Small modulation period Ti/TiN superhard nanometer multilayer film prepared by multi-arc ion plating

A multi-arc ion plating, modulation cycle technology, applied in the direction of ion implantation plating, coating, sputtering plating, etc., can solve the problem of short service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

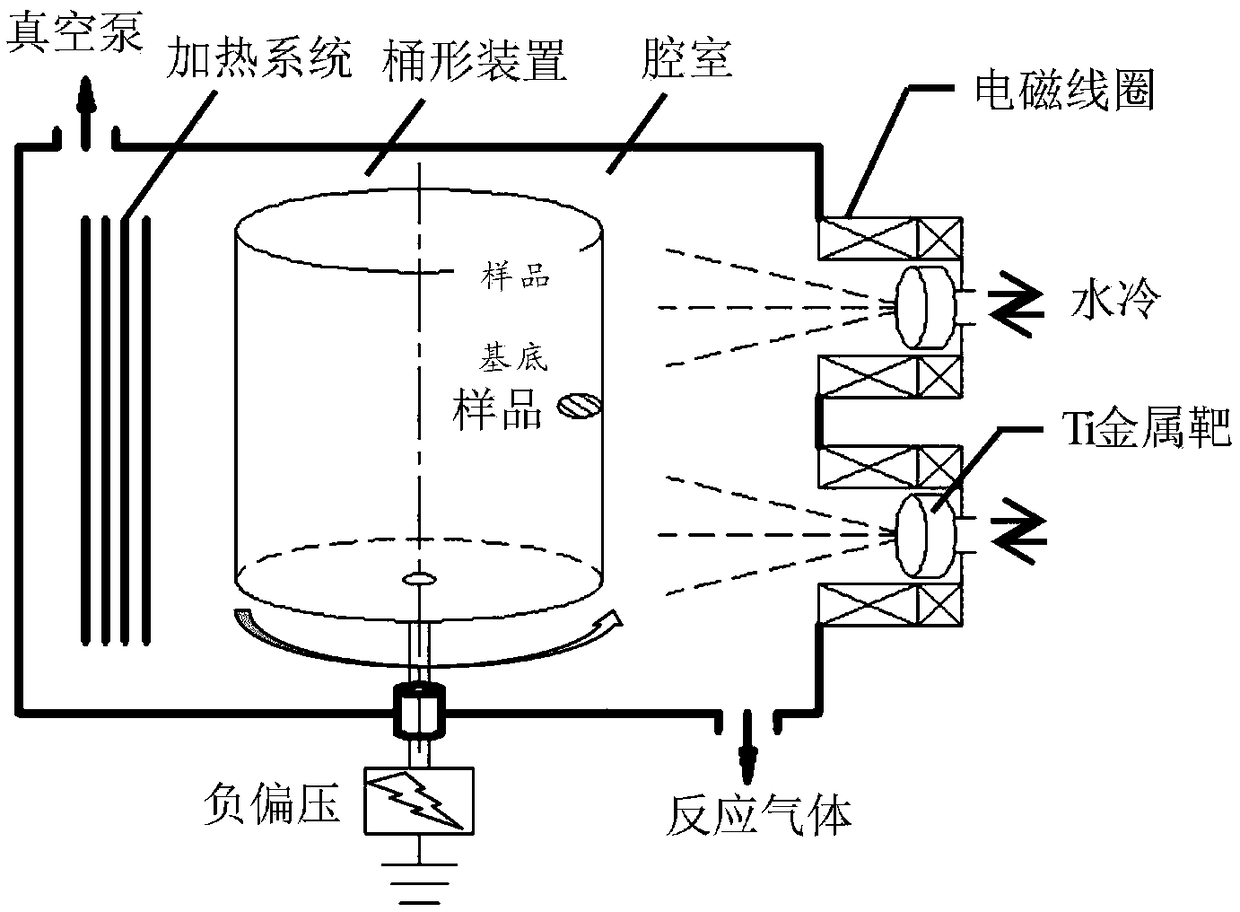

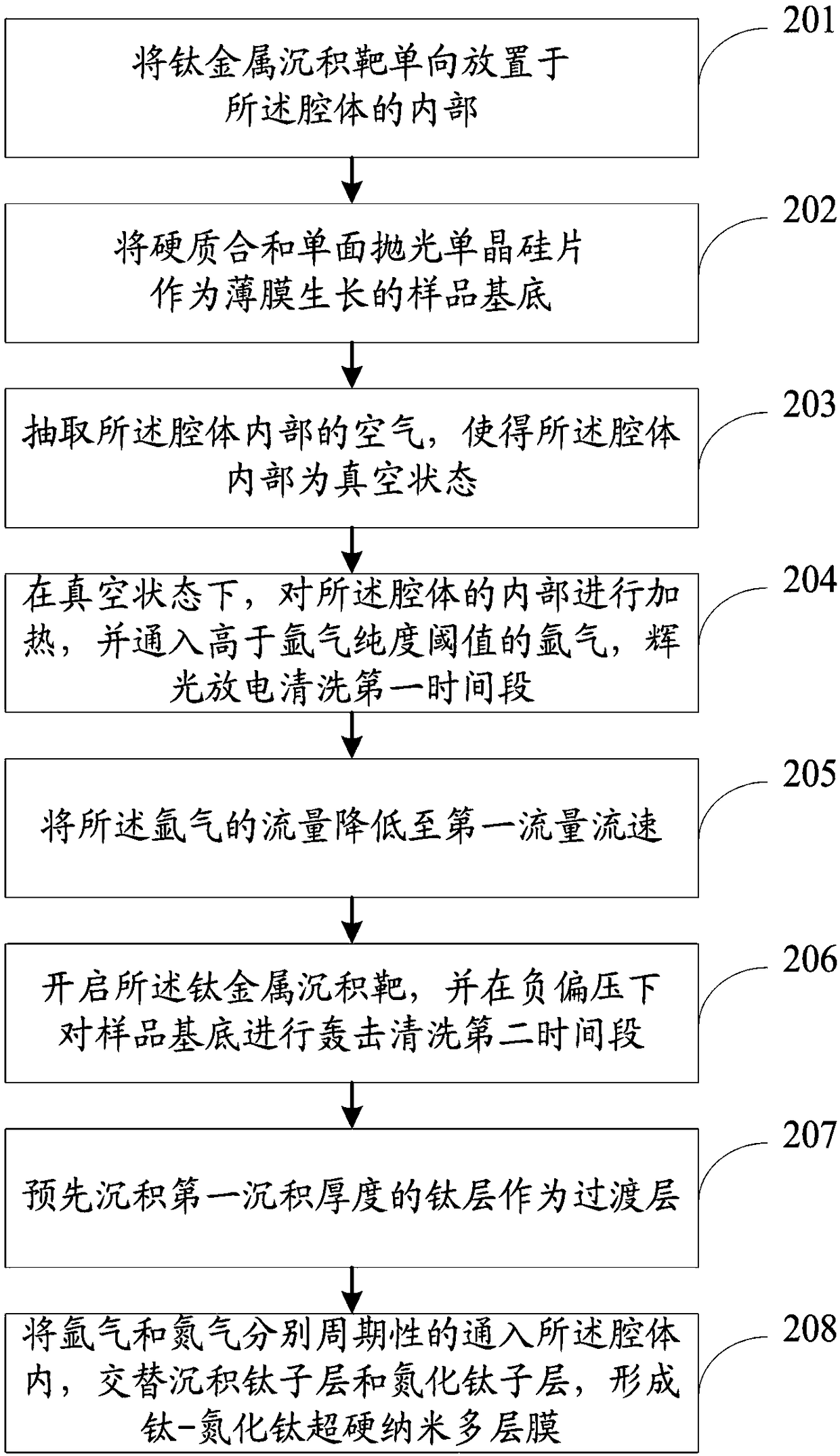

[0040] figure 2 The flow chart of the preparation method for the multi-arc ion plating provided by the present invention to prepare the small modulation period Ti / TiN superhard nano-multilayer film, as figure 2 As shown, a preparation method of multi-arc ion plating to prepare small modulation period Ti / TiN superhard nano-multilayer film, comprising:

[0041] Step 201: placing a titanium metal deposition target unidirectionally inside the cavity.

[0042] The invention adopts multi-arc ion plating technology to prepare Ti / TiN nanometer multilayer films with different modulation periods. Two circular Ti metal deposition targets with a purity of 99.99% are used, placed in one direction, the center distance between the upper and lower targets is 250mm, and the arc current is 70-75A.

[0043] Step 202: Use cemented carbide and single-sided polished single-crystal silicon wafers as sample substrates for film growth.

[0044] Cemented carbide and single-sided polished single-crys...

Embodiment 1

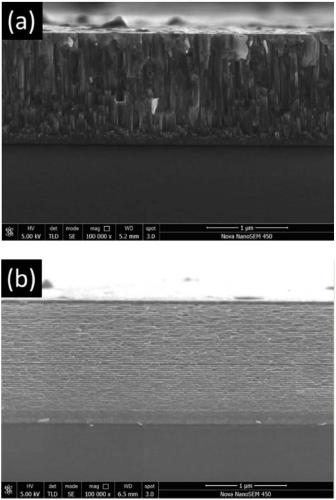

[0061] Two circular surface deposition targets with a purity of 99.99% were used, placed in one direction, the center distance between the upper and lower targets was 250mm, and the arc current was 70A. Cemented carbide and single-sided polished single-crystal silicon (100) slices were selected as substrates for film growth, and the substrate of cemented carbide was a block of 15×15×4 mm, which was ground and polished on the LCZMP-2 automatic metallographic sample grinding and polishing machine to The surface roughness is R a ≈0.8 μm. The samples were ultrasonically cleaned for 10 min in deionized water, acetone and absolute ethanol in sequence, dried and put into the chamber. During the preparation process, the revolution of the workbench is 10r / min. Before the experiment, the vacuum degree of the cavity was evacuated to 2×10 -2 Pa, preheat to 300°C, first pass high-purity argon gas at 150cm3 / min, glow discharge to clean the substrate for 10-15min, and reduce the flow rate...

Embodiment 2

[0063] Two circular surface deposition targets with a purity of 99.99% were used, placed in one direction, the center distance between the upper and lower targets was 250mm, and the arc current was 70A. Cemented carbide and single-sided polished single-crystal silicon (100) slices were selected as substrates for film growth, and the substrate of cemented carbide was a block of 15×15×4 mm, which was ground and polished on the LCZMP-2 automatic metallographic sample grinding and polishing machine to The surface roughness is R a ≈0.8 μm. The samples were ultrasonically cleaned for 10 min in deionized water, acetone and absolute ethanol in sequence, dried and put into the chamber. During the preparation process, the revolution of the workbench is 10r / min. Before the experiment, the vacuum degree of the cavity was evacuated to 2×10 -2 Pa, preheated to 300 ° C, first pass high-purity argon 150cm 3 / min, the substrate is cleaned by glow discharge for 10-15min, and the argon gas f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com