Method for manufacturing thin film solar cell ID (identification) by using laser edge deletion device

A technology of solar cells and thin-film batteries, which is applied in laser welding equipment, circuits, electrical components, etc., can solve the problems of high input cost, large occupied space, waste of power energy, etc., and achieves reduced input costs, beautiful appearance, and improved work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

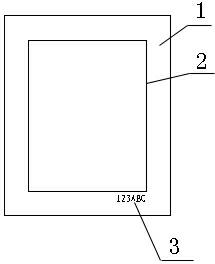

[0019] Embodiment one: with reference to attached figure 1 , where 1 is the glass substrate exposed after the battery undergoes edge insulation treatment, and the film layer removed by the edge treatment includes silicon-based series thin-film batteries, cadmium telluride series thin-film batteries, copper indium gallium tin series thin-film batteries or organic compound material thin-film batteries The back transparent conductive film, the photoelectric conversion layer and the front transparent conductive film; 2 is the edge insulation wire of the thin film solar cell, the inside of the insulation wire is the effective battery area, and the edge insulation treatment is performed outside. 3 is the ID preparation area reserved during the edge insulation treatment according to the prior design, and the ID area is outside the insulated wire and connected to the film layer in the edge-scanning area. The design and control of the ID area can be implemented through the software ope...

Embodiment 2

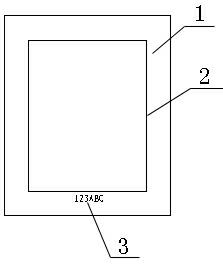

[0020] Embodiment two: with reference to attached figure 2 , where 1 is the glass substrate exposed after the edge insulation treatment of the battery, and the film layer removed by the edge treatment includes silicon-based series thin-film batteries, cadmium telluride series thin-film batteries, copper indium gallium tin series thin-film batteries or organic compound material thin-film batteries The back transparent conductive film, the photoelectric conversion layer and the front transparent conductive film; 2 is the edge insulation wire of the thin film solar cell, the inside of the insulation wire is the effective battery area, and the edge insulation treatment is performed outside. 3 is a small area for ID preparation reserved during the edge insulation treatment according to the prior design. The ID area is outside the insulating line and is not connected to the film layer in the edge-swept area. The design and control of the ID area can be implemented through the softw...

Embodiment 3

[0021] Embodiment three: with reference to attached image 3 , in order not to affect the performance and appearance of the battery, this area is generally designed outside the effective battery area of the thin film solar cell. The production of ID is based on the pre-made ID character design through the software system of the laser edge sweeper, and the galvanometer scanning system of the laser edge sweeper is used to pass the high-energy-density laser through the glass substrate film to achieve the effect of displaying the ID. . In this diagram, the ID consists of numbers, English letters or other characters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com