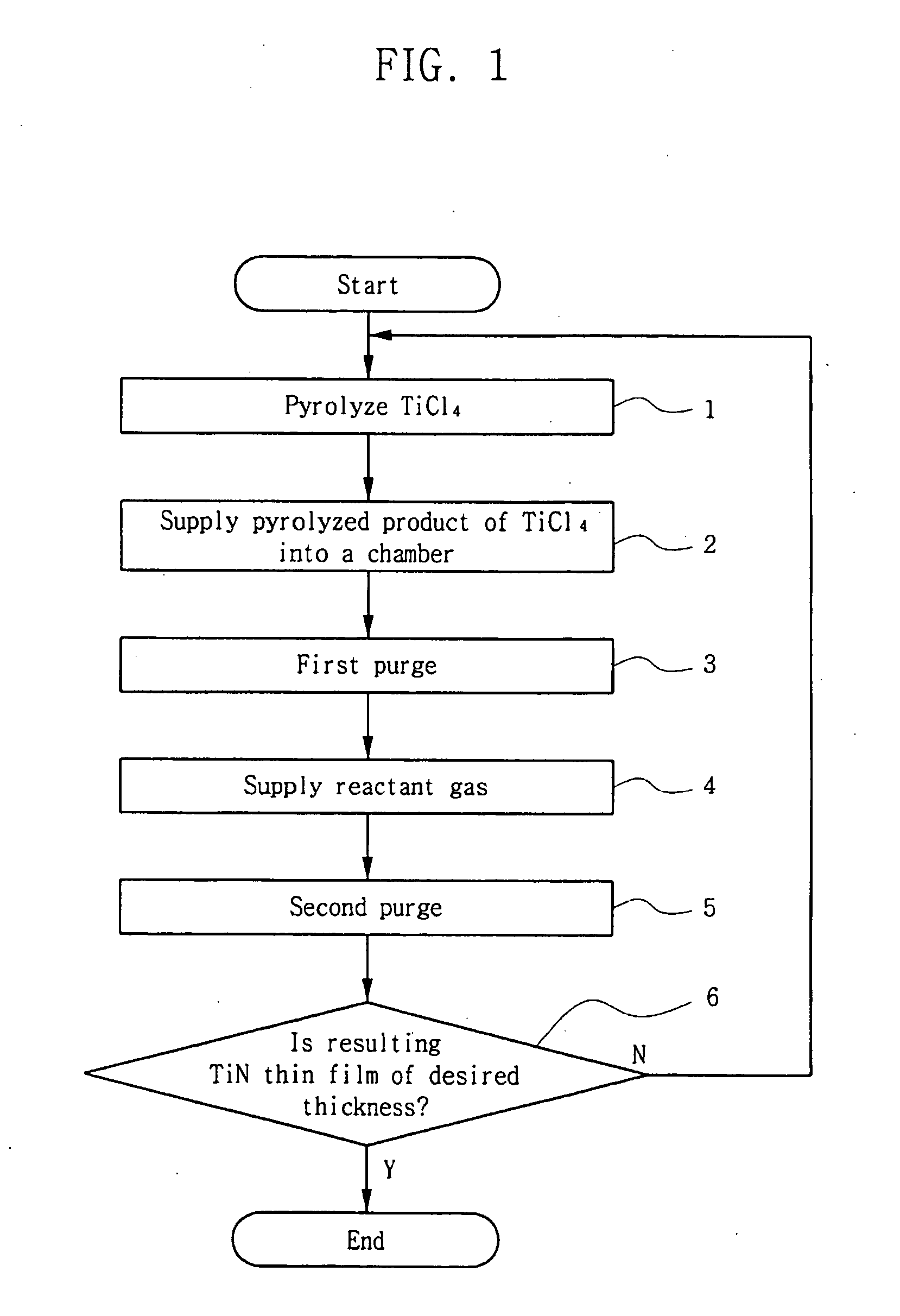

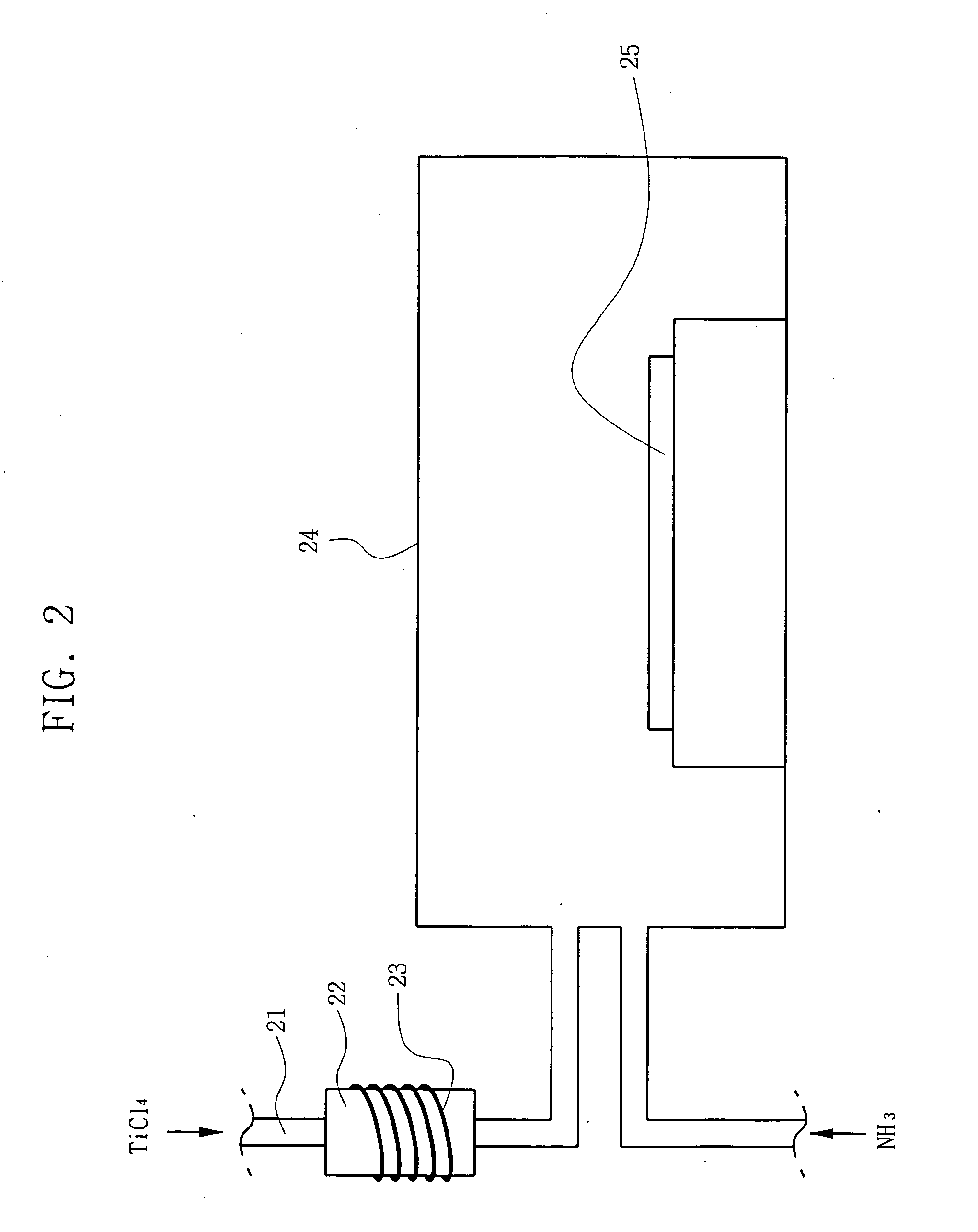

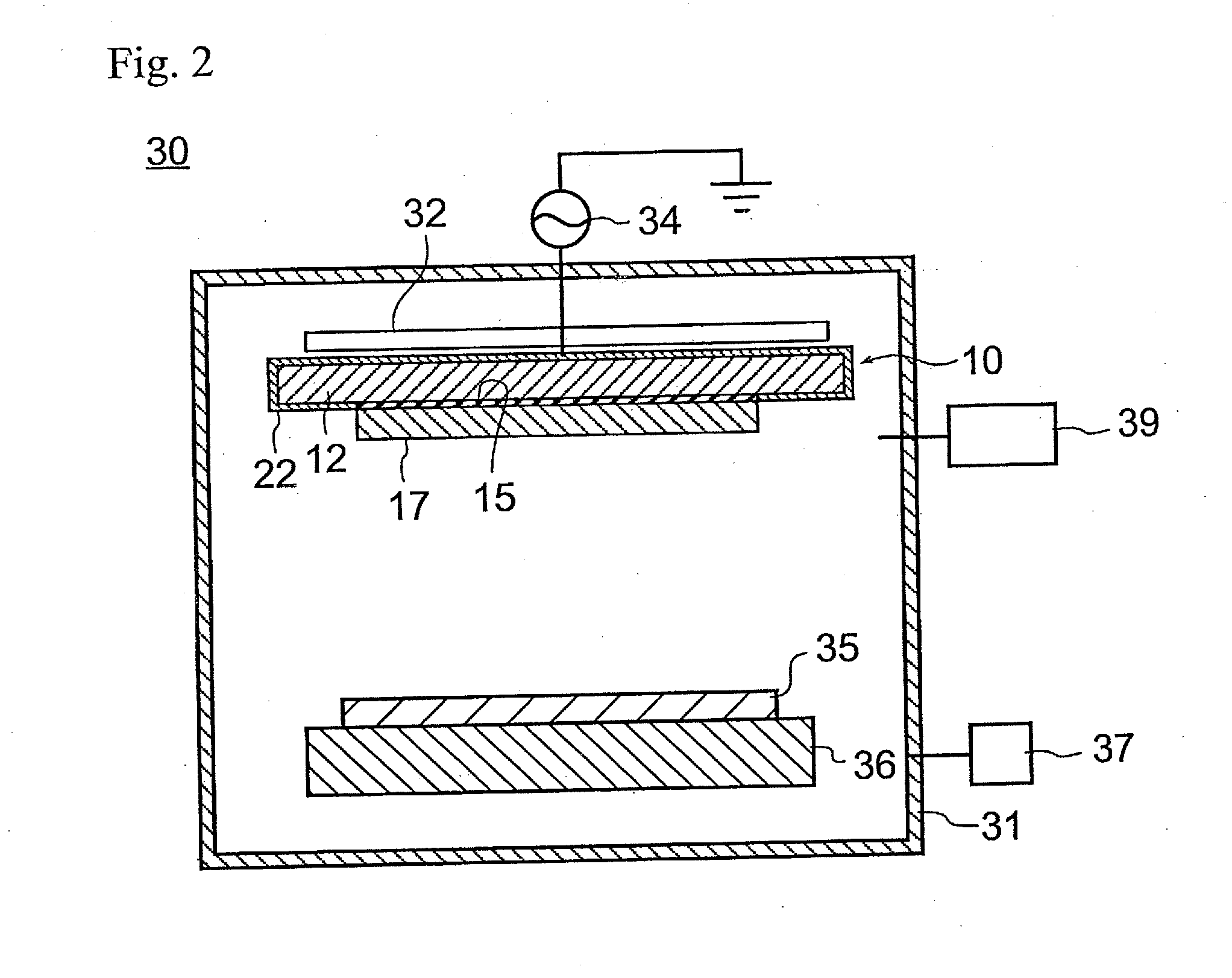

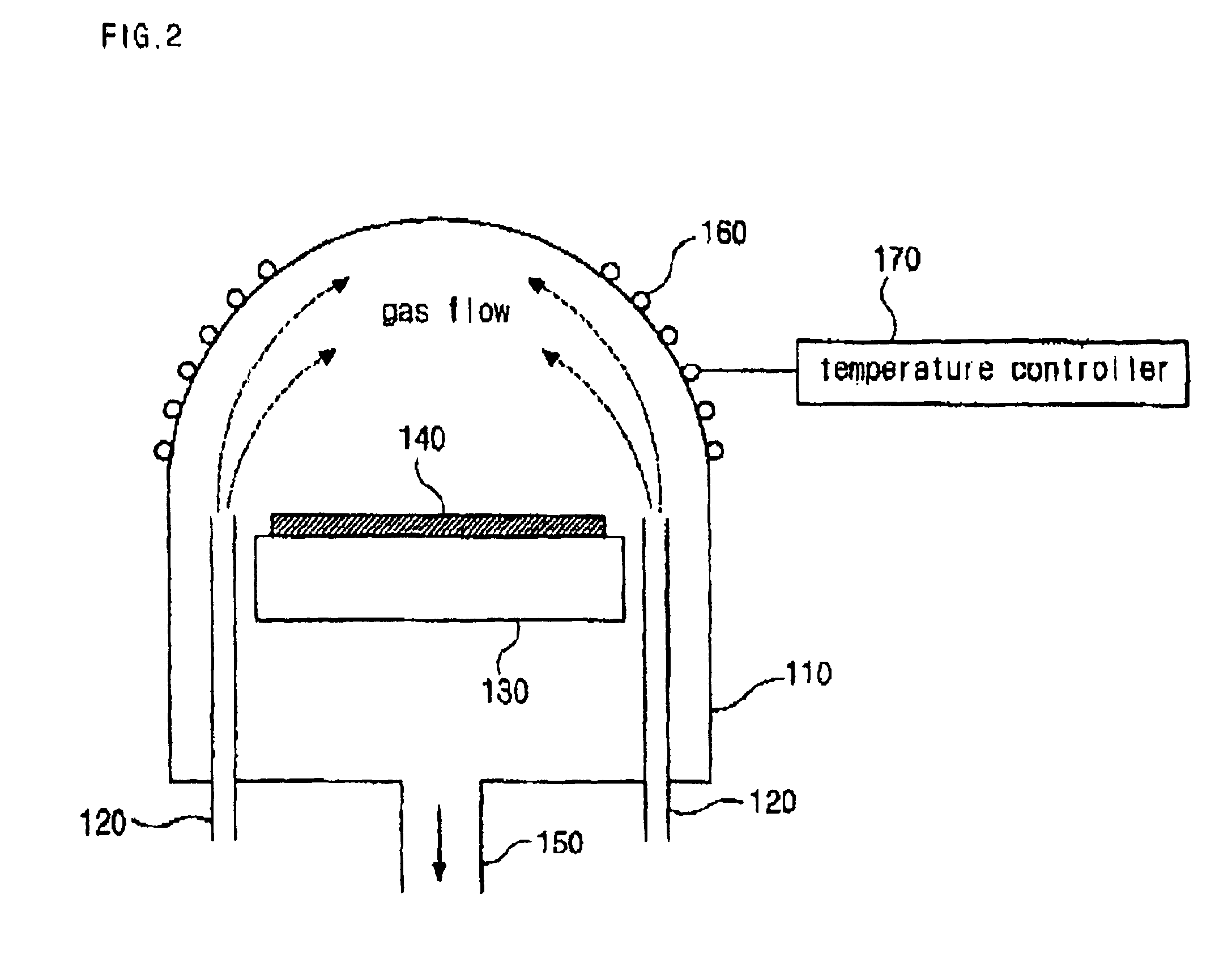

Method and apparatus of forming thin film using atomic layer deposition

InactiveUS20060024964A1Enhance ALD reactionIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTin thin filmsAtomic layer deposition

The method of forming a TiN thin film using an atomic layer deposition (ALD) method includes thermally decomposing TiCl4; introducing a pyrolyzed product of the TiCl4 into the chamber; supplying a first purge gas into the chamber; supplying a reactant gas into the chamber, thereby forming a TiN thin film; and supplying a second purge gas into the chamber. The apparatus of forming a TiN thin film includes a gas conduit having an entrance line into which a source gas, TiCl4 is introduced; a heater installed around the gas conduit and thermally decomposing the introduced source gas, TiCl4, in advance to make a secondary source gas; and a chamber being connected to the gas conduit and having a reaction room in which the TiN thin film is formed by the reaction of the secondary source gas and NH3 as a reactant gas. Therefore, a TiN thin film growth rate can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Target device, sputtering apparatus and method for manufacturing a target device

ActiveUS20130186752A1The material is lowReduce adhesionCellsVacuum evaporation coatingTin thin filmsMaterials science

To provide a target device that can easily be reused in which the amount of gas discharge is small. The present invention is a target device including a backing plate and a target plate that is fixed to the backing plate with a metal brazing material, in which a protective film made of a TiN thin film in which a proportion of (111) plane is at a maximum is formed on an exposed portion of the backing plate. The discharge amount of gas is small, and the brazing material that adheres when fixing the target plate can be easily peeled off.

Owner:ULVAC INC

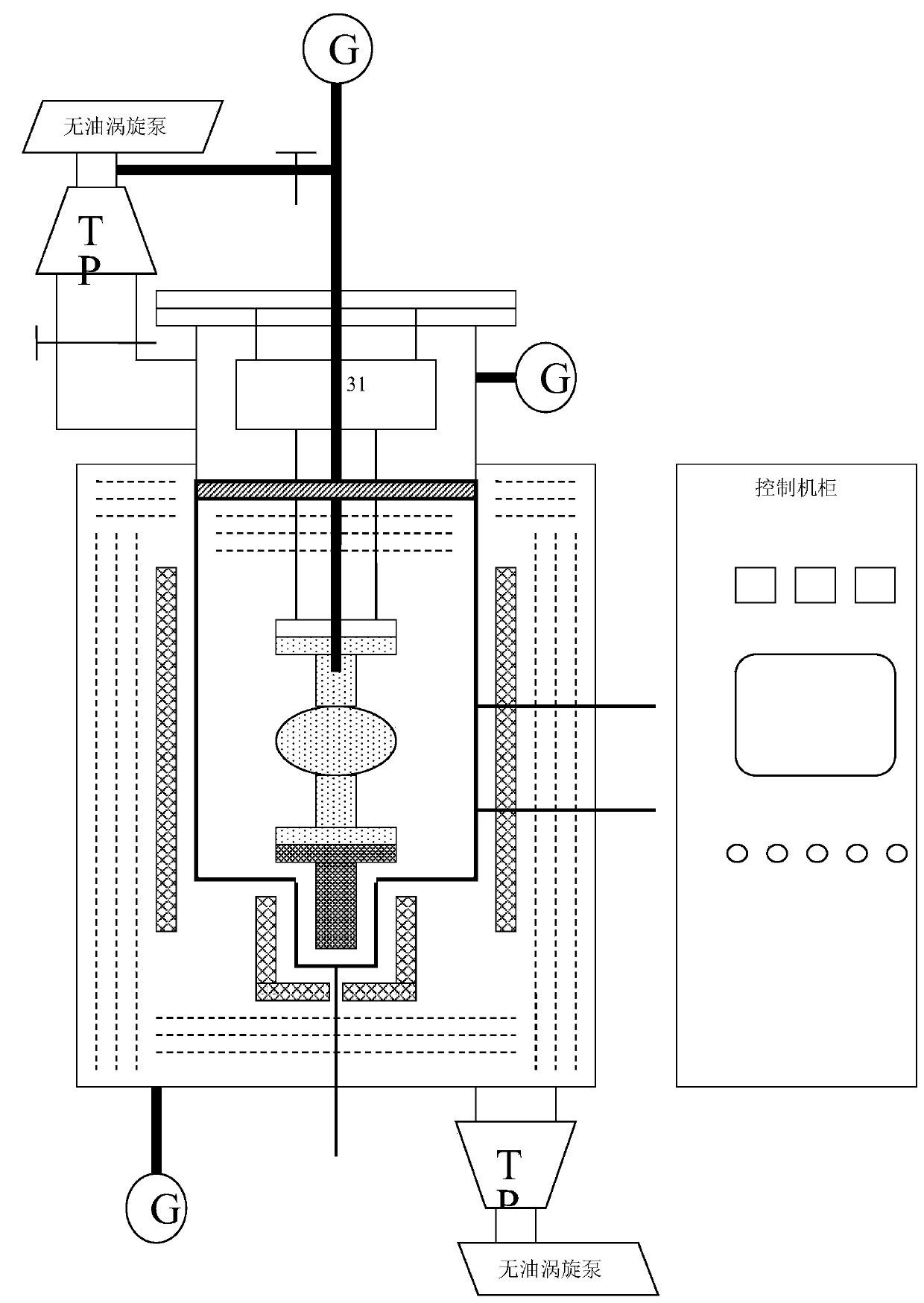

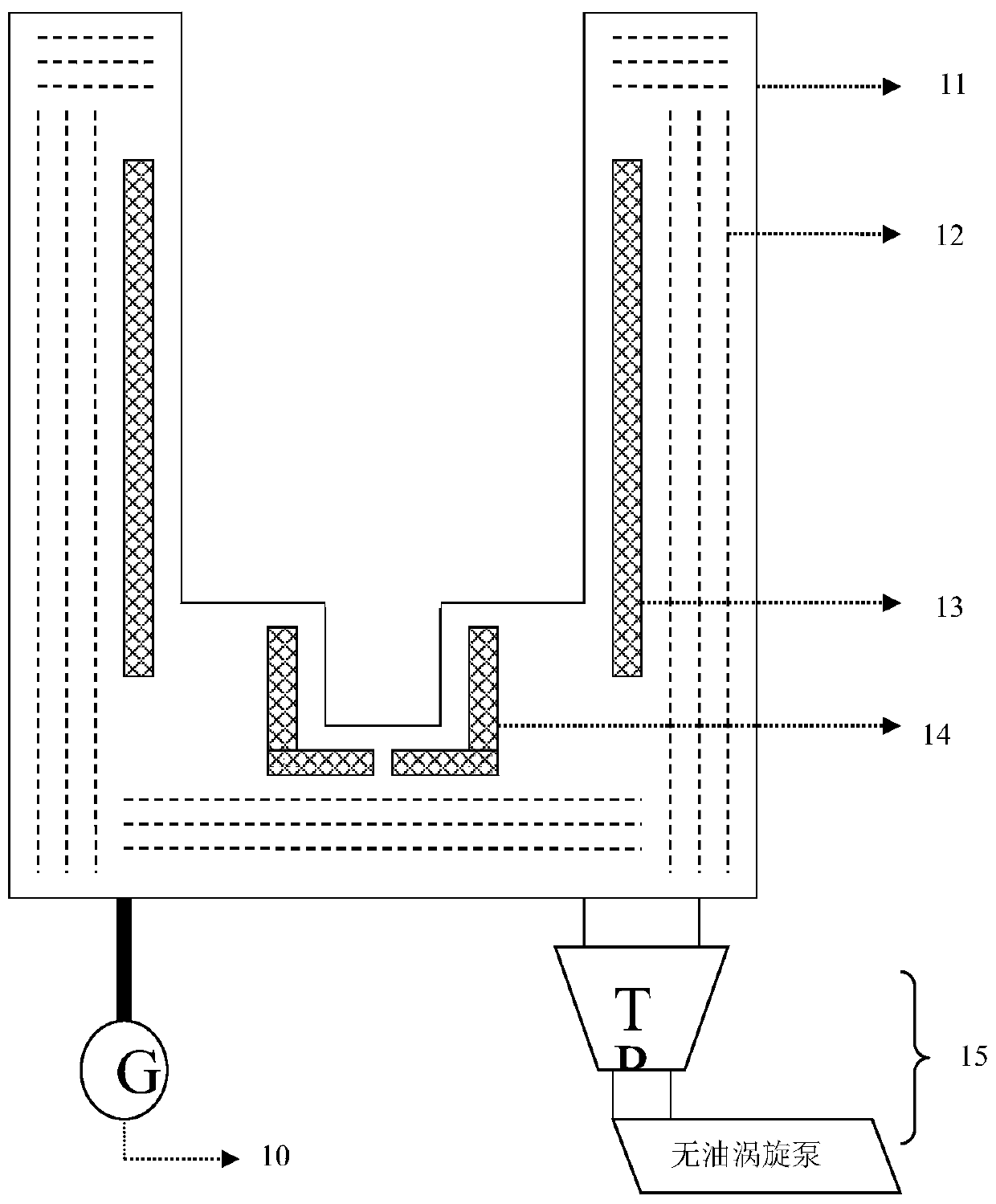

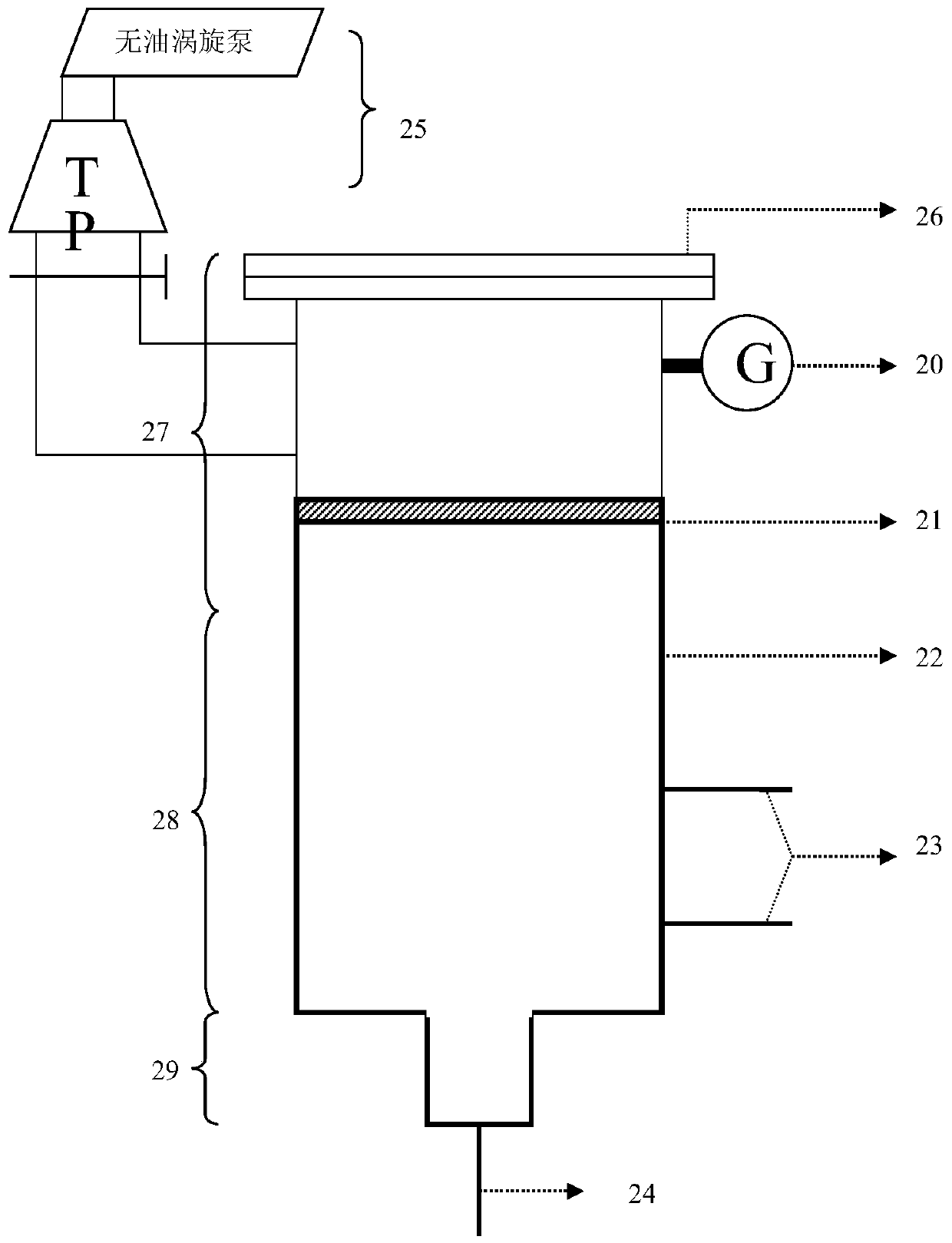

Method for plating triniobium stannide film on inner surface of pure niobium cavity and vacuum furnace

ActiveCN111074208ASolve the brittleSolve usabilityVacuum evaporation coatingSputtering coatingNiobiumCrucible

The invention discloses a method for plating a triniobium stannide film on the inner surface of a pure niobium cavity and a vacuum furnace. The vacuum furnace is characterized by including a double vacuum structure consisting of an external vacuum system and an internal vacuum system, wherein the external vacuum system is internally provided with a heater heating the internal vacuum system and a temperature measuring probe used for measuring the temperature of a set area of the internal vacuum system; and the internal vacuum system is internally provided with a niobium cavity hoisting device,the rotating hoisting device is used for connecting the niobium cavity to be plated with a film and a stannum crucible, and the niobium cavity is rotated circularly through a transmission mechanism. Through the vacuum furnace, the pure niobium cavity can be internally plated with a layer of pure, completely-covering and evenly-distributed triniobium stannide film, and thus application of triniobium stannide to a superconducting cavity is achieved.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI +1

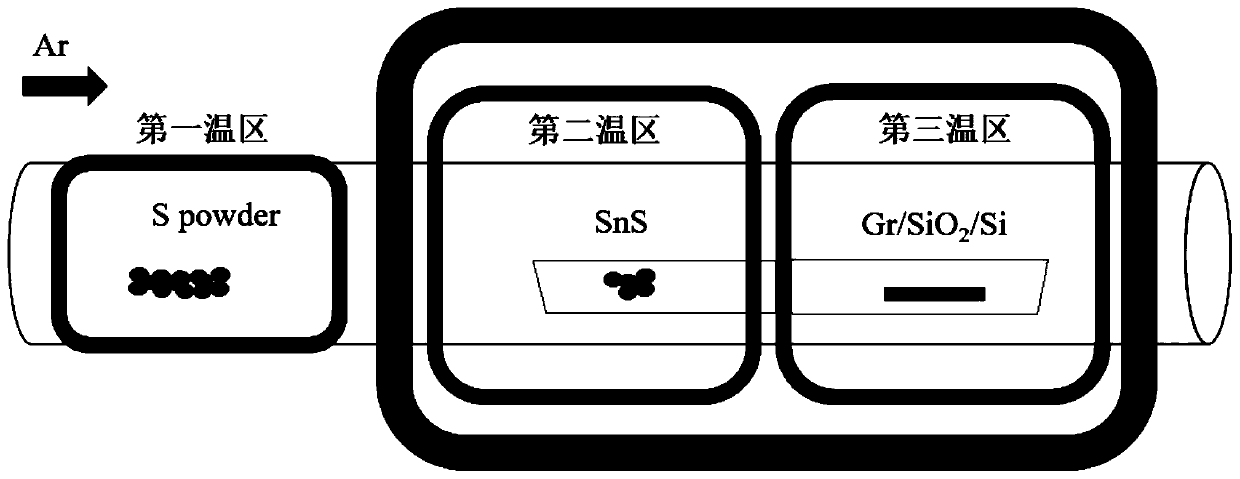

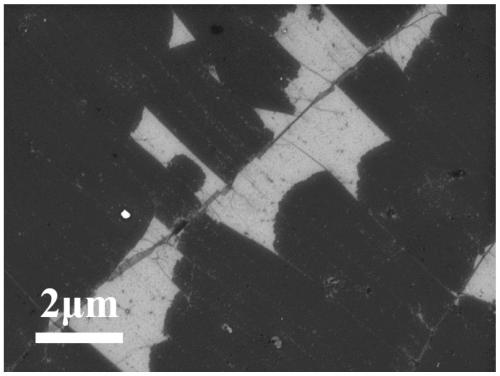

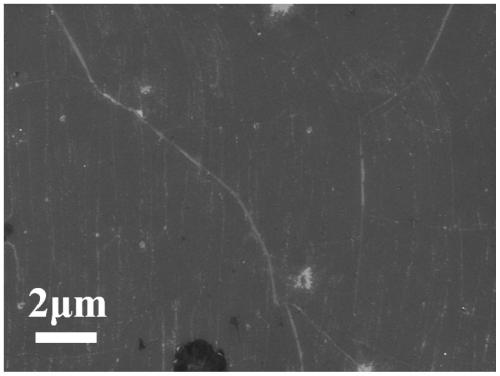

Single-layer tin disulfide thin film and two-dimensional heterojunction and preparation method thereof

InactiveCN111106166ASmall sizeUniform thickness distributionSemiconductor devicesHeterojunctionThin membrane

The invention discloses a single-layer tin disulfide thin film and a two-dimensional heterojunction and a preparation method thereof. Stannous sulfide powder and sulfur powder are used as raw materials, a large-area single-layer tin disulfide semiconductor thin film is prepared and generated on a graphene substrate by using a chemical vapor deposition method, and a novel two-dimensional vertical heterostructure is constructed. The single-layer tin disulfide film prepared by the method is flat in structure and uniform in thickness, and the size can be effectively controlled by changing processconditions; the two-dimensional heterojunction is formed by the single-layer tin disulfide thin film and a graphene film with the single atomic layer thickness, so that the structural characteristicsof a material system can be improved, and the single-layer tin disulfide thin film can be applied to a micro-nano optoelectronic device.

Owner:XIAMEN UNIV

Solar cell structure and preparing method thereof

InactiveCN101257054AImprove mobilityIncrease short circuit currentFinal product manufactureSolid-state devicesSolubilityIndium

A solar cell structure and manufacture method thereof, using C60(OH)24 as n type material of hetero-junction, the conjugate conducting polymer PEDOT being p type material of hetero-junction, the two materials are polymerized into blended alloplasm tunica conjunctiva with single wall carbon nano-tube as anodic on the glass plate with indium oxide stannous thin film, aluminum film is as cathode; the method for manufacturing is: first the C60 with 99.5% purity is added into the mix solution of concentrated nitric acid and concentrated sulfuric acid for activating under ultrasonic oscillation, then NaOH water solution is added for reaching pH 7, evaporating solvent to obtain water-solubility crystal C60(OH)24; a glass plate coating with indium oxide tin thin film is cleaned in acetone by ultrasonic;single wall nano carbon tube is purified by the oxidation process of concentrated nitric acid and concentrated sulfuric acid; the water solution made by C60(OH)24, PEDOT and single wall carbon nano-tube under ultrasonic oscillation is coated on the indium oxide tin thin film, drying 45 minutes under 120 EDG C forming blended alloplasm tunica conjunctiva.

Owner:宁波市鑫友光伏有限公司

Method for manufacturing thin film solar cell ID (identification) by using laser edge deletion device

InactiveCN102237442AImprove performanceBeautiful appearanceFinal product manufactureLaser beam welding apparatusSimple Organic CompoundsIndium

The invention relates to a method for manufacturing thin film solar cell ID (identification) by using a laser edge deletion device, belonging to the technical field of thin film solar cells. The technical scheme of the invention comprises the following steps: carrying out edge insulation on the cell by using the laser edge deletion device; carrying out edge insulation in designed regions in advance; carrying out ID preparation according to a designedly reserved region, wherein the reserved region is outside an effective region of the thin film solar cell and can not affect the performances and appearance of the cell; and using the laser edge deletion device to prepare the ID in the region reserved in advance. The method provided by the invention is compatible with an existing production preparation process of the thin film solar cell without using a device specially used for ID marking, thus the input cost of devices can be greatly reduced; the method is applied to a series of silicon-based thin film cells, a series of cadmium telluride thin film cells, a series of copper indium gallium tin thin film cells or organic compound material thin film cells and the like; and the method has the simple manufacturing process, is easy to operate and control and can be utilized to effectively improve the work efficiency.

Owner:BAODING TIANWEI GRP CO LTD +1

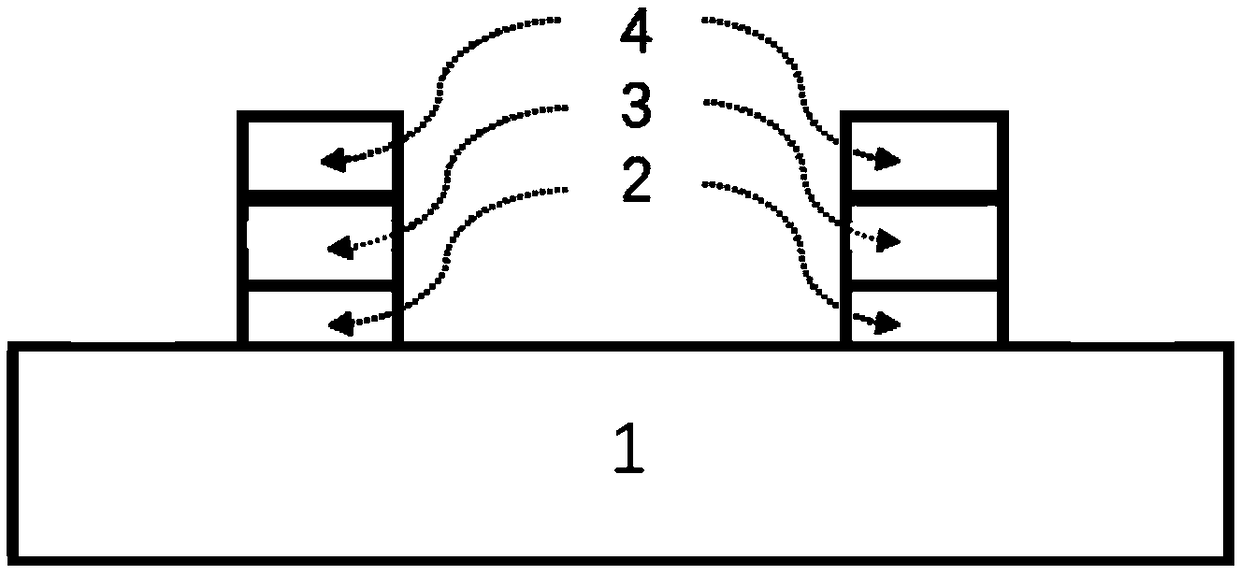

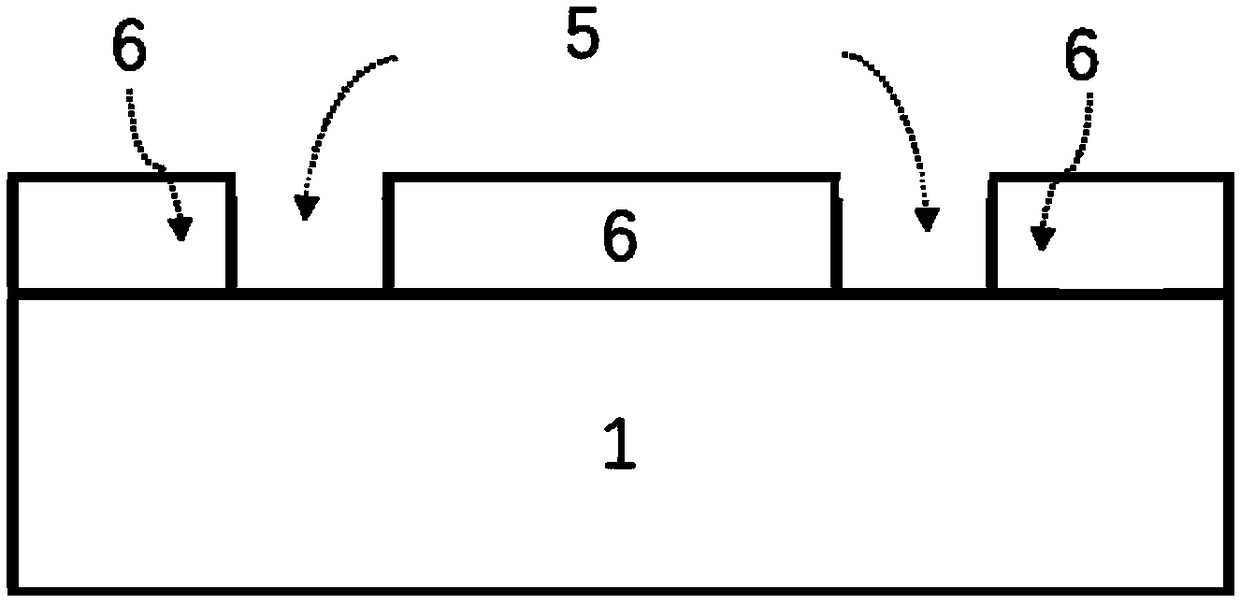

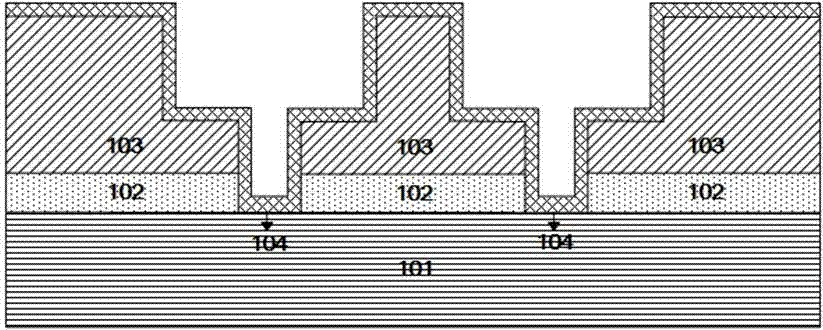

Preparation method of GaN-based HEMT gold-free ohmic contact electrode based on TiN

ActiveCN109037050AReduce manufacturing costLow process temperatureVacuum evaporation coatingSputtering coatingOhmic contactAlloy

The invention discloses a preparation method of a GaN-based HEMT gold-free ohmic contact electrode based on TiN. The method comprises the following steps: photolithography forming a source-drain electrode pattern; Surface treatment of GaN-based epitaxy at source-drain electrode pattern; Depositing a metal layer without a gold source drain electrode, and stripping to form a source drain electrode;GaN-based HEMT deposited with source and drain electrodes was annealed to form gold-free source and drain ohmic contact electrodes. A low-temperature magnetron sputter TiN film is adopted, TiN was recrystallized and reacted with other electrode metals by post-annealing alloys, The conductivity of low-temperature sputtered TiN is greatly improved and the process of preparing TiN thin film at high temperature is avoided, which is beneficial to reduce the process temperature, simplify the process flow, improve the process compatibility and reduce the manufacturing cost of a GaN-based HEMT device.

Owner:ZHONGSHAN INST OF MODERN IND TECH SOUTH CHINA UNIV OF TECH +1

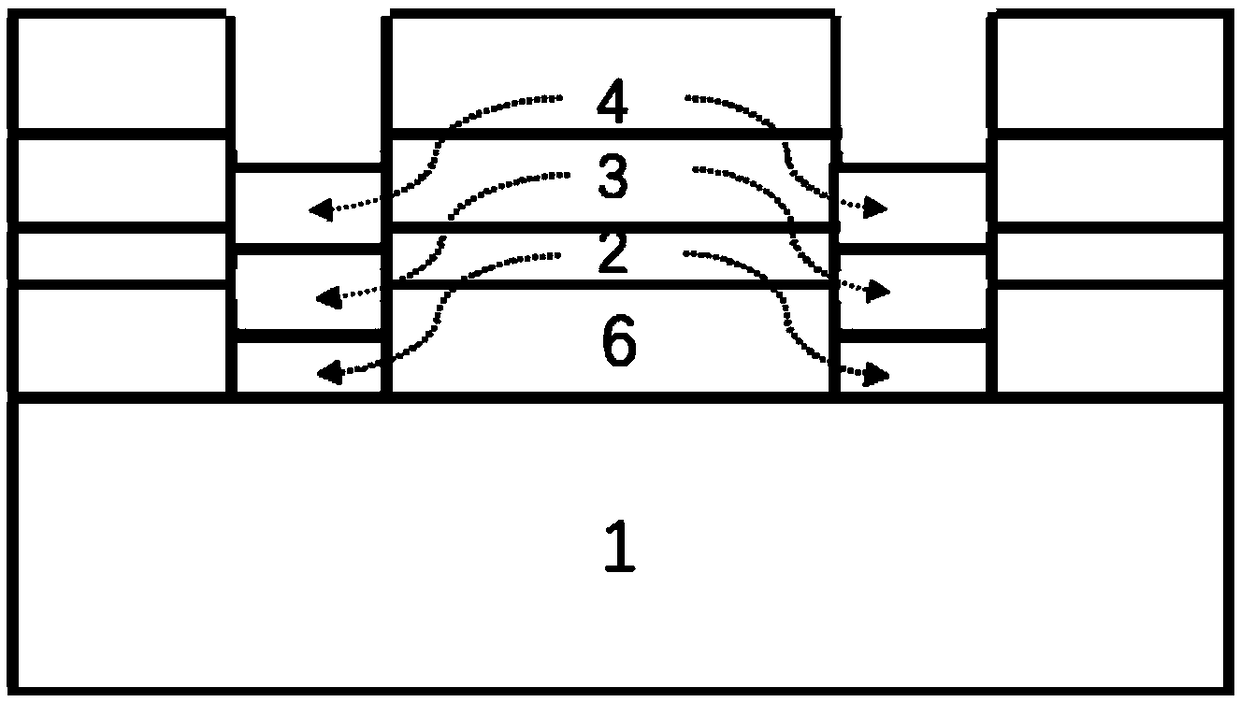

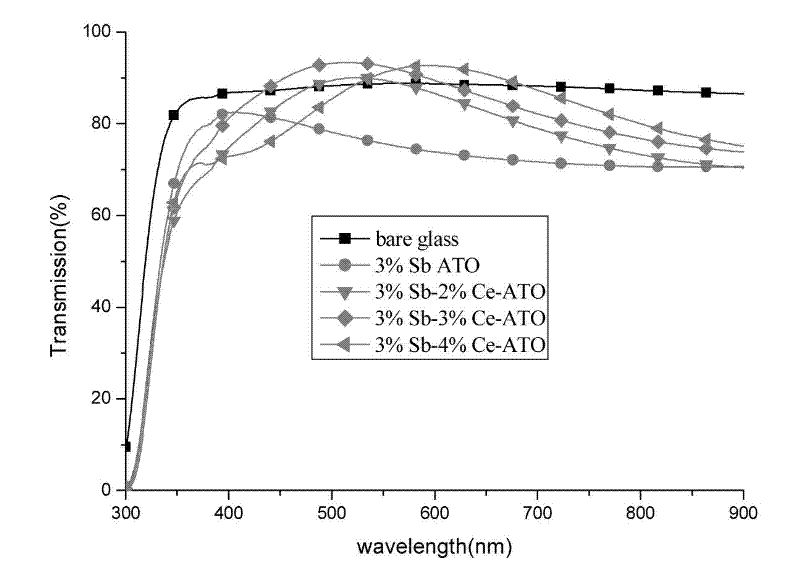

Cerium-antimony codoped tin oxide thin film, powder and preparation method thereof

The invention discloses a cerium-antimony codoped tin oxide thin film and a preparation method thereof, and the thin film comprises cerium oxide, antimony oxide and tin oxide, wherein the ratio of the amount-of-substance ratio of cerium element to antimony element to tin element is 1-4: 1-4: 100. The invention further discloses cerium-antimony codoped tin oxide powder and the preparation method thereof, and the powder comprises the cerium oxide, the antimony oxide and the tin oxide, wherein the amount-of-substance ratio of the cerium element to the antimony element to the tin element is 1-4: 1-4: 100. The preparation method of the cerium-antimony codoped tin oxide thin film / powder, disclosed by the invention is simple, low in cost, simple in production process and suitable for production by various enterprises; and the prepared cerium-antimony codoped tin oxide thin film is plated on a white glass base material, the shielding efficiency of obtained film-coated glass at 300-380nm is above 60%, and the transmittance at 380-780nm is 85-92% (used white glass is only 85%).

Owner:广东泰祥建材实业发展有限公司 +1

Copper-connection structure and manufacturing method of copper-connection structure

InactiveCN103681478AQuality improvementImprove performanceSemiconductor/solid-state device detailsSolid-state devicesHigh densityHeat stability

The invention belongs to the technical field of semiconductors, and particularly relates to a copper-connection structure and a manufacturing method of the copper-connection structure. Based on an original copper-connection structure, a double-layer Ru / TiAlN structure is used as a diffusion impervious layer / adhesion layer / seed crystal layer structure. The manufacturing method includes the particular steps that an atomic layer deposition method is adopted, a TiAlN thin film is firstly deposited on an insulating medium layer, a Ru thin film is then deposited, and finally electrocoppering is directly carried out to obtain the copper-connection structure. As Al is added in the TiAlN thin film, the amorphous TiAlN thin film can be obtained, and the Cu diffusion impervious performance better than that of a TiN thin film can be obtained. According to the copper-connection structure, the amorphous TiAlN thin film with high density is used, channels, such as crystal boundaries, for rapid diffusion do not exist, the ideal diffusion impervious performance and the ideal heat stability are provided, and a practical and reliable scheme is provided for the copper-connection technology of 22nm and smaller-than-22nm technological nodes.

Owner:FUDAN UNIV

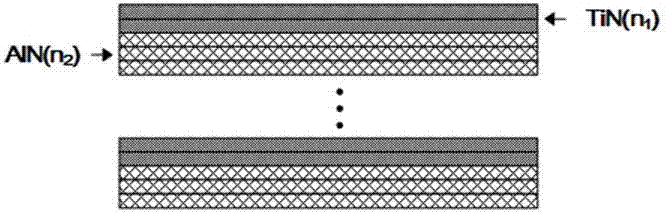

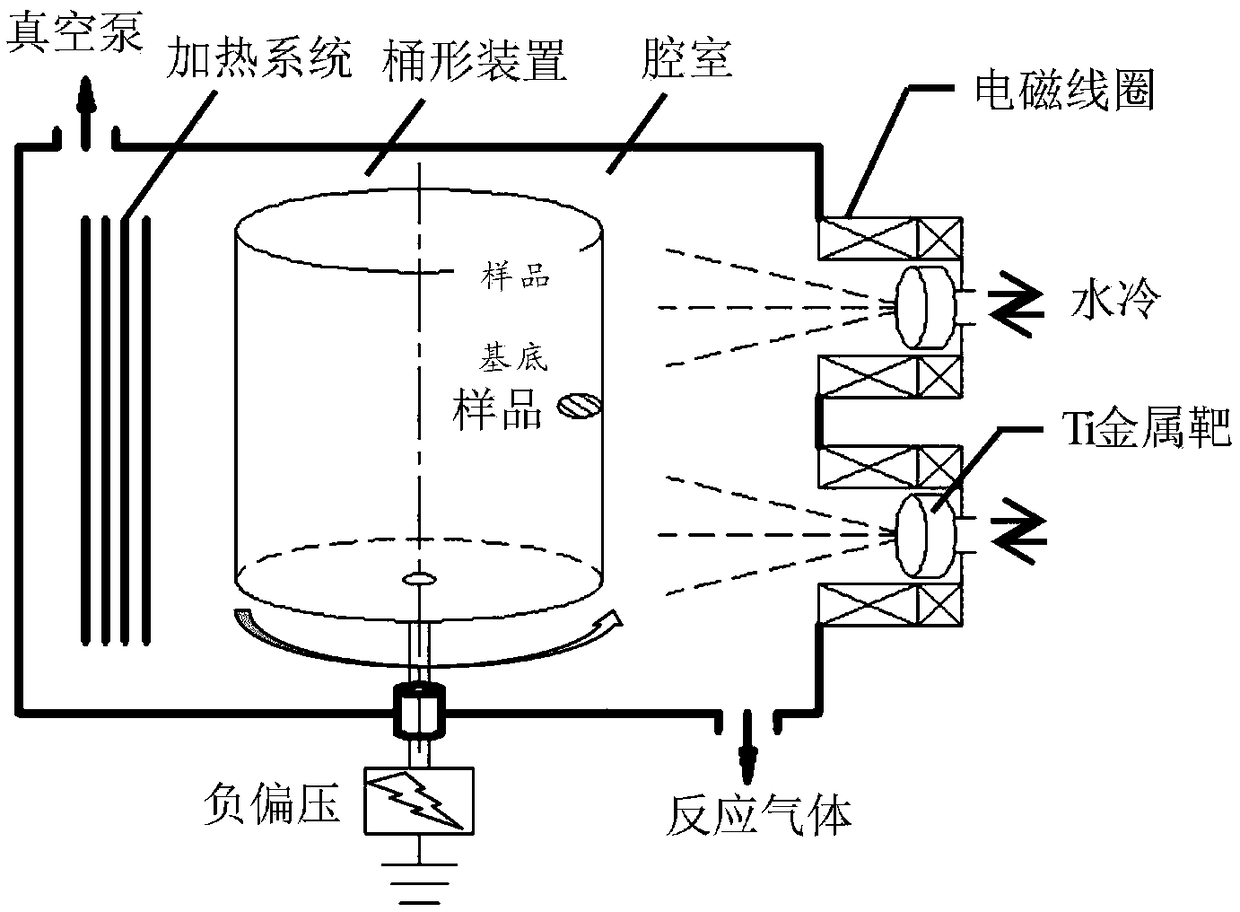

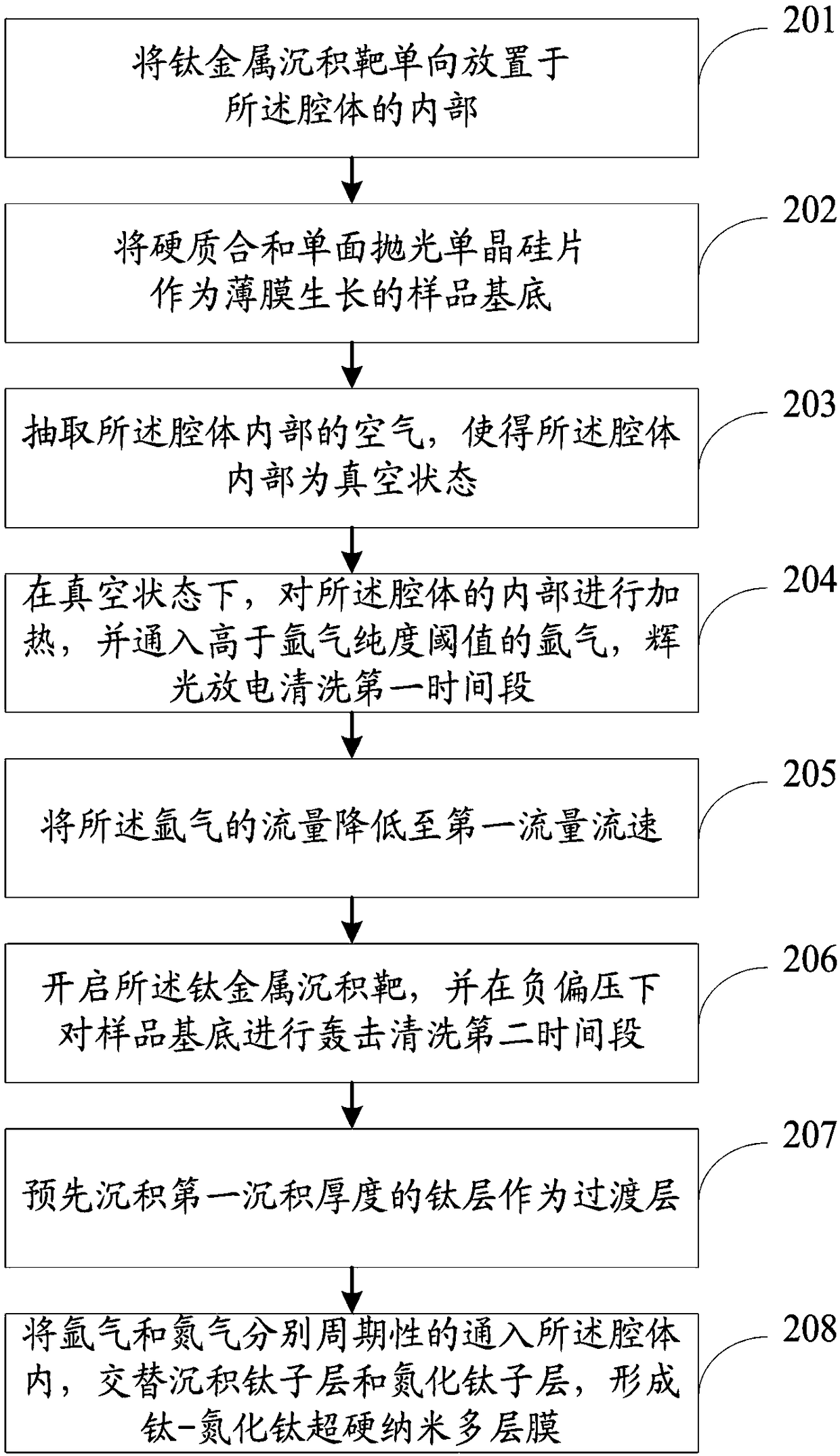

Small modulation period Ti/TiN superhard nanometer multilayer film prepared by multi-arc ion plating

ActiveCN109440069AExtended service lifeHigh hardnessVacuum evaporation coatingSputtering coatingTitanium metalAlloy

The invention discloses a small modulation period Ti / TiN superhard nanometer multilayer film prepared by multi-arc ion plating. A preparation method of the film comprises the steps that a titanium metal deposition target is placed in a chamber in one direction; a hard alloy and a single-side polished single crystalline silicon wafer are used as a sample substrate for the growth of the thin film; air inside the chamber is extracted, and thus the inner part of the chamber is in a vacuum state; under the vacuum state, the inner part of the chamber is heated, argon gas above the purity threshold is injected, and glow discharge cleaning is conducted in the first time period; the flow of the argon gas is reduced to the first flow rate; the titanium metal deposition target is opened, and in the second time period, the sample substrate is bombarded and cleaned under negative bias pressure; and a titanium layer with a first deposition thickness is deposited in advance as a transition layer, theargon gas and nitrogen gas are correspondingly and periodically injected into the chamber, a titanium substratum and a titanium nitride substratum are alternately deposited to form the small modulation period Ti / TiN superhard nanometer multilayer film prepared by multi-arc ion plating. The service life of products produced based on the TiN thin film is prolonged.

Owner:SHANDONG UNIV

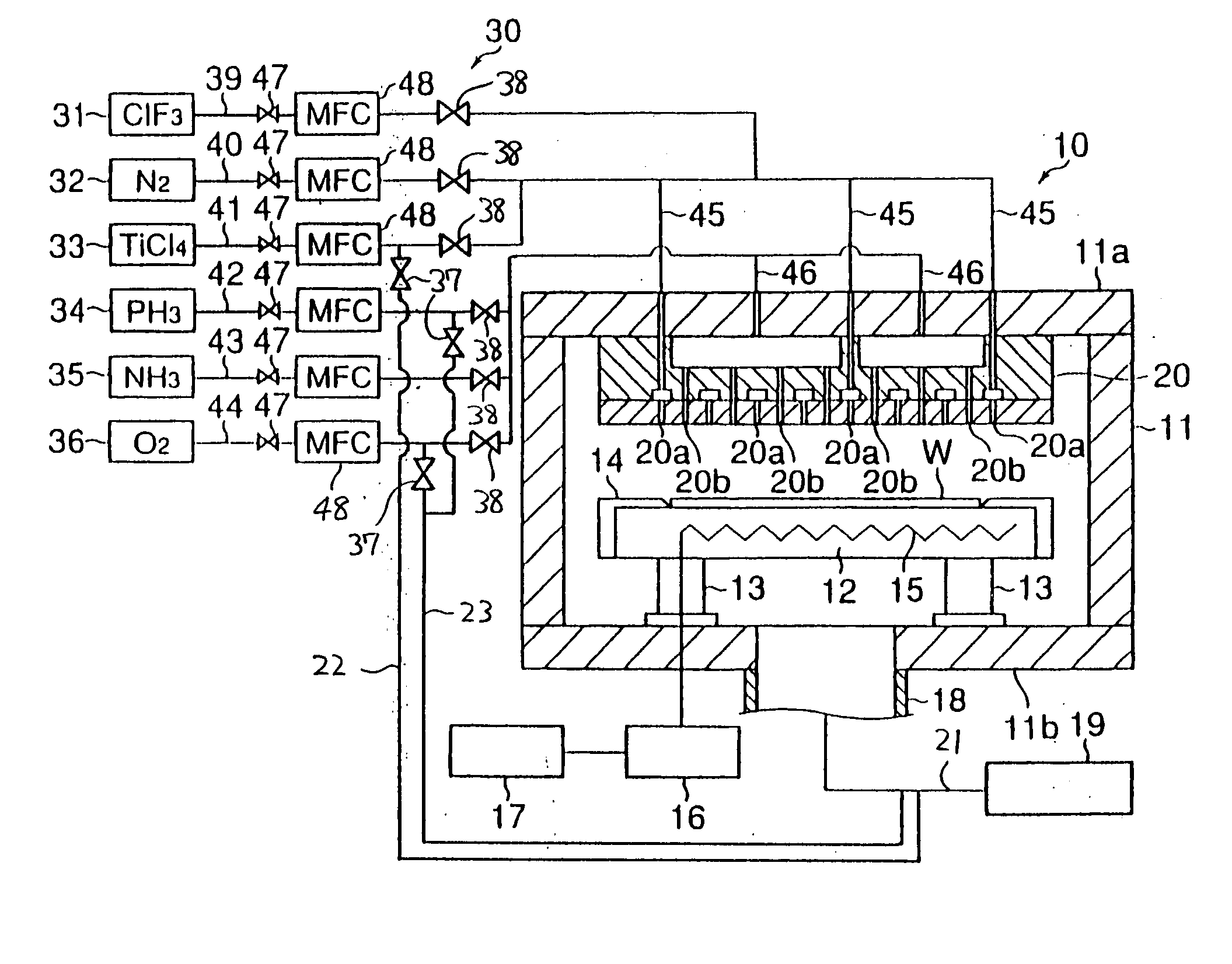

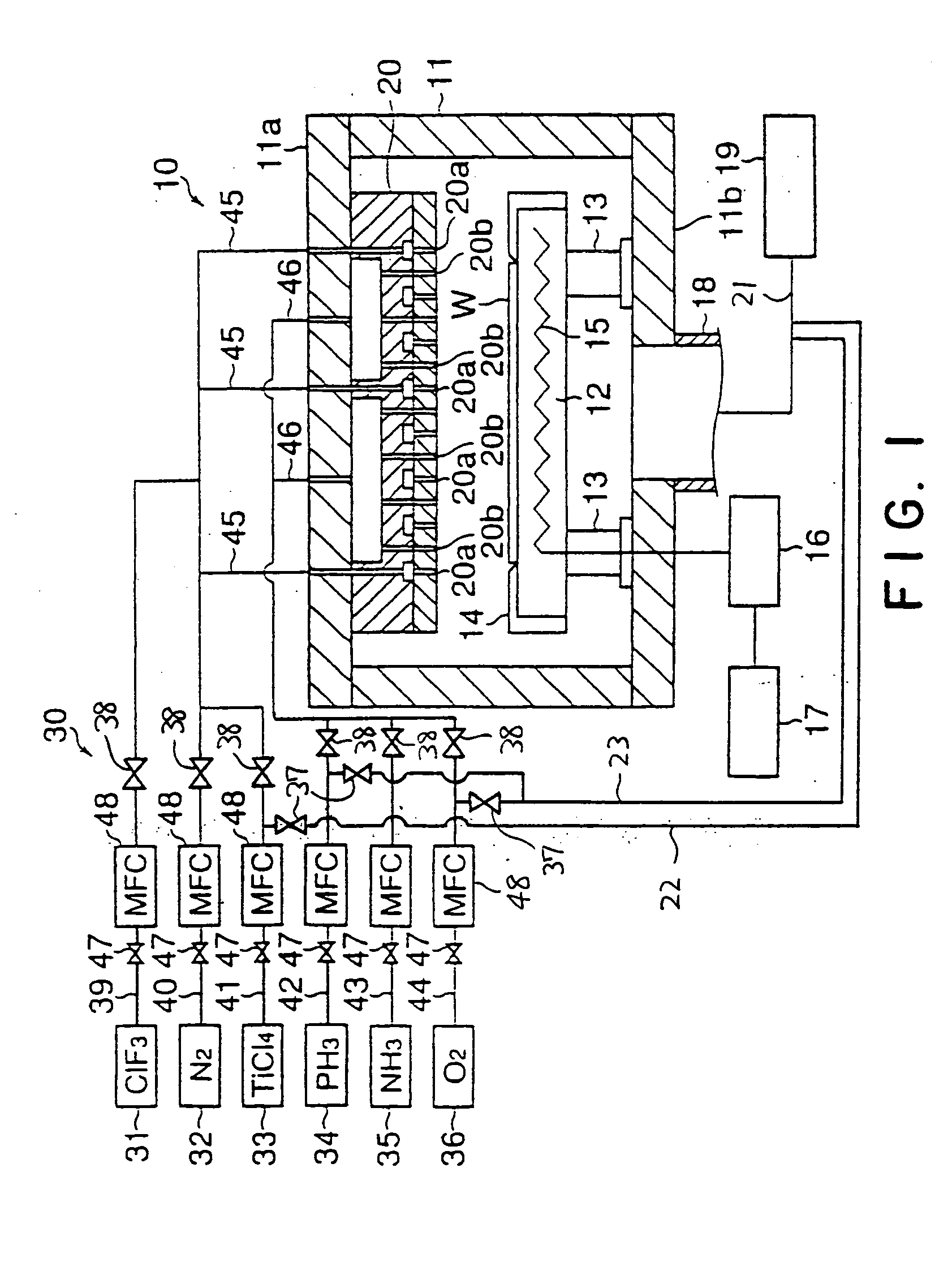

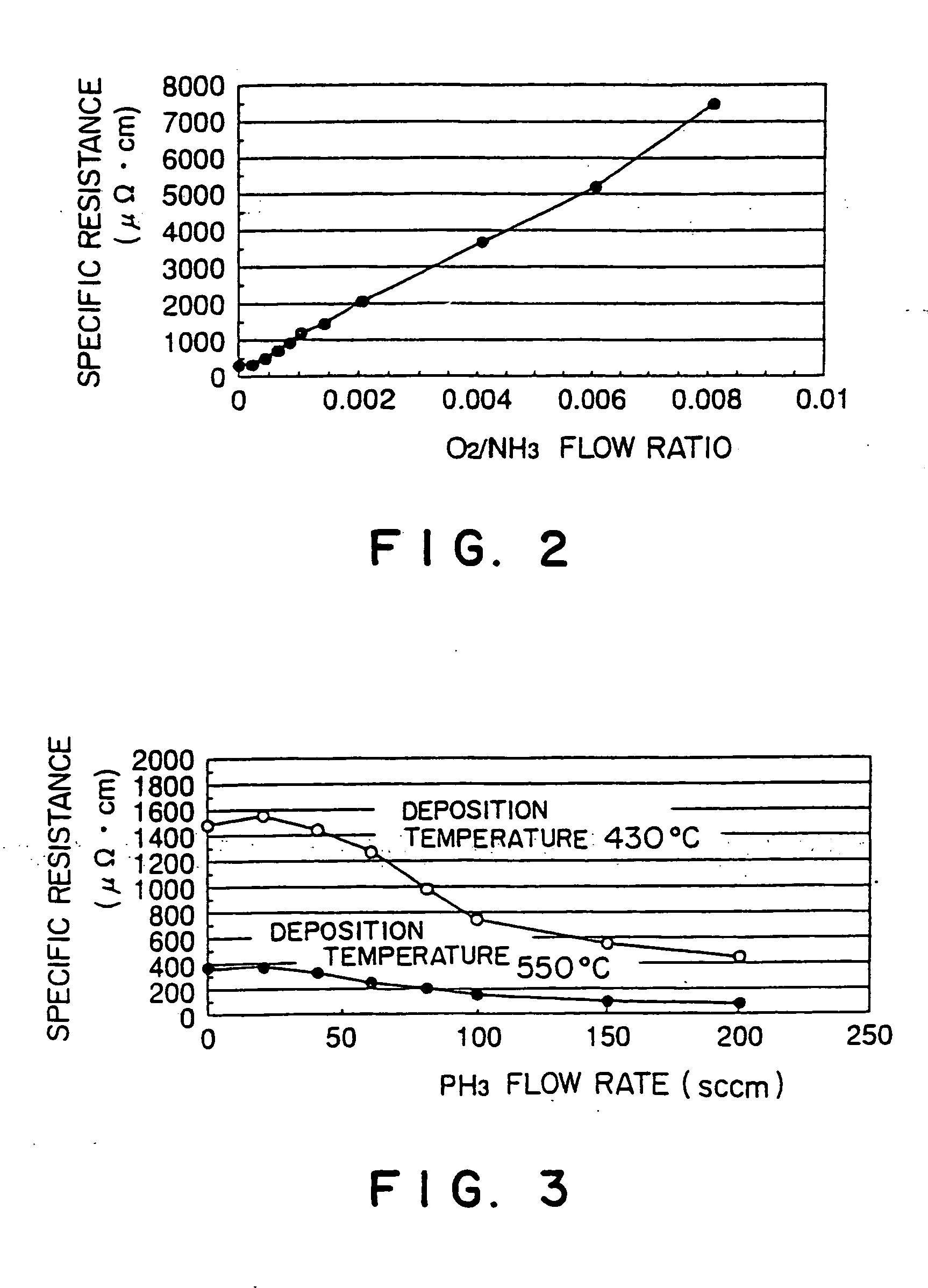

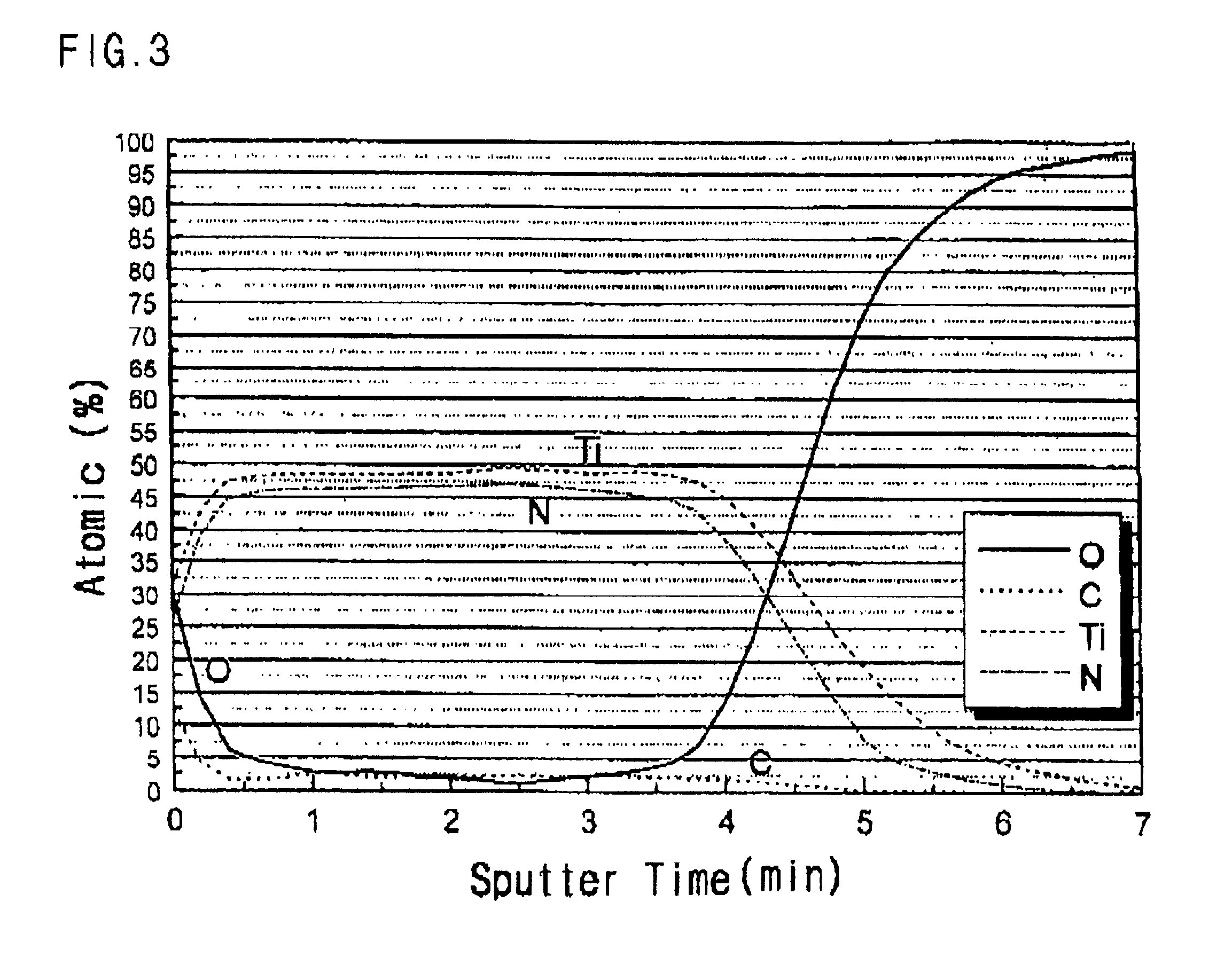

Method for depositing metallic nitride series thin film

InactiveUS20050089634A1Quality improvementHigh barrier propertiesSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceNitride

The present invention generally relates to a method for depositing a metallic nitride series thin film, typically a TiN-series thin film. The TiN-series thin film according to the present invention is formed by a CVD, and contains Ti, O and N to have a higher barrier characteristic than those of conventional TiN thin films, so that TiN-series thin film can suitably used as a barrier layer. In addition, a TiN-series thin film according to the present invention is formed by a CVD, and contains Ti, N and P to have a lower resistance than those of conventional TiN films, so that TiN-series thin film can suitably used as a barrier layer or a capacitor top electrode. Moreover, if a TiN-series thin film containing Ti, O, N and P is formed by a CVD, the TiN-series thin film can have both of a high barrier characteristic and a low resistance characteristic.

Owner:OTSUKI HAYASHI

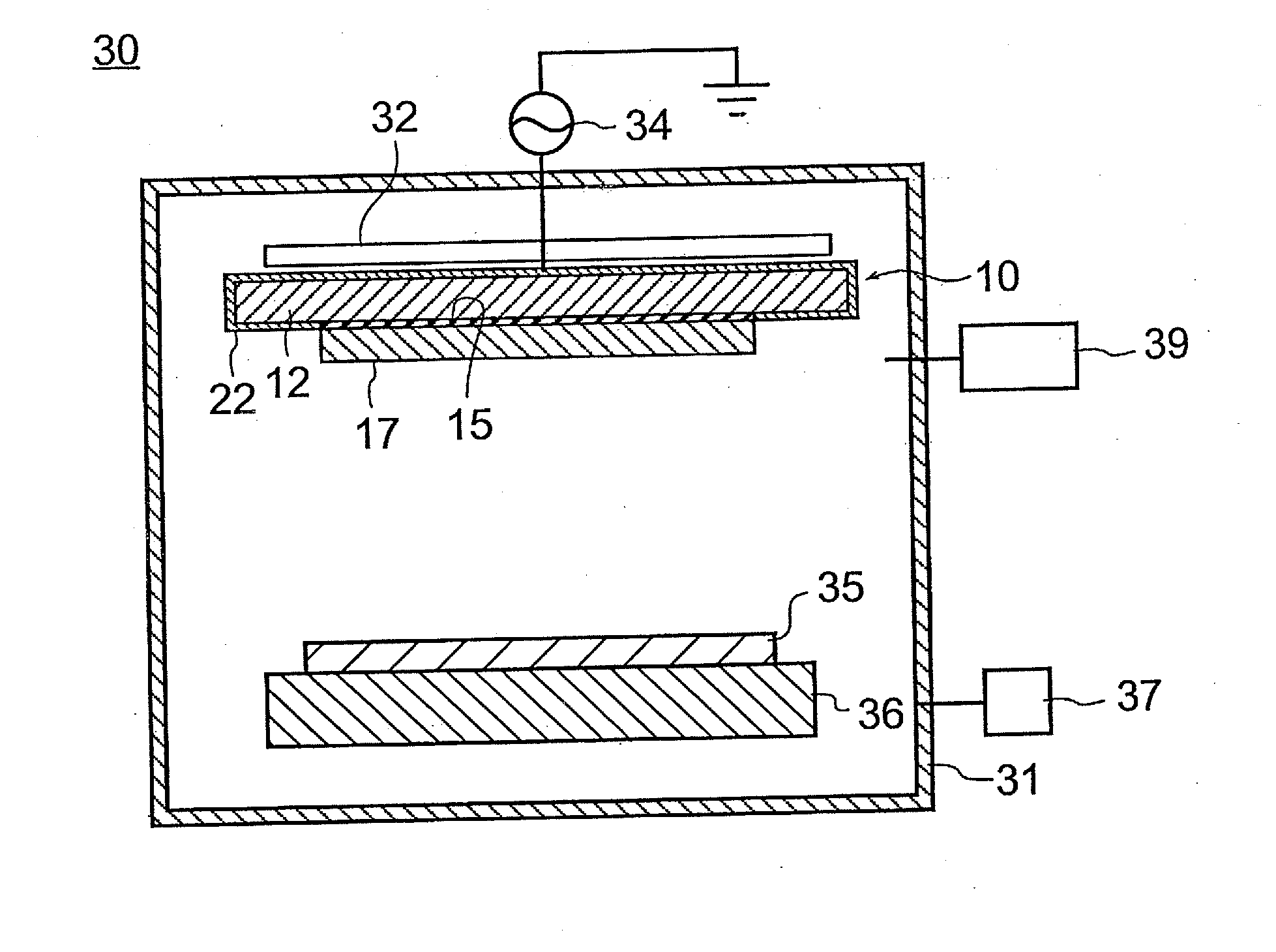

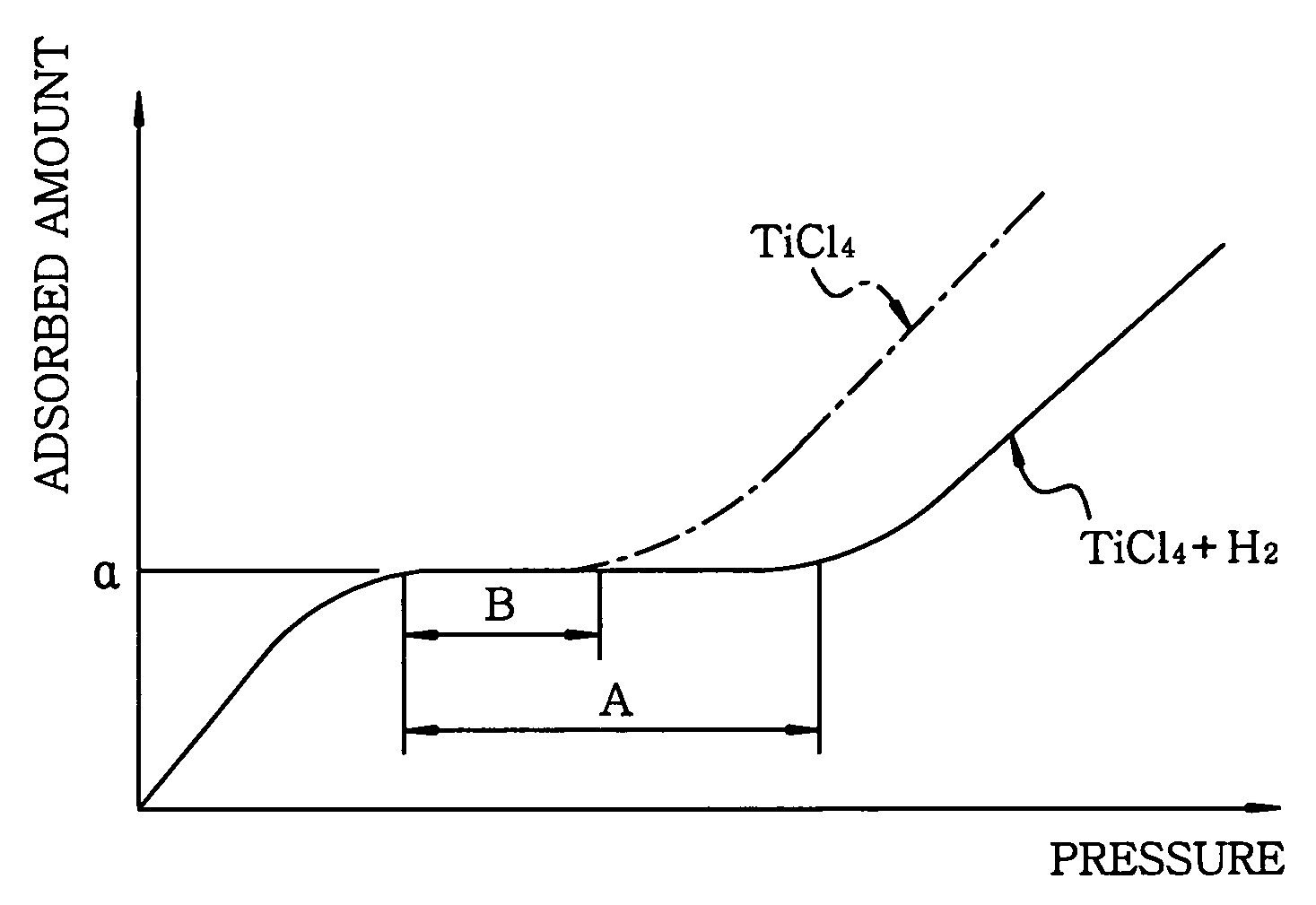

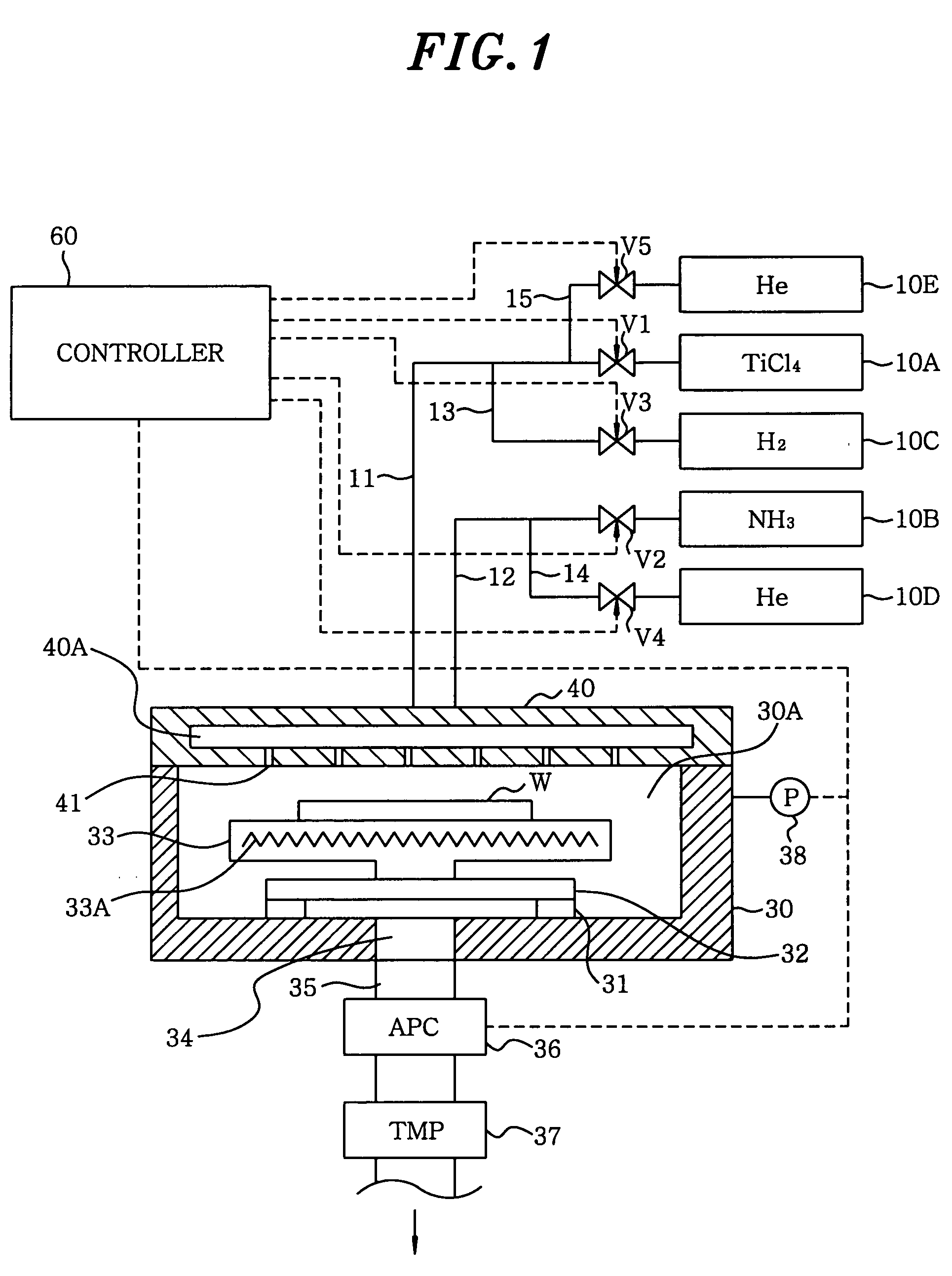

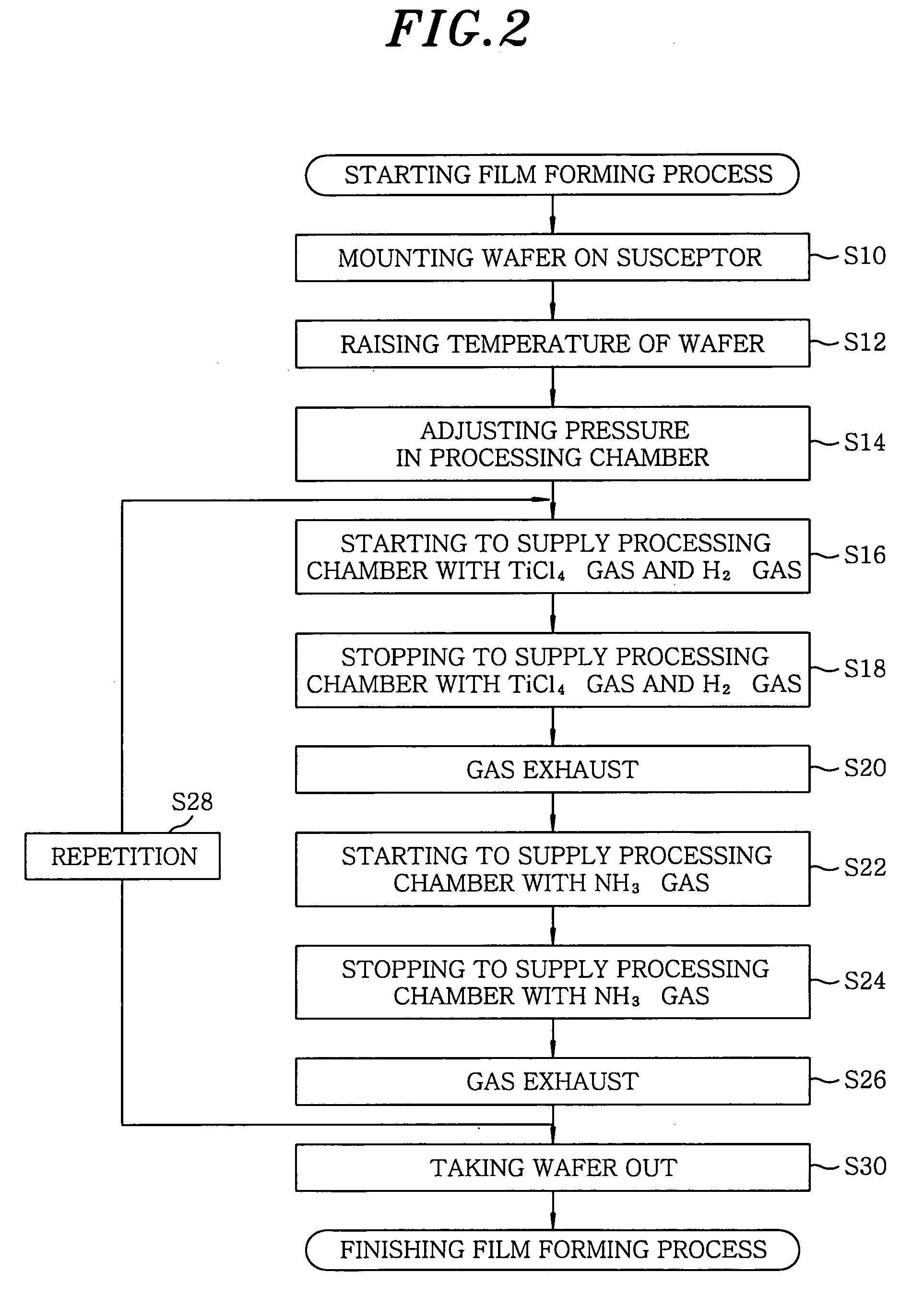

Method of Forming Thin Film, Thin Film Forming Apparatus, Program and Computer-Readable Information Recording Medium

InactiveUS20080241385A1Increase ratingsIncrease adsorption densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetallurgyPhysical chemistry

A method of rapidly forming a thin film of high quality through film formation by alternate feeding of raw gases. In particular, a method of forming a TiN thin film, comprising repeating operations including causing TiCl4 gas as a raw gas to be adsorbed on a substrate or TiCl4 molecules adsorbed on a substrate and feeding NH3 gas as a reactant gas in a treating chamber so as to effect reaction of TiCl4 and NH3 leading to formation of a TiN film, which method further comprises an operation of, prior to the adsorption of TiCl4 gas on the substrate, feeding reducing H2 gas in the treating chamber (30) so as to change TiCl4 to a state of enhanced likelihood of adsorption on the substrate (e.g., TiCl3).

Owner:TOKYO ELECTRON LTD

Method of forming a MOCVD-TiN thin film

The present invention discloses a method of forming a titanium nitride (TiN) thin film on a substrate disposed on a susceptor in a reaction chamber with low carbon content, low resistivity, and excellent step coverage. The method forming the TiN thin film includes feeding vapor of a Tetrakis Diethylamino Titanium (TDEAT) precursor and ammonia (NH3) gas into the reaction chamber, wherein a ratio of a vaporization rate of the TDEAT precursor to a flow rate of the ammonia gas is a value in the range of 1 mg / min:20 sccm to 1 mg / min:100 sccm; maintaining an atmosphere in the reaction chamber at a pressure in the range of 0.5 to 3.0 Torr; and heating the substrate to a temperature in the range of 300 to 400 degrees Celsius (° C.).

Owner:JUSUNG ENG

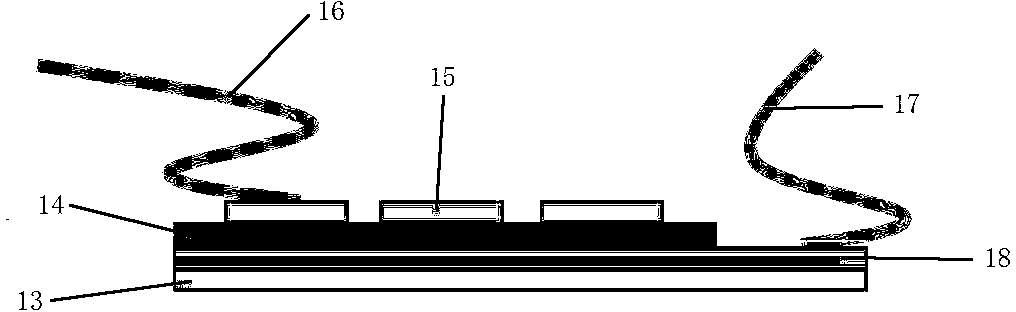

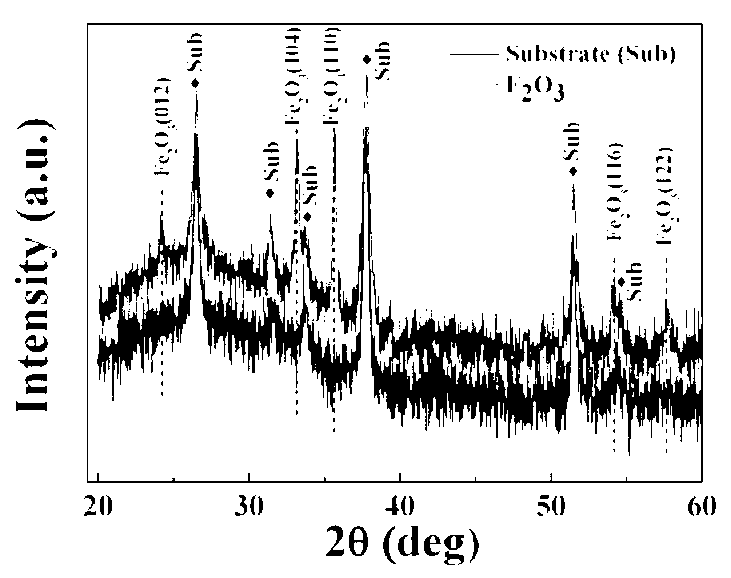

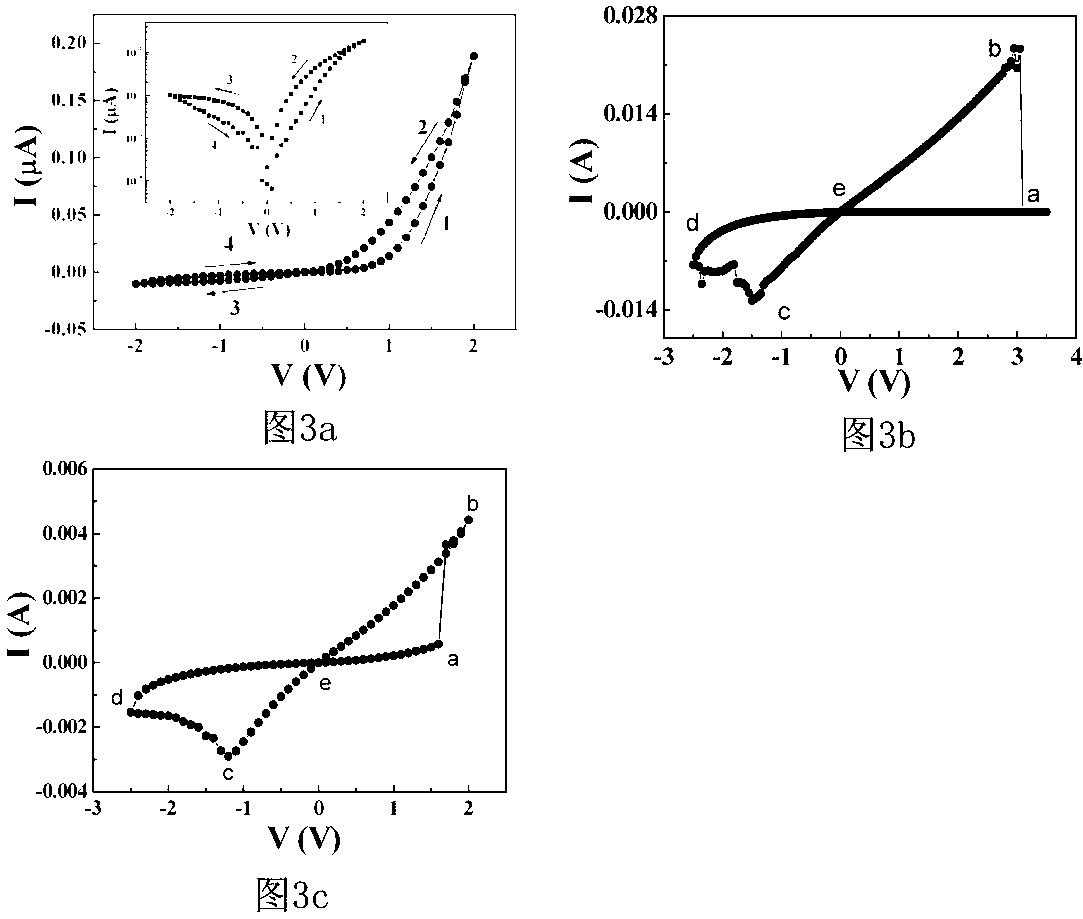

Bipolar resistive access memory and preparation method thereof

InactiveCN103199195AObvious rectification effectImprove conductivityElectrical apparatusDigital storagePlatinumEngineering

The invention discloses a bipolar resistive access memory and a preparation method thereof. The bipolar resistive access memory comprises an insulating substrate, an upper electrode film, a lower electrode film, wherein a resistive layer material is arranged between the upper electrode film and the lower electrode film. The bipolar resistive access memory is characterized in that the upper electrode film is a film made of one of platinum, copper or gold, the lower electrode film is a fluorine-doped tin oxide film, and the resistive layer material is an alpha-Fe2O3 polycrystalline film; and the structure of the memory is made of Pt or Cu or Au / alpha-Fe2O3 / FTO. The bipolar resistive access memory has the advantages of small size, simple structure, no volatilization, quick read-write availability, low working voltage, low energy-consumption, no moving part, no destructive read out and the like.

Owner:HEBEI UNIVERSITY

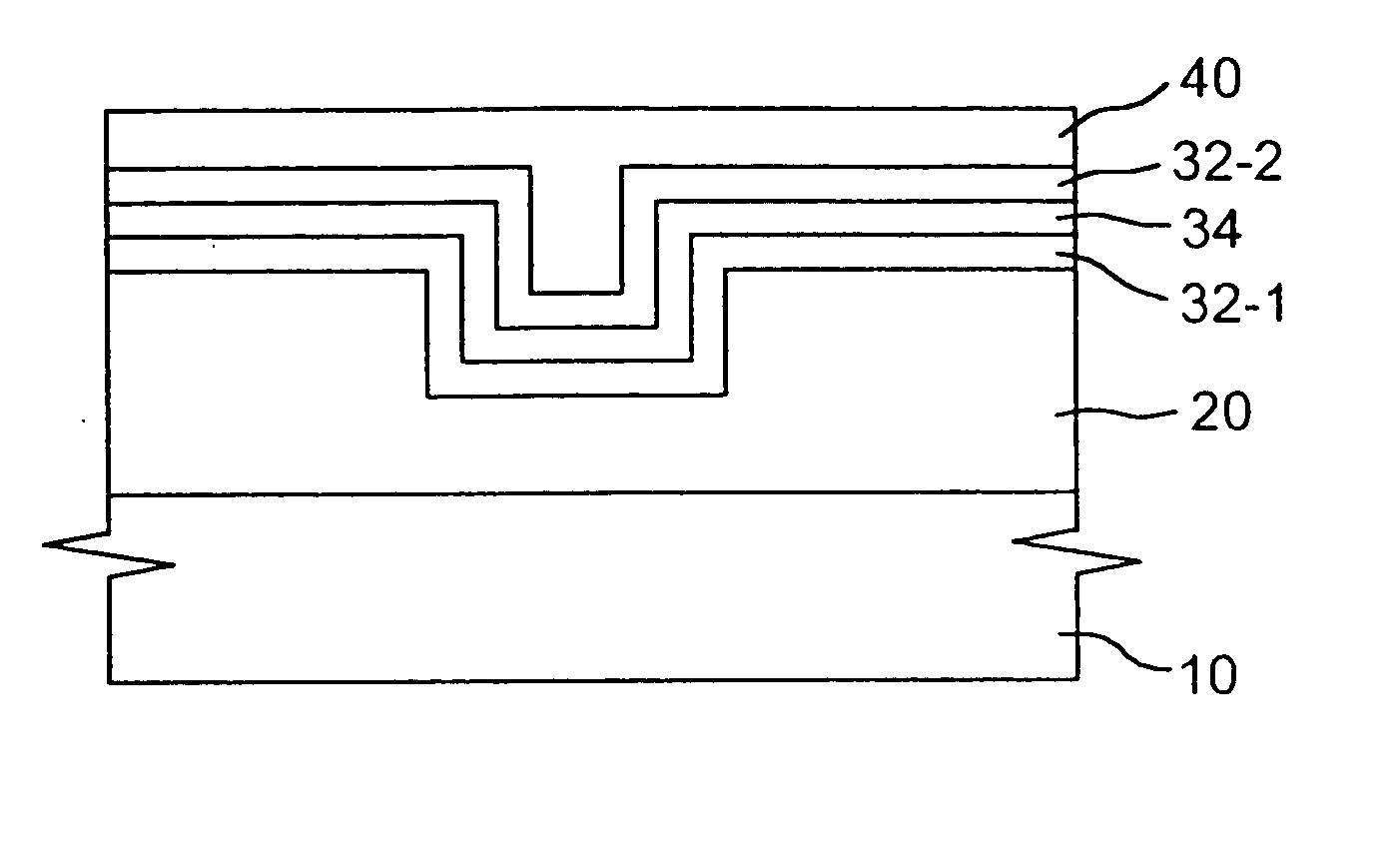

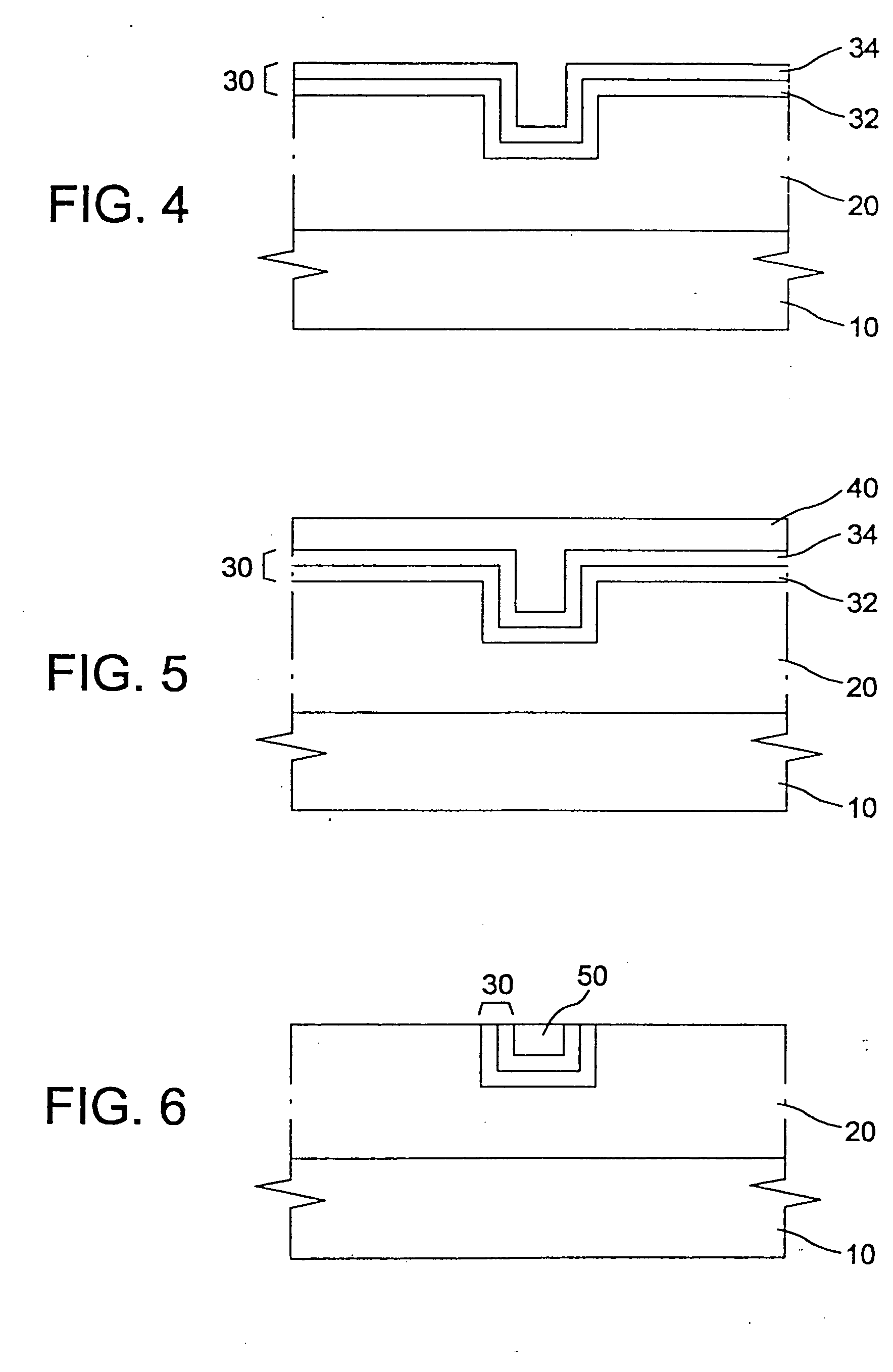

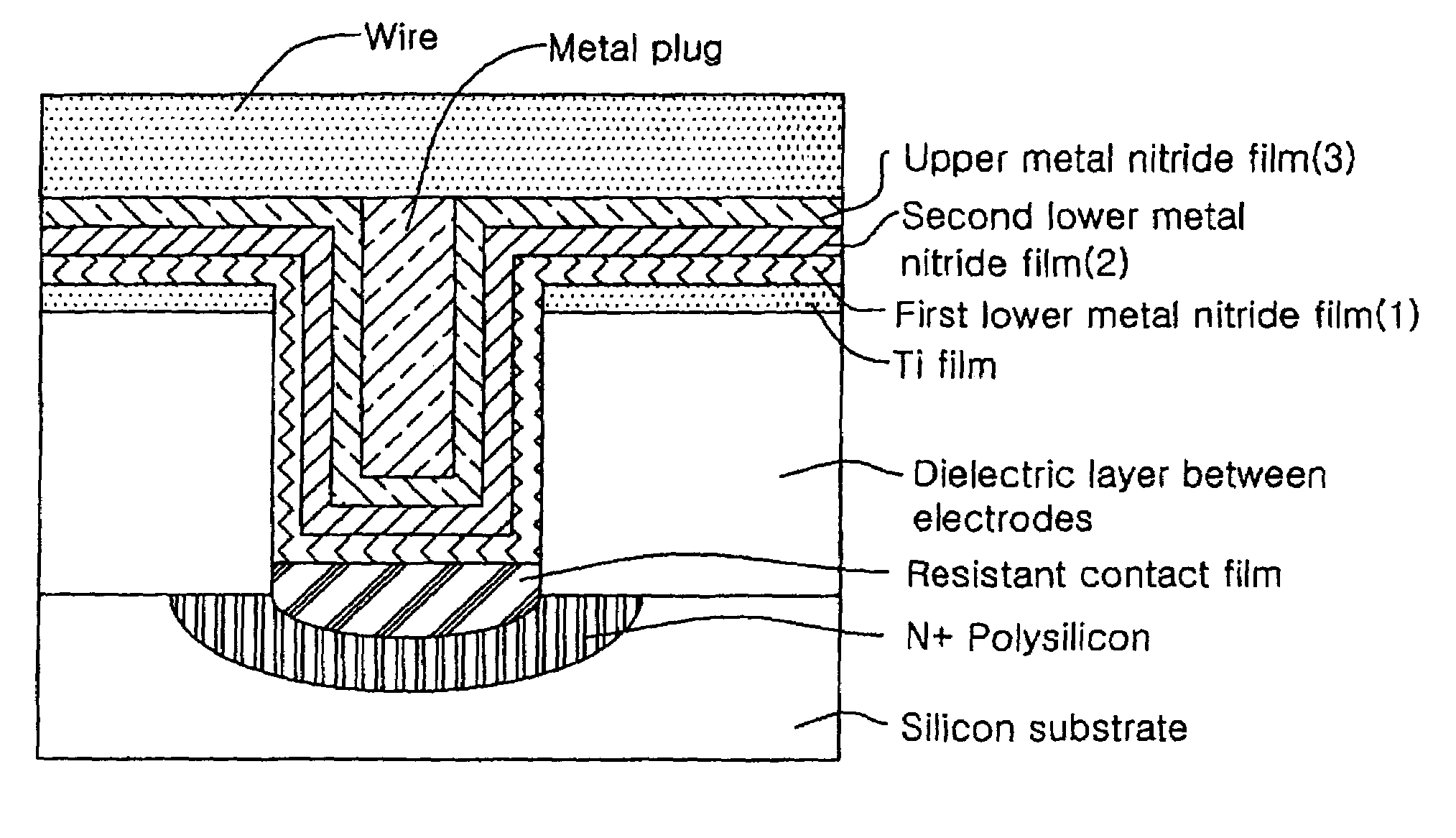

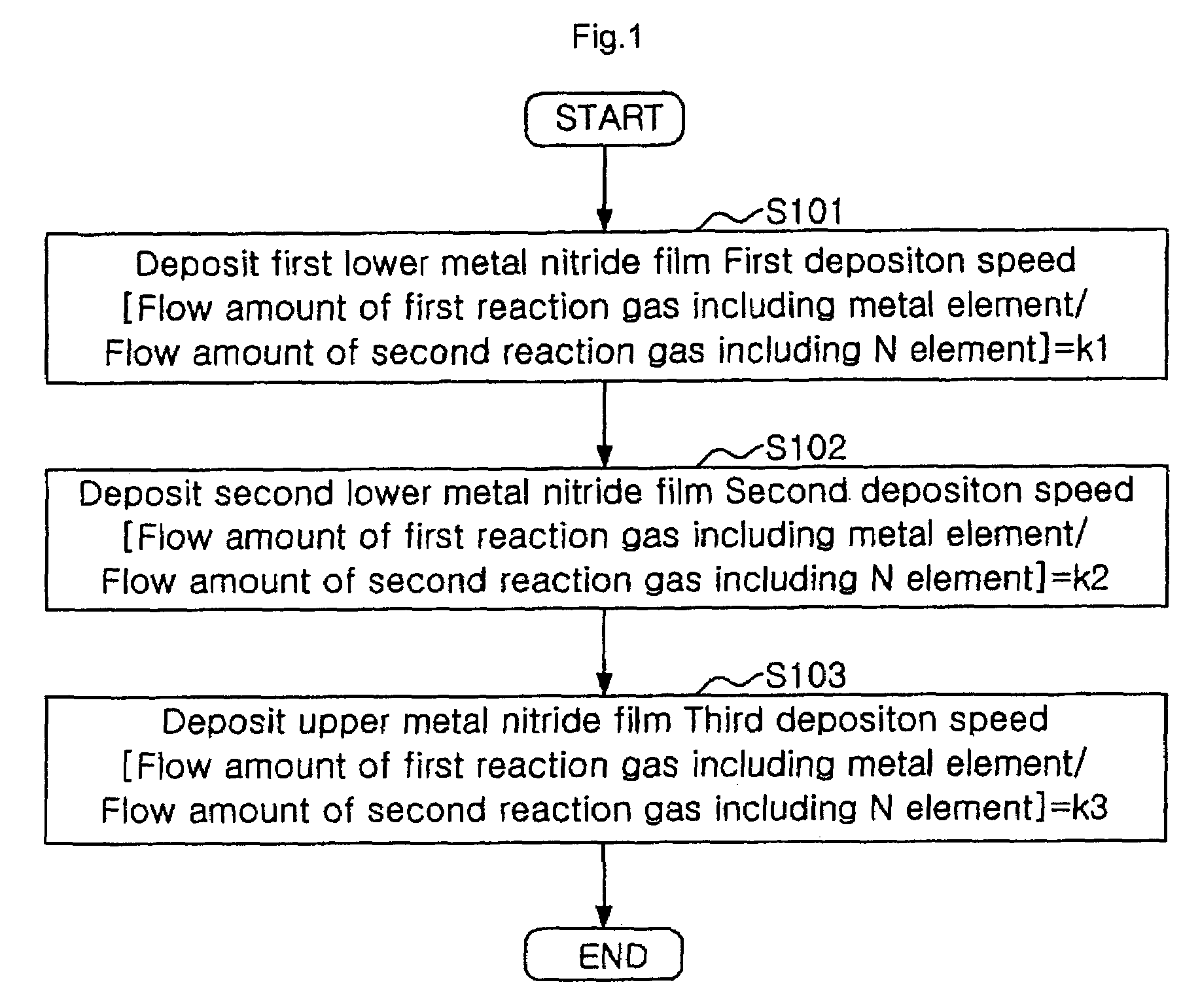

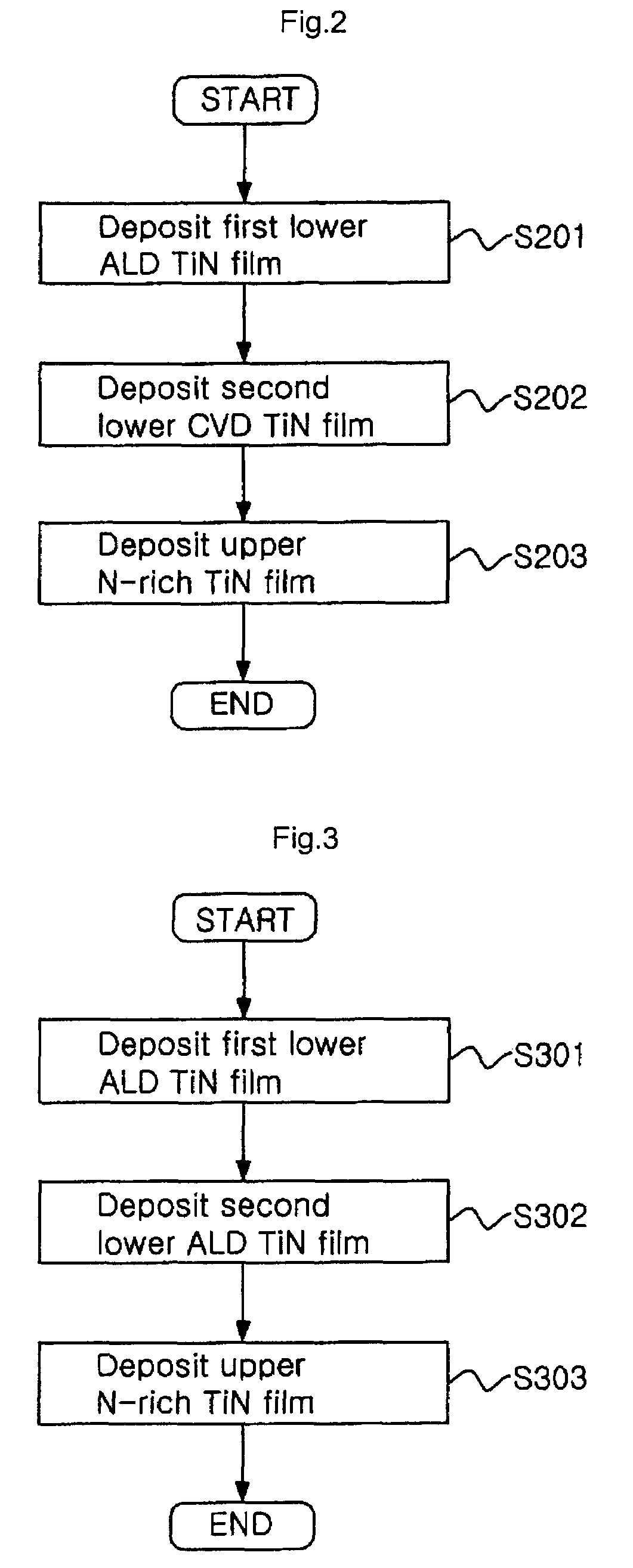

Deposition method of TiN thin film having a multi-layer structure

ActiveUS7253101B2High aspect ratioReduce depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin membraneTin thin films

Provided is a method of depositing a metal nitride film having a multilayer structure and different deposition speeds on a substrate. The method is performed by forming a first lower metal nitride film on the substrate at a first deposition speed, forming a second lower metal nitride film on the first lower metal nitride film at a second deposition speed, and forming an upper metal nitride film having a large content of nitrogen (N) on a lower TiN film which is formed by the forming of the first lower metal nitride film and the second lower metal nitride film, at a third deposition speed, to improve stability with respect to exposure to air / moisture. The deposition speed of the metal nitride film having a multi-layer structure satisfies a relationship that the second deposition speed≧the first deposition speed≧the third deposition speed.

Owner:WONIK IPS CO LTD

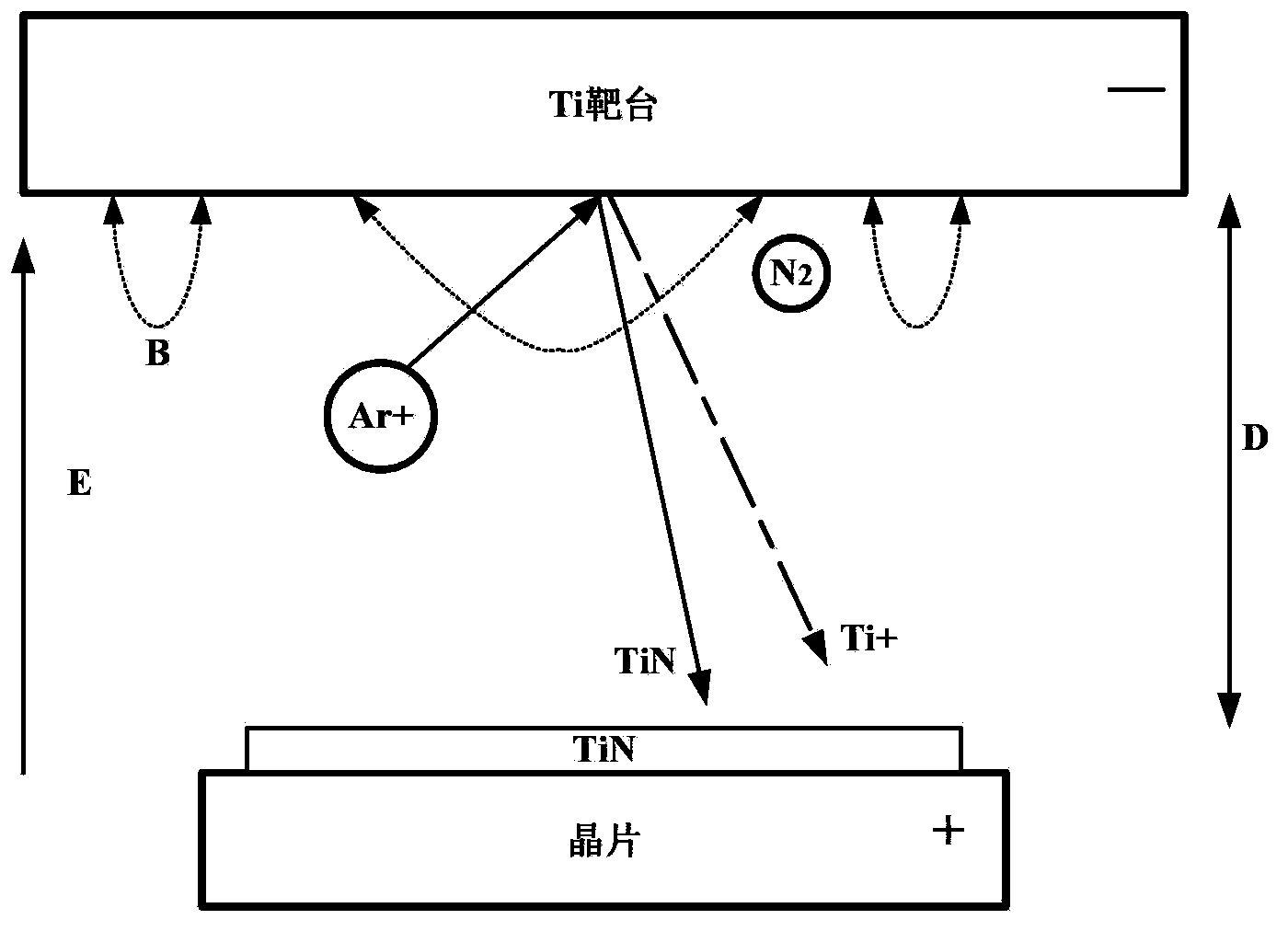

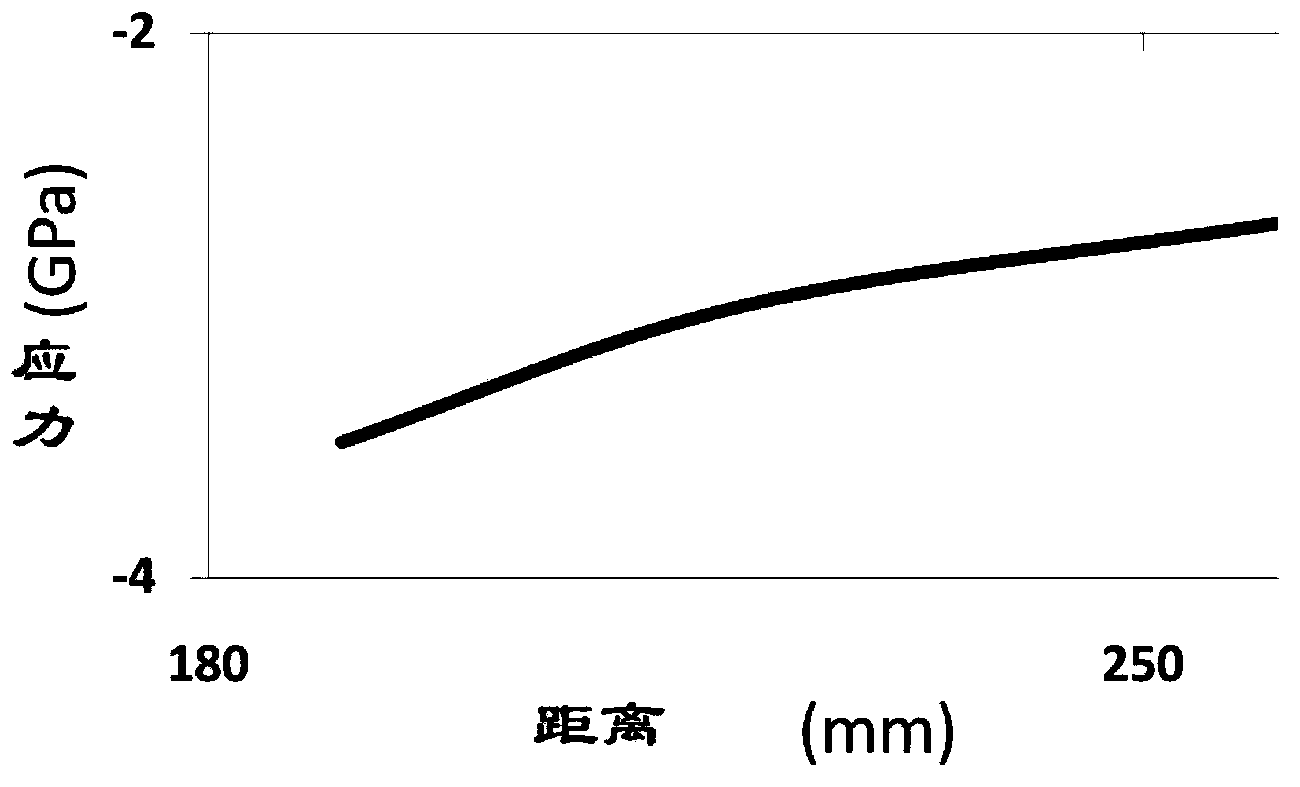

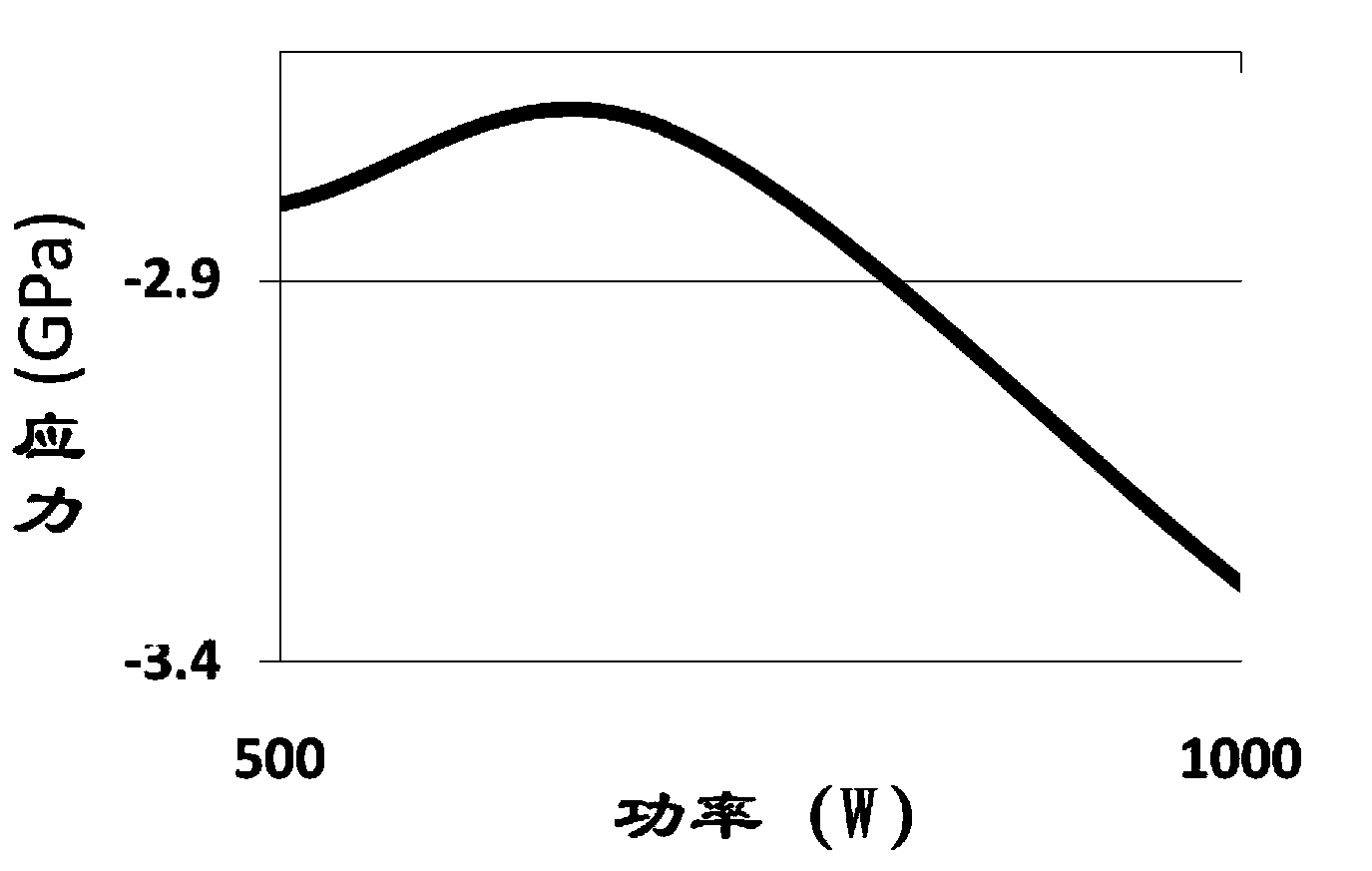

Method for preparing TiN through utilizing physical vapor deposition (PVD)

InactiveCN103540893AImprove the rate of amorphizationIncrease kinetic energyVacuum evaporation coatingSemiconductor/solid-state device manufacturingNoble gasNitrogen gas

Disclosed is a method for preparing TiN through PVD,comprising: in a vacuum environment inflated with nitrogen and a noble gas, making the noble gas to have glow discharge to form noble gas ions; nitridizing a chip surface and a Ti target surface by using the nitrogen; the noble gas ions bombarding the Ti target surface under electric field acceleration for sputtering TiN and Ti ions; the TiN depositing, under the action of the electric field, on the chip surface to form a TiN layer, and the Ti ions being incident on the chip surface to make the TiN layer to have a stress. The method is characterized in that: kinetic energy when the Ti ions are incident on the chip surface is increased to improve a non-crystallization rate of the TiN layer, thereby increasing the stress of the TiN layer. The method for preparing TiN through PVD according to the present invention improves kinetic energy when the Ti ions are incident on the chip surface by controlling process parameters to improve the non-crystallization rate of the TiN, thereby increasing the stress of the TiN thin film.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com