A kind of high tenacity multi-block copolyester elastomer and preparation method thereof

A copolyester elastomer and multi-block technology, which is applied in the field of block copolyester and its preparation, can solve the problems of limited application and high brittleness, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

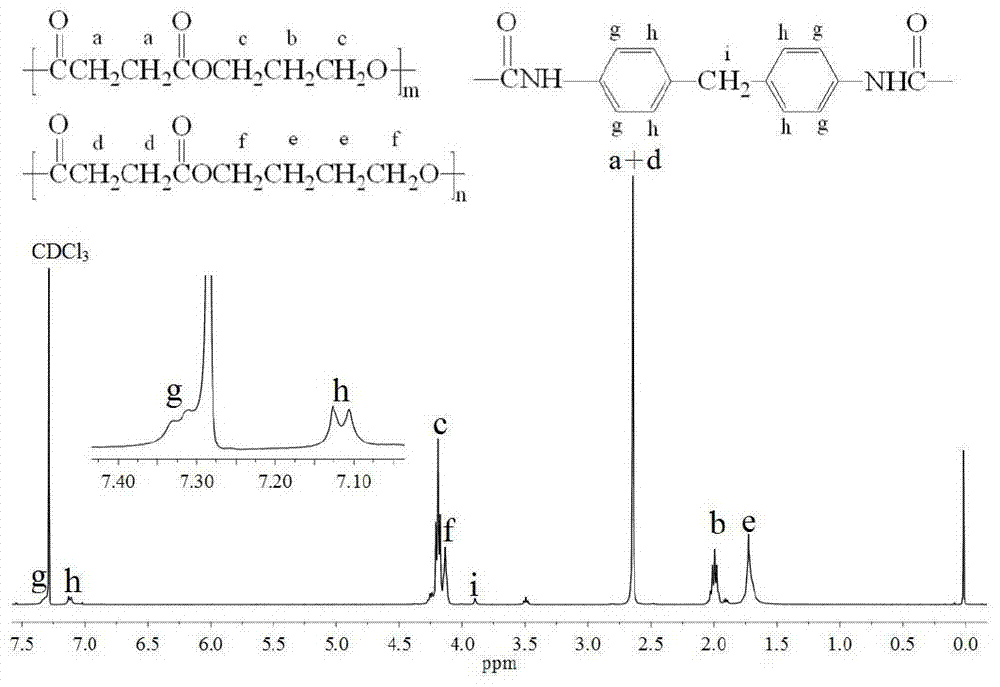

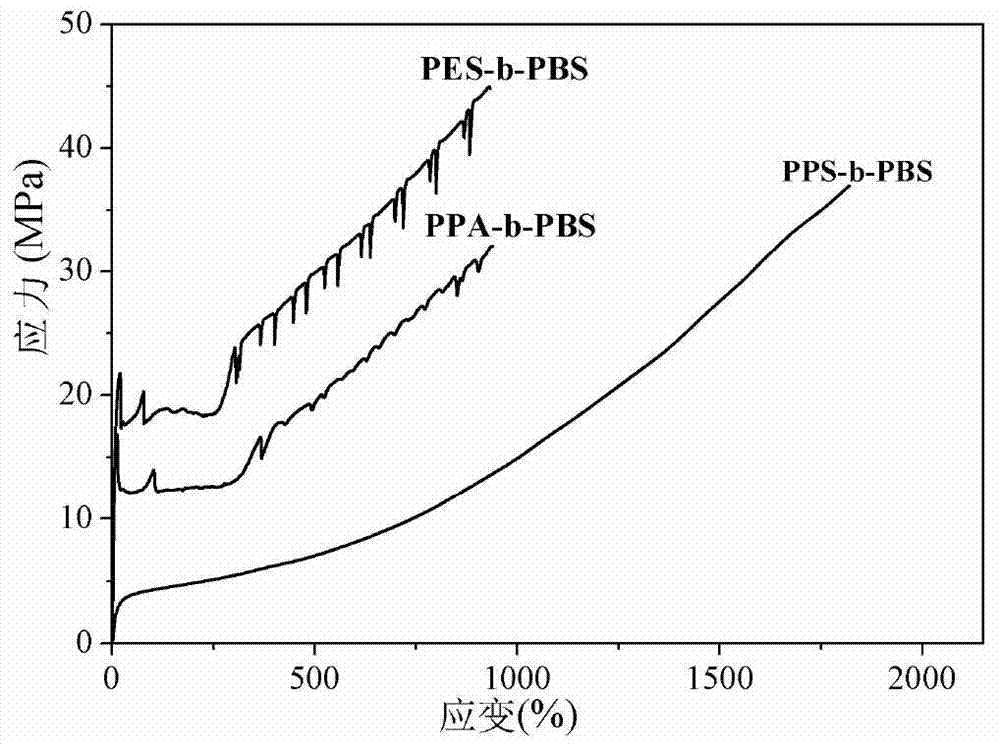

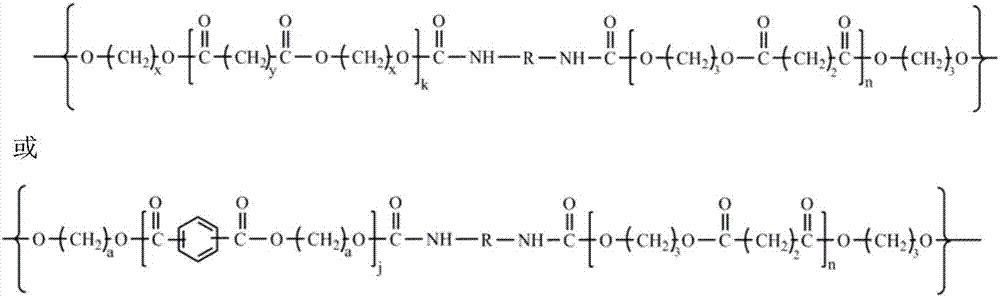

[0027] Put hydroxyl-terminated polytrimethylene succinate with an intrinsic viscosity of 0.11dL / g and hydroxyl-terminated polyethylene succinate with an intrinsic viscosity of 0.11dL / g in a reaction device at a weight ratio of 5:5 , under the protection of nitrogen, stir and heat up until it is completely melted, then add chain extender toluene diisocyanate in an amount of 10% of the total amount of the prepolymer, and react at 150 ° C for 1 hour to obtain the product.

[0028] The intrinsic viscosity of the obtained product was 1.53dL / g; the melting point was 100.5°C; the tensile strength of the film was 37.8MPa, and the elongation at break was 1620%.

Embodiment 2

[0030] Put hydroxyl-terminated poly(trimethylene succinate) with an intrinsic viscosity of 0.32dL / g and hydroxyl-terminated poly(butylene adipate) with an intrinsic viscosity of 0.22dL / g in the reaction device at a weight ratio of 10:1 In the process, under the protection of nitrogen, stir and heat up to its complete melting, then add chain extender diphenylmethane diisocyanate in an amount of 1.8% of the total amount of the prepolymer, and react at 100°C for 3 hours to obtain the product.

[0031] The intrinsic viscosity of the obtained product is 1.23dL / g; the melting point is 40.8°C; the tensile strength of the film is 10.2MPa, and the elongation at break is 2207%.

Embodiment 3

[0033] The hydroxyl-terminated poly(trimethylene succinate) with an intrinsic viscosity of 0.24 dL / g and the hydroxyl-terminated poly(trimethylene sebacate) with an intrinsic viscosity of 0.33 dL / g are placed in the reaction device in a weight ratio of 6:4, Stir and heat up under the protection of nitrogen until it is completely melted, then add chain extender 1,6-hexamethylene diisocyanate in an amount of 4.1% of the total amount of the prepolymer, and react at 120°C for 2 hours to obtain the product.

[0034] The intrinsic viscosity of the obtained product is 2.84dL / g; the melting point is 84.5°C; the tensile strength of the film is 38.7MPa, and the elongation at break is 1206%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com