Method for depositing metallic nitride series thin film

a technology of metallic nitride and thin film, which is applied in the direction of coatings, solid-state devices, chemical vapor deposition coatings, etc., can solve the problems of deteriorating electrical characteristics, particularly severe design rules, and down and high density integration of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Referring now to the accompanying drawings, the preferred embodiments of the present invention will be described in detail below.

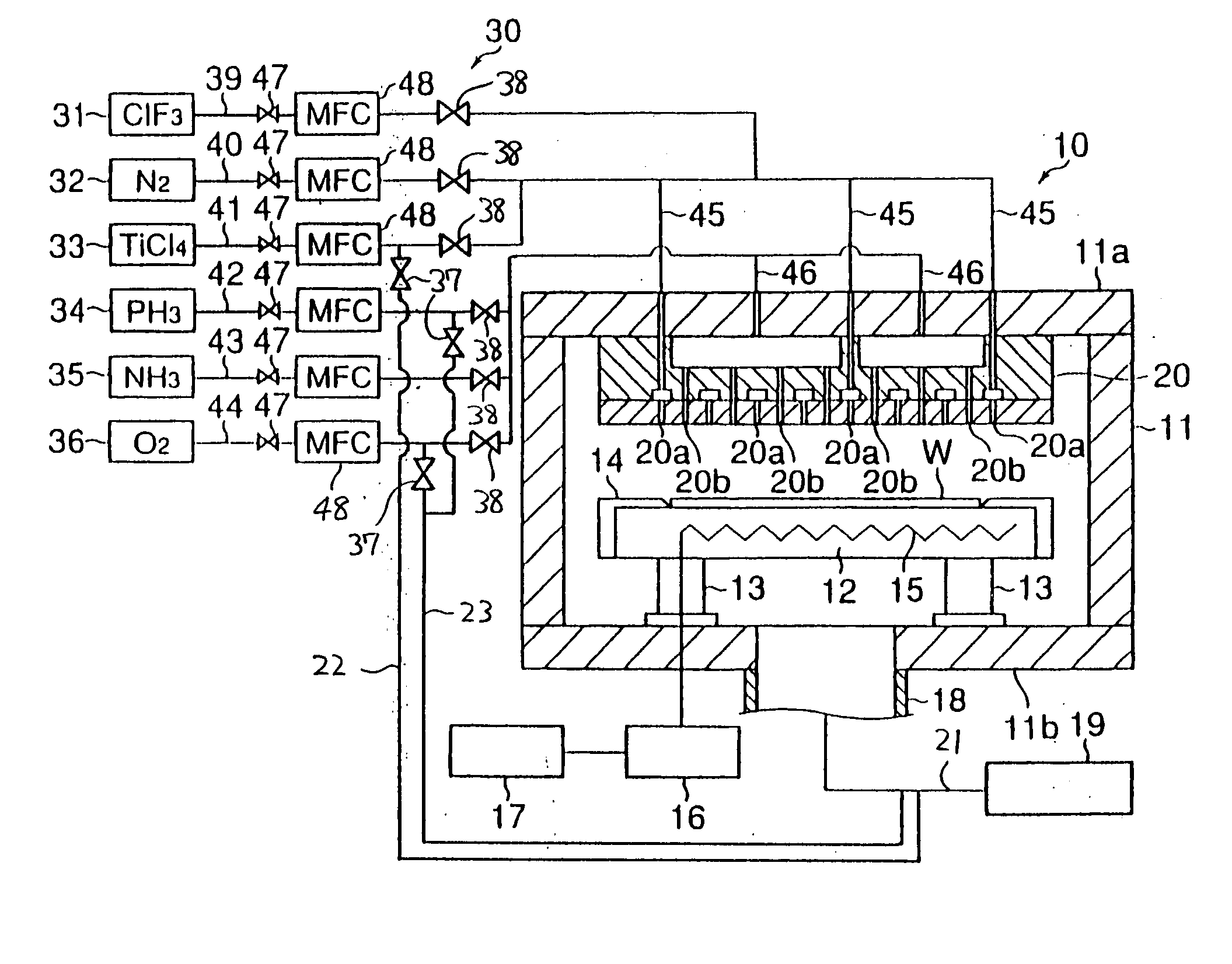

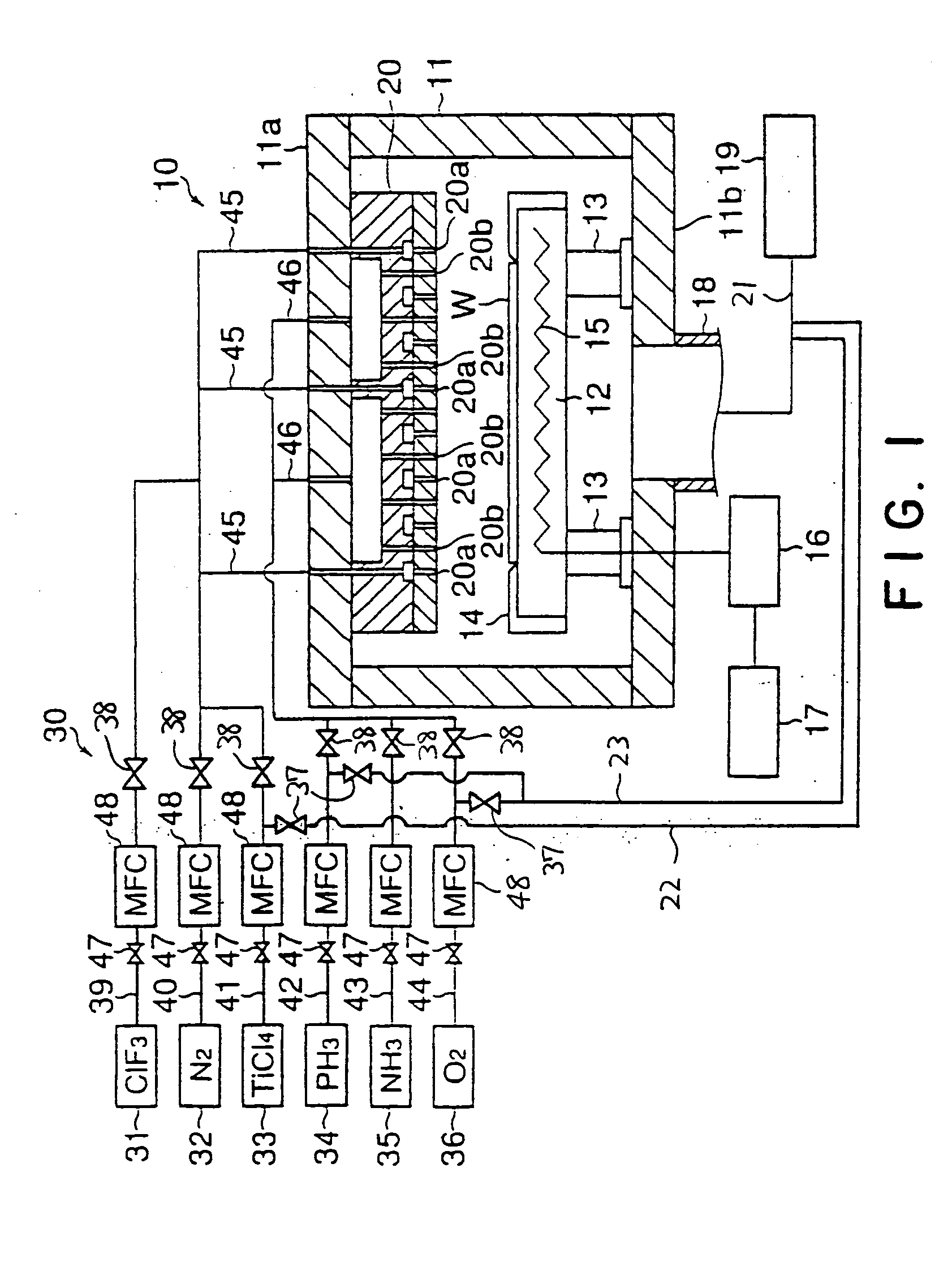

[0050]FIG. 1 is a sectional view of a deposition system for depositing a TiN-series thin film according to the present invention. This deposition system has a substantially cylindrical airtight process vessel 11, in which a susceptor 12 for horizontally supporting a semiconductor wafer W serving as an object to be processed is arranged while being supported on a cylindrical supporting member 13. On the outer edge portion of the susceptor 12, a guide ring 14 for guiding the semiconductor wafer W is provided. In addition, a heater 15 is embedded in the susceptor 12. When an electrical power is fed to the heater 15 from a power supply 16, the heater 15 heats the semiconductor waver W, which is an object to be processed, to a predetermined temperature. The power supply 16 is connected to a controller 17 which controls the output of the heater 15 in acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com