Copper-connection structure and manufacturing method of copper-connection structure

A copper interconnect structure and copper electroplating technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor surface adhesion, unsuitable diffusion barrier layers, etc., to improve performance and reliability. , Improve diffusion barrier ability and thermal stability, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

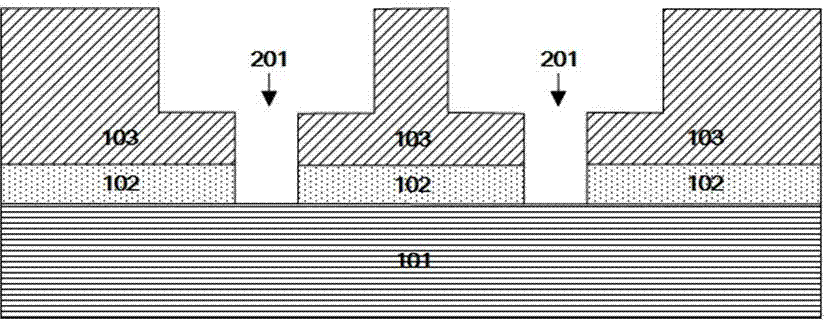

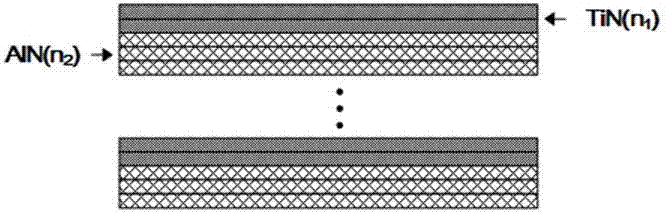

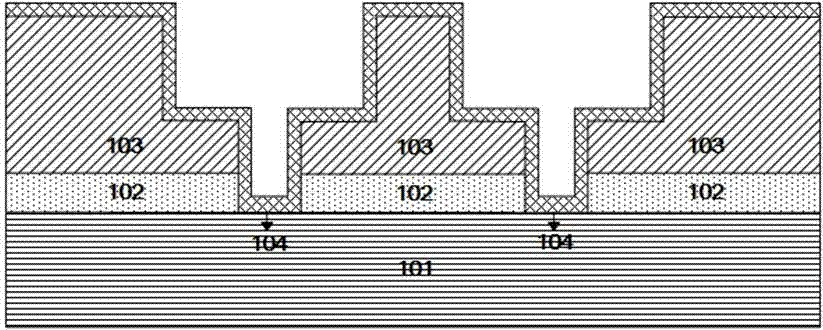

[0022] Further detailed description will be made below in conjunction with the accompanying drawings and specific embodiments. In the drawings, for the convenience of description, the thicknesses of layers and regions are enlarged and reduced, and the sizes shown do not represent actual sizes. The same reference numerals represent the same components , its repeated description will be omitted.

[0023] The Ru / TiAlN diffusion barrier layer proposed by the present invention and its preparation method are applicable to the copper interconnection technology of various semiconductor integrated circuits. What is described below is the process flow of an embodiment of the Ru / TiAlN diffusion barrier layer prepared by the present invention .

[0024] First, on the Si(100) substrate 101, the standard CMOS process is used to complete the cleaning of the silicon wafer. The specific process mainly includes: using a mixed solution of sulfuric acid and hydrogen peroxide, standard cleaning SC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com