Method for plating triniobium stannide film on inner surface of pure niobium cavity and vacuum furnace

A vacuum furnace and inner surface technology, applied in the field of particle accelerators and superconductors, can solve the problems of poor thermal conductivity and cannot be used as a block, and achieve the effect of improving the Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

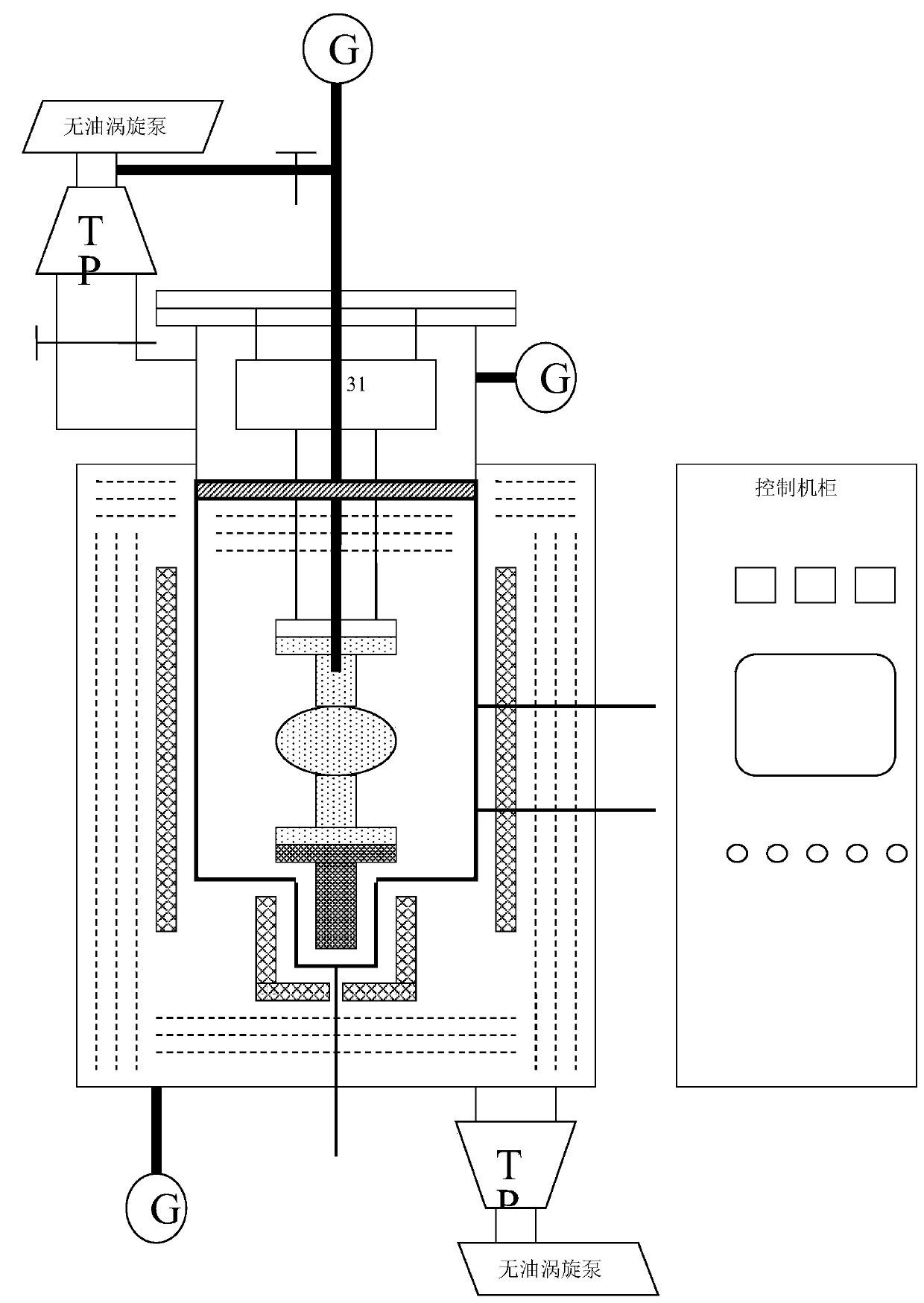

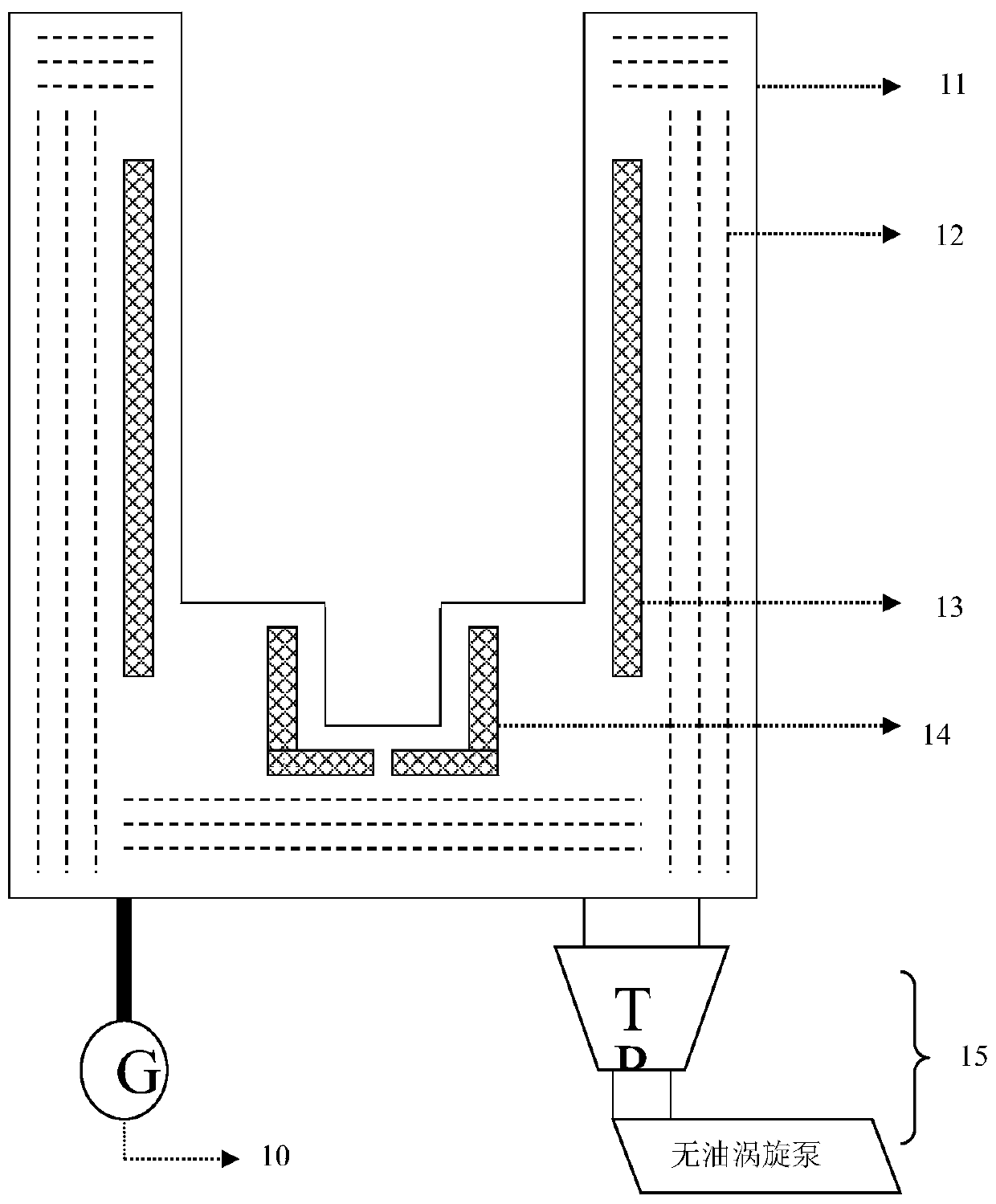

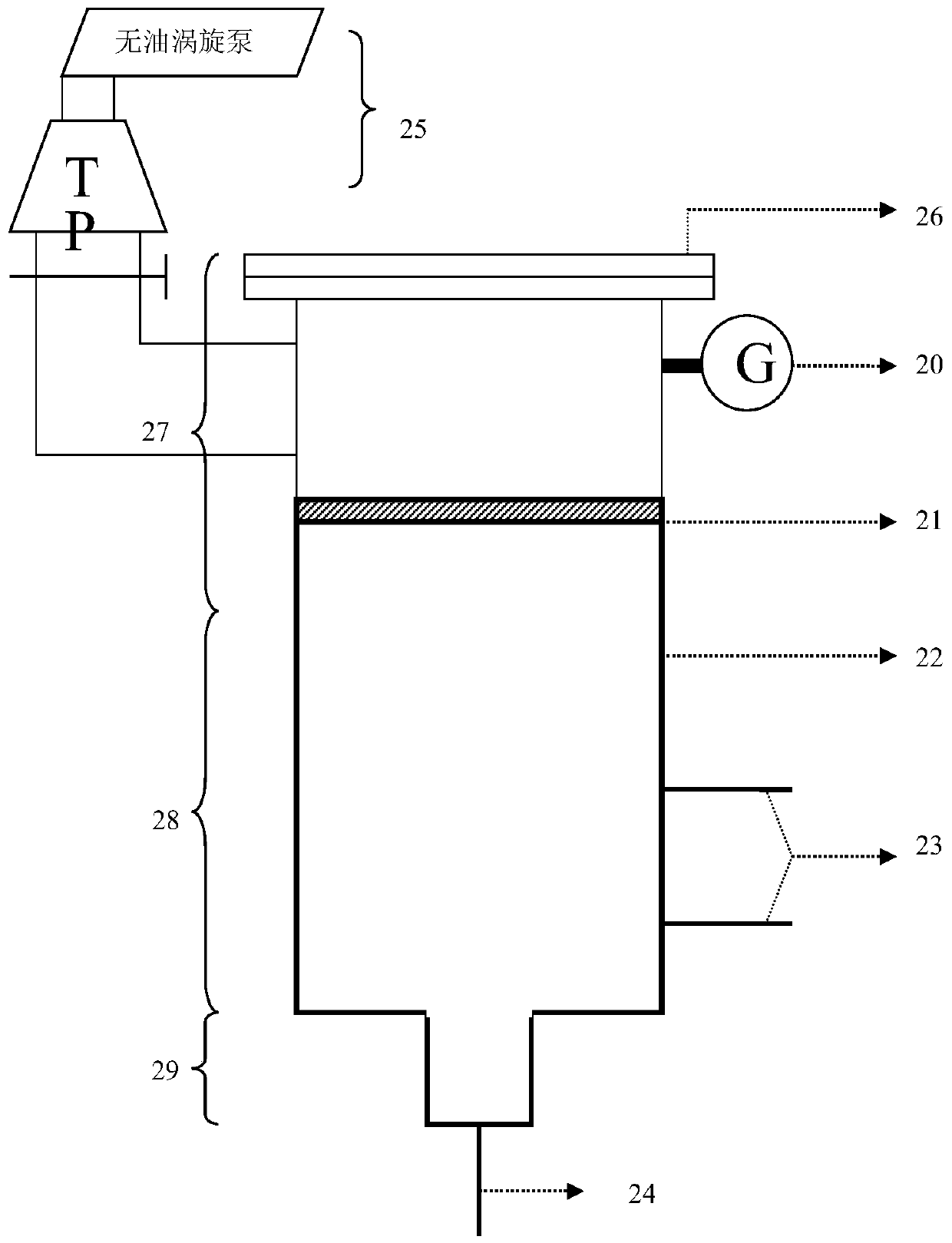

[0028] The overall structure of the niobium-three-tin coating vacuum furnace of the present invention is as follows figure 1 As shown, the furnace body is a double-vacuum structure, including an outer vacuum system and an inner vacuum system. Among them, the vacuum outside the furnace is used to place the heater, temperature measuring probe, insulation shielding layer, and cooling water channel of the outer furnace shell, etc.; the vacuum inside the furnace is used to place the niobium cavity to be plated during the coating process. In addition, for the coating requirements of the superconducting cavity, a rotating lifting device is designed to connect the niobium cavity to be coated and the tin crucible, and the niobium cavity is cyclically rotated through the transmission mechanism. Finally, in order to accurately monitor and control the coating parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com